The question of whether cheese is cleaned during production often arises due to its natural aging and ripening processes, which can involve molds, bacteria, and surface imperfections. While cheese is not cleaned in the traditional sense, many varieties undergo specific treatments to manage their appearance and texture. For instance, hard cheeses like Parmesan may have their rinds brushed or washed to remove excess mold or debris, while soft cheeses might be gently wiped or turned to ensure even ripening. Additionally, some cheeses are intentionally washed with brine, wine, or other solutions to develop unique flavors and textures. These practices are part of the artisanal process, ensuring the cheese remains safe and palatable while preserving its distinct character.

| Characteristics | Values |

|---|---|

| Process | Cheese cleaning is a standard practice in the dairy industry to remove surface mold, dirt, and other contaminants. |

| Methods | Mechanical (brushing, scraping), chemical (salt, acid, or alkaline solutions), or a combination of both. |

| Frequency | Regularly, depending on the type of cheese and storage conditions (e.g., weekly for hard cheeses, more often for soft cheeses). |

| Purpose | To maintain quality, appearance, and safety by preventing excessive mold growth and spoilage. |

| Types of Cheese Cleaned | Primarily hard and semi-hard cheeses (e.g., Cheddar, Parmesan, Gouda); soft cheeses are less commonly cleaned due to their delicate texture. |

| Industry Standards | Follows guidelines from organizations like the FDA, USDA, and EU food safety regulations. |

| Health Impact | Proper cleaning reduces the risk of foodborne illnesses caused by surface contaminants. |

| Consumer Perception | Generally accepted as a necessary step to ensure cheese safety and quality. |

| Environmental Impact | Waste from cleaning solutions is managed to minimize environmental harm. |

| Alternatives | Some artisanal cheesemakers avoid cleaning, relying on natural molds or wax coatings instead. |

Explore related products

What You'll Learn

Cleaning Process Overview

Cheese cleaning is a meticulous process that varies depending on the type of cheese and its intended use. For instance, hard cheeses like Parmesan or Cheddar often undergo a brine wash during aging to remove surface mold and bacteria, ensuring a clean rind that’s safe for consumption. In contrast, soft cheeses such as Brie or Camembert may have their rinds gently wiped with a cloth dampened in a mild salt solution to maintain texture while eliminating unwanted microorganisms. This targeted approach highlights the importance of tailoring cleaning methods to the cheese’s characteristics.

The cleaning process begins with an assessment of the cheese’s condition. Surface mold on aged cheeses is typically scraped off using a sterile knife, followed by a rinse with a food-grade sanitizing solution (e.g., a mixture of 1 tablespoon of white vinegar per cup of water). For cheeses with natural rinds, such as Gruyère, a dry brush is often used to remove debris without compromising the rind’s integrity. It’s crucial to avoid over-cleaning, as excessive moisture can encourage bacterial growth or alter the cheese’s flavor profile.

In industrial settings, cheese cleaning is standardized to meet safety regulations. For example, large wheels of cheese are often treated with a controlled application of heat (around 50–60°C) to kill surface bacteria, followed by a light coating of edible wax or plastic film to prevent recontamination. Small-scale producers might opt for more traditional methods, such as hand-rubbing cheeses with olive oil or wine to inhibit mold growth while enhancing flavor. Both approaches prioritize hygiene without sacrificing quality.

Home enthusiasts cleaning cheese should focus on minimal intervention. For example, if mold appears on a block of hard cheese, cut off the affected area at least 1 inch deep, ensuring no spores remain. Soft cheeses with mold should be discarded entirely, as the spores can penetrate deeply. Always store cleaned cheese in airtight containers at temperatures below 4°C to prolong freshness. Proper tools, like non-reactive knives and clean brushes, are essential to avoid introducing contaminants during the process.

The ultimate goal of cleaning cheese is to preserve its integrity while ensuring safety. Whether through industrial treatments or home remedies, the process demands precision and respect for the cheese’s unique properties. By understanding the specific needs of each type of cheese, one can effectively clean it without compromising its texture, flavor, or shelf life. This balance between hygiene and craftsmanship is what distinguishes a well-cleaned cheese from a poorly handled one.

4C Graded Cheese Recall Alert: What You Need to Know

You may want to see also

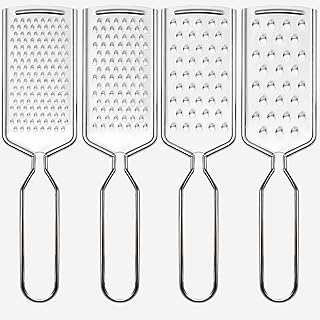

Tools and Equipment Used

Cheese cleaning is a delicate process that requires precision and the right tools to maintain quality and safety. The equipment used varies depending on the type of cheese and the scale of production, but certain tools are indispensable across the board. For artisanal cheesemakers, a cheese harp—a wire cutter with a wooden handle—is essential for slicing large wheels into manageable portions without damaging the rind. In industrial settings, automated cheese slicing machines with adjustable blades ensure uniformity and efficiency, handling hundreds of kilograms per hour. Both tools prioritize cleanliness, often made from stainless steel to prevent bacterial growth and facilitate easy sanitization.

