Wisconsin is known for its cheese, and the state is a national and world leader in cheese production. Wisconsin has a long history of cheesemaking, dating back to the 19th century, and is home to numerous cheese factories and dairy farms, many of which are family-owned and offer tours and tastings. The state is renowned for its high-quality cheese, with stringent standards for cheesemaking and dairy product quality, and its cheese makers have won numerous awards for their craft. Wisconsin produces a wide variety of cheeses, including popular varieties such as cheddar, American, mozzarella, and gouda, as well as unique cheeses such as cheese curds and brick cheese.

| Characteristics | Values |

|---|---|

| Commercial cheesemaking history | Commercial cheesemaking in Wisconsin dates back to the nineteenth century. |

| Early cheesemaking operations | Began on farmsteads in the Michigan and Wisconsin territories, with large-scale production starting in the mid-1800s. |

| First documented cheesemaking cooperative | Opened by A. Pickett in 1841 near Lake Mills. |

| First large-scale cheese factory | Opened by Chester Hazen. |

| Dairy farms in Wisconsin | Almost a quarter of the country's dairy farms are in Wisconsin, many of which are family-owned. |

| Dairy production | Wisconsin dairy farms produce more than 23 billion pounds of milk annually, about 14% of the country's total milk supply. |

| Cheese production | Wisconsin is the top cheese-producing state, making about 26%-27% of the country's cheese. |

| Cheese varieties | Wisconsin cheese factories produce more than 350-600 varieties of specialty cheese, including brick, colby, cold pack, and limburger. |

| Cheese production volume | Wisconsin manufactured 3.36 billion pounds of cheese in 2019. |

| Cheese consumption | The average American consumes more than 27 pounds of cheese each year. |

| Cheese-making process | Wisconsin cheesemakers use about 90% of the state's milk supply to make cheese. |

| Sustainability | Wisconsin cheese factories, such as Cedar Grove, prioritize sustainable and environmentally friendly practices in their cheese-making processes. |

| Cheese curds | Ellsworth is known as the "Cheese Curd Capital of Wisconsin" and hosts the annual Cheese Curd Festival. |

| Cheese capital | Union Star near Appleton, Willow Creek Cheese facility in Berlin, and Weyauwega Star Dairy in Weyauwega are also famous for their cheese varieties. |

| Master cheesemakers | Wisconsin is home to about 60 master cheesemakers, with Nasonville Dairy having four of them. |

Explore related products

What You'll Learn

Wisconsin's cheese-making history

Wisconsin's cheese-making tradition dates back to the 19th century. In the 1800s, dairy farms began to spring up across the state, with farmers making cheese to preserve excess milk. At a time when storage and transportation were limited, cheese kept longer than milk or butter.

Charles Rockwell was among the state's earliest cheesemakers, beginning production at Koshkonong near Fort Atkinson in 1837. In 1841, Anne Pickett established Wisconsin's first commercial cheese factory, using milk from her neighbours' cows. By the 1860s, Wisconsin was experiencing an industrial revolution in dairy production, with operations moving from farmsteads into factories to meet the growing demand for dairy products. The number of cheese factories in the state grew from 30 in 1860 to over 700 in 1880, with production concentrated in Sheboygan County (where factories primarily produced cheddar cheese) and Green County (where factories mainly produced Swiss and limburger cheese).

Wisconsin cheesemakers also developed original cheeses, such as Brick and Colby. By the 1920s, over 2,800 cheese factories existed in the state, which collectively produced more than 500 million pounds of cheese per year. Wisconsin also became the first state to grade its cheese for quality in 1921.

Today, Wisconsin is still the largest producer of cheese in the United States, with almost a quarter of the country's dairy farms residing in the state. Many of these farms are family-owned and open to the public for tastings and tours. Wisconsin is also the only US state that requires that a licensed cheesemaker supervise the making of commercial cheese, and it is the only state to offer a master cheesemaker programme.

Cheese-Making Process: A Kid-Friendly Explanation

You may want to see also

Dairy farming and early cheesemaking

Dairy farming and cheesemaking have been a part of Wisconsin's history and culture for centuries. While dairy farming was uncommon in the state's early years, with farmers focusing on other crops like wheat, cows were typically tended to by women on farmsteads, who made cheese and butter from the milk.

