Lactose-free cottage cheese is crafted to accommodate individuals with lactose intolerance, offering a creamy, protein-rich option without digestive discomfort. The process begins with traditional cottage cheese production, where milk is curdled using bacterial cultures and rennet to separate curds from whey. The key difference lies in the addition of lactase enzyme during or after curdling, which breaks down lactose into simpler sugars (glucose and galactose) that are easier to digest. After curdling, the mixture is cut, cooked, and drained to form the characteristic curds. The final product is often blended for a smoother texture, then packaged and labeled as lactose-free. This method ensures the cheese retains its nutritional benefits and flavor while eliminating lactose, making it a versatile and inclusive dairy option.

| Characteristics | Values |

|---|---|

| Starting Material | Regular cottage cheese made from cow's milk |

| Lactose Removal Method | Addition of lactase enzyme |

| Enzyme Function | Breaks down lactose (milk sugar) into simpler sugars: glucose and galactose |

| Lactose Content | Significantly reduced, typically below 0.5 grams per serving (considered lactose-free by FDA standards) |

| Taste and Texture | Similar to regular cottage cheese, slightly sweeter due to glucose and galactose |

| Nutritional Profile | Similar to regular cottage cheese, with slightly higher sugar content due to broken-down lactose |

| Shelf Life | Similar to regular cottage cheese, typically 7-14 days refrigerated |

| Labeling | Must be clearly labeled as "lactose-free" |

Explore related products

What You'll Learn

- Milk Selection: Uses lactose-free or lactase-treated milk as the base for cottage cheese production

- Curdling Process: Acid or enzymes are added to coagulate milk, separating curds from whey

- Lactase Enzyme Addition: Lactase breaks down lactose in milk before curdling, ensuring lactose-free curds

- Draining and Washing: Curds are drained, washed to remove whey, and excess lactose

- Packaging and Storage: Cottage cheese is packaged, sealed, and stored to maintain freshness and quality

Milk Selection: Uses lactose-free or lactase-treated milk as the base for cottage cheese production

The foundation of lactose-free cottage cheese lies in the careful selection of milk. Unlike traditional cottage cheese, which uses regular milk containing lactose, lactose-free cottage cheese starts with milk that has been specifically treated to address this sugar. This is crucial for individuals with lactose intolerance, who experience digestive discomfort when consuming lactose.

Two primary methods are employed for milk selection in lactose-free cottage cheese production: using lactose-free milk or utilizing lactase-treated milk. Lactose-free milk is produced by adding the enzyme lactase to regular milk. Lactase breaks down lactose into simpler sugars, glucose and galactose, which are easily digestible even for those with lactose intolerance. This pre-treated milk, now lactose-free, serves as the base for cottage cheese production, ensuring the final product is suitable for lactose-intolerant consumers.

The alternative method involves using milk that has been directly treated with lactase during the cheese-making process. In this approach, regular milk is used initially, and lactase is added at a specific stage of cottage cheese production. The enzyme acts upon the lactose present in the milk, breaking it down before the curds are formed. This method allows for the use of standard milk while still achieving a lactose-free end product.

Both milk selection methods offer advantages. Using pre-treated lactose-free milk simplifies the cheese-making process, as the lactose breakdown has already occurred. However, lactase treatment during production allows for greater control over the timing and dosage of the enzyme, potentially optimizing the lactose breakdown process.

Regardless of the method chosen, meticulous attention to detail is paramount during milk selection. The quality and freshness of the milk, whether lactose-free or lactase-treated, directly impact the taste, texture, and overall quality of the final lactose-free cottage cheese product.

