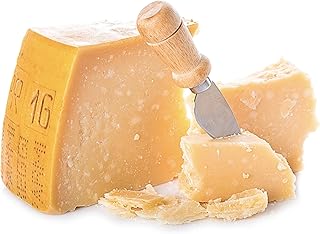

Parmesan is a hard, granular Italian cheese with a nutty flavour, traditionally made from cow's milk. It is one of the most ancient and unique cheeses, with strict regulations surrounding its production. The name Parmigiano Reggiano is protected by law, and the cheese must be produced in a restricted geographic area, using stringent methods. The process of making Parmesan involves heating a combination of whole and naturally skimmed milk in copper vats, adding ingredients like rennet and whey to form curds, and then ageing the cheese for at least 12 months.

Explore related products

What You'll Learn

Parmesan is made from cow's milk

Parmesan is a hard, granular Italian cheese, produced from cow's milk and aged for at least 12 months. Outside of the European Union and Lisbon Agreement countries, it is often an imitation of the original Italian cheese. In the EU, the term Parmesan may only be used to refer to Parmigiano Reggiano, which is protected under law and must be made in a restricted geographic area, using stringently defined methods.

In the US, the Code of Federal Regulations includes a Standard of Identity for "Parmesan and Reggiano cheese", which defines the production process and the final result. According to this, Parmesan must be made from cow's milk, cured for at least 10 months, and contain no more than 32% water and no less than 32% milk fat. In Canada, there are no restrictions on aging time, and regulations only define moisture and fat levels.

When making Parmesan at home, it is possible to use store-bought, pasteurized milk. The milk is heated slowly to 91-93F, and then the calcium chloride is added. It is important to ensure that all equipment is thoroughly cleaned and sanitized due to the long aging time of Parmesan.

The Making of Bagged Cheese: Process Explained

You may want to see also

It's aged for at least 12 months

Parmesan cheese is aged for a minimum of 12 months. This long ageing process is one of the reasons for the cheese's distinctive sharpness. The cheese is traditionally made from cow's milk, with whole milk and naturally skimmed milk combined and then distributed into copper vats for heating. During this two-step heating process, additional ingredients like whey and rennet are added to form the curd.

The length of ageing varies depending on the desired flavour and texture of the cheese. For example, Cello Copper Kettle is aged for 16 months, creating a sweeter taste through the natural fermentation of the milk. Parmesan-style cheeses, such as Grana Padano, are typically aged for a minimum of 9 months. The ageing process also depends on the size of the cheese, as a larger cheese has a better surface-to-mass ratio for ageing, while a smaller cheese will dry out more quickly.

During the ageing process, the cheese must be carefully maintained to ensure proper ripening. This includes regularly brushing or rubbing down the mould with a stiff brush or coarse cloth. After about 1-2 weeks, the rind should harden, and a light coat of oil will help to discourage mould growth and facilitate its removal.

The ageing process is so important to the character of the cheese that, in Europe, the length of ageing is included in the special seals that identify Parmesan as authentic. These seals also include the identification number of the dairy, the production month and year, a code identifying the individual wheel, and stamps regarding the ageing length.

Cheese Dust: How is This Magic Made?

You may want to see also

The milk is heated in copper vats

Parmesan is one of the most ancient and unique cheeses, and its recipe has been perfected over centuries. The process of making Parmesan cheese involves heating milk in copper vats, a traditional method that adds a distinct character to the cheese.

The milk used for Parmesan is typically cow's milk, and it is heated in copper vats in a two-step process. Firstly, whole milk and naturally skimmed milk are combined and poured into the vats. The milk is then heated slowly and carefully to a specific temperature range of 91-93 degrees Fahrenheit. This temperature range is crucial for the next steps in the cheese-making process. Using a milk pot in a water bath is a common method to achieve this temperature, but direct heating on a stove top can also be done with caution.

During this initial heating step, additional ingredients like calcium chloride are added to the milk. This step is important as it helps set the foundation for the cheese's texture and flavour. The milk's temperature must be carefully monitored and controlled to ensure it does not exceed the desired range. The milk's consistency might start to change during this stage, indicating that it is ready for the next steps in the transformation into cheese.

The use of copper vats is a traditional technique that has been passed down through generations of cheesemakers. Copper is an excellent conductor of heat, ensuring even heating throughout the milk. This even heating is essential for the consistent development of the cheese's texture and flavour. The copper vats also impart a unique and subtle flavour to the cheese during the heating process, contributing to the overall complexity of Parmesan's taste profile.

The heating process in the copper vats is a critical step in the art of making Parmesan cheese. It sets the stage for the formation of curds, which will eventually become the firm and granular Parmesan cheese. The temperature range and duration of heating impact the final product's texture and flavour, so cheesemakers must carefully control this step to ensure a consistent and high-quality result.

The Art of Making Brousse Cheese

You may want to see also

Explore related products

Rennet is added to form the curd

The use of rennet means that traditionally made Parmesan is not halal, as it is a restricted ingredient in a Muslim's diet. However, some cheese producers are rethinking the process of cheese-making to keep up with the changing times. For example, Cello Cheese uses microbial rennet, also known as "vegetarian rennet", in all of its cheeses, so vegetarians and those requiring halal food can safely enjoy Parmesan.

The amount of rennet added depends on the type of milk used. If using a higher-temperature pasteurized milk, the recipe must be adjusted to compensate. In this case, the amount of rennet is increased, and the coagulation time is decreased. However, if using a better-quality, raw milk, the rennet should be decreased by 25-30%, and the coagulation time should be reduced by 40-50%.

Before adding the rennet, the milk is heated slowly to 91-93°F (32-34°C). This is best done using a milk pot in a water bath, although it can be done directly on a stove top with careful heating.

The Art of Bulgarian Feta: A Traditional Cheese-Making Journey

You may want to see also

It's a protected designation of origin (PDO) product

Parmigiano-Reggiano is a protected designation of origin (PDO) product. This means that it is a geographical indication of the European Union that preserves the designations of origin of food products. The designation was created in 1992 and its main purpose is to designate products that have been produced, processed, and developed in a specific geographical area, using the recognized traditional methods and ingredients from the region concerned. The characteristics of the products protected are linked to their terroir, history, and traditions. The European or UK PDO logo, whose use is compulsory, documents this link.

The PDO system is in place to protect the reputation of regional foods and eliminate unfair competition and the misleading of consumers by non-genuine products, which may be of inferior quality or have a different flavor. The legislation also aims to ensure equal conditions of competition between producers.

While the PDO system only automatically guarantees protection throughout the EU, and any greater geographical protection must be legally pursued on a case-by-case basis, the US does respect the Parmigiano-Reggiano PDO status as a distinctive style of cheese that can only be made in Italy. However, "Parmesan" has been ruled as a generic term that can be used to refer to cheeses made in the US or elsewhere in the world in the style of Parmigiano-Reggiano.

Square Cheese: The Secret of Its Making

You may want to see also

Frequently asked questions

Parmesan cheese is traditionally made from cow's milk. Additional ingredients like whey and rennet are added to form the curd.

Parmesan cheese is typically aged for at least 12 months. However, some varieties are aged for longer, up to 16 months, to create a sweeter flavour.

Parmigiano Reggiano is the name for Parmesan cheese that is produced in a restricted geographic area in northern Italy, using specific methods. Outside of Europe, the term Parmesan is used more generically to refer to a variety of hard Italian-style grating cheeses.