Cheese is a beloved food worldwide, with over a thousand types produced in various countries. The process of making cheese involves coagulating milk protein, separating the curds from the whey, and then shaping and ageing the curds. The shaping stage is where the final product begins to take form. Shaping is often done using moulds, which can be made of baskets or hoops, resulting in round or rectangular blocks of cheese. The moulds are designed to allow water to escape, and the amount of pressure applied depends on the desired hardness of the cheese.

| Characteristics | Values |

|---|---|

| How cheese gets its shape | Curds are pressed into molds or forms to achieve their final shape |

| What are curds | Solid form of milk after it is curdled |

| How are curds formed | Milk is curdled using rennet or acid to separate curds (solid) from whey (liquid) |

| Shaping process | Curds are pressed into molds or brined, depending on the cheese type |

| Molds | Can be in the form of baskets or hoops, resulting in cylindrical or block-shaped cheese |

| Pressure | The amount of pressure applied depends on the hardness of the cheese |

| Aging | Cheese is then aged for days or years to develop flavor and texture |

Explore related products

What You'll Learn

The role of curds and whey

The process of cheese-making involves several steps, and the role of curds and whey is integral to this process. Curds and whey are formed when milk is curdled using rennet or acid. This process separates the milk into solid curds and liquid whey. The curds are then drained, and the whey is released.

The curds are then stirred and gently heated, further releasing whey and concentrating the solids. The amount of whey released depends on the desired texture of the cheese. For drier, firmer cheeses like Parmesan, the curds are cut smaller to release more whey. On the other hand, larger curds retain more moisture, resulting in softer cheeses like Brie.

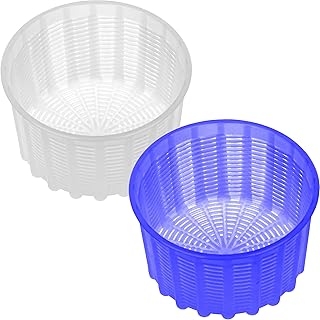

Once the whey is drained, the curds are ready to be shaped into cheese. Cheesemakers press the soft curds into molds, which can be baskets or hoops, to create standardized shapes. The molds are designed to allow water to escape, and the pressure applied unifies the curds into a single solid body. The harder the desired cheese, the more pressure is applied during this step.

After the curds have solidified into the desired shape, the cheese is then salted and aged under controlled conditions. During aging, the cheese develops its distinct flavors, textures, and aromas. The aging process can take anywhere from a few days to several years, depending on the type of cheese being made.

Cheese and Magnesium: A Healthy Combination?

You may want to see also

Salting and brining

There are two main technologies for salting cheese: dry salting and brine salting. In dry salting, salt is scattered, milled, or rubbed on the surface of a block of curd after the cheese is pressed and the moisture degree has been lowered. The salt at the surface slowly enters the cheese, and moisture is extracted from the surface of the cheese to dissolve the salt crystals.

Brine salting involves submerging the cheese in a saturated salt brine solution for a given length of time. The brine solution is made by mixing salt and water until the salt no longer dissolves. The density of the brine causes the cheese to float, so the top surface of the cheese will need to be salted. The cheese is then left to brine for a certain amount of time, with the general rule being one hour per pound per one inch of thickness of cheese. The brining process can be done in various ways, such as in a rack system, a 'river'-type system, or a mixed system. The brine solution should be kept cool and stored in a non-reactive container.

Salt affects the texture of the cheese by altering its protein structure and removing moisture. The presence of salt in certain concentrations can also change how microbes and enzymes behave, which can have a drastic effect on the texture and flavour of the cheese.

Velveeta Cheese: Does it Age Like Fine Wine?

You may want to see also

Pressing and moulding

Cheesemakers press the curds into the desired mould, applying more pressure for harder cheeses. This pressure forces out any remaining moisture, driving out water and unifying the curds into a single solid mass. The moulds themselves are designed to allow water to escape, further contributing to the dehydration process. This pressing and moulding stage is crucial in determining the final texture of the cheese, with harder cheeses requiring more pressure to remove excess moisture.