Does Hiland Cottage Cheese Contain Live Cultures? A Detailed Look

You may want to see also

Curdling Process: Acid or enzymes are added to coagulate milk, separating curds from whey

The curdling process is a critical step in making lactose-free cottage cheese, as it transforms milk into curds and whey, setting the foundation for further lactose removal. This process begins with the addition of either acid or enzymes to the milk, which lowers its pH and causes it to coagulate. When using acid, typically lactic acid or vinegar, it is carefully measured and added to the milk while it is gently heated. The acid disrupts the milk’s protein structure, causing the casein proteins to bond together and form curds. This method is precise, as too much acid or heat can lead to a grainy texture, while too little may result in insufficient curdling. The milk is stirred slowly during this process to ensure even distribution of the acid and consistent curd formation.

Alternatively, enzymes such as rennet or microbial transglutaminase can be used to coagulate the milk. Rennet, derived from animal sources or produced microbially, contains chymosin, an enzyme that specifically targets kappa-casein in milk, causing it to clot. This method is often preferred for its ability to produce a cleaner break between curds and whey, resulting in a smoother texture. Microbial enzymes are a suitable option for vegetarian or lactose-free products, as they are not animal-derived. The enzyme is added to the milk at a controlled temperature, typically around 30-35°C (86-95°F), and allowed to act for a specific period, usually 30 to 60 minutes, depending on the enzyme’s strength and desired curd firmness.

Once the milk has fully curdled, the mixture is left to rest, allowing the curds to settle and separate from the whey. This resting period is crucial, as it ensures that the curds are firm enough to retain their shape during the next steps of processing. The whey, which contains most of the lactose, is then drained off, significantly reducing the lactose content of the final product. In lactose-free cottage cheese production, this whey is often further processed to remove any remaining lactose, ensuring the cheese meets dietary requirements.

The curds are then cut into smaller pieces to release more whey and achieve the desired texture. Cutting the curds also helps to expel moisture, which is essential for the final consistency of the cottage cheese. After cutting, the curds are gently cooked to expel additional whey and firm up further. This step requires careful temperature control to avoid overcooking, which can make the curds rubbery. The curds are then rinsed with water to remove any residual acid or enzymes and to cool them down, preparing them for the final stages of production.

Finally, the curds are drained and mixed with a lactose-free cream or milk substitute to achieve the characteristic creamy texture of cottage cheese. This step not only enhances the mouthfeel but also ensures that the product remains lactose-free. The finished curds are then packaged, often with added salt or seasonings, and refrigerated to maintain freshness. The curdling process, whether achieved through acid or enzymes, is thus a meticulous and essential part of creating lactose-free cottage cheese, ensuring both texture and lactose reduction are optimized.

Creative Cottage Cheese Green Jello Recipe: A Unique Dessert Twist

You may want to see also

Lactase Enzyme Addition: Lactase breaks down lactose in milk before curdling, ensuring lactose-free curds

Lactase enzyme addition is a crucial step in producing lactose-free cottage cheese, as it directly addresses the lactose content in milk. Lactose, a natural sugar found in milk, can cause digestive discomfort for individuals with lactose intolerance. By introducing lactase, an enzyme that specifically breaks down lactose into simpler sugars (glucose and galactose), manufacturers ensure that the final product is suitable for lactose-sensitive consumers. This process begins before the milk is curdled, allowing the enzyme to effectively hydrolyze lactose molecules throughout the liquid. The result is a milk base that retains its essential properties for cheese-making but is significantly reduced in lactose content, paving the way for lactose-free curds.

The addition of lactase enzyme is a precise and controlled process. Typically, the enzyme is added to the milk while it is still in its liquid form and maintained at an optimal temperature to activate the lactase without denaturing it. This temperature range usually falls between 40°C to 45°C (104°F to 113°F), as lactase functions most efficiently within this window. The milk is gently stirred to ensure even distribution of the enzyme, allowing it to come into contact with as many lactose molecules as possible. The duration of this treatment varies depending on the concentration of lactose and the desired level of lactose reduction, but it generally ranges from 30 minutes to a few hours. This step is critical, as incomplete lactose breakdown could leave residual lactose in the final product, potentially causing issues for sensitive individuals.

