Whey is a byproduct of the coagulation of proteins and fats in milk and cream during the cheese-making process. It is essentially the water that is removed from the curds to make cheese. Traditionally, cheesemakers considered whey a waste product and disposed of it by discharging it into waterways, spraying it onto farmland, or selling it as animal feed. However, whey is an excellent source of protein, and nowadays, cheesemaking companies market their leftover whey to companies that produce protein-enriched products such as protein shakes and bars. Whey is also used in various other applications, such as food recipes, natural pest control, beauty solutions, and lacto-fermentation. In the context of Parmesan cheese, whey is extracted from the curd through cutting, stirring, and heating. The degree of whey extraction contributes to the particular style of cheese. Parmesan cheese, in particular, is known to be virtually lactose-free, with a maximum lactose content of 0.10 milligrams per 100 kilocalories of the product, making it safe for those with lactose intolerance to consume.

| Characteristics | Values |

|---|---|

| Do they add whey back to Parmesan cheese? | No, whey is removed during the cheese manufacturing process. |

| Why is whey removed from Parmesan cheese? | To remove lactose, which 75% of the world's population cannot digest. |

| What happens to the leftover whey? | Traditionally, whey was considered a waste product and was discarded by discharging it into waterways, spraying it onto farmland, or selling it as animal feed. |

| Are there any other uses for leftover whey? | Yes, whey can be used in cooking (e.g., making ricotta, mozzarella, or butter), natural pest control, beauty solutions (e.g., skin toner or hair conditioner), and lacto-fermentation. |

| Is Parmesan cheese safe for people with whey allergies? | Yes, Parmesan is an old/hard cheese with low or no whey, and it is generally safe for people with whey allergies or lactose intolerance. |

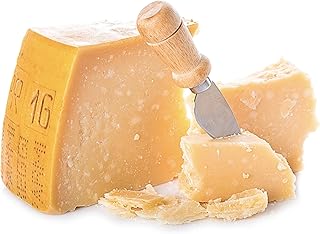

Explore related products

What You'll Learn

Whey is extracted from curd during the cheesemaking process

Whey is a byproduct of the coagulation of proteins and fats in milk and cream during the cheesemaking process. It is essentially the water that is removed from the curds to make cheese. Whey is extracted from curd in different ways during the cheesemaking process. The curd is cut and stirred after the initial coagulation, and it can also be heated. Then the curds are drained, and many cheeses are made by pressing the curds in a mold.

In the early days of large-scale cheesemaking, cheesemakers would have to find creative ways to use their whey. Farmstead cheesemakers commonly fed it directly back to the animals as a protein source, and many still do. However, once cheesemaking became industrial, the industry had to find another way to dispose of all the "waste". Because whey is an excellent source of protein, cheesemaking companies began marketing their leftover product to companies that make protein-enriched products such as protein shakes and bars.

Today, there is such a large demand for industrial whey protein that marginal cheese has become the by-product, and whey the primary product for some large-scale cheesemakers. Whey is also used to make ricotta, a classic whey cheese from Scandinavia. To make ricotta, the whey is often heated with fresh milk and citric acid, and then the curds are harvested. Whey can also be used to make butter; after letting it cool for a few hours, the cream in the whey will rise to the top and can be scooped away for butter-making.

Whey is extracted from curd during the Parmesan cheesemaking process. Parmesan is made through a process called rennet coagulation, which uses a group of animal enzymes to start the coagulation (solidifying) process. Cow's milk starts to coagulate from the addition of rennet, and liquid whey starts to separate from a firm curd of casein micelles, milk's main type of protein. After the curd has formed, it is cut into rice-size pieces to further promote the expulsion of whey and reduce the cheese's moisture content. The mixture of curd and whey is cooked at 131°F (55°C) to promote curd contraction and further whey expulsion.

The Mystery of Parmesan Cheese and Sawdust

You may want to see also

Parmesan is a lactose-free cheese

Parmesan cheese is made through a process called rennet coagulation, where rennet, a group of animal enzymes, is added to cow's milk to start the coagulation process. Liquid whey then separates from a firm curd of casein micelles, which is milk's main type of protein. The curd is then cut into rice-size pieces to promote whey expulsion and reduce moisture content. The mixture of curd and whey is cooked at 131°F (55°C) to further promote whey expulsion. Knitting and pressing also help with whey expulsion and the fusion of the curd.

The maturation period of Parmesan cheese can range from 12 to over 40 months, and during this time, the proteins in the cheese undergo a process similar to pre-digestion, breaking down into smaller compounds that the body can easily absorb. The final texture and flavour of the cheese depend on the maturation time. Generally, hard, aged cheeses like Parmesan have lower lactose content because the lactose in the curd changes to lactic acid during aging.

While Parmesan is considered lactose-free, some lactose-intolerant individuals have reported experiencing symptoms after consuming it. This could be due to a dairy allergy, sensitivity to the aging process, or a histamine allergy. Additionally, some sources of Parmesan may not be authentic, and shredded Parmesan in particular has been noted as not being real Parmesan. Lactose-intolerant individuals who wish to consume Parmesan can try taking a lactase pill before consumption.

Is Parmesan Cheese Halal? What Muslims Need to Know

You may want to see also

Whey is considered a waste product

Whey is the liquid byproduct of the cheesemaking process. It is the yellow-green watery part of milk (serum) that remains when the curd is separated during cheesemaking. Whey accounts for about 85-90% of the volume of milk and contains about 55% of the nutrients in milk. It is composed of approximately 70% lactose, 14% protein, 9% minerals, 4% fat, and 3% lactic acid.

