Washed-rind or smear-ripened cheeses are periodically treated with brine or mold-bearing agents. This encourages the growth of certain bacteria on their surface, giving them a distinctive flavour and smell. The practice of washing cheese rinds started in France, where 16th-century monks made cheeses in their monasteries as a way to feed themselves. The conditions in monastery cellars were ideal for cheese bacteria, but because the conditions weren’t easily controlled, the cheeses were more liable to develop bad rinds. To avoid this, the monks washed the rinds with whatever they had to hand – often beer or brandy. This style of rind washing created softer, creamier cheeses.

| Characteristics | Values |

|---|---|

| Washing solution | Brine (saltwater) or various alcohols such as beer, wine, whisky, or brandy |

| Bacteria | Brevibacterium linens |

| Texture | Firm, nutty, creamy, oozy, soft, moist, sticky, or hard |

| Taste | Pungent, savoury, nutty, or meaty |

| Rind colour | Red, orange, or reddish-orange |

| Rind texture | Wet, tacky, or sticky |

| Cheese type | Soft, semi-soft, semi-hard, or hard |

| Examples | Taleggio, Langres, Vacherin Mont d'Or, Gruyère, Winnimere, Epoisses de Bourgogne, Stinking Bishop, Rollright, Ogleshield |

Explore related products

What You'll Learn

The origin of washed rind cheese

Monks in the medieval age were brewers and distillers, and they started experimenting with lacing their cheese brine with alcohol for added flavour, complexity, and preservation. These "monastic" cheeses, with their origins in the Franciscan monasteries of France and Belgium, are creamier and have a higher moisture content.

The process of making washed rind cheese involves regularly washing the cheese, particularly during the early stages of production, which makes it labour-intensive compared to other cheese-making methods. The washing is done with brine or mould-bearing agents, which encourage the growth of certain bacteria on the surface, giving the cheese its distinctive flavour and texture.

The most famous British washed-rind cheese is Stinking Bishop, a soft cheese made in Gloucestershire. The name comes from the Stinking Bishop pears used to make the perry that the cheese is washed in. Another award-winning British washed-rind cheese is Rollright, made in Oxfordshire.

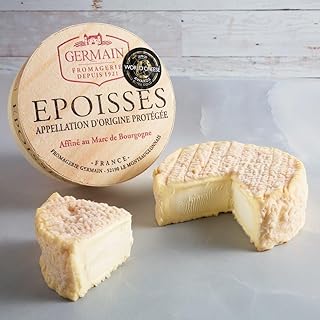

Some of the well-known washed-rind cheeses from the continent include Gruyère, Taleggio, Reblochon, and Epoisses de Bourgogne, each with its unique flavour and texture.

Rootie's Blue Cheese: A Tasty Mystery Unveiled

You may want to see also

The process of making washed rind cheese

The process of making washed-rind cheese involves periodically curing the cheese in a solution of saltwater brine or mould-bearing agents, such as beer, wine, brandy, and spices. This process encourages the growth of certain bacteria, such as Brevibacterium linens, which give the cheese its distinctive flavour, texture, and

The practice of washing cheese rinds is believed to have originated in France during the 16th century, when monks made cheeses in their monasteries to feed themselves. The humid and closed conditions in the monastery cellars were ideal for cheese bacteria, but also made the cheeses more susceptible to developing bad rinds. To address this issue, the monks began washing the rinds with whatever liquids were readily available, often beer or brandy. This technique resulted in the creation of softer, creamier cheeses, such as Epoisses de Bourgogne, one of the earliest examples of washed-rind cheese.

A similar practice emerged concurrently in mountainous regions, where the extreme humidity also posed challenges for controlling the growth of cheese bacteria. In these areas, cheesemakers typically used brine for washing rinds since drinkable water was more readily available than alcohol. This method produced harder cheeses, such as Gruyère, which originated in the Swiss Alps.

Today, washed-rind cheeses can be found in a variety of textures, ranging from soft and creamy to hard and grate-able. The washing process can be done with a damp cloth or brush, and the frequency can vary from once or twice to several times a day. The washing solution not only inhibits the growth of undesirable moulds but also fosters the development of bacteria that contribute to the unique characteristics of washed-rind cheeses.

Who Invented Cheesecake? A Historical Mystery

You may want to see also

Different types of washed rind cheese

Washed-rind or smear-ripened cheeses are periodically treated with brine or mould-bearing agents, resulting in the growth of certain bacteria that give them their distinctive flavours and reddish-orange hue. There are hard and soft washed-rind cheeses. The softer ones are sometimes distinguished as "smear-ripened", while the term "washed rind" is sometimes reserved for the hard ones.

