Aging cheese, also known as ripening, is a meticulous process that transforms fresh curds into complex, flavorful cheeses. It involves controlling temperature, humidity, and airflow in specialized environments, allowing beneficial bacteria and molds to develop. Over time, these microorganisms break down proteins and fats, creating unique textures and tastes. Hard cheeses like Parmesan age for months or even years, while softer varieties like Brie mature more quickly. The art of aging requires patience and expertise, as factors like rind treatment and turning the cheese significantly influence the final product. This process not only enhances flavor but also extends shelf life, making aged cheese a prized delicacy in culinary traditions worldwide.

| Characteristics | Values |

|---|---|

| Temperature | Typically maintained between 45°F to 55°F (7°C to 13°C), depending on the cheese type. |

| Humidity | Controlled at 80-95% relative humidity to prevent drying and encourage mold growth. |

| Duration | Varies widely: soft cheeses (2-4 weeks), semi-hard (2-6 months), hard cheeses (6 months to several years). |

| Environment | Aged in caves, cellars, or climate-controlled rooms with proper ventilation. |

| Microbial Activity | Bacteria and molds (e.g., Penicillium) break down proteins and fats, developing flavor and texture. |

| Turning/Flipping | Cheeses are regularly turned to ensure even moisture distribution and mold growth. |

| Brining/Washing | Some cheeses are brined or washed with solutions (e.g., saltwater, wine, or beer) to enhance flavor and texture. |

| Coating | Cheeses may be coated with wax, ash, or herbs to protect and add flavor. |

| pH Changes | Acidity increases during aging, contributing to flavor and preservation. |

| Moisture Loss | Hard cheeses lose moisture, becoming denser, while soft cheeses retain more moisture. |

| Flavor Development | Complex flavors emerge from enzymatic activity, microbial action, and chemical changes. |

| Texture Changes | Soft cheeses become creamier, while hard cheeses develop a crumbly or crystalline texture. |

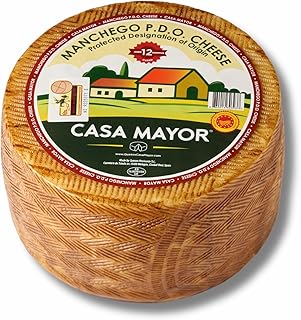

Explore related products

$12.24 $29.99

What You'll Learn

- Temperature Control: Aging cheese requires precise temperature regulation to encourage proper ripening and flavor development

- Humidity Management: Maintaining optimal humidity levels prevents mold growth and ensures cheese texture remains ideal

- Mold Cultivation: Encouraging beneficial molds like Penicillium enhances flavor and contributes to unique cheese characteristics

- Turning and Flipping: Regularly turning cheese wheels prevents uneven aging and promotes consistent moisture distribution

- Aging Time: Different cheeses age for varying durations, from weeks to years, to achieve desired flavors

Temperature Control: Aging cheese requires precise temperature regulation to encourage proper ripening and flavor development

Cheese aging is a delicate dance where temperature acts as the lead, guiding the transformation from fresh curds to complex, flavorful masterpieces. The ideal temperature range for most cheeses falls between 50°F and 55°F (10°C and 13°C). This cool environment slows bacterial activity, allowing enzymes to gradually break down proteins and fats, releasing the amino acids and fatty acids responsible for cheese's distinctive flavors. Deviations from this range can be disastrous: higher temperatures accelerate aging, leading to overly sharp or bitter flavors, while lower temperatures stall the process, resulting in a bland, underdeveloped cheese.

Think of temperature as the conductor of an orchestra, each degree influencing the tempo and harmony of the aging symphony.

Achieving precise temperature control requires specialized equipment. Aging rooms are equipped with thermostats and humidity controls, often utilizing cooling units designed specifically for cheese maturation. Some artisanal cheesemakers employ traditional methods, such as aging in natural caves where temperatures remain consistently cool and humid. Regardless of the method, regular monitoring is crucial. Fluctuations, even minor ones, can disrupt the delicate balance of microbial activity, impacting the final product's texture and taste.

Imagine a painter meticulously layering colors, each stroke dependent on the precise consistency of the paint. Similarly, cheesemakers rely on consistent temperature to build the intricate flavor profile of their cheeses.