The first documented cheesemaking cooperative in Wisconsin was opened by A. Pickett in 1841 and operated from his home near Lake Mills. However, selling Wisconsin-made cheese outside the state was challenging during these early years, as buyers preferred cheese from New York. This led to the creation of dairy boards, facilitating connections between cheese buyers and sellers, and call boards, which allowed for bidding on cheese products.

The industrialization of the cheese industry in Wisconsin occurred gradually, and scholars debate the identity of the first large-scale cheese factory in the state. Despite this, Wisconsin became the largest producer of cheese in the United States in the early 1900s, with its cheese gaining popularity and production capacity increasing during the 1910s. By 1919, Wisconsin produced over 63% of the nation's cheese.

Wisconsin's cheesemaking reputation continued to grow, and by 1936, the Wisconsin Cheese Exchange was used to set national prices for cheese. The state's cheese factories reached their peak in 1922, with 2,807 factories, after which many smaller plants closed or merged. Wisconsin's commitment to quality and innovation in cheesemaking has persisted, becoming the first state to require licensed cheesemakers in 1915 and the first to mandate cheese grading in 1921.

The Grilled Cheese Origin Story: A Country's Comfort Food

You may want to see also

Commercial cheesemaking

The state's cheese production and popularity continued to grow throughout the twentieth century. In 1915, Wisconsin became the first state to require cheesemakers to be licensed, and in 1921, it became the first state to require grading of its cheese. By 1936, the Wisconsin Cheese Exchange was setting national prices for cheese, and the state's cheese factories reached their peak number of 2,807 in 1922. However, many smaller plants closed or merged with larger ones after this time.

Wisconsin's dairy industry is known for its innovation and craftsmanship, and the state is now a national and world leader in cheese production. The state is home to more than 126 cheese plants, producing over 350 varieties of cheese, including many unique to Wisconsin, such as brick, colby, cold pack, and limburger. Wisconsin also leads the nation in the production of popular varieties such as Cheddar, American, Mozzarella, Muenster, and Brick. The state's cheese is not only produced sustainably but is also award-winning, with its cheesemakers taking top honours at the World Championship Cheese Contest.

The process of making cheese on a commercial scale involves a series of specialised steps and equipment. Milk is first pasteurised and then cooled to a specific temperature. Starter cultures and rennet are added to the milk to begin the cheesemaking process. The milk then begins to curdle, forming curds and whey. The curds are cut and stirred, and then cooked to the desired temperature. After cooking, the curds are drained and placed in cheese moulds, where they are pressed to form a solid mass. The cheese is then salted and aged, developing flavour and texture over time.

Cheese in England: When Did It Begin?

You may want to see also

Explore related products

Cheese factories and tours

Wisconsin is a national and world leader in cheese production, with almost a quarter of the country's dairy farms residing in the state. Many of these farms are family-owned and open to the public for tastings and tours. The state's cheese is not only produced sustainably but is also prize-winning, with Wisconsin hosting the World Championship Cheese Contest annually and taking home top honours.

There are several cheese factories and shops in Wisconsin that offer tours and tastings. Here are some options to consider:

Union Star

Union Star, founded in 1911, is a small and family-owned cheese shop located near Appleton. They offer tours that showcase how milk from local dairies is transformed into squeaky cheese curds, aged cheddar, and flavoured Muenster cheese.

Ellsworth Cooperative Creamery

Located in Ellsworth, the "Cheese Curd Capital of Wisconsin," this creamery produces classic white cheddar cheese curds and other creamery products. Ellsworth hosts the annual Cheese Curd Festival, featuring thousands of pounds of cheese curds, craft beers, local wines, and ciders. The cooperative creamery also has a new factory store in Menomonie that offers deep-fried cheese curds and other treats.

LaClare Family Creamery

Northeast of Fond du Lac, this goat cheese manufacturer offers self-guided tours that include a visit to their goat farm. Their shop features a variety of cheeses, wine, ice cream, and other specialty products. They also have an on-site cafe serving farm-to-table dishes.

Door County Creamery

This cheese shop and goat dairy farm in Door County offers tours where guests can sample locally made cheeses and homemade gelato. During the tour, visitors can meet the farm animals and browse the shop, which sells goat cheese, spreads, handcrafted soaps, and more.

