Cheese is mostly made from milk, with most of the liquid drained away. To transform the remaining fats and proteins into cheese, makers add cultures, microscopic molds, bacteria, and/or yeasts. While not all cheeses require mold for production, it is an integral part of the cheesemaking process for certain varieties. Molds help develop unique flavors and textures by eating the proteins and sugars in the milk, resulting in chemical changes. The most common types of mold used to make cheese are Penicillium (P.) Roqueforti, P. Glaucum, and P. Candidum. These molds are added to milk during processing to create blue cheeses like Gorgonzola, while other soft-ripened kinds like Brie have mold mixed into the rind during the ripening process.

| Characteristics | Values |

|---|---|

| Is mold used in the process of making cheese? | Yes |

| Is mold safe to eat? | Yes, if it is required in the production process. |

| What types of mold are used in cheesemaking? | Penicillium (P.) Roqueforti, P. Glaucum, and P. Candidum. |

| What types of cheese use mold? | Blue cheese, soft-ripened cheese, Gorgonzola, Stilton, Brie, Roquefort, Camembert, etc. |

| What is the function of mold in cheesemaking? | Mold helps develop unique flavors and textures by eating the proteins and sugars in the milk, resulting in chemical changes. |

| How is mold applied to cheese? | Mold is primarily applied to the outside of the cheese. For blue cheese, mold spores are injected into the curds. |

| How is mold growth controlled? | By brushing, salting, or brining the cheese regularly. |

Explore related products

What You'll Learn

Blue cheese is made by injecting spores into the curds

Moulds are used in the process of making cheese. Some of the most common types of mould used include Penicillium (P.) Roqueforti, P. Glaucum, and P. Candidum. The mould is used as an additive to produce certain effects, such as the white mould on brie and camembert, which serves as a rind to protect and mellow the cheese.

Blue cheese is a type of cheese that is made with mould spores. It is a cheese with a complex microflora and has primary (lactic acid bacteria), secondary (Penicillium roqueforti), and other microorganisms, including non-starter lactic acid bacteria and yeasts. The blue veins in the cheese are caused by the growth of Penicillium roqueforti, a mould that requires oxygen to grow. To create this open structure, cheesemakers pierce the cheese core with steel needles.

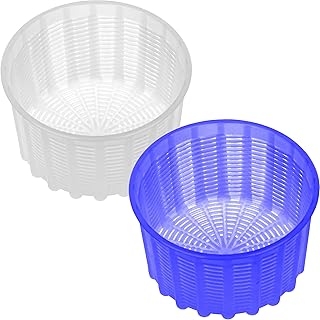

After the curds have been formed, they are ladled into containers to be drained and formed into a wheel of cheese. At this stage, the Penicillium roqueforti inoculum is sprinkled on top of the curds, and the curd granules are knit in moulds to form cheese loaves with an open texture. The whey drainage continues for 10-48 hours, and the moulds are frequently inverted to promote this process. Salt is then added to act as a preservative and to provide flavour.

Finally, the cheese is ripened by ageing it in a temperature-controlled environment. During this ripening period, the temperature and humidity are monitored to ensure the cheese does not spoil and develops its optimal flavour and texture. The flavour of blue cheese is dominated by methyl ketones generated through β-oxidation of free fatty acids, with butyric (C4) and caproic (C6) acids, and 2-heptanone being the major compounds responsible for the strong, piquant flavour.

Cheese Tamales: Choosing the Perfect Cheese

You may want to see also

Brie and Camembert are examples of external mold-ripened cheeses

Mold is an integral part of the cheesemaking process, and some cheeses are made with white surface mold and have mold mixed into them during production. Brie and Camembert are examples of external mold-ripened cheeses, also known as "bloomy rind" cheeses. They are both soft-ripened French cheeses, with some variants carrying protected AOC status. To make Brie and Camembert, the milk is inoculated with Penicillium candidum, the signature white mold of "bloomy" cheeses. This mold, along with yeasts like Geotrichum candidum, forms the white bloomy rind early in the aging process. As it grows, cheesemakers pat it down to form the smooth, snowy coating characteristic of these cheeses. The yeasts also contribute to the flavor of the cheese.

To ensure the proper growth of white mold on Brie and Camembert, several conditions must be met. The cheese must be stored at the correct temperature, typically around 12°C, and the humidity must be between 90% and 95%cheese must be turned regularly to prevent moisture buildup. G. candidum contributes to the ripening of nearly all surface mold-ripened cheeses, including Brie and Camembert. On ripened Camembert or Brie, G. candidum is covered by a white layer of Penicillium camemberti which first appears around day 6 of ripening.

The white mold on brie and camembert serves as a rind to protect and mellow the cheese. Some of the most common mold types include Penicillium (P.) roqueforti, P. glaucum, and P. candidum. Cheese is unique in its makeup as it requires certain types of mold to produce certain cheeses. The differences in cheeses' appearance, taste, and texture depend on the type of milk, bacteria present, length of aging, and processing methods.

