In the whimsical world of *Tiny Cow*, increasing the worth of your cheese is a key strategy for success. Players must focus on optimizing their cows' productivity, upgrading their farms, and mastering the art of cheese crafting. By feeding cows high-quality feed, investing in better equipment, and strategically timing cheese production, players can enhance both the quantity and quality of their cheese. Additionally, participating in events, completing quests, and trading with other players can unlock rare ingredients and recipes, further boosting the value of your cheese. Understanding the game’s mechanics and planning long-term goals are essential to maximizing your cheese’s worth and climbing the ranks in this charming farming simulation.

| Characteristics | Values |

|---|---|

| Cheese Quality | Higher quality cheese (e.g., aged or rare types) increases worth. |

| Cow Happiness | Happier cows produce higher-value cheese. |

| Cow Level | Higher-level cows produce more valuable cheese. |

| Cheese Aging | Aging cheese in the game increases its value over time. |

| Special Feed | Using premium or special feed improves cheese quality and worth. |

| Decorations | Adding decorations to the farm can boost cheese value. |

| Quests & Achievements | Completing quests or achievements may reward high-value cheese items. |

| Market Demand | Selling cheese when demand is high increases its worth. |

| Cheese Combinations | Combining different cheeses can create rare, high-value products. |

| Limited-Time Events | Participating in events often yields exclusive, valuable cheese items. |

| Upgrading Facilities | Upgrading cheese-making facilities improves overall cheese quality. |

| Social Interactions | Trading or gifting cheese with friends can increase its value. |

Explore related products

What You'll Learn

- Optimize Feed Quality: High-quality feed improves milk yield, directly boosting cheese production and value

- Breed Selection: Choose high-yield dairy breeds to maximize milk output for cheese-making

- Hygiene Practices: Maintain clean milking areas to prevent contamination, ensuring premium cheese quality

- Aging Techniques: Properly age cheese to enhance flavor, texture, and market value

- Packaging & Branding: Use attractive, sustainable packaging and strong branding to increase perceived worth

Optimize Feed Quality: High-quality feed improves milk yield, directly boosting cheese production and value

Feeding your tiny cow a premium diet isn't just about indulgence; it's a strategic investment in your cheese production. Think of it as fueling a high-performance engine. Just as a race car needs top-tier fuel to reach its full potential, your cow needs nutrient-dense feed to maximize milk output, the foundation of your cheese.

High-quality feed, rich in protein, fiber, and essential vitamins and minerals, directly translates to richer, creamier milk. This, in turn, yields more cheese per milking and enhances its flavor profile and texture. Imagine the difference between a bland, watery cheese and a rich, complex one – the feed makes all the difference.

But what constitutes "high-quality" feed? It's not just about expensive brands. Focus on a balanced diet tailored to your cow's age, breed, and production stage. For lactating cows, aim for a total mixed ration (TMR) with 16-18% crude protein, 28-32% neutral detergent fiber (NDF), and adequate levels of calcium, phosphorus, and vitamins A, D, and E. Consult a veterinarian or animal nutritionist to formulate a precise plan.

Consider incorporating forage like alfalfa hay or silage, known for their high protein and digestibility. Supplement with grains like corn or barley for energy, and don't forget access to clean, fresh water at all times.

Remember, quality feed is an investment, not an expense. While it may cost more upfront, the increased milk production and superior cheese quality will significantly boost your overall yield and profitability. Think long-term: healthier cows, higher output, and a premium product that commands a higher price.

Finally, monitor your cow's body condition score regularly. A score of 3 (on a scale of 1-5) indicates optimal health and milk production. Adjust feed quantities and composition as needed to maintain this ideal condition. By prioritizing feed quality, you're not just feeding your cow; you're nurturing the foundation of your cheese-making success.

Should You Pre-Bake the Crust for a Cheesy Cheesecake?

You may want to see also

Breed Selection: Choose high-yield dairy breeds to maximize milk output for cheese-making

Selecting the right dairy breed is the cornerstone of maximizing cheese production in a small-scale operation like Tiny Cow. High-yield breeds such as Holstein-Friesian, Jersey, and Brown Swiss are renowned for their exceptional milk output, with Holsteins averaging 23,000 pounds of milk annually. However, milk volume alone isn’t the sole criterion. Jersey cows, for instance, produce milk with 5% butterfat and 3.7% protein, ideal for rich, flavorful cheeses, while Holsteins yield milk with 3.2% fat and 3.0% protein, better suited for lower-fat cheeses. Align breed selection with your cheese type to ensure both quantity and quality.

