Air drying cheese is a traditional method used to preserve and enhance its flavor, texture, and shelf life. This process involves exposing cheese to controlled temperature and humidity levels, allowing moisture to evaporate gradually while promoting the growth of beneficial molds and bacteria. Ideal for hard and semi-hard cheeses like Parmesan or Cheddar, air drying requires a well-ventilated space, proper shelving, and consistent monitoring to prevent spoilage. By mastering this technique, cheese enthusiasts can achieve a firmer texture, concentrated flavor, and extended longevity, making it a valuable skill for both home cheesemakers and aficionados.

Explore related products

What You'll Learn

- Choose the Right Cheese: Select hard or semi-hard varieties like cheddar, parmesan, or gouda for best results

- Prepare the Cheese: Cut into desired sizes, ensuring even drying and proper air circulation

- Set Up Drying Area: Use a clean, well-ventilated space with consistent temperature and low humidity

- Monitor Drying Time: Check regularly, flipping cheese to prevent mold and ensure even drying

- Store Properly: Once dry, wrap in wax paper or store in airtight containers for longevity

Choose the Right Cheese: Select hard or semi-hard varieties like cheddar, parmesan, or gouda for best results

Hard and semi-hard cheeses are the ideal candidates for air drying due to their lower moisture content and denser structure. Unlike soft cheeses, which can become overly dry or develop undesirable textures, varieties like cheddar, parmesan, and gouda maintain their integrity during the drying process. This is because their moisture levels are already relatively low, typically ranging between 30% to 40% for semi-hard cheeses and even lower for hard cheeses like parmesan. When air-dried, these cheeses lose moisture gradually, concentrating their flavors and developing a pleasingly firm texture without becoming brittle or crumbly.

Selecting the right cheese is not just about moisture content; it’s also about flavor profile and intended use. Cheddar, for instance, becomes sharper and more intense as it dries, making it perfect for grating over dishes or pairing with crackers. Parmesan, already a hard cheese, transforms into a rich, umami-packed ingredient ideal for enhancing soups, salads, or pasta. Gouda, with its slightly sweet and nutty notes, develops a deeper complexity when air-dried, becoming a standout addition to cheese boards or sandwiches. Each cheese reacts uniquely to air drying, so consider how the process will amplify its natural characteristics.

To maximize success, start with high-quality, aged cheeses. Younger cheeses may not have the necessary density or flavor concentration to benefit from air drying. For example, a 12-month aged gouda will yield better results than a 6-month version. Similarly, opt for block cheeses rather than pre-shredded varieties, as the latter often contain additives that can interfere with the drying process. If you’re unsure, consult with a cheesemonger or refer to the cheese’s moisture content label, aiming for varieties below 40% moisture for best results.

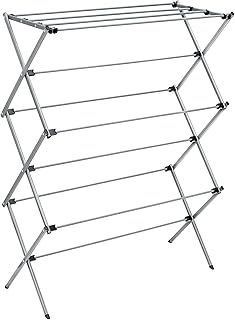

Practical tips can further enhance your air-drying experience. Cut the cheese into uniform pieces, such as thin slices or small cubes, to ensure even drying. Store the pieces in a well-ventilated area, like a wire rack or a dedicated drying box, away from direct sunlight and at room temperature (around 68°F to 72°F). Monitor the cheese daily, flipping the pieces to prevent moisture buildup on one side. Depending on the size and humidity levels, the drying process can take anywhere from a few days to a week. Once the cheese feels firm but not hard, it’s ready to be stored in an airtight container for future use.

In conclusion, choosing the right cheese for air drying is a blend of science and artistry. By focusing on hard or semi-hard varieties and considering factors like age, moisture content, and flavor profile, you can transform everyday cheeses into concentrated, versatile ingredients. Whether you’re aiming to elevate your cooking or simply reduce food waste, air drying cheddar, parmesan, or gouda is a rewarding technique that highlights the cheese