While whey has valuable components, including functional proteins, peptides, lipids, vitamins, minerals, and lactose, it is considered a waste product due to the challenges associated with its disposal. The disposal of whey can pose serious environmental hazards if not properly managed. Cheese whey is an effluent with strong organic and saline content, and its improper disposal can lead to significant environmental pollution. The high biochemical and chemical oxygen demand (BOD and COD) of whey contributes to its environmental impact.

Historically, cheesemakers had to find creative ways to utilize or dispose of whey. Farmstead cheesemakers commonly fed whey back to animals as a protein source, but when cheesemaking became industrialized, alternative methods were needed. To address the issue of whey disposal, the cheesemaking industry began marketing leftover whey to companies producing protein-enriched products, such as protein shakes and bars. This led to a shift where, for some large-scale cheesemakers, whey became the primary product, and cheese became the byproduct.

Today, there is a growing focus on sustainable practices and the circular economy, driving the development of innovative waste systems and technologies to upcycle whey and reduce its environmental impact. Various approaches are being explored, including the use of whey in biogas production, non-thermal techniques for whey beverage production, and the utilization of whey as a raw material in sustainable bio-economy initiatives.

Is Kraft Shredded Parmesan Cheese Vegetarian-Friendly?

You may want to see also

Explore related products

Whey is fed to animals as a protein source

Whey is a highly nutritious by-product of the cheese-making process. It is the liquid portion of milk that separates from the curds during cheese production. Whey contains whey protein, which is a valuable source of protein, as well as lactose (milk sugar). While humans can consume whey protein as a supplement, it is also commonly fed to animals as a protein source.

Farmstead cheesemakers have traditionally fed whey to their animals, and many still do. It is particularly beneficial for lactating cows, as it helps prevent milk fat depression. Additionally, calves fed milk replacers containing up to 89% dried whey have shown favourable growth rates. Whey can also be added to grass and legume silages, improving their quality and digestibility.

For backyard chicken keepers, whey can be mixed with feed to provide a protein boost, especially during moulting when chickens need extra protein to grow new feathers. However, it is important to note that there is limited calcium left in whey at this stage, as most of it has been used to maintain the structure of the cheese.

While whey is a valuable source of protein for animals, the rise of industrial cheesemaking has led to the marketing of whey to companies producing protein-enriched products for human consumption, such as protein shakes and bars. The demand for whey protein has grown so much that, for some large-scale cheesemakers, whey has become the primary product, with cheese as the by-product.

The Meatball Conundrum: Parmesan, Essential or Excess?

You may want to see also

Parmesan is made through rennet coagulation

Parmesan cheese is made through a process called rennet coagulation. Rennet is a group of animal enzymes that start the coagulation (solidifying) process. Calf rennet is the most commonly used animal rennet, and it is derived from the inner lining of calves' fourth stomachs. The calves are usually male dairy calves, which are raised for veal. When added to milk, rennet triggers the formation of curds, which are then separated from the liquid whey. This process results in a semi-solid cheese mass that can be further processed into various types of cheese.

During the coagulation process, cow's milk starts to coagulate from the addition of rennet. Liquid whey starts to separate from a firm curd of casein micelles, which is milk's main type of protein. Once the curd has formed, it is cut into rice-size pieces to further promote the expulsion of whey and reduce the cheese's moisture content. This is done using a traditional tool called a spino. The mixture of curd and whey is then cooked at 131°F (55°C) to promote curd contraction and further whey expulsion. The curd continues to fuse to form a larger cheese mass, and pressing helps with further whey expulsion and promotes a complete fusion of the curd.

Parmesan cheese is a hard cheese traditionally produced in specific regions in northern Italy. It has a strong, nutty flavour and grainy texture that can vary depending on the maturation period. The maturation period can range from 12 months to more than 40 months, and during this time, the proteins in the cheese undergo a process similar to pre-digestion, where they are broken down into smaller compounds that are more easily absorbed by the body.

While milk is an essential part of cheesemaking, Parmesan is virtually lactose-free. Lactose is the main type of carbohydrate found in milk, but around 75% of the world's population cannot digest it due to a deficiency of lactase, the enzyme that helps digest lactose. When whey is removed from the curd during cheese manufacturing, the lactose is removed along with it, resulting in Parmesan being safe for those with lactose intolerance to consume.

Traditionally, Parmesan cheese has been made using animal-derived rennet, which contributes to its distinct flavour and texture. However, in recent years, the use of animal-derived rennet has raised concerns among vegetarians, vegans, and those with religious or dietary restrictions. To cater to the growing demand for animal-free cheese options, manufacturers have developed alternative rennet sources, such as microbial rennet produced through fermentation by microorganisms. Microbial rennet tends to produce a milder flavour and softer texture than animal-derived rennet.

Kraft's Parmesan Cheese: Why the Need to Refrigerate?

You may want to see also

Frequently asked questions

Whey is removed from Parmesan cheese during the manufacturing process to make the cheese lactose-free. This makes it suitable for people with lactose intolerance.

Traditionally, whey was considered a waste product and often discarded by discharging it into waterways or spraying it onto farmland. However, nowadays, it is commonly fed to animals as a protein source or sold to companies that produce protein-enriched products such as protein shakes and bars.

While it is not a common practice to add whey back to Parmesan cheese, it is possible to do so. Some people with allergies or intolerances to whey may prefer Parmesan cheese without the added whey.

There may be some benefits to adding whey back to Parmesan cheese, such as enhancing the flavor or improving the texture of other products. However, the primary benefit of removing whey from Parmesan cheese is to make it lactose-free and suitable for those with lactose intolerance.