Different cheeses demand specific temperature nuances. Hard cheeses like Parmesan thrive in slightly cooler temperatures (around 50°F) to encourage slow, gradual crystallization of amino acids, resulting in their signature granular texture and nutty flavor. In contrast, softer cheeses like Brie require slightly warmer temperatures (around 55°F) to promote the growth of surface molds, contributing to their creamy interior and bloomy rind. Understanding these nuances allows cheesemakers to tailor the aging environment, coaxing out the unique characteristics of each cheese variety.

Just as a chef adjusts oven temperatures for different dishes, cheesemakers fine-tune aging conditions to unlock the full potential of each cheese.

Mastering temperature control is an art honed through experience and meticulous observation. Cheesemakers learn to "read" their cheeses, recognizing subtle changes in texture, aroma, and appearance that indicate the need for temperature adjustments. This intuitive understanding, combined with scientific knowledge, allows them to guide the aging process, transforming humble milk into a symphony of flavors, all orchestrated by the precise control of temperature.

Does Sprouts Sell Raw Cheese? Exploring Availability and Options

You may want to see also

Humidity Management: Maintaining optimal humidity levels prevents mold growth and ensures cheese texture remains ideal

Cheese aging is a delicate dance of time, temperature, and humidity, where the latter often plays an unsung yet pivotal role. Humidity management is critical because it directly influences two key factors: mold growth and cheese texture. Too much moisture, and unwanted molds can take over, spoiling the cheese. Too little, and the cheese can dry out, losing its desired creaminess or crumbly texture. Striking the right balance ensures the cheese develops its intended flavor and consistency, making humidity control a cornerstone of the aging process.

To maintain optimal humidity levels, cheesemakers often rely on specialized aging environments, such as climate-controlled caves or refrigerated rooms. For hard cheeses like Parmesan, humidity levels are typically kept around 80–85%, while softer cheeses like Brie thrive in higher humidity, often 90–95%. Monitoring tools like hygrometers are essential for precision, as even slight deviations can impact the final product. For home aging, a wine fridge with a humidity control feature or a DIY setup using a cooler with a bowl of water can suffice, though consistency is harder to achieve without professional equipment.

The relationship between humidity and mold is particularly nuanced. Desirable molds, such as those in blue cheese, require specific humidity ranges to flourish without overtaking the cheese. Unwanted molds, however, can proliferate in overly damp conditions, ruining the batch. To prevent this, cheesemakers often employ techniques like regular turning and brushing of the cheese, which helps manage surface moisture. Additionally, some cheeses are treated with protective coatings, such as wax or natural rinds, to regulate moisture absorption and loss.

Practical tips for humidity management include maintaining airflow to prevent stagnant moisture pockets and using salt to control surface humidity, as it naturally draws out excess moisture. For softer cheeses, wrapping them in breathable materials like cheesecloth can help retain moisture without trapping it. Conversely, harder cheeses benefit from more exposure to air, often placed on racks to allow even drying. Understanding the specific needs of each cheese type is key, as a one-size-fits-all approach can lead to subpar results.

In conclusion, humidity management is both an art and a science, requiring careful attention to detail and a deep understanding of cheese behavior. By mastering this aspect of aging, cheesemakers can ensure their products develop the desired texture and flavor profiles, turning raw ingredients into culinary masterpieces. Whether in a professional setting or at home, the principles remain the same: monitor, adjust, and respect the process, and the cheese will reward you with its full potential.

Discover Hidden Cheese Stashes on Reaper's Coast: A Tasty Guide

You may want to see also

Mold Cultivation: Encouraging beneficial molds like Penicillium enhances flavor and contributes to unique cheese characteristics

The presence of mold in cheese is not a sign of spoilage but rather a deliberate and carefully managed process that transforms ordinary dairy into a complex, flavorful masterpiece. Among the myriad of microorganisms involved, Penicillium species stand out as the unsung heroes of cheese aging, particularly in varieties like Camembert, Brie, and Blue Cheese. These molds are not just tolerated; they are actively cultivated to impart distinct textures, aromas, and tastes that define the character of the cheese.

To encourage beneficial mold growth, cheesemakers follow a precise regimen. The process begins with inoculation, where Penicillium spores are introduced to the cheese surface either by spraying, dipping, or adding them directly to the milk. For instance, in the production of Roquefort, Penicillium roqueforti spores are mixed into the curd, while for Brie, Penicillium camemberti is applied externally. The dosage of spores is critical—typically ranging from 10^4 to 10^6 colony-forming units per milliliter of milk—to ensure even colonization without overwhelming the cheese. Humidity and temperature control are equally vital; most Penicillium molds thrive in environments with 85-95% humidity and temperatures between 7-12°C, conditions meticulously maintained in aging cellars.

