Squeeze cheese, a convenient and versatile dairy product, operates through a combination of innovative packaging and careful processing. Typically, the cheese is first melted and blended with emulsifiers and stabilizers to achieve a smooth, spreadable consistency. This mixture is then cooled and packaged into flexible, airtight containers designed for easy dispensing. When pressure is applied to the container, the cheese is forced out through a small nozzle, allowing for precise and mess-free application. The airtight seal ensures freshness and prevents spoilage, while the controlled dispensing mechanism makes squeeze cheese a popular choice for both culinary and snacking purposes. Understanding the science behind its production and packaging sheds light on why this product remains a staple in many households.

| Characteristics | Values |

|---|---|

| Product Type | Processed cheese in a squeezable tube or bottle |

| Texture | Smooth, spreadable, and easily dispensed |

| Packaging | Flexible plastic tube or bottle with a nozzle for controlled dispensing |

| Ingredients | Cheese (often pasteurized), milk, salt, emulsifiers, preservatives |

| Functionality | Designed for convenience, easy application, and mess-free use |

| Storage | Typically requires refrigeration after opening |

| Shelf Life | Varies by brand, but generally 2-4 weeks after opening |

| Common Uses | Sandwiches, crackers, snacks, cooking, and garnishing |

| Dispensing Mechanism | Squeeze-based, allowing precise control over the amount dispensed |

| Flavor Varieties | Cheddar, American, mozzarella, pepper jack, and more |

| Target Audience | Families, children, and individuals seeking convenience |

| Advantages | Portability, ease of use, reduced mess, and portion control |

| Disadvantages | Contains additives, may lack the flavor of natural cheese |

| Brands | Examples: Easy Cheese, Kraft, President, and store-specific brands |

| Nutritional Content | Varies; generally high in fat, sodium, and calories |

| Environmental Impact | Plastic packaging raises sustainability concerns |

Explore related products

What You'll Learn

- Mechanical Dispensing Mechanism: Squeeze cheese uses a plunger or piston to push cheese through a nozzle

- Packaging Design: Flexible tubes or bottles allow controlled pressure for easy dispensing

- Cheese Consistency: Soft, spreadable texture ensures smooth flow without clogging the nozzle

- Preservatives and Additives: Stabilizers and emulsifiers maintain consistency and extend shelf life

- Airtight Seal: Prevents oxidation and spoilage, keeping cheese fresh until fully consumed

Mechanical Dispensing Mechanism: Squeeze cheese uses a plunger or piston to push cheese through a nozzle

Squeeze cheese operates on a simple yet ingenious mechanical principle: a plunger or piston system. This mechanism is the unsung hero behind the ease of dispensing creamy, spreadable cheese with a gentle squeeze. Here’s how it works: when pressure is applied to the container, the plunger or piston moves downward, forcing the cheese through a narrow nozzle. This design ensures consistent portion control and minimizes mess, making it a favorite for both home cooks and food service professionals.

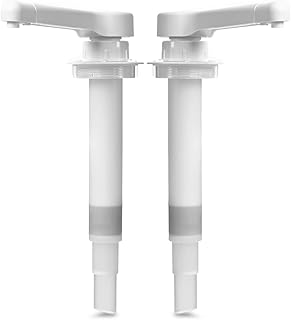

Consider the anatomy of a squeeze cheese package. The plunger, typically made of food-grade plastic, fits snugly inside the tube or bottle. As you squeeze, the plunger advances incrementally, maintaining constant pressure on the cheese. The nozzle, often tapered or ridged, shapes the cheese as it exits, allowing for precise application—whether you’re topping a cracker or garnishing a dish. This system is particularly effective for semi-soft cheeses, which have the ideal viscosity to flow smoothly without clogging.

For optimal performance, store squeeze cheese upright to prevent air pockets from forming near the nozzle. If the cheese becomes too firm, gently massage the container to warm it slightly, easing the plunger’s movement. Avoid over-squeezing, as this can cause the cheese to splatter or the plunger to jam. For food service settings, portion control is key: a single squeeze typically dispenses about 10–15 grams of cheese, ideal for consistent plating.

Comparing this mechanism to other dispensing methods, such as pump bottles or jars, highlights its efficiency. Unlike pumps, which can introduce air and cause spoilage, the plunger system creates a near-airtight seal, preserving freshness. Jars, while versatile, lack the precision and convenience of a squeeze mechanism. For families with children, squeeze cheese is a practical choice—its mess-free design encourages independence, and the controlled portions help manage snack sizes for kids aged 3 and up.

In conclusion, the mechanical dispensing mechanism of squeeze cheese is a marvel of simplicity and functionality. By understanding its design and following practical tips, users can maximize its utility in various settings. Whether in a busy kitchen or a packed lunchbox, this system ensures that every squeeze delivers the perfect amount of cheese, every time.

