Processed American cheese is a type of cheese made from cheddar, Colby, or similar cheeses, in conjunction with sodium citrate, which acts as an emulsifier and prevents the cheese from separating during pasteurization. It was invented in the 1910s by James L. Kraft, the founder of Kraft Foods Inc., who obtained a patent for his manufacturing process in 1916. This type of cheese is known for its mild, salty flavor, creamy texture, and low melting point. It is commonly used in sandwiches, cheeseburgers, and as an ingredient in dishes such as macaroni and cheese.

Explore related products

What You'll Learn

Processed American cheese is made from cheddar, Colby, or similar cheeses

Processed American cheese is a type of cheese made from cheddar, Colby, or similar cheeses, along with other ingredients. The process of making it involves grinding traditional cheese, combining it with emulsifying agents and other additives, and then heating the mixture until it forms a homogeneous blend. This process was invented in Switzerland as a way to reduce cheese waste, but it was perfected and patented by Canadian-American entrepreneur James L. Kraft in 1916.

The use of additives and the manufacturing process differentiate processed American cheese from its traditional counterparts. According to US regulations, to be labelled as "American cheese", it must be made from cheddar, Colby, washed curd cheese, or granular cheese, or a combination of these. The addition of other ingredients, such as an emulsifying agent, salt, colouring, acidifying agents, and dairy fat sources, is also permitted, but the final product must be at least 51% cheese.

Cheddar and Colby cheeses are commonly used as the base for processed American cheese. These cheeses are blended together to create a product with an approachable flavour and easy meltability. The addition of sodium citrate, an important additive, prevents the cheese fats from separating during the heating process and changes the consistency of melted cheese from stringy to gluey, making it ideal for use in dishes like macaroni and cheese.

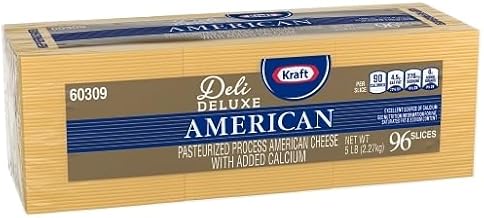

Processed American cheese is often sold in individually wrapped slices, unwraped slices in stacks, or unsliced blocks. The individually wrapped slices, commonly known as "singles", tend to be the least like traditional cheese in terms of taste and texture. Blocks of American cheese, on the other hand, are more similar to traditional cheese and are sliced to order at deli counters. This type of cheese is a popular choice for sandwiches and cheeseburgers due to its versatility, flavour, and adhesive properties.

The Real Ingredients Behind Cooper Cheese's Unique Flavor

You may want to see also

It is made with sodium citrate, which emulsifies the cheese

Processed American cheese is made with sodium citrate, an additive that acts as an emulsifier. This means that sodium citrate changes the consistency of melted cheese from "stringy" to "gluey", as well as preventing the cheese from separating during the pasteurization process. The emulsification process involves grinding traditional cheese, combining it with emulsifying agents and other ingredients, and then heating the mixture until it forms a melted homogeneous mixture. This process was first patented by James L. Kraft in 1916, and the term "American cheese" soon came to refer to this processed variety, rather than the more traditional (and expensive) cheddars also made and sold in the US.

Sodium citrate is an important additive in the production of processed American cheese, as it helps to control the texture and consistency of the final product. The addition of sodium citrate also means that processed American cheese has a low melting point, making it a versatile and reliable cooking ingredient that is commonly used in sandwiches, cheeseburgers, and Philly cheesesteaks.

The use of sodium citrate in processed American cheese has been controversial, with some people arguing that the high level of additives means that it cannot be considered a "real" cheese. However, others point out that all cheese is processed to some degree, and that the term "American cheese" simply refers to a specific type of processed cheese made from a blend of cheddar, Colby, or similar cheeses.

While the individual slices of processed American cheese found in grocery stores may have a less authentic cheese flavour, the blocks of American cheese sold at deli counters are usually made from real cheese, with fewer chemicals and extracts, resulting in a fresher and more flavourful taste.

The Ultimate Pimento Cheese Ingredients List

You may want to see also

It is pasteurised, heated to 150 °F for 30 seconds

Pasteurisation is a critical step in the production of processed American cheese. This process involves heating the cheese mixture to a specific temperature and holding it there for a set period. In the case of American cheese, the mixture is heated to 150 °F (66 °C) for a minimum of 30 seconds.

This precise temperature and time combination is essential for effective pasteurisation, which has multiple benefits for the final product. Firstly, it helps to kill any harmful bacteria that may be present in the cheese, improving its safety for consumption. Pasteurisation also plays a role in standardising the composition of the cheese. By controlling the temperature and time during this process, manufacturers can ensure consistent levels of milk fat, moisture, salt, and pH value in the final product.

The pasteurisation step is made possible by the addition of sodium citrate to the cheese mixture. This additive acts as an emulsifying agent, preventing the cheese fats from separating during heating. In other words, it keeps the mixture homogeneous, resulting in a smooth and consistent texture. Sodium citrate also contributes to the characteristic meltability of American cheese, allowing it to be used in a wide range of dishes without becoming greasy or breaking apart.

