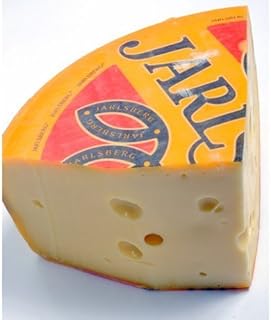

Jarlsberg is a mild, semi-soft, cow's milk cheese with a nutty flavour and Swiss-type holes, or eyes, in a distinctive yellow interior. It was developed in Norway in the 1950s and is now produced in Norway, Ireland and the US state of Ohio. The exact recipe is a closely guarded trade secret, but it is possible to make a Norwegian-style Jarlsberg at home, and the process involves heating milk, adding bacterial culture, cutting curds, and allowing the cheese to age.

Explore related products

What You'll Learn

Heating the milk

The first step in making Jarlsberg cheese is to heat the milk to 98°F (37°C). This can be done by placing the milk in a pot or sink of very warm water. If using a pot on the stove, heat the milk slowly, stirring continuously to ensure even heating. Alternatively, some recipes suggest heating the milk to 92°F (33°C) in a double boiler.

Once the milk reaches the desired temperature, it is time to add the culture. The milk should then be allowed to sit still for about 30 minutes. During this time, the culture will work its magic, and the rennet will coagulate the curd, transforming the milk into a thick, semi-solid mass. It is normal for the temperature to drop slightly during this process, and you will notice the milk beginning to thicken after about 15 minutes.

While you are waiting, it is important to sanitize the mold and cloth that will be used for the final cheese. Once the curd has sufficiently coagulated and thickened, use a long knife to cut the surface in a crosshatch pattern, creating a grid of approximately one-inch squares. Allow this to rest for 3-5 minutes, giving the whey time to rise into the cuts.

Now, use a ladle, spoon, or thin wired whisk to cut the curd into large pea-sized pieces as evenly as possible. Continue stirring for about 20 minutes, allowing the curd to release whey and firm up before the final heating stage.

The next step is to begin drying out the curds by slowly increasing the heat to 102°F (39°C). This is achieved by first removing around 30% of the whey and replacing it with an equal volume of warm water at about 140°F (60°C). This process helps to reduce lactose levels and limit bacteria growth and acid production, resulting in a sweeter-tasting cheese. The warm water should be added slowly to the curds while stirring continuously, ensuring they remain separate and moving. This step should take around 20-30 minutes, and the final temperature should reach approximately 102°F.

Real Cheese: What's Inside This Delicious Dairy Product?

You may want to see also

Adding bacterial culture

The process of making Jarlsberg cheese involves adding bacterial culture to cheese milk. The bacterial culture is added after heating the milk to 98°F (37°C). The milk is then left to sit for 30 minutes, during which time the culture works to coagulate the curd. It is important to maintain the warmth of the milk during this process, although a slight drop in temperature is acceptable. After about 15 minutes, the milk will start to thicken, and a firm curd will develop.

Once the firm curd has formed, it is time to start cutting. Use a long knife to cut the surface in a crosshatch pattern to a depth of about one inch. Allow the curd to rest for 3-5 minutes, during which time the whey will rise through the cuts. Then, use a ladle, spoon, or thin wire whisk to cut the curd into large pea-sized pieces as evenly as possible. Continue stirring for approximately 20 minutes to release the whey and firm up the curd before the final heating.

The next step is to dry out the curds by slowly increasing the heat to 102°F (39°C). This is achieved by removing a portion of the whey and adding back warm water over a period of 20-30 minutes. First, allow the curd to settle to the bottom of the pot and then remove 30% of the whey. Stir the curds well, and then add back a volume of warm water that is about half of what was removed. The water should be added slowly to the curds while continuously stirring to keep them separate and moving. The final temperature should be around 102°F (39°C).

The curds are then held at the final cook temperature while being stirred for about 30-45 minutes. This step helps to further limit bacteria growth and acid production, resulting in a sweeter cheese.

Vegan Cheese: What's in This Dairy Alternative?

You may want to see also

Curdling and cutting

After heating the milk to 98°F (37°C), the culture is added. The milk is then left to set still for 30 minutes, during which time the rennet coagulates the curd. It is important to keep the milk warm during this period, although a slight drop in temperature is acceptable. After about 15 minutes, the milk will begin to thicken, and a firm curd will develop.