The role of Penicillium extends beyond mere colonization. As the mold grows, it produces enzymes that break down proteins and fats, releasing amino acids and fatty acids that contribute to the cheese’s flavor profile. In blue cheeses, the mold’s mycelium creates distinctive veins, while in surface-ripened cheeses like Camembert, it forms a bloomy rind that softens the interior. This biological activity is a delicate balance; too much mold can lead to bitterness, while too little results in a bland product. Cheesemakers often turn or brush the cheese to control mold growth, ensuring it develops uniformly.

Comparing mold-ripened cheeses to their non-mold counterparts highlights the transformative power of Penicillium. For example, a young, unaged cheddar lacks the earthy, nutty notes found in a mature cheddar, which develops through the action of bacteria rather than mold. In contrast, a wheel of Brie owes its creamy texture and mushroomy flavor entirely to Penicillium camemberti. This comparison underscores the mold’s ability to not just preserve but elevate cheese, turning it into a sensory experience that varies dramatically across types.

For home cheesemakers or enthusiasts, experimenting with mold cultivation requires attention to detail. Start with a high-quality starter culture and maintain strict hygiene to prevent unwanted bacteria. Use a hygrometer and thermometer to monitor aging conditions, and be patient—mold-ripened cheeses can take weeks or even months to reach their peak. Finally, embrace the unpredictability; each batch will be unique, influenced by factors like milk quality and environmental conditions. By mastering mold cultivation, you unlock the potential to create cheeses that are not just food but works of art.

Hard Cheese Benefits: Why It's a Liver-Friendly Dairy Choice

You may want to see also

Explore related products

$7.99

$7.99

Turning and Flipping: Regularly turning cheese wheels prevents uneven aging and promotes consistent moisture distribution

Cheese aging is a delicate dance of time, temperature, and moisture, where the slightest imbalance can lead to flawed results. One critical yet often overlooked step in this process is the regular turning and flipping of cheese wheels. This practice is not merely a ritual but a scientific necessity to ensure even aging and optimal flavor development. By rotating the wheels, cheesemakers prevent the accumulation of excess moisture on one side, which could lead to mold growth or uneven texture. For instance, a 40-pound wheel of cheddar aged for 12 months should be turned at least once every two weeks to maintain consistency.

Consider the mechanics of moisture distribution within a cheese wheel. As cheese ages, it naturally loses moisture, but this process is not uniform. The bottom of the wheel, which rests on the aging surface, tends to dry out faster than the top. Without regular turning, the bottom could become overly hard while the top remains soft, creating a textural imbalance. Flipping the wheel redistributes this moisture gradient, ensuring that the entire surface dries at a similar rate. This is particularly crucial for semi-hard cheeses like Gruyère or Gouda, where a uniform texture is essential for both slicing and melting qualities.

From a practical standpoint, turning cheese wheels requires careful technique to avoid damaging the rind. For smaller wheels (under 10 pounds), a simple flip by hand suffices, but larger wheels may require specialized tools like cheese harps or spatulas. The frequency of turning depends on the cheese variety and desired aging time. For example, a young, moist cheese like Brie may need turning weekly, while a harder cheese like Parmesan can be turned monthly. Always wear gloves to prevent transferring oils or bacteria to the rind, which could alter the flavor profile.

The benefits of regular turning extend beyond texture to flavor development. As the wheel is rotated, different parts are exposed to the aging environment, allowing for a balanced interaction with ambient molds and bacteria. This exposure ensures that the entire wheel develops a consistent flavor profile, rather than having one side dominate with stronger or weaker notes. For artisanal cheesemakers, this step is non-negotiable, as it directly impacts the final product’s quality and marketability. A well-turned wheel of aged cheese commands a premium, reflecting the care and precision invested in its creation.

In conclusion, turning and flipping cheese wheels is a cornerstone of the aging process, marrying science with craftsmanship. It is a task that demands attention to detail and a deep understanding of how cheese evolves over time. By mastering this technique, cheesemakers can produce wheels that are not only visually appealing but also consistently delicious, slice after slice. Whether you’re a professional or a hobbyist, incorporating this practice into your aging routine will elevate your cheese from good to exceptional.

