Blue goat cheese is a unique variety of cheese that combines the complexity of goat milk's flavour with the richness of blue mould. Blue goat cheese is made from goat milk, which is commonly used to make cultured dairy products, including cheese. The distinct blue veining in the cheese is created by adding a mould called penicillium and puncturing the cheese with a needle to allow air in and facilitate the growth of blue ribbons. Blue goat cheese offers a range of flavours and textures, from crumbly to creamy, mild to tangy, and earthy to peppery.

| Characteristics | Values |

|---|---|

| Ingredients | Raw goat milk, live cheese cultures, penicillium roqueforti, cheese salt |

| Mold | Blue veins are created by piercing the cheese to allow oxygen to enter, aiding the growth of blue mold |

| Texture | Smooth and creamy |

| Taste | Bold and peppery, with hints of earthy mushrooms |

| Pairings | Honey, sliced pear, walnuts |

Explore related products

Goat milk's unique flavour

Goat milk is known for its unique flavour, which is described as complex and intense, with earthy and tangy nuances. This distinct taste comes from capric acid, a fatty acid that promotes good intestinal bacteria in humans. Goat's milk has a relatively low lactose content, making goat cheese a suitable option for those with lactose intolerance.

The versatility of goat milk allows it to develop intricate flavour profiles and a wide range of cheese types. Chèvre, for example, is a term for traditional French goat's cheese that encompasses a variety of flavours and textures, from crumbly to creamy, mild to tangy, and young to mature. Fresh variants of Chèvre are often enjoyed within a few days of production, offering a vibrant and pronounced flavour.

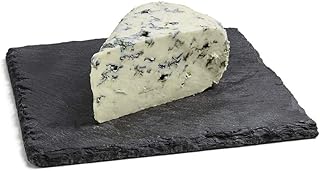

Blue goat cheese, in particular, combines the complexity of goat milk's flavour with the richness of blue mould. The blue veins in this type of cheese are created by piercing the cheese to allow oxygen to reach the centre, promoting the growth of the mould. This technique results in a dramatic contrast between the blue mould and the creamy white interior of the cheese.

One recipe for blue goat cheese involves heating pasteurized goat milk to 72 degrees Fahrenheit and adding heavy cream to create a "blue log." This method results in blue mould forming on the outside of the log, providing a striking visual contrast. Another recipe, known as "Caprizola," combines a Camembert-style "bloomy rind" with a blue Gorgonzola-type cheese. This cheese is wrapped in two-ply cheese paper to protect it from ultraviolet light and control oxygen exposure, ensuring the mould ripens properly.

Cheese Varieties: Pepsin Rennet's Role and Rich Taste

You may want to see also

Penicillium mould

Blue goat cheese gets its distinct blue veining from a mould called Penicillium. Once the Penicillium is added to the cheese, the cheese wheels are punctured with a needle to allow air in and encourage the development of blue ribbons. This process creates a dramatic contrast between the blue exterior and the creamy white interior of the cheese.

To make blue goat cheese, pasteurised goat milk is heated to around 70-72 degrees Fahrenheit. A Mesophilic culture is then sprinkled onto the milk's surface. Blue mould powder is added directly to the curds in the centre of the cheese, and the cheese is pierced to help the blue spores grow.

The foil wrapping used for blue goat cheese blocks ultraviolet light, which can adversely affect the flavour. It also keeps oxygen out, preventing the blue mould from overtaking the cheese. Plastic wrap can be used to limit oxygen exposure, but it doesn't block ultraviolet light as effectively as foil.

Blue goat cheese has a smooth and creamy texture, with a distinct aroma and flavour. The tang of goat's milk softens during maturation, resulting in subtle hints of earthy mushrooms and cream. Blue goat cheese pairs well with honey, sliced pear, and walnuts.

