Replacing the wire on a cheese board is a straightforward task that can extend the life of your cutting board and ensure it remains functional for slicing cheese efficiently. Over time, the wire on a cheese board can become dull, frayed, or broken, making it less effective for cutting. To replace it, you’ll typically need a new wire cutter specifically designed for cheese boards, a screwdriver, and possibly pliers. Start by removing the old wire, which is usually held in place by screws or clips, then carefully thread the new wire through the grooves or slots, ensuring it is taut and securely fastened. This process not only restores the board’s functionality but also ensures a clean and precise cut for your cheese.

| Characteristics | Values |

|---|---|

| Tools Needed | Pliers, wire cutter, replacement wire (specific gauge for cheese board), screwdriver (if necessary) |

| Wire Type | Typically stainless steel or galvanized steel, food-grade |

| Wire Gauge | Varies by cheese board model, commonly 12-16 gauge |

| Steps | 1. Remove old wire by loosening screws or clips holding it in place. 2. Cut new wire to appropriate length. 3. Thread new wire through grooves or holes in the board. 4. Secure wire with screws or clips, ensuring tension is even. |

| Maintenance | Regularly check wire for rust or damage; replace as needed |

| Safety Tips | Wear gloves to avoid sharp wire edges; ensure wire is securely fastened to prevent accidents |

| Common Issues | Wire slipping, uneven tension, rust formation |

| Cost | Replacement wire typically costs $5-$15, depending on length and quality |

| Availability | Replacement wire available at kitchen supply stores or online retailers |

| DIY vs. Professional | Most replacements can be done DIY, but complex boards may require professional assistance |

Explore related products

$8.99 $9.99

What You'll Learn

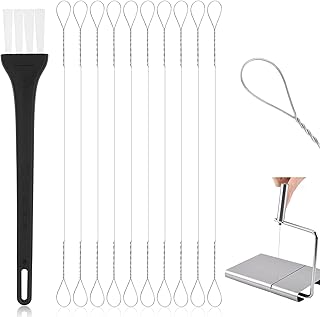

- Gather Tools & Materials: Wire cutter, pliers, replacement wire, and a new tension wheel if needed

- Remove Old Wire: Loosen tension, cut wire, and carefully pull it out of the board

- Prepare New Wire: Measure, cut, and attach the wire to the tension wheel securely

- Install Wire: Thread wire through the board’s grooves and tighten using the tension wheel

- Test & Adjust: Ensure wire is taut, test cutting cheese, and adjust tension if necessary

Gather Tools & Materials: Wire cutter, pliers, replacement wire, and a new tension wheel if needed

Replacing the wire on a cheese board is a straightforward task, but having the right tools and materials is crucial for a smooth process. Start by gathering a wire cutter, pliers, replacement wire, and a new tension wheel if the existing one is worn or damaged. These tools ensure precision and safety, preventing unnecessary frustration or mistakes. The wire cutter is essential for cleanly removing the old wire, while pliers help manipulate the new wire into place. Replacement wire should match the gauge and length of the original to maintain functionality. If the tension wheel is compromised, replacing it ensures the wire stays taut and effective for slicing cheese.

Consider the quality of your materials to ensure longevity. Opt for stainless steel replacement wire, as it resists rust and corrosion, ideal for frequent use in food preparation. When selecting a tension wheel, choose one made of durable plastic or metal that fits your cheese board model. Check the wire gauge—typically 18 to 20 gauge—to ensure compatibility. If you’re unsure about the specifications, consult the manufacturer’s guidelines or measure the old wire for accuracy. Investing in high-quality materials now saves time and effort in the long run.

Before beginning, inspect your tools for sharpness and functionality. A dull wire cutter can fray the wire, making it difficult to work with. Pliers should have a firm grip to avoid slipping, which could damage the cheese board or injure your hands. If your tools are worn, consider upgrading to ergonomic options designed for precision work. Keep a clean workspace to avoid losing small parts like screws or tension wheel components. Organization is key—lay out all materials in advance to streamline the process.

For those new to this task, practice patience and attention to detail. Start by loosening the tension wheel (if applicable) and carefully cutting the old wire close to the wheel without damaging the board. Use pliers to feed the new wire through the grooves, ensuring it’s centered and secure. Tighten the tension wheel gradually, testing the wire’s tautness as you go. Over-tightening can warp the board, while under-tightening renders the wire ineffective. If you encounter resistance, double-check the wire’s alignment before applying more force.