Once the lactase has sufficiently broken down the lactose, the milk is ready for the curdling process. Traditional cottage cheese production involves adding an acid or rennet to the milk to separate it into curds and whey. Since the lactose has already been hydrolyzed, the curds formed during this stage are inherently lactose-free. The whey, which contains the remaining lactose-derived sugars and other soluble components, is then drained off, leaving behind the solid curds. These curds are further processed—washed, cut, and cooked—to achieve the characteristic texture and flavor of cottage cheese, all while maintaining their lactose-free status.

Quality control is essential during the lactase enzyme addition process to ensure the effectiveness and safety of the final product. Manufacturers often test the milk before and after lactase treatment to confirm the reduction in lactose levels. Advanced techniques, such as high-performance liquid chromatography (HPLC), can accurately measure lactose concentration, ensuring compliance with lactose-free standards. Additionally, the enzyme itself must be of food-grade quality and sourced from reputable suppliers to guarantee safety and efficacy. Proper documentation and adherence to regulatory guidelines are also critical to maintaining consumer trust in lactose-free products.

In summary, lactase enzyme addition is a scientifically grounded and meticulously executed method for creating lactose-free cottage cheese. By breaking down lactose in milk before curdling, this process ensures that the resulting curds are free from lactose, making the product accessible to those with lactose intolerance. The precision in enzyme application, temperature control, and quality assurance measures collectively contribute to the production of a safe, delicious, and inclusive dairy option. This approach not only meets dietary needs but also expands the market for cottage cheese, catering to a broader audience.

Does Cottage Cheese Contain Whey? Uncovering the Truth About Its Composition

You may want to see also

Explore related products

Draining and Washing: Curds are drained, washed to remove whey, and excess lactose

After the curds have formed in the lactose-free cottage cheese-making process, the next crucial step is draining and washing. This stage is essential for removing whey and excess lactose, ensuring the final product is not only lactose-free but also has the desired texture and consistency. The process begins by gently ladling or pouring the curds into a colander or a cheesecloth-lined strainer. This initial draining allows the whey, a liquid byproduct of curdling, to separate from the curds. The whey contains a significant amount of lactose, so its removal is vital for achieving a lactose-free product.

Once the majority of the whey has drained off, the curds are transferred to a clean container or a cheesecloth for further washing. Washing the curds involves rinsing them with cold water, which serves a dual purpose. Firstly, it helps to eliminate any remaining whey and lactose, ensuring the curds are as lactose-free as possible. Secondly, the cold water helps to cool the curds, slowing down the acid-producing bacteria and preventing the cheese from becoming too acidic or crumbly. The curds are gently stirred during this washing process to ensure even exposure to the water and thorough removal of whey.

The washing process is repeated several times, with fresh cold water used each time, until the water runs clear, indicating that most of the whey and lactose have been removed. This meticulous washing is a key factor in producing lactose-free cottage cheese, as it significantly reduces the lactose content. The duration and frequency of washing can vary depending on the specific recipe and the desired lactose level, but it typically takes multiple rinses to achieve the required result.

As the curds are washed, they also begin to firm up, contributing to the characteristic texture of cottage cheese. The washing process helps to create a cleaner flavor profile by removing any residual whey proteins and lactose that could otherwise impart a tangy or sweet taste. After the final wash, the curds are allowed to drain thoroughly, ensuring that excess moisture is removed. This step is crucial for achieving the right consistency, as too much moisture can make the cottage cheese watery, while too little can result in a dry, crumbly texture.

Throughout the draining and washing process, care must be taken to handle the curds gently to avoid breaking them down excessively. The goal is to maintain the integrity of the curds while effectively removing whey and lactose. This delicate balance ensures that the final lactose-free cottage cheese has a pleasant, creamy texture and a mild, fresh flavor. Proper draining and washing are, therefore, fundamental to the success of lactose-free cottage cheese production, directly impacting both the sensory qualities and the lactose content of the finished product.