Chili Cheese Fries: A Delicious Combination of Ingredients

You may want to see also

Oxygen exposure

However, controlling oxygen exposure is also important to prevent the blue mould from overtaking the cheese. Wrapping the cheese in foil or plastic wrap can limit oxygen exposure and protect the cheese from unwanted discolouration. Foil is particularly effective at blocking ultraviolet light, which can negatively impact the flavour of blue cheeses.

In some cases, cheesemakers may opt to add blue mould powder directly to the curds in the centre of the cheese. This technique, used in the Caprizola goat cheese variety, results in blue flecks rather than distinct veins. The cheese is then pierced to help the blue spores grow and develop.

Cuba's Cheese-Making Legacy: A Local Delicacy

You may want to see also

Explore related products

Blue veins

Blue goat cheese gets its distinct blue veining from a mould called penicillium. Once the mould is added to the cheese, the cheese wheels are punctured with a needle to allow air in and let the blue ribbons develop. The blue veins cover their ivory-coloured centre, extending piquancy throughout. The texture is smooth and creamy, creating a distinct sensation. The foil wrapping blocks the ultraviolet light that can adversely affect the flavour of blue goat cheese. It also keeps oxygen out so that the blue veins do not take over.

One recipe for blue goat cheese involves heating one gallon of pasteurised goat milk to 72 degrees Fahrenheit. Another recipe heats one gallon of pasteurised goat milk and one cup of heavy cream (from a goat or cow) to 70 degrees Fahrenheit. The second recipe also adds blue mould powder directly to the curds in the centre of the cheese to create a Camembert-style "bloomy rind" with some blue spots inside. This cheese is then also punctured to help the blue spores grow.

The Mystery of Swiss Cheese Holes: A Scientific Explanation

You may want to see also

Creamy texture

Blue goat cheese is known for its creamy texture, which is achieved through a combination of factors, including the production process, the type of milk used, and the addition of certain ingredients.

The creamy texture of blue goat cheese is influenced by the use of goat's milk, which has a unique flavor and composition compared to cow's or sheep's milk. Goat's milk contains capric acid, a flavorful fatty acid that contributes to the creamy mouthfeel and makes it a popular choice for those with lactose intolerance.

To create the characteristic blue veins, the cheese is pierced or punctured with needles to allow oxygen to reach the center, promoting the growth of blue mold. This process, known as "needling," creates a contrast between the blue veins and the creamy white interior of the cheese.

Additionally, some blue goat cheese recipes incorporate heavy cream to enhance the creaminess. For example, the "Caprizola" recipe, a cross between Camembert and blue cheese, includes heavy cream in its ingredients, resulting in a smoother and richer texture.

The aging process also plays a role in developing the creamy texture. Blue goat cheese, such as "Billy Blue," is often aged for several months, allowing the flavors and texture to mature and soften, contributing to its creamy characteristic.

The combination of goat's milk, needling technique, addition of cream, and aging process results in a blue goat cheese with a smooth, creamy texture that melts in the mouth and offers a unique sensory experience.

The Making of Stan's Pimento Cheese: A Southern Delicacy

You may want to see also

Frequently asked questions

Blue goat cheese is made from goat's milk and a mould called Penicillium.

Blue goat cheese has a distinctive bleu flavour and a creamy texture. The tang of goat's milk softens with maturation, taking on hints of mushroom and cream.

To make blue goat cheese, heat one gallon of pasteurised goat's milk to 72 degrees Fahrenheit. Sprinkle mesophilic culture on the surface of the milk and pierce the cheese to allow oxygen in, helping the blue mould to grow.

Blue goat cheese is a great substitute for cow's milk blue cheese. Goat's milk is commonly used to make cultured dairy products and its flavour profile pairs well with the richness of blue mould.

Examples of blue goat cheese include Billy Blue, made from the milk of pasture-grazed Wisconsin goats, and Caprizola, a crossover recipe that combines a Camembert-style "bloomy rind" with a blue Gorgonzola-type cheese.