When integrating high-yield breeds, consider the resource demands of each. Holsteins require larger feed quantities due to their size and production levels, whereas Jerseys are more feed-efficient, converting forage into milk more effectively. For a small-scale farm, Jerseys may offer a better balance of output and maintenance costs. Additionally, monitor breeding age—heifers should calve between 22–26 months to optimize lifetime productivity. Pairing breed selection with a tailored nutrition plan can further enhance milk yield, ensuring every cow reaches her genetic potential.

A comparative analysis of breed performance reveals trade-offs. Brown Swiss cows, for example, produce milk with higher solids, perfect for hard cheeses, but their yield is lower than Holsteins. Crossbreeding can mitigate these limitations; a Holstein-Jersey cross might combine high yield with improved fat content. However, avoid overbreeding, as it can lead to health issues like mastitis or reduced fertility. Regular health checks and a controlled breeding program are essential to sustain productivity without compromising animal welfare.

Finally, the choice of breed should align with your cheese-making goals and operational scale. For artisanal cheeses, prioritize breeds with higher fat and protein content, even if it means slightly lower milk volume. For bulk production, focus on breeds that maximize output while maintaining acceptable milk quality. Pair breed selection with efficient milking practices, such as twice-daily milking for Holsteins or once-daily for lower-stress breeds like Jerseys. By strategically selecting and managing high-yield dairy breeds, Tiny Cow can significantly increase cheese worth through optimized milk production and quality.

Is Polly-O Ricotta Cheese Supervised by the Orthodox Union (OU)?

You may want to see also

Hygiene Practices: Maintain clean milking areas to prevent contamination, ensuring premium cheese quality

Clean milking areas are the foundation of premium cheese quality. Contamination from bacteria, dirt, or other pathogens can compromise milk integrity, leading to subpar cheese flavor, texture, and safety. Even trace amounts of contaminants can multiply during the aging process, ruining an entire batch. For tiny cow operations, where resources are limited, preventing contamination is far more cost-effective than addressing it after the fact.

Step 1: Pre-Milking Preparation

Before milking, ensure the cow’s udder and flanks are thoroughly cleaned. Use a mild, food-safe disinfectant solution (e.g., 0.5% iodine solution) and disposable wipes to remove dirt and bacteria. Allow the udder to dry completely before attaching milking equipment. For tiny cow setups, invest in a portable, easy-to-clean milking stool or stand to minimize contact with the ground, a common source of contamination.

Step 2: Equipment Sanitization

Milking equipment—buckets, hoses, and machines—must be sanitized after every use. Wash with hot water (at least 140°F/60°C) and a dairy-specific detergent, then rinse thoroughly. Follow with a sanitizing solution (e.g., 200 ppm chlorine solution) for 5–10 minutes. Air-dry equipment on a clean rack to prevent towel lint or dust contamination. Replace worn or cracked equipment immediately, as these can harbor bacteria.

Step 3: Post-Milking Handling

Filter milk immediately after milking using a dairy filter (40–60 micron) to remove debris. Cool the milk to below 40°F (4°C) within 30 minutes to slow bacterial growth. Store in food-grade, airtight containers. For tiny cow operations, consider batching milk in smaller quantities to ensure rapid cooling and reduce the risk of temperature fluctuations.

Cautions and Best Practices

Avoid using harsh chemicals that may leave residues or taint milk flavor. Never reuse cleaning cloths or wipes—dispose of them after each use. Train all handlers in proper hygiene protocols, including wearing clean clothing and washing hands before milking. Regularly audit your cleaning procedures to identify and address gaps.

Maintaining clean milking areas is a non-negotiable practice for tiny cow operations aiming to produce premium cheese. By implementing rigorous hygiene protocols, you safeguard milk quality, enhance cheese flavor, and protect consumer health. The effort invested in cleanliness directly translates to higher cheese value, making it a cornerstone of success in artisanal dairy production.

Philly Cheese Steak: Cheese Whiz or Not? The Debate Explored

You may want to see also

Explore related products

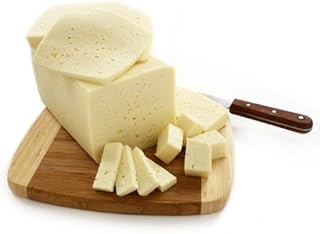

Aging Techniques: Properly age cheese to enhance flavor, texture, and market value

Aging cheese is an art that transforms a simple dairy product into a complex, high-value delicacy. Proper aging enhances flavor, texture, and aroma, making it a critical step in increasing the worth of cheese in *Tiny Cow*. The process relies on controlling temperature, humidity, and time, allowing natural enzymes and bacteria to work their magic. For instance, a young cheddar aged for 6 months develops a sharper flavor and firmer texture, commanding a higher price than its fresher counterpart. Understanding these principles is the first step in mastering cheese aging.

