Processed cheese, often found in slices or spreads, is a popular dairy product known for its convenience and versatility. While it may not resemble traditional cheese in texture or flavor, processed cheese is indeed derived from milk. The primary ingredient in processed cheese is typically milk or milk products, such as cheese curds, whey, or milk proteins, which are combined with emulsifiers and other additives to create a smooth, consistent texture. Despite the processing and additional ingredients, milk remains a fundamental component, ensuring that processed cheese retains its dairy-based identity.

| Characteristics | Values |

|---|---|

| Contains Milk | Yes, processed cheese contains milk as a primary ingredient. |

| Milk Source | Typically made from cow's milk, but can also include milk from other animals. |

| Milk Content | At least 51% milk solids (as per U.S. FDA regulations for pasteurized process cheese). |

| Additional Ingredients | Emulsifiers (e.g., sodium phosphate), salt, preservatives, and sometimes whey or milk protein concentrate. |

| Processing | Milk is pasteurized, mixed with emulsifiers, heated, and blended to create a uniform texture. |

| Texture | Smooth, meltable, and consistent due to processing and added emulsifiers. |

| Shelf Life | Longer than natural cheese due to added preservatives and processing. |

| Nutritional Value | Contains calcium, protein, and fat from milk, but may have higher sodium and additives compared to natural cheese. |

| Labeling | Must be labeled as "processed cheese" or "cheese product" if it does not meet standards for natural cheese. |

| Common Uses | Sliced cheese, cheese singles, sauces, and snacks. |

Explore related products

$1.19

What You'll Learn

Milk Content in Processed Cheese

Processed cheese, often labeled as "cheese food" or "cheese product," is a staple in many households, prized for its meltability and long shelf life. Despite its convenience, a common question arises: does it actually contain milk? The answer is yes, but the milk content is not as straightforward as in natural cheeses. Processed cheese is made by blending one or more natural cheeses with emulsifying agents, such as sodium phosphate, and often additional milk or whey. This combination allows for a smoother texture and extended preservation. However, the milk used in processed cheese is typically in a modified form, often as milk solids or reconstituted milk, which raises questions about its nutritional value compared to whole milk or natural cheese.

Analyzing the milk content in processed cheese reveals a nuanced picture. According to the U.S. Food and Drug Administration (FDA), processed cheese must contain at least 51% real cheese, which inherently includes milk. The remaining ingredients may include milk protein concentrates, whey, or nonfat milk solids, all derived from milk. For instance, a popular processed cheese slice might list "milk, water, milk protein concentrate, whey, and sodium citrate" among its ingredients. While these components are milk-based, they are processed to enhance stability and texture, often at the expense of some natural nutrients found in fresh milk or cheese. This distinction is crucial for consumers, especially those with dietary restrictions or preferences.

For those monitoring lactose intake, understanding the milk content in processed cheese is essential. Processed cheese generally contains less lactose than natural cheese because the culturing and aging processes break down lactose. However, the addition of milk solids or whey can reintroduce small amounts of lactose. Individuals with severe lactose intolerance should exercise caution, as even trace amounts can trigger discomfort. Reading labels carefully and opting for products with lower milk-derived additives can help mitigate this risk. For example, some processed cheese products are labeled as "lactose-free," indicating they have been treated with lactase enzyme to break down lactose.

From a nutritional standpoint, the milk content in processed cheese contributes to its protein and calcium levels, but it often falls short in other areas. Natural cheese retains more vitamins and minerals due to minimal processing, whereas processed cheese may contain added sodium and preservatives. For instance, a single slice of processed cheese can contain up to 300 mg of sodium, compared to 150 mg in a similar portion of natural cheddar. Parents and health-conscious consumers should consider this when incorporating processed cheese into diets, especially for children or those with hypertension. Balancing convenience with nutritional value is key.

In practical terms, processed cheese can be a versatile ingredient in cooking due to its milk-based composition. Its high meltability, derived from milk proteins and emulsifiers, makes it ideal for dishes like grilled cheese sandwiches, burgers, or sauces. However, for recipes requiring the rich flavor and texture of natural cheese, processed cheese may not suffice. Home cooks can experiment by blending processed cheese with natural varieties to achieve both meltability and authentic cheese flavor. For example, mixing processed cheese with shredded cheddar in a queso dip can enhance creaminess while retaining a more robust taste. Understanding the milk content and its role in processed cheese empowers consumers to make informed choices tailored to their culinary and dietary needs.

Mexican Cheese vs. Monterey Jack: Are They the Same?

You may want to see also

Types of Milk Used in Processing

Processed cheese, often labeled as cheese food or cheese product, relies heavily on milk as its primary ingredient. The type of milk used in processing varies widely, each contributing unique characteristics to the final product. Whole milk, with its higher fat content, is commonly used to create a creamy texture and rich flavor. However, for those seeking a lighter option, skim or low-fat milk is often employed, reducing calorie content while maintaining the essential protein structure necessary for cheese formation.