Finally, test the new wire by slicing a firm cheese like cheddar or gouda. If the wire cuts smoothly without snagging, you’ve succeeded. If not, adjust the tension or recheck the wire’s placement. Regular maintenance, such as cleaning the wire and tension wheel after use, extends the life of your cheese board. With the right tools and materials, this task becomes a simple, satisfying DIY project that keeps your cheese board in prime condition for years to come.

Does Cold Pack Cheese Require Refrigeration? Essential Storage Tips Revealed

You may want to see also

Remove Old Wire: Loosen tension, cut wire, and carefully pull it out of the board

The first step in replacing the wire on a cheese board is to remove the old wire, a task that requires precision and care to avoid damaging the board. Begin by loosening the tension on the wire, which is typically held in place by a small screw or bolt at each end of the board. Use a screwdriver to turn these fasteners counterclockwise, gradually releasing the tension until the wire is slack. This step is crucial, as attempting to cut a taut wire can lead to it snapping back dangerously or causing splintering in the wood.

Once the tension is released, carefully cut the wire using wire cutters or heavy-duty scissors. Position the cut at a point where the wire is most accessible, usually near one of the fasteners. Ensure the cut is clean and straight to prevent fraying, which could complicate the removal process. After cutting, gently pull the wire out of the board, starting from the cut end. Work slowly and methodically, as rushing can cause the wire to catch on the wood fibers or damage the grooves where it sits.

A practical tip is to use a pair of needle-nose pliers to grip the wire if it’s difficult to pull by hand. This tool provides better control and reduces the risk of slipping, which could lead to injury or board damage. If the wire is particularly stubborn, apply a small amount of penetrating oil to the grooves where the wire sits, allowing it to loosen over a few minutes before attempting removal again.

Comparatively, this process is similar to replacing a string on a musical instrument, where tension must be released before the old component can be safely removed. The key difference lies in the material and purpose: cheese board wires are sturdier and embedded in wood, requiring more caution to avoid splintering or cracking. By approaching this step with patience and the right tools, you set the stage for a smooth replacement process, ensuring your cheese board remains functional and aesthetically pleasing.

Mastering the Art of Baking Brie Cheese in a Brie Baker

You may want to see also

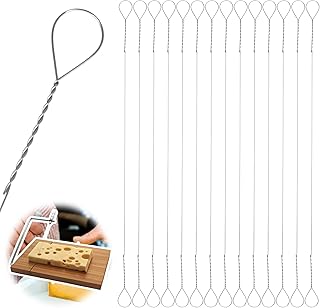

Prepare New Wire: Measure, cut, and attach the wire to the tension wheel securely

The tension wheel is the unsung hero of your cheese board, and attaching the wire securely is crucial for smooth, precise slicing. Begin by measuring the wire to ensure it spans the board with enough slack for tensioning but not so much that it becomes unwieldy. A good rule of thumb is to add 6–8 inches to the length of the board to account for wrapping around the wheel and securing the ends. Use a sturdy wire cutter designed for metal to achieve a clean cut, avoiding fraying that could compromise strength.

Attaching the wire to the tension wheel requires precision and the right tools. Most cheese boards use a slotted or grooved wheel, so thread the wire through the slot, ensuring it sits firmly in place. If your wheel has a screw mechanism, wrap the wire around the axle and tighten the screw securely, but not so tight that it risks damaging the wire or wheel. For added stability, consider using a small pliers to hold the wire taut while tightening, ensuring it doesn’t slip during use.

A common mistake is underestimating the importance of wire tension. Too loose, and the wire won’t slice effectively; too tight, and it risks snapping under pressure. After attaching the wire, test the tension by gently pulling it across the board. It should feel firm but not rigid, allowing for smooth slicing without excessive force. If adjustments are needed, loosen the tension wheel slightly and retest until the desired tension is achieved.

Finally, consider the wire material for longevity. Stainless steel is ideal for its durability and resistance to rust, especially if you frequently slice acidic cheeses. Avoid wires with rough edges or signs of wear, as these can tear the cheese or break during use. With the wire securely attached and properly tensioned, your cheese board is ready to deliver clean, precise slices for years to come.

McDonald's Breakfast Menu: Bacon, Egg, and Cheese McMuffin Availability

You may want to see also

Explore related products

Install Wire: Thread wire through the board’s grooves and tighten using the tension wheel

Replacing the wire on a cheese board is a straightforward task that can extend the life of your cutting board and ensure clean, precise slices. The key to a successful replacement lies in the installation process, specifically how you thread the wire through the board's grooves and tighten it using the tension wheel. This method not only secures the wire but also ensures it maintains the correct tension for effective cutting.