Is Cottage Cheese High in Carbs? A Nutritional Breakdown

You may want to see also

Packaging and Storage: Cottage cheese is packaged, sealed, and stored to maintain freshness and quality

Once lactose-free cottage cheese is produced through the enzymatic breakdown of lactose using lactase, the focus shifts to packaging and storage to ensure the product remains fresh, safe, and of high quality. The packaging process begins with the cheese being transferred into containers, which are typically made of food-grade materials such as plastic tubs or cups. These containers are designed to be airtight and leak-proof to prevent contamination and moisture loss. The choice of packaging material is critical, as it must be compatible with the product and capable of withstanding refrigeration temperatures without degrading or altering the flavor of the cheese.

After filling, the containers are immediately sealed using advanced sealing technology, such as heat sealing or vacuum sealing, to create a barrier against external air and microorganisms. This step is essential for extending the shelf life of lactose-free cottage cheese, as exposure to air can lead to spoilage and the growth of bacteria. Some manufacturers also incorporate tamper-evident seals to ensure consumer confidence in the product's integrity. The sealed containers are then labeled with essential information, including the product name, ingredients, nutritional facts, expiration date, and storage instructions, to comply with regulatory requirements and inform consumers.

Storage conditions play a pivotal role in maintaining the freshness and quality of lactose-free cottage cheese. The product is typically stored under refrigeration at temperatures between 2°C and 4°C (36°F to 39°F) to slow down bacterial growth and enzymatic activity. Proper inventory management, such as the "first in, first out" (FIFO) method, ensures that older stock is used before newer stock, minimizing the risk of spoilage. Additionally, the storage area must be clean, dry, and free from strong odors to prevent contamination and maintain the cheese's flavor profile.

For distribution and retail, lactose-free cottage cheese is often packed in insulated containers with cooling packs to maintain the cold chain during transit. This is crucial to prevent temperature abuse, which can compromise the product's quality and safety. Retailers are instructed to store the cheese in refrigerated display cases, ensuring it remains within the recommended temperature range until it is purchased by consumers. Clear storage guidelines on the packaging, such as "Keep Refrigerated" and "Best Used By," help consumers handle the product correctly at home.

Finally, manufacturers may employ additional preservation techniques, such as modified atmosphere packaging (MAP), where the air inside the container is replaced with a gas mixture (e.g., nitrogen and carbon dioxide) to further inhibit bacterial growth and extend shelf life. This method is particularly useful for lactose-free cottage cheese, as it is more susceptible to spoilage due to the absence of lactose, which naturally acts as a preservative in regular cottage cheese. By combining meticulous packaging, sealing, and storage practices, producers ensure that lactose-free cottage cheese reaches consumers in optimal condition, delivering the expected taste, texture, and nutritional benefits.

Cottage Cheese for Weight Loss: Optimal Daily Serving Guide

You may want to see also

Frequently asked questions

Lactose-free cottage cheese is typically made by adding lactase enzyme to regular cottage cheese. The lactase breaks down the lactose (milk sugar) into simpler sugars, glucose and galactose, which are easier to digest for those with lactose intolerance.

No, lactose-free cottage cheese is still made from traditional dairy milk. The lactose is removed or broken down through the addition of lactase enzyme, rather than using non-dairy alternatives like almond or soy milk.

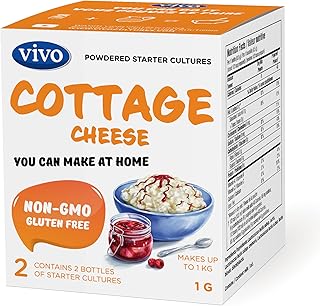

Yes, lactose-free cottage cheese can be made at home by adding liquid lactase enzyme drops to regular cottage cheese and allowing it to sit for a period of time, usually several hours, to break down the lactose. However, it's often more convenient to purchase pre-made lactose-free cottage cheese from stores.