Beyond cutting, brining tanks play a critical role in cleaning and preserving cheese. These tanks, typically made of food-grade plastic or stainless steel, are used to immerse cheese in brine solutions that remove surface impurities and inhibit mold growth. For example, a 10% salt brine solution is commonly used for hard cheeses like cheddar, while softer varieties like mozzarella require a milder 6% brine. Temperature control is crucial; brining tanks often come with built-in thermostats to maintain optimal conditions, usually between 4°C and 12°C. Regular cleaning of these tanks with food-safe sanitizers is mandatory to prevent cross-contamination.

For surface cleaning, cheese brushes are a staple in both small and large operations. These brushes, often featuring soft bristles made from natural materials like boar hair, gently remove dust, mold, and debris without harming the cheese’s texture. In contrast, air compressors are employed in modern facilities to blow away surface particles using controlled bursts of air, a method particularly useful for aged cheeses with delicate rinds. Both tools must be sanitized after each use, with brushes soaked in a 200 ppm chlorine solution for at least 10 minutes to ensure hygiene.

Finally, UV-C light systems are emerging as a high-tech solution for cheese cleaning, especially in large-scale production. These systems use ultraviolet light to kill surface bacteria and mold spores without chemicals, making them ideal for organic cheese production. A typical UV-C treatment lasts 30–60 seconds per side, depending on the cheese’s thickness and the light’s intensity. While expensive to install, they offer long-term cost savings by reducing the need for chemical sanitizers and minimizing waste from spoiled batches. Each tool, whether traditional or cutting-edge, serves a specific purpose in ensuring cheese remains clean, safe, and ready for consumption.

Why Jimmy John's Turkey Sandwiches Skip the Cheese: Explained

You may want to see also

Frequency of Cleaning Cheese

Cheese cleaning frequency varies widely depending on the type of cheese and its intended use. Hard cheeses like Parmesan or Cheddar, with their low moisture content, rarely require cleaning beyond occasional brushing to remove surface mold. In contrast, soft cheeses such as Brie or Camembert, with higher moisture levels, may develop mold more frequently and benefit from gentle wiping with a damp cloth every 2–3 days when stored properly. Understanding these differences is crucial for maintaining both safety and flavor.

For home cheese storage, the frequency of cleaning is tied to observation and environment. If you notice mold on semi-soft cheeses like Gouda or Swiss, trim the affected area with a 1-inch margin and consume the rest promptly. Avoid cleaning these cheeses more than once a week, as excessive handling can introduce contaminants. Always store cheese in the refrigerator at 35–40°F (2–4°C) and wrap it in wax or parchment paper to minimize moisture buildup, reducing the need for frequent cleaning.

In commercial settings, cleaning frequency is dictated by hygiene standards and production methods. Aged cheeses are often cleaned during the aging process to remove surface mold and ensure even ripening. For example, wheels of Gruyère may be brushed and turned weekly, while blue cheeses like Stilton are minimally handled to preserve their natural rind development. Industrial practices prioritize consistency, with cleaning schedules tailored to each cheese’s moisture content and desired texture.

A persuasive argument for mindful cleaning frequency is its impact on flavor and texture. Over-cleaning can strip away beneficial molds and bacteria essential for flavor development, particularly in aged or surface-ripened cheeses. Conversely, neglecting cleaning can lead to off-flavors or spoilage. Striking the right balance—cleaning only when necessary and using appropriate tools like sterile brushes—preserves the cheese’s integrity while ensuring safety. This approach respects the artisanal nature of cheese-making and enhances the sensory experience for consumers.

Why Pulled String Cheese Tastes Better: The Science Behind the Stretch

You may want to see also

Explore related products

Health and Safety Standards

Cheese production and handling are subject to stringent health and safety standards to prevent contamination and ensure consumer safety. These standards vary by region but generally include regulations on hygiene, temperature control, and the use of additives. For instance, the U.S. Food and Drug Administration (FDA) mandates that cheese-making facilities maintain surfaces in a "clean and sanitized condition" to prevent pathogen growth. Similarly, the European Union’s regulations require regular testing for harmful bacteria such as *E. coli* and *Listeria monocytogenes* in dairy products. Compliance with these standards is not optional; it is a legal requirement for producers to avoid outbreaks and recalls.