Once the firm curd has formed, use a long knife to cut the surface in a crosshatch pattern to a depth of about one inch. Allow this to rest for 3-5 minutes as the whey rises in the cuts. Then, use a ladle, spoon, or thin wired whisk to cut the curd into large pea-sized pieces as evenly as possible. Continue stirring for about 20 minutes, allowing the curd to release whey and firm up before the final heating.

The next step is to dry out the curds by slowly increasing the heat to 102°F (39°C). First, remove a portion of the whey and add back warm water over a period of 20-30 minutes. Begin by allowing the curd to settle to the bottom of the pot and then remove 30% of the whey. Stir the curds well. This step helps to reduce lactose and limit bacteria growth and acid production, resulting in a sweeter cheese. Next, add back a volume of warm water (about 140°F) that is approximately half of what was removed. This water should be added slowly to the curds while stirring continuously, just enough to keep them separate and moving. The water addition should take about 20-30 minutes, and the final temperature should be about 102°F.

Limburger Cheese: US Production and History

You may want to see also

Explore related products

Draining and replacing whey

Draining and replacing the whey is a crucial step in making Jarlsberg cheese. This process helps the curds release whey and firm up before the final heating. Here's a detailed guide on how to perform this step:

Draining the Whey:

- Allow the curd to settle to the bottom of the pot.

- Remove approximately 30% of the whey. This step helps in reducing lactose content and limiting bacteria growth and acid production, resulting in a sweeter cheese.

- Use a sieve and ladle to ensure that only the whey is drained out, separating it from the curds.

Replacing the Whey:

- Add back an equal amount of warm water to the original level of the whey. The water temperature should be around 60°C (140°F), which will bring the curd temperature up to 38°C (100°F).

- Turn on the heat to low and gently warm the curds to 42°C/108°F over a period of 30 minutes, stirring continuously.

- Continue stirring for about 20 minutes to allow the curd to release more whey and firm up further.

By following these steps, you will effectively drain and replace the whey during the Jarlsberg cheese-making process, contributing to the development of its distinctive texture and flavour.

The Making of Kraft Cheese Slices: Process Explained

You may want to see also

Pressing and moulding

The pressing and moulding process gives Jarlsberg cheese its distinctive shape and texture. The cheese is typically produced in 10-kilogram wheels, with an approximate diameter of 330 millimetres and a height of 95 to 105 millimetres. The mould used in the pressing process helps to achieve this consistent size and shape.

During the pressing and moulding stage, the curds are compressed and shaped, removing any remaining whey and creating a firm, cohesive mass. The mould also facilitates the formation of the cheese's characteristic "eyes" or holes. These holes are a result of the action of bacteria and the specific pressing and moulding technique employed.

After the pressing and moulding process, the cheese is removed from the mould and allowed to age. This ageing process further develops the texture and flavour of the cheese, and allows the "eyes" to fully form. The cheese is typically aged for a minimum of three months, with some variations aged for up to 15 months.

The Magic Ingredients Behind Münster Cheese's Unique Flavor

You may want to see also

Frequently asked questions

Jarlsberg is a mild, semi-soft, cow's milk cheese with a buttery, nutty flavour. It has a distinctive yellow, semi-firm interior and a smooth, shiny-yellow body.

Jarlsberg cheese is of Norwegian origin. It was developed in the 1950s by Professor Ole Martin Ystgaard of the Dairy Institute at the Agricultural University of Norway. It is named after a Norwegian nobleman, Count Wedel Jarlsberg, who owned land near Oslo, in an area where an earlier version of the cheese was produced in the 1800s.

The exact process of making Jarlsberg cheese is a trade secret. However, it involves heating milk to around 33°C (92°F) and adding bacterial culture. The milk is then left to set for 30 minutes, after which the curds are cut and stirred. The curds are then heated and placed in a cheese mould. The cheese is then aged for at least three months.

Jarlsberg cheese has a semi-soft to semi-firm texture, depending on the ageing time. It is known for its distinctive "eyes" or holes, which are formed by the action of bacteria that is added to the cheese during production.

Jarlsberg cheese is produced in Norway, Ireland, and the US state of Ohio. It is available in many countries, including the United States, the United Kingdom, Australia, and Brazil. It can be purchased from specialty cheese shops or online retailers.