Cheese Bridge Area Secret Exit: Unveiling the Hidden Path

You may want to see also

Packaging Design: Flexible tubes or bottles allow controlled pressure for easy dispensing

Flexible packaging, such as tubes or bottles, plays a pivotal role in the functionality of squeeze cheese by enabling controlled pressure for easy dispensing. Unlike rigid containers, these materials conform to the force applied, ensuring a consistent and manageable flow of the product. This design is particularly crucial for cheese, which requires a balance between viscosity and ease of use. When pressure is applied to the tube or bottle, the walls deform uniformly, pushing the cheese out without causing splatter or waste. This mechanism not only enhances user experience but also preserves the product’s freshness by minimizing exposure to air.

Consider the practical application: a parent preparing a quick snack for a child or a chef garnishing a dish. The ability to dispense cheese with precision is essential. Flexible packaging allows for gradual or rapid release depending on the force applied, making it versatile for various uses. For instance, a gentle squeeze might yield a thin, controlled stream ideal for decorating a plate, while a firmer grip can quickly deposit a dollop for a sandwich. This adaptability is a direct result of the packaging’s ability to respond to user input, ensuring the product meets diverse needs without requiring additional tools.

From a design perspective, the choice of material is critical. Most squeeze cheese containers are made from polyethylene or similar plastics, which offer the right balance of flexibility and durability. These materials are lightweight, reducing shipping costs and environmental impact, while also being resistant to punctures and leaks. The nozzle or cap design further enhances functionality, often featuring a narrow opening to regulate flow and prevent spillage. Some brands incorporate a reclosable cap to maintain freshness, ensuring the cheese remains usable over multiple servings.

One often-overlooked benefit of flexible packaging is its role in portion control. For health-conscious consumers, the ability to dispense precise amounts of cheese is invaluable. A single squeeze can deliver a measured portion, typically around 10–15 grams, depending on the product. This not only supports dietary goals but also reduces food waste by allowing users to use exactly what they need. Manufacturers can further assist consumers by including serving size indicators on the packaging, such as markings that show how much product is dispensed with each squeeze.

In conclusion, the success of squeeze cheese hinges on its packaging design, particularly the use of flexible tubes or bottles. This innovation ensures controlled pressure for easy dispensing, catering to a wide range of applications and user preferences. By combining the right materials, nozzle design, and portion control features, manufacturers create a product that is both functional and user-friendly. Whether for convenience, precision, or sustainability, flexible packaging stands out as a key factor in making squeeze cheese a staple in kitchens and lunchboxes alike.

How Quickly Does Cheese Mold? Factors Affecting Growth and Prevention

You may want to see also

Cheese Consistency: Soft, spreadable texture ensures smooth flow without clogging the nozzle

The secret to a flawless squeeze cheese experience lies in its consistency. A soft, spreadable texture is paramount, ensuring the cheese glides effortlessly through the nozzle without clogging. This isn't just about convenience; it's about delivering a consistent, enjoyable product with every squeeze. Imagine the frustration of a clogged nozzle mid-snack – a scenario easily avoided with the right texture.

Achieving this ideal consistency involves a delicate balance. Too runny, and the cheese lacks structure, becoming messy and difficult to control. Too thick, and it becomes a struggle to dispense, leading to wasted product and frustrated consumers. Manufacturers carefully select cheese varieties and employ specific processing techniques to achieve this Goldilocks zone – a texture that's "just right."

Consider the science behind it. Soft cheeses, naturally higher in moisture content, are ideal candidates for squeeze packaging. During production, these cheeses are often blended with emulsifiers and stabilizers. These ingredients act like tiny molecular bridges, preventing fat separation and ensuring a smooth, homogenous texture. Think of it as a microscopic scaffolding system, holding the cheese together while allowing it to flow freely.

This focus on consistency isn't just about functionality; it's about taste and texture. A smooth, spreadable cheese enhances the sensory experience. It melts effortlessly on crackers, blends seamlessly into dips, and adds a creamy richness to sandwiches. The ease of dispensing encourages experimentation, allowing consumers to get creative with their cheese applications.

From a practical standpoint, the soft, spreadable texture of squeeze cheese offers several advantages. It's perfect for on-the-go snacking, eliminating the need for utensils and minimizing mess. It's also a lifesaver for parents, providing a quick and easy way to add protein and calcium to their children's meals. For those with limited hand strength or dexterity, the ease of dispensing makes squeeze cheese a more accessible option.

Perfect Broccoli and Cheese in Your NuWave Oven: Easy Steps

You may want to see also

Explore related products

Preservatives and Additives: Stabilizers and emulsifiers maintain consistency and extend shelf life

Squeeze cheese, a convenient and popular snack, owes its smooth texture and extended shelf life to a carefully balanced mix of stabilizers and emulsifiers. These additives are the unsung heroes behind the product’s consistency, ensuring it remains pourable yet thick enough to cling to crackers or pretzels. Without them, the cheese would separate into oily and solid components, rendering it unappealing and unusable. Understanding their role reveals the science behind this everyday convenience.

Stabilizers, such as carrageenan or xanthan gum, are often added in concentrations of 0.1% to 0.5% by weight to create a uniform texture. These compounds act like molecular scaffolding, trapping water and fat molecules to prevent separation. For instance, carrageenan, derived from seaweed, forms a gel-like structure that keeps the cheese homogeneous. Emulsifiers, like sodium phosphate or mono- and diglycerides, work in tandem by reducing surface tension between oil and water, allowing them to blend seamlessly. A typical dosage of sodium phosphate might range from 0.2% to 0.4%, ensuring the cheese remains smooth and spreadable.