To begin, select the right environment for aging. Ideal conditions include a cool, consistent temperature between 50°F and 55°F (10°C–13°C) and humidity levels around 85–90%. Fluctuations can halt or spoil the aging process, so invest in a dedicated aging fridge or a well-insulated space. For *Tiny Cow* producers, a small wine fridge with a humidity control feature can be a cost-effective solution. Wrap the cheese in cheesecloth or wax paper to protect it while allowing it to breathe, and place it on racks to ensure proper air circulation.

The aging duration varies by cheese type and desired outcome. Soft cheeses like Brie may only need 4–6 weeks, while hard cheeses like Parmesan can age for 12 months or more. For *Tiny Cow* cheeses, aim for a sweet spot: 3–6 months for semi-hard varieties like Gouda or Swiss. During this time, regularly flip the cheese to prevent moisture buildup and mold growth. For added complexity, experiment with natural rinds by introducing specific molds or bacteria cultures, such as *Penicillium camemberti* for a bloomy rind effect.

Caution must be taken to avoid common pitfalls. Over-aging can lead to an overly pungent flavor or crumbly texture, while under-aging may result in blandness. Monitor the cheese weekly, noting changes in appearance and aroma. If unwanted mold appears, gently wipe it off with a cloth dipped in vinegar. Additionally, avoid overcrowding the aging space, as poor airflow can lead to inconsistent results. Patience is key—rushing the process will undermine the cheese’s potential value.

Finally, proper aging not only elevates flavor and texture but also increases market appeal. Aged cheeses are perceived as premium products, allowing *Tiny Cow* producers to charge higher prices. Label the cheese with its age and unique characteristics, such as "6-Month Aged Sharp Cheddar," to attract discerning buyers. Pair this with storytelling about the aging process to further justify the price point. By mastering aging techniques, *Tiny Cow* can turn ordinary cheese into a sought-after, high-value product.

Tillamook Cheese Factory: Are Pepperoni Sticks Still on the Menu?

You may want to see also

Packaging & Branding: Use attractive, sustainable packaging and strong branding to increase perceived worth

In the artisanal cheese market, first impressions are everything. Your packaging is the silent salesperson, conveying quality, sustainability, and brand personality before a single taste. For Tiny Cow, this means ditching generic plastic wraps and embracing materials that whisper "premium" and "eco-conscious." Think compostable cellulose film, recyclable paperboard boxes with embossed logos, or even reusable glass jars for specialty cheeses. These choices not only elevate perceived value but also align with the growing consumer demand for sustainable practices, creating a ripple effect of positive brand association.

Consider the unboxing experience. A well-designed package should be a sensory journey, engaging sight, touch, and even sound. Incorporate tactile elements like textured paper, embossed patterns, or a subtle scent of fresh hay. Include a story card detailing the cheese's origin, aging process, and suggested pairings. This transforms a simple purchase into a curated experience, fostering a deeper connection with your brand and justifying a higher price point.

Branding is the soul of your cheese, the intangible essence that differentiates Tiny Cow from the herd. Develop a visual identity that reflects your unique story and values. Is Tiny Cow a playful, farm-to-table brand? Opt for whimsical illustrations and hand-drawn typography. Leverage a minimalist, modern aesthetic with clean lines and muted colors for a more sophisticated, artisanal image. Consistency across packaging, website, and marketing materials builds recognition and trust, essential for commanding premium prices.

Don't underestimate the power of storytelling. Weave a narrative around your cheese, highlighting the care, tradition, and craftsmanship behind each wheel. Share the story of your cows, the pasture they graze on, and the hands that meticulously craft each batch. This emotional connection transforms cheese from a commodity into a cherished experience, allowing you to charge a premium for the intangible value of authenticity and heritage.

Finally, remember that packaging and branding are investments, not expenses. While sustainable materials and high-quality design may come at a higher cost, they pay dividends in increased perceived value, customer loyalty, and brand differentiation. Think of it as dressing your cheese for success, ensuring it stands out on the shelf and commands the attention – and price – it deserves.

Wild Sardina: Exploring Its Themes, Not Cheese, in Depth

You may want to see also

Frequently asked questions

To increase cheese worth, focus on upgrading your cheese production facilities, hiring skilled workers, and researching advanced cheese recipes in the game.

Yes, breeding high-quality cows with better traits can produce higher-quality milk, which in turn increases the worth of the cheese you make.

Yes, using premium items like "Golden Mold" or "Aged Spices" can significantly increase the value of your cheese.

Completing quests often rewards you with resources, upgrades, or special items that can enhance your cheese production and increase its worth.