One critical aspect of health and safety in cheese production is the control of microbial growth. Cheese is a perishable food, and its moisture content and pH levels create an environment conducive to bacterial proliferation. Producers often use pasteurization to kill harmful microorganisms, but even pasteurized cheese can become contaminated during handling or storage. For example, soft cheeses like Brie and Camembert are more susceptible to *Listeria* contamination due to their higher moisture content. To mitigate this risk, manufacturers must adhere to strict storage guidelines, such as maintaining refrigeration temperatures below 4°C (39°F) and ensuring proper packaging to prevent cross-contamination.

Another key consideration is the use of additives and preservatives in cheese. While some additives, like natamycin, are approved for inhibiting mold growth on the surface of cheese, their usage must comply with safety limits. For instance, the FDA permits natamycin in shredded cheese at a maximum concentration of 20 parts per million (ppm). Consumers with allergies or sensitivities should also be aware of potential allergens, such as milk proteins or added enzymes, which must be clearly labeled on packaging. Transparency in labeling not only adheres to health and safety standards but also empowers consumers to make informed choices.

Practical tips for consumers can further enhance safety when handling cheese at home. Always store cheese in the refrigerator and wrap it properly to prevent exposure to air, which can accelerate spoilage. When serving, use clean utensils to avoid introducing bacteria from other foods. For pregnant women, the elderly, and immunocompromised individuals, it is advisable to avoid soft, unpasteurized cheeses due to the higher risk of *Listeria* infection. By understanding and following these guidelines, both producers and consumers play a vital role in upholding health and safety standards in cheese consumption.

Calculating Weight Watchers Points for Halloumi Cheese: A Quick Guide

You may want to see also

Impact on Cheese Quality

Cheese cleaning practices significantly influence flavor profiles, texture, and safety, often in ways consumers don’t realize. For instance, surface-ripened cheeses like Brie or Camembert undergo regular brushing or wiping to remove excess mold growth. This process not only maintains appearance but also controls moisture levels, ensuring the rind develops evenly. Without such intervention, unwanted bacteria could dominate, leading to off-flavors or even spoilage. However, over-cleaning can strip away beneficial microorganisms essential for flavor complexity, highlighting the delicate balance required in this practice.

Consider the role of brine baths in cleaning fresh cheeses like mozzarella or feta. These baths not only remove impurities but also contribute to the cheese’s final texture and salt content. For example, a 10-15% brine solution is typically used for feta, with immersion times ranging from 24 to 48 hours. If the brine is not regularly replaced or its concentration is inconsistent, the cheese may absorb excessive salt or develop a grainy texture. Conversely, inadequate cleaning in the brine stage can leave behind whey proteins or debris, compromising both taste and shelf life.

From a safety perspective, cleaning is critical in preventing pathogens like Listeria monocytogenes, particularly in soft cheeses. Pasteurized milk reduces risk, but post-production handling still matters. For instance, washing equipment with a 200 ppm chlorine solution between batches is standard practice in many dairies. However, even trace residues of cleaning agents can alter cheese flavor if not thoroughly rinsed. This underscores the need for precise protocols—a single oversight can render an entire batch unsafe or unpalatable.

Artisanal cheesemakers often debate the merits of natural vs. mechanical cleaning methods. Hand-rubbing cheeses with salt or ash preserves traditional textures but is labor-intensive and inconsistent. Mechanical brushes offer uniformity but risk damaging delicate rinds. For example, aged Goudas benefit from periodic turning and brushing to remove surface mold, but aggressive handling can crack the rind, exposing the interior to contaminants. The choice of method thus becomes a trade-off between efficiency and quality preservation.

Finally, consumer expectations shape how cleaning impacts perceived quality. A study found that 72% of cheese buyers associate a clean, uniform rind with freshness, even though some imperfections are natural. This pressure drives producers to prioritize aesthetics over microbial diversity, potentially homogenizing flavors. For home enthusiasts, the takeaway is clear: when cleaning homemade cheese, prioritize consistency and gentleness. Use food-grade brushes, monitor brine salinity, and avoid over-handling to preserve both safety and character.

Are Cheese Doritos Gluten-Free? A Crunchy Snack Fact Check

You may want to see also

Frequently asked questions

Yes, cheese is typically cleaned during the production process to remove any surface impurities or mold before packaging.

Depending on the type of cheese, it may be brushed, washed, or cleaned during the aging process to control mold growth and maintain quality.

Restaurants often clean the outer rind of hard cheeses before grating or serving, but soft cheeses are usually served as-is unless specified otherwise.

Yes, cheese is cleaned at various stages of production, including curd handling, pressing, and surface treatment, to ensure hygiene and safety.