The process of pasteurisation is a key differentiator between traditional and processed American cheese. Traditional cheese, without the addition of emulsifying agents, would separate and not form a homogeneous mixture when heated to 150 °F. This is why federal laws mandate that processed American cheese be labelled as "pasteurised process American cheese" if it is made from more than one type of cheese.

Feta Cheese: Wisconsin's Finest Dairy Product

You may want to see also

Explore related products

It is packaged in slices or blocks

Processed American cheese is packaged in a variety of ways, including individually wrapped slices, unwrapped slices sold in stacks, or unsliced blocks. The slices are commonly known as "singles" and are typically the least like traditional cheese in terms of taste and texture. They are convenient for consumers who want pre-sliced cheese for sandwiches or burgers. On the other hand, blocks of American cheese are more similar to traditional cheese and are often sliced to order at deli counters. This option provides a fresher and more flavorful experience due to the reduced number of chemicals and extracts compared to the individually packaged slices.

The packaging and presentation of American cheese play a significant role in its popularity and versatility. The individually wrapped slices are highly convenient for consumers who want a quick and easy option for their meals. They are also portion-controlled, making it simple to grab a single slice for a sandwich or a snack. These slices are designed to be consistent in size and thickness, ensuring uniformity in products. However, the processing and packaging methods can affect the taste and texture of the cheese, making it less like traditional, natural cheese.

In contrast, the blocks of American cheese offered at deli counters appeal to consumers seeking a more authentic cheese experience. These blocks are cut into slices of varying thicknesses, allowing customers to customize their cheese portions. The deli cheese tends to have a shorter ingredient list, focusing primarily on cheese and a few additional components. This simplicity results in a product that tastes closer to real cheese, with a more pronounced flavor and a fresher quality.

The different packaging options cater to diverse consumer preferences and needs. Those who prioritize convenience and uniformity may opt for the individually wrapped slices, while consumers seeking a more natural cheese experience are likely to prefer the blocks or freshly sliced cheese from the deli. The variety in packaging also contributes to the versatility of American cheese, making it suitable for various dishes, from sandwiches and burgers to cooked recipes that require melted cheese. Whether in slices or blocks, the packaging plays a crucial role in the perception and functionality of processed American cheese.

Vegan Cheese: Melting Mystery with Coconut Oil

You may want to see also

It was invented in the 1910s by James L. Kraft

Processed American cheese was invented in the 1910s by James L. Kraft, the founder of Kraft Foods Inc. Kraft obtained a patent for his manufacturing process in 1916 and began marketing it in the late 1910s. The term "American cheese" quickly became associated with this processed variety, rather than the traditional, more expensive cheddars also produced and sold in the US.

Kraft's innovation built on earlier developments in cheese processing. In 1911, Walter Gerber and Fritz Stettler in Switzerland created processed cheese by adding sodium citrate to melted Emmentaler cheese, allowing the mixture to be re-cooled into a solid. This longer-lasting cheese was also resistant to separating when melted and had a uniform look and behaviour. However, it was Kraft who first commercialised the product, creating the first shelf-stable, sliced processed cheese, which was introduced in 1950.

Processed American cheese is made from cheddar, Colby, or similar cheeses, combined with sodium citrate. This additive allows the cheese to be pasteurised without its components separating, giving it a smooth and meltable texture. The mixture is heated to at least 150 °F (66 °C) for a minimum of 30 seconds during pasteurisation. The final product is controlled for percentage of milkfat, moisture, salt and pH value, as well as flavour, body, texture, colour, and meltability.

The processed cheese is then packaged in individually wrapped slices, unwrapped slices sold in stacks, or unsliced blocks. The individually wrapped slices, often known as 'singles', differ most from traditional cheese, while blocks of American cheese are more similar and are sliced to order at deli counters. American cheese is commonly used in sandwiches and cheeseburgers due to its versatility and meltability.

The Cheesy Truth Behind Olive Garden's Signature Dish

You may want to see also

Frequently asked questions

Processed American cheese is a type of cheese made from cheddar, Colby, or similar cheeses, in conjunction with sodium citrate, which permits the cheese to be pasteurized without its components separating. It is mild with a creamy texture and salty flavor, has a medium-firm consistency, and has a low melting point.

Processed American cheese is made from cheddar, Colby, washed curd cheese, or granular cheese, or any mixture of two or more of these. It also contains an emulsifying agent, salt, coloring, acidifying agents, and optional dairy fat sources.

Traditional cheese is ground, combined with emulsifying agents and other ingredients, mixed and heated until it forms a melted homogeneous mixture. The cheese mixture is then heated to a temperature of at least 150 °F (66 °C) for a minimum of 30 seconds during pasteurization.

Processed American cheese is commonly used in sandwiches and cheeseburgers due to its versatile nature and meltable texture. It is also used in dishes such as tuna noodle casserole and macaroni and cheese.