Soft Washed-Rind Cheeses

Soft washed-rind cheeses are sometimes distinguished as "smear-ripened". Examples of soft washed-rind cheeses include:

- Limburger

- Taleggio

- Epoisses de Bourgogne

- Winnimere

- Stinking Bishop

- Rollright

Hard Washed-Rind Cheeses

The term "washed rind" is sometimes reserved for hard cheeses. Examples of hard washed-rind cheeses include:

- Appenzeller

- Gruyère

- St James

The Craft of Colby Cheese: A Tasty Tutorial

You may want to see also

Explore related products

How to identify washed rind cheese

Washed-rind or smear-ripened cheeses are easily identifiable by their distinctive characteristics. The most famous washed-rind cheeses are the runny, high-moisture varieties, which are often soft and pungent. These are usually aged for a few months and have a moist or sticky exterior. The rind is typically reddish-orange in colour and has a strong, stinky aroma. The smell is often described as reminiscent of a farmyard, barnyard animals, or sweaty feet.

The softer washed-rind cheeses are sometimes distinguished as "smear-ripened", while the term "washed rind" is reserved for the harder varieties. The harder cheeses are usually aged for longer, from five to twelve months, and are less pungent in smell. They are also less moist and less sticky. The rind of these cheeses tends to be more of a golden hue, rather than the reddish-orange of the softer varieties.

The process of washing the rinds of these cheeses encourages the growth of certain bacteria, which give them their distinctive flavours and smells. The washing is done with a saltwater brine solution or with alcohol, such as beer, wine, or brandy. The washing can be done by soaking, gently rubbing, splashing, or spraying the cheese. The washing process changes the makeup of the cheese, creating an environment that is more amenable to bacteria that thrive in salty, humid, and ammoniated conditions. The most common bacterium is brevibacterium linens, which is also found on human skin and is responsible for the stinky smell of the cheese.

Some well-known examples of washed-rind cheeses include Taleggio, Langres, Vacherin Mont d’Or, Gruyère, and Epoisses de Bourgogne.

Godminster Cheese: Handmade in Rural England

You may want to see also

How to serve washed rind cheese

Washed rind cheeses are almost universally smelly, with an intense aroma of farmyard and/or sweaty feet. They are also usually quite pungent, with a reddish-orange rind. The rind is sometimes edible, but this is a matter of preference, as it can be bitter. When serving washed rind cheese, it is important to consider the type of cheese, as there are many varieties. Soft washed rind cheese should be plump and moist; avoid brown or cracking pieces. Hard washed rind cheeses will have an orange-brown crust on the outside, which is not recommended for eating.

Soft washed rind cheeses, such as Limburger, are creamy and oozy. They are best served at room temperature to allow their full flavour to develop. They can be served as part of a cheese course, or used in cooking. For example, Limburger is often used in grilled cheese sandwiches or melted on top of dishes like onion soup.

Hard washed rind cheeses, such as Gruyère, are firmer and drier. They can be grated or shaved and are often used in cooking. They can also be served as part of a cheese course, paired with floral, honeyed, or fruity beverages like Riesling or Belgian ale.

There are also semi-hard washed rind cheeses, such as Appenzeller. These can be sliced or grated and are versatile in cooking. They can also be served as part of a cheese course, paired with a variety of beverages.

When serving washed rind cheese, it is important to consider the intensity of the flavour and aroma. These cheeses can be quite strong, so it is often best to serve them in smaller portions or as part of a larger cheese course. They can also be paired with other strong flavours, like a chutney or jam, to balance out their pungency.

Mac & Cheese: Wheat Pasta, Where's It Made?

You may want to see also

Frequently asked questions

Washed-rind or smear-ripened cheese is periodically treated with brine or saltwater to prevent undesirable mould from forming. This encourages the growth of certain bacteria on the surface, giving it a distinctive flavour.

Washed-rind cheese is often described as "stinky" and "pungent". However, this strong aroma leads to big, meaty flavours.

Some famous washed-rind cheeses include Gruyère, Winnimere, Taleggio, Langres, Vacherin Mont d'Or, Epoisses, and Stinking Bishop.

The rind of the cheese is washed or moistened with a damp cloth or brush during the maturation process. This can be done anywhere from once or twice to several times a day.

The practice of washing cheese rinds started in France by 16th-century monks who made cheese in their monasteries as a means of sustenance. Due to the uncontrolled conditions in the monastery cellars, the cheeses were prone to developing bad rinds. To address this, the monks washed the rinds with beer or brandy, which were more readily available than clean drinking water.