Begin by selecting a wire that matches the specifications of your cheese board. Most boards use a standard gauge wire, typically around 18 to 20 gauge, which balances durability and flexibility. Once you have the appropriate wire, locate the grooves on your cheese board. These grooves are usually found along the edges of the board and are designed to guide the wire. Start by feeding one end of the wire into the groove, ensuring it follows the path smoothly. Patience is crucial here, as forcing the wire can cause it to kink or damage the board.

After threading the wire through the grooves, the next step involves the tension wheel. This small but essential component is what allows you to adjust the wire’s tightness. Position the wire around the tension wheel, following the manufacturer’s instructions for proper alignment. Turn the wheel clockwise to tighten the wire gradually. Over-tightening can cause the wire to snap, while under-tightening may result in ineffective cutting. Aim for a tension that allows the wire to move slightly when pressed but remains taut enough to slice through cheese effortlessly.

A practical tip is to test the wire’s tension by gently pressing down on it with a piece of cheese. If it slices cleanly without excessive force, the tension is correct. If the wire feels too loose or tight, adjust the tension wheel accordingly. Regularly checking and adjusting the tension will ensure your cheese board remains functional over time. Additionally, keep the wire clean by wiping it down after each use to prevent cheese buildup, which can affect its performance.

In conclusion, installing the wire on a cheese board is a simple yet precise process. By carefully threading the wire through the grooves and using the tension wheel to achieve the right tightness, you can maintain a functional and efficient cheese board. This small maintenance task not only saves you money but also enhances your cheese-cutting experience, making it a worthwhile skill to master.

Is Italian Herb and Cheese Bread Still Available at Subway?

You may want to see also

Test & Adjust: Ensure wire is taut, test cutting cheese, and adjust tension if necessary

Once the new wire is threaded through the cheese board, achieving the right tension is critical for clean, effortless cuts. A slack wire will wobble and tear the cheese, while an overly tight wire risks snapping under pressure. Start by pulling the wire as taut as possible without straining the board’s mechanism. Use the tightening screws or bolts (typically located at the ends of the board) to secure it evenly, ensuring both sides are balanced. A simple visual check—does the wire sit straight and flat across the cutting plane?—can confirm initial alignment.

Testing the wire’s functionality is the next essential step. Select a firm cheese, such as cheddar or Gruyère, and apply gentle downward pressure to slice through it. Observe the wire’s behavior: does it glide smoothly, or does it catch and drag? A properly tensioned wire will cut with minimal resistance, leaving a clean edge. If the cheese crumbles or the wire bends, the tension is likely too loose. Conversely, if the wire feels rigid and difficult to move, it may be too tight, risking breakage during heavier use.

Adjusting tension requires precision. Loosen the screws slightly if the wire is too tight, turning them counterclockwise in small increments (about ¼ turn at a time). Retighten and retest until the wire moves freely but remains stable. If the wire is too loose, tighten the screws gradually, alternating between sides to maintain even tension. For boards with adjustable pegs or sliding mechanisms, slide the wire holders closer together or farther apart as needed. Always retest after each adjustment to ensure the wire performs optimally.

Practical tips can streamline this process. Use a ruler or straightedge to verify the wire’s alignment before testing, especially on boards with longer cutting surfaces. For boards with multiple wires, adjust one wire at a time, ensuring each is taut and functional before moving to the next. If the wire continues to slip or feels uneven despite adjustments, inspect the board’s mechanism for wear or damage—worn screws or cracked grooves may require repair or replacement.

The goal of testing and adjusting is not just functionality but longevity. Proper tension reduces stress on the wire and board, extending their lifespan. Regularly check tension after extended use or if the wire feels less responsive. By treating this step as a calibration process rather than a one-time fix, you ensure the cheese board remains a reliable tool for precise, elegant slicing.

Do Taco Cabana's Chicken Flautas Include Cheese? Find Out Here!

You may want to see also

Frequently asked questions

You’ll need a new cheese board wire (ensure it’s the correct size), pliers, and a screwdriver if your board has screws holding the wire in place.

Loosen any screws or clamps holding the wire in place, then carefully unwind the old wire from the board using pliers to avoid damage to the board.

Thread the new wire through the grooves or slots on the board, ensuring it’s taut and evenly aligned. Secure it with screws or clamps, then test the tension before use.