Cedar Grove

Cedar Grove is a small-scale, 100-year-old cheese factory that exemplifies sustainability. Their tour focuses on their organic, hormone-free cheese-making process and their commitment to environmentally friendly practices. Visitors can sample their award-winning artisan cheeses, such as Faarko (a semi-soft mix of cow's and goat's milk) and Donatello (a rich goat's milk cheese).

Willow Creek Cheese

Located in Berlin, this family-owned cheese facility offers tours where visitors can sample master cheesemaker Jon Meitzig's Red Willow cheese, aged and washed in a beer and salt mix for a unique, meaty flavour.

American Cheese: What Animal Does It Come From?

You may want to see also

Varieties of Wisconsin cheese

Wisconsin is a national and world leader in cheese production, with the state's cheese factories producing over 600 varieties of specialty cheese. In 2019, Wisconsin manufactured 3.36 billion pounds of cheese, accounting for 26-27% of all cheese produced in the United States—more than any other state. Wisconsin is the top producer of several popular varieties of cheese, including:

- Cheddar—a classic, versatile cheese with a sharp, nutty flavor. The state is particularly known for its aged cheddars and white cheddar cheese curds.

- Muenster—a mild, semi-soft cheese with a creamy texture and a hint of sweetness.

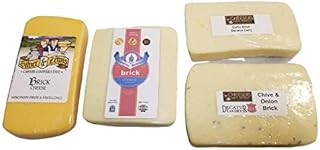

- Brick—a mild, semi-soft cheese ranging in color from white to pale yellow. Invented in 1877 by John Jossi, brick cheese is a Wisconsin original.

- Colby—another variety of cheese that originated in Wisconsin, colby is a mild, semi-hard cheese with a creamy texture and a slightly sweet and nutty flavor.

- Cold Pack—a variety of cheese unique to Wisconsin, cold pack cheese is a spreadable, creamy cheese often served on crackers or bread.

- Limburger—a strong-smelling, semi-soft cheese with a pungent, salty flavor. Limburger is another type of cheese that is produced only in Wisconsin.

- Mozzarella—a soft, stretchy cheese with a mild flavor, often used in pizzas, caprese salads, and other Italian dishes.

- American—a type of cheese that is processed and typically made from a blend of different cheeses, American cheese is known for its smooth, creamy texture and mild flavor.

In addition to these popular varieties, Wisconsin also offers a range of other unique cheeses, such as the award-winning Faarko, a semi-soft blend of cow's and goat's milk, and Donatello, a rich cheese made from goat's milk, both crafted at the Cedar Grove cheese factory. For a unique twist on a classic, the Union Star factory offers flavored Muenster cheese, along with aged cheddar and fresh cheese curds. The Willow Creek Cheese facility produces Red Willow cheese, which is aged and washed in a beer and salt mix, giving it a meaty flavor. The Weyauwega Star Dairy factory, meanwhile, is known for its tangy feta and nutty Parmesan, as well as its record-breaking string cheese.

Delicious Corn Cheese Balls: A Quick, Easy Snack

You may want to see also

Frequently asked questions

Commercial cheesemaking in Wisconsin dates back to the nineteenth century. Early cheesemaking operations began on farmsteads in the Michigan and Wisconsin territories, with large-scale production starting in the mid-1800s. Wisconsin became the largest producer of cheese in the United States in the early 1900s.

Wisconsin is the first in the production of many popular cheese varieties, including cheddar, American, mozzarella, brick, muenster, and limburger. Wisconsin also manufactures cheese curds, gouda, aged cheddar, colby, cold pack, and string cheese.

Some famous cheesemakers in Wisconsin include Nasonville Dairy, which has four Master Cheesemakers and has earned several awards for its cheese, and Union Star, a small, family-owned factory founded in 1911 that produces cheese curds, aged cheddar, and flavored muenster cheese. The Weyauwega Star Dairy cheese factory is known for its string cheese, which was featured in the Guinness Book of World Records for being the longest at 1.5 miles.

Wisconsin is the top cheese-producing state in the United States, manufacturing 3.36 billion pounds of cheese in 2019, accounting for about 26-27% of the country's total cheese production. Wisconsin has over 126 cheese plants, producing more than 600 varieties of cheese.