While these additives are essential for functionality, their use is not without scrutiny. Critics often question the health implications of consuming synthetic stabilizers and emulsifiers regularly. However, regulatory bodies like the FDA classify most of these additives as GRAS (Generally Recognized as Safe) when used within approved limits. For example, carrageenan is considered safe for consumption in amounts up to 0.5% in dairy products. Practical tips for consumers include checking labels for additive names and opting for products with simpler ingredient lists if concerned.

Comparatively, natural alternatives like lecithin (derived from soybeans) are gaining traction as emulsifiers, appealing to health-conscious consumers. However, these options may not always match the efficacy of synthetic additives, potentially compromising texture or shelf life. Manufacturers must strike a balance between consumer demand for "clean labels" and the functional requirements of squeeze cheese. This tension highlights the complexity of modern food science and the trade-offs inherent in product development.

In conclusion, stabilizers and emulsifiers are the backbone of squeeze cheese, ensuring it remains a reliable, convenient snack. By understanding their roles and limitations, consumers can make informed choices, while manufacturers can innovate to meet evolving preferences. Whether synthetic or natural, these additives underscore the intricate interplay between chemistry and culinary convenience.

Perfectly Reheat Your Bacon Egg and Cheese Sandwich Every Time

You may want to see also

Airtight Seal: Prevents oxidation and spoilage, keeping cheese fresh until fully consumed

Squeeze cheese, a convenient and portable snack, owes much of its longevity to the airtight seal that encases it. This seal is not just a barrier; it’s a critical component that prevents oxidation, the chemical reaction between cheese and oxygen that leads to spoilage. By eliminating exposure to air, the seal ensures that the cheese remains fresh from the first squeeze to the last, maintaining its flavor, texture, and safety for consumption.

Consider the science behind oxidation: when cheese is exposed to oxygen, it undergoes a series of reactions that break down fats and proteins, resulting in off-flavors, discoloration, and a rancid smell. For example, hard cheeses like cheddar can develop a sharp, unpleasant taste, while softer varieties may become slimy or moldy. The airtight seal acts as a shield, halting these processes in their tracks. Manufacturers achieve this by using materials like high-density polyethylene or laminated films, which are impermeable to oxygen and moisture. This design is particularly crucial for single-serve squeeze cheese packets, where even minimal exposure to air can accelerate spoilage.

From a practical standpoint, the airtight seal offers consumers a hassle-free experience. Unlike traditional cheese blocks that require refrigeration and wrapping, squeeze cheese can be stored at room temperature until opened. This makes it an ideal option for on-the-go snacking, picnics, or emergency food supplies. However, it’s essential to note that once the seal is broken, the cheese becomes vulnerable to oxidation. To maximize freshness, consumers should refrigerate the product after opening and consume it within 7–10 days. For those who use squeeze cheese sparingly, transferring the contents to a smaller, resealable container can help minimize air exposure.

Comparatively, the airtight seal in squeeze cheese outperforms traditional storage methods in terms of convenience and efficiency. While vacuum-sealed cheese blocks or wax-coated varieties also aim to reduce oxygen exposure, they often require additional steps like rewrapping or refrigeration. Squeeze cheese, on the other hand, is designed for immediate use and minimal fuss. Its portability and extended shelf life make it a superior choice for busy individuals, parents packing school lunches, or outdoor enthusiasts. The seal’s effectiveness lies in its simplicity: it does one job exceptionally well, ensuring the cheese stays fresh until fully consumed.

In conclusion, the airtight seal in squeeze cheese is a testament to packaging innovation, combining functionality with user convenience. By preventing oxidation and spoilage, it not only preserves the cheese’s quality but also reduces food waste. Whether you’re a frequent user or an occasional snacker, understanding the role of this seal can help you make the most of this versatile product. So, the next time you squeeze out a serving, remember: it’s not just cheese—it’s science in action.

Low Fat vs. Full Fat Cheese: Which is Healthier for You?

You may want to see also

Frequently asked questions

Squeeze cheese is typically made from a blend of cheese (often cheddar or American), whey, milk, salt, and emulsifiers like sodium phosphate or citric acid. These ingredients are processed into a smooth, spreadable consistency that can be easily dispensed from a tube or can.

Squeeze cheese is processed using high heat (pasteurization) and often contains preservatives like sorbic acid or sodium benzoate. The airtight packaging and low moisture content also prevent bacterial growth, allowing it to remain shelf-stable until opened.

Squeeze cheese is considered a processed cheese product rather than natural cheese. It contains real cheese but is blended with other ingredients to achieve its smooth, spreadable texture and extended shelf life.

Squeeze cheese can be used both as a snack and in cooking. It’s great for topping crackers, sandwiches, or vegetables, and can also be melted into sauces, scrambled eggs, or casseroles for added flavor. Its convenience makes it versatile for various culinary uses.