Unraveling the Origins of the Term 'Government Cheese

You may want to see also

Aging Time: Different cheeses age for varying durations, from weeks to years, to achieve desired flavors

The duration of cheese aging is a critical factor in determining its final flavor, texture, and aroma. Cheeses can age for as little as a few weeks or as long as several years, with each passing day contributing to a unique transformation. For instance, a young cheddar aged for 2-3 months will have a mild, slightly tangy flavor and a smooth texture, whereas an aged cheddar that has matured for 1-2 years will develop a sharper, more complex taste and a crumbly consistency. This variation in aging time allows cheesemakers to create a diverse range of products, from fresh and creamy cheeses like mozzarella (typically aged for 1-2 weeks) to hard, granular cheeses like Parmigiano-Reggiano, which can age for 12-36 months.

Consider the aging process as a delicate balance of science and art. During aging, moisture evaporates, and the cheese's pH decreases, creating an environment that encourages the growth of specific bacteria and molds. These microorganisms break down the cheese's proteins and fats, releasing flavor compounds and contributing to the development of its characteristic taste. For example, blue cheeses like Roquefort or Gorgonzola are aged for 2-6 months, during which time the Penicillium mold grows, creating the distinctive blue veins and pungent flavor. In contrast, hard cheeses like Gruyère or Pecorino Romano require a longer aging period of 6-12 months to develop their complex, nutty flavors and hard, granular textures.

To achieve the desired flavor profile, cheesemakers must carefully monitor the aging process, adjusting temperature, humidity, and airflow as needed. A general rule of thumb is that softer cheeses age more quickly, often reaching their peak flavor within 2-8 weeks, while harder cheeses require a slower, more gradual aging process, typically lasting several months to a year or more. For instance, a soft, bloomy-rind cheese like Camembert should be aged at around 50-55°F (10-13°C) and 90-95% humidity for 3-4 weeks, whereas a hard, alpine-style cheese like Comté requires aging at 50-54°F (10-12°C) and 85-90% humidity for 6-12 months. By understanding these aging parameters, cheese enthusiasts can better appreciate the nuances of different cheeses and make informed decisions when selecting or storing them.

A comparative analysis of aging times reveals that some cheeses, like fresh chèvre or ricotta, are best consumed within days of production, as they do not undergo a significant aging process. Others, like aged gouda or cheddar, can be aged for 1-5 years, developing increasingly complex flavors and textures over time. For those interested in experimenting with cheese aging at home, it's essential to start with a suitable cheese, such as a young cheddar or gouda, and provide a consistent aging environment with a temperature range of 45-55°F (7-13°C) and 80-85% humidity. Regularly monitoring the cheese's progress and adjusting the aging conditions as needed will help ensure a successful outcome. By embracing the variability of aging times, cheese lovers can discover new favorites and deepen their appreciation for the art of cheesemaking.

In practice, understanding the aging time of different cheeses can also inform proper storage and serving techniques. For example, younger, softer cheeses should be stored in the refrigerator and brought to room temperature before serving to allow their flavors to fully express. In contrast, older, harder cheeses can be stored at cooler temperatures and served slightly chilled to preserve their texture and flavor. By considering the unique aging characteristics of each cheese, enthusiasts can optimize their enjoyment and appreciation of this diverse and fascinating food. Whether you're a casual cheese lover or a dedicated aficionado, exploring the world of cheese aging times offers a rich and rewarding journey into the heart of this ancient craft.

Mac and Cheese Feast: Calculating Pounds to Feed 200 Guests

You may want to see also

Frequently asked questions

Aging cheese, also known as ripening, is a process where cheese is stored under controlled conditions of temperature and humidity to allow bacteria and molds to transform its texture and flavor over time.

The aging time varies depending on the type of cheese, ranging from a few weeks for fresh cheeses like mozzarella to several years for hard cheeses like Parmigiano-Reggiano.

Temperature is critical in aging cheese; it affects the rate of bacterial activity and moisture loss. Cooler temperatures slow down aging, while warmer temperatures accelerate it, though too high a temperature can spoil the cheese.

Humidity helps maintain the cheese's moisture content and prevents it from drying out. Proper humidity levels also support the growth of desirable molds and bacteria on the cheese's surface.

Yes, cheese can be aged at home by creating a controlled environment, such as using a wine fridge or a cool, humid basement. The cheese should be wrapped in cheese paper or wax, and regularly turned to ensure even aging. Monitoring temperature and humidity is key to success.

![Artisan Cheese Making at Home: Techniques & Recipes for Mastering World-Class Cheeses [A Cookbook]](https://m.media-amazon.com/images/I/81eH1+cYeZL._AC_UY218_.jpg)