The specific moulds used can vary, but most result in either round or rectangular shapes, yielding cylinders or blocks of cheese. These shapes are common among popular varieties such as cheddar, brie, and Parmesan. The mould also imparts a distinctive texture to the cheese's surface, which may be smooth or marked with patterns from the mould.

In addition to shaping the cheese, the moulds can also facilitate ageing. During the ageing process, molecular changes occur within the cheese, causing it to harden and develop a more intense flavour. The mould may contribute to this process by allowing the growth of beneficial microbes that enhance the cheese's flavour and texture. The ageing duration depends on the desired cheese variety and can range from a few days to several years.

Feta Cheese: Does It Get Moldy?

You may want to see also

Explore related products

The origin of 'cheese'

Cheese is an ancient food whose origins predate recorded history. There is no conclusive evidence indicating where cheesemaking first originated, whether in Europe, Central Asia, or the Middle East. The earliest proposed dates for the origin of cheesemaking range from around 8000 BCE when sheep were first domesticated. The process of cheesemaking was likely discovered accidentally when milk was stored in a container made from the stomach of an animal, and the milk curdled due to the rennet from the stomach.

The word "cheese" itself also has an unknown origin, perhaps deriving from a PIE root "*kwat-" meaning "to ferment, become sour". When the Romans began to make hard cheeses for their legionaries, a new word started to be used: "formaticum", from "caseus formatus", meaning "cheese shaped in a mould". This is the root of the modern words for cheese in many Romance languages, such as "fromage" in French, "formaggio" in Italian, and "queso" in Spanish.

In the cheesemaking process, milk is collected from dairy farms and undergoes strict quality and purity tests to ensure it meets safety standards. It is then filtered and standardised, with the milk fat, cream, or protein content adjusted to create a consistent base for cheese production. The milk is then pasteurised to eliminate harmful bacteria and heated to a specific temperature to kill pathogens.

Cheese is made by curdling milk using rennet or an acid, which separates the curds (solid) from the whey (liquid). The curds are then drained, shaped, salted, and aged to develop flavour and texture. The exact process varies by each cheese type, but the fundamental steps remain the same. Cheesemakers can press the soft curds into moulds to create standardised shapes, with the moulds taking the form of baskets or hoops.

Subway's Italian Herbs and Cheese: Gone for Good?

You may want to see also

How cheese is aged

Cheese ripening, or maturation, is responsible for the distinct flavour of cheese. It is one of the most important elements of the cheesemaking process. The process is characterised by a series of complex physical, chemical, and microbiological changes that incorporate bacteria, enzymes, and environmental contaminants.

Aging allows cheese to develop its full flavour, aroma, and texture. The longer cheese ages, the more intense its flavour becomes. The aging period is also a key component in allowing certain cheeses to reach their unique texture. For example, Swiss cheese starts to form holes as it ages, giving it its characteristic texture. Similarly, the ageing process causes crumbly cheeses like cheddar to harden.

The aging process can be as simple as putting cheese in a plastic bag, vacuum sealing it, and letting it mature. However, it can also be more complicated, with techniques to prime the surface of the cheese. Some cheeses are aged in cheese caves, where high humidity and proper air circulation are maintained. Temperature also plays a role in cheese aging. The temperature in aging rooms ranges between 48 and 57 degrees Fahrenheit, with a humidity level between 88 and 98 percent.

The aging time varies depending on the type of cheese. Each type of cheese requires a different aging period, ranging from 3 months to over a year for certain types of cheese. For example, Parmesan cheese is aged for one year, while Cello Copper Kettle cheese is aged for 16 months. Some cheeses, like Swiss cheese, are aged in stages, where they are moved between different caves or environments.

Cheese's Journey to America: A Historical Account

You may want to see also

Frequently asked questions

Most cheeses get their shape when the curds are pressed into a mold or form. The harder the cheese, the more pressure is applied. The pressure drives out moisture and unifies the curds into a single solid body. Most molds are round or rectangular, resulting in cylinders or blocks of cheese.

Cheese molds can take the form of baskets or hoops. Basket molds are only open on one end, and hoop molds are bottomless, meaning they only wrap around the sides of the curd.

Yes, some cheeses, like mozzarella, are brined after being placed in molds. Pressing expels any remaining whey and gives the cheese its signature shape and texture.