Philly Cheesesteak: The Perfect Cheese Combination

You may want to see also

Mold is added to milk to make blue-veined cheeses

Blue-veined cheeses are made by adding mould to milk. This process involves several steps, each contributing to the unique flavour, texture, and characteristics of the final product. Firstly, specific bacteria strains are added to milk to form a "cheese culture", which helps good bacteria flourish and develop a rich flavour. In the case of blue cheese, the bacteria used are lactic acid bacteria. Subsequently, mould is added to the mixture. The most common type of mould used in blue cheese is Penicillium roqueforti, which creates the distinctive blue veins. This mould requires oxygen to grow, so the cheese is pierced to create air tunnels, facilitating the growth of the mould culture.

During the ripening and ageing phase, the temperature and humidity are carefully monitored to ensure optimal flavour and texture development. The maturation time varies depending on the type of blue cheese being crafted, typically ranging from several weeks to several months. Throughout this ageing process, the mould continues to grow and produce enzymes that enhance the flavour and texture of the cheese. The final product is then cut and wrapped, ready for consumption.

It is important to note that while mould is added to milk to make blue-veined cheeses, not all cheeses require mould for production. The moulds used in cheesemaking, such as Penicillium roqueforti, are carefully selected and cultivated to ensure safety and achieve the desired characteristics in the cheese. Consuming cheese with mould is safe if the mould is intended to be there as part of the production process.

The addition of mould is not limited to blue-veined cheeses alone. Other cheeses that contain mould in their manufacturing process include Gorgonzola, Stilton, Brie, Camembert, and Roquefort. Each of these cheeses uses mould to develop distinct flavours, textures, and appearances, showcasing the versatility of mould in cheesemaking.

Feta Cheese: A Versatile Ingredient for Your Next Dish

You may want to see also

Explore related products

Mold is a fungus that grows on cheese, intentionally or unintentionally

Cheese is made by curdling dairy milk using an enzyme known as rennet and then draining off the liquid. The curds that are left behind are salted and aged. Differences in the taste, texture, and appearance of cheese depend on the type of milk, bacteria present, length of aging, and processing methods.

Some of the most common types of mold used in cheese-making include Penicillium (P.) Roqueforti, P. Glaucum, and P. Candidum. These molds are used to produce blue cheeses like Gorgonzola and soft-ripened cheeses like Brie and Camembert. The white mold on these cheeses serves as a rind to protect and mellow the cheese, adding a creamy texture and a white color to the rind during the ripening process.

While mold is an important part of the cheese-making process for certain varieties, it can also be a sign of spoilage. It is important to properly store cheese to prevent mold growth and to check for any signs of mold before consuming. If mold is present on soft cheeses, it should be discarded, while hard cheeses can be salvaged by cutting around the molded area.

In conclusion, mold is a fungus that can grow on cheese unintentionally due to spoilage or intentionally during the cheese-making process to create unique flavors and textures. Proper storage and handling of cheese are important to ensure food safety and maintain the desired characteristics of the cheese.

Oaxaca Cheese: Melty, Stringy, and Perfect for..

You may want to see also

Cheese molds and cheese cultures are not the same thing

Cheese molds and cheese cultures are two different things and are both crucial in the process of making cheese. Cheese molds are applied to the outside of the cheese, while cheese cultures are used to form the substance of the cheese inside. Cheese molds are fungal starter cultures with lipolytic and proteolytic enzymes that contribute to flavor production and cheese ripening. They are essential in making certain kinds of cheeses, such as blue-veined cheeses, and soft cheeses like brie and camembert. The mold adds a creamy texture and a white color to the rind during the ripening process.

Cheese cultures, on the other hand, are a group of specific bacteria strains combined to make a particular type of cheese. They aid in the development of good bacteria in the milk, resulting in a richer and more enhanced flavor. Cheese cultures are essential in making aged cheeses like cheddar, gouda, mozzarella, brie, and camembert. They help raise the acidity of milk by converting lactose into lactic acid, which is necessary for the milk to split into curds, an essential ingredient in cheese production.

It is important to note that while most cheeses are made by adding bacteria through cheese cultures, some cheeses do contain mold as part of their manufacturing process, such as gorgonzola, stilton, brie, roquefort, blue, and camembert. These molds are safe to consume as they are intended to be part of the cheese's makeup. However, if mold appears on a cheese that is not meant to have it, and it changes the appearance, texture, or odor of the cheese, it is no longer safe to eat.

Cheese molds and cheese cultures work together in the cheesemaking process, each contributing to the unique texture, flavor, and appearance of the final product. While they serve different purposes, both are essential in creating the desired consistency and taste of the cheese.

Creating a Cheesy Charcuterie: Selecting the Perfect Cheeses

You may want to see also

Frequently asked questions

Yes, molds are used in the process of making cheese. While not all cheeses require mold for production, it is an integral part of making certain cheeses. Molds help develop unique flavors and textures by eating the proteins and sugars in the milk, resulting in chemical changes.

Some cheeses that require molds in their production include blue cheeses like Gorgonzola and soft-ripened kinds like Brie, Camembert, and Roquefort.

The most common types of mold used to make cheese are Penicillium (P.) Roqueforti, P. Glaucum, and P. Candidum.