The choice of milk also influences the cheese's melting properties and shelf life. For instance, milk with higher fat content tends to produce cheese that melts more smoothly, making it ideal for dishes like grilled cheese sandwiches or cheese sauces. Conversely, low-fat milk-based processed cheeses may require additional stabilizers to achieve a similar melt, though they offer a healthier alternative for calorie-conscious consumers. Manufacturers often balance these factors to meet specific product requirements, ensuring both taste and functionality.

In some cases, processed cheese incorporates milk from different sources, such as goat or sheep milk, to cater to niche markets or dietary preferences. Goat milk, for example, is easier to digest for some individuals and imparts a distinct tangy flavor to the cheese. Sheep milk, rich in fat and protein, results in a denser, more luxurious product. These alternatives, while less common, highlight the versatility of milk in cheese processing and its ability to cater to diverse consumer needs.

For those with lactose intolerance or dairy allergies, processed cheese made from plant-based milk has emerged as a viable option. Soy, almond, and oat milk are increasingly used to create dairy-free cheese products that mimic the texture and flavor of traditional cheese. While these alternatives may lack the complexity of dairy-based cheese, advancements in processing techniques have significantly improved their quality, making them a practical choice for specific dietary restrictions.

Understanding the types of milk used in processing not only sheds light on the composition of processed cheese but also empowers consumers to make informed choices. Whether prioritizing health, flavor, or dietary needs, the milk base plays a pivotal role in determining the final product's attributes. By recognizing these variations, one can better navigate the wide array of processed cheese options available in the market.

Does Cheese Affect Your Health, Digestion, or Weight? Find Out!

You may want to see also

Milk Alternatives in Processed Cheese

Processed cheese, often labeled as cheese slices or spreads, traditionally relies on milk as its primary ingredient. However, the rise of dietary restrictions, allergies, and ethical concerns has spurred innovation in milk alternatives for processed cheese production. These alternatives not only cater to lactose-intolerant or vegan consumers but also offer unique flavor profiles and nutritional benefits. Common substitutes include soy, almond, oat, and coconut milk, each bringing distinct textures and tastes to the final product. For instance, almond milk imparts a subtle nuttiness, while coconut milk adds a creamy richness. Manufacturers must carefully balance these alternatives with emulsifiers and stabilizers to achieve the desired consistency and meltability characteristic of processed cheese.

When selecting a milk alternative for processed cheese, consider the target audience and desired outcome. For example, soy milk is high in protein, making it suitable for health-conscious consumers, but its strong flavor may overpower milder cheese varieties. Oat milk, on the other hand, is neutral in taste and naturally creamy, ideal for creating a smooth, spreadable texture. Coconut milk, though rich, can solidify at lower temperatures, requiring additional processing to ensure stability. Almond milk, while low in calories, may require fortification with calcium and vitamin D to match the nutritional profile of traditional dairy-based cheese. Experimenting with blends, such as combining oat and almond milk, can yield innovative products that appeal to diverse preferences.

Incorporating milk alternatives into processed cheese involves more than substitution—it requires precise formulation to maintain quality. For instance, plant-based milks often lack the natural fats and proteins found in dairy, necessitating the addition of emulsifiers like lecithin or stabilizers like carrageenan. Fermentation techniques can also enhance flavor and texture, mimicking the tanginess of traditional cheese. For home chefs, creating alternative-based processed cheese starts with heating the chosen milk substitute, adding acid (like lemon juice) to curdle it, and blending in nutritional yeast for a cheesy flavor. Pressing the mixture to remove excess moisture and chilling it will result in a sliceable, dairy-free cheese alternative.

From a market perspective, milk alternatives in processed cheese represent a growing opportunity. Brands like Daiya and Violife have successfully launched vegan cheese slices using coconut and almond milk, proving consumer demand exists. However, challenges remain, such as achieving the meltability and stretchiness associated with dairy cheese. Innovations like using microbial transglutaminase (a natural enzyme) to improve texture are gaining traction. For businesses, investing in research and development to refine these alternatives can lead to products that rival traditional processed cheese in both taste and functionality, tapping into the expanding plant-based market.

Ultimately, milk alternatives in processed cheese are not just a trend but a response to evolving consumer needs. Whether driven by health, ethics, or curiosity, these alternatives offer versatility and inclusivity in the dairy aisle. For manufacturers, understanding the unique properties of each alternative and mastering their application is key to creating appealing products. For consumers, exploring these options opens doors to new flavors and dietary possibilities. As technology advances, the line between dairy and dairy-free processed cheese will continue to blur, offering something for everyone.

Bread and Cheese Sandwich: Uncovering the Key Reactants in This Classic Combo

You may want to see also

Explore related products

Role of Milk Proteins in Cheese

Milk proteins are the backbone of cheese, dictating its texture, flavor, and meltability. Casein, the primary protein in milk, forms a complex network during curdling, trapping fat and moisture to create the cheese matrix. This structure is crucial in both natural and processed cheeses, though the latter often modifies it through heating and emulsification. Without milk proteins, cheese would lack its characteristic body and ability to stretch or melt, making them indispensable even in highly processed varieties.

Consider the role of whey proteins, often overlooked but vital in processed cheese. During cheese production, whey is typically separated from curds, but in processed cheese, it’s reintroduced or retained to enhance functionality. Whey proteins act as emulsifiers, stabilizing the blend of cheese, oils, and additives. This ensures a smooth, consistent texture, preventing oil separation or graininess. For instance, beta-lactoglobulin, a whey protein, binds water and fat, contributing to the creamy mouthfeel of processed cheese slices.

To understand the practical impact, examine the melting behavior of processed cheese. Milk proteins, particularly casein, undergo controlled denaturation during processing, allowing them to form a uniform melt when heated. This is why processed cheese melts smoothly and evenly, unlike some natural cheeses that can become stringy or oily. Manufacturers often add sodium citrate or phosphates to further manipulate protein interactions, ensuring optimal meltability. Home cooks can replicate this by adding a pinch of sodium citrate (1-2% of cheese weight) to shredded natural cheese for a processed-like melt.

However, the manipulation of milk proteins in processed cheese isn’t without trade-offs. While it enhances convenience and consistency, it can alter nutritional profiles. For example, excessive heat treatment during processing may reduce protein digestibility or alter amino acid availability. Consumers seeking higher protein content should compare labels, as some processed cheeses dilute milk proteins with fillers like starch or gums. Opting for varieties with higher milk solids (typically listed as "cheese culture" or "milk protein concentrate") ensures a more nutrient-dense product.

In summary, milk proteins are the unsung heroes of processed cheese, driving texture, melt, and stability. By understanding their role, consumers can make informed choices, whether selecting store-bought options or experimenting with homemade versions. While processed cheese relies on milk proteins, the degree of processing and added ingredients can vary widely, making label scrutiny essential for those prioritizing nutrition or flavor.

Atlanta Bread Company's Cheese Brand: Unveiling Their Signature Selection

You may want to see also

Labeling Milk in Processed Cheese Products

Processed cheese products often contain milk, but the labeling can be confusing for consumers. By law, any product labeled as "cheese" must contain milk, but processed cheese products may use terms like "cheese food," "cheese product," or "cheese spread," which can include milk derivatives or even non-milk fats. To ensure clarity, look for the ingredient list, where milk or milk-based components like whey, milkfat, or milk protein concentrate should be listed. Understanding these nuances helps consumers make informed choices, especially for those with lactose intolerance or dairy allergies.

When examining labels, pay attention to the order of ingredients, as they are listed by weight. If milk or a milk derivative appears near the beginning, it indicates a higher proportion. For instance, a product with "milk, whey, and milkfat" as the first three ingredients likely contains significant milk content. Conversely, if non-milk fats like palm oil or coconut oil appear early, the milk content may be minimal. This simple check can help consumers gauge the dairy presence in processed cheese products, ensuring they align with dietary needs or preferences.

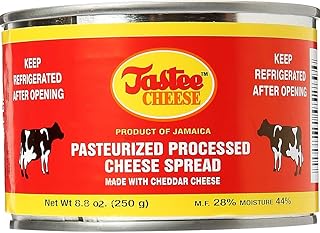

Regulatory bodies like the FDA require specific labeling for processed cheese products. For example, "Pasteurized Process Cheese" must contain at least 51% real cheese, while "Pasteurized Process Cheese Food" requires only 51% cheese with added whey or milk proteins. Products labeled "Pasteurized Process Cheese Spread" must have a moisture content above 44% and may include more non-milk fats. Familiarizing oneself with these classifications can demystify labels and help consumers identify products that meet their expectations for milk content.

For those with dietary restrictions, cross-contamination and hidden milk derivatives are critical concerns. Ingredients like casein, sodium caseinate, lactose, and whey are milk-based but may not be immediately recognizable. Additionally, natural or artificial flavors in processed cheese could be derived from milk. Manufacturers are required to declare milk as a major allergen, often noted with a "Contains: Milk" statement. However, smaller producers or imported products may not follow these guidelines strictly, making it essential to scrutinize labels carefully or contact the manufacturer for clarification.

Practical tips for navigating processed cheese labels include using apps or tools that scan barcodes to provide detailed ingredient breakdowns. For families, understanding milk content is crucial for children’s diets, as dairy is a primary calcium source. However, excessive consumption of processed cheese, often high in sodium and additives, should be moderated. For example, a single serving (28g) of processed cheese can contain 400–600mg of sodium, approaching a third of the daily limit for adults. Balancing nutritional needs with label awareness ensures informed and healthy choices.

Perfect Pairings: Best Drinks to Enjoy with a Philly Cheesesteak

You may want to see also

Frequently asked questions

Yes, processed cheese is made from milk or milk products, such as cheese, whey, or milk solids, combined with emulsifiers and other additives.

Yes, processed cheese is classified as a dairy product because its primary ingredient is milk or milk-derived components.

Processed cheese typically contains lower levels of lactose due to the manufacturing process, but individuals with severe lactose intolerance should still exercise caution or choose lactose-free alternatives.

No, processed cheese often contains less milk fat and protein compared to natural cheese, as it is blended with other ingredients like emulsifiers and stabilizers.

No, by definition, processed cheese must contain milk or milk-derived ingredients to be labeled as cheese. However, there are non-dairy cheese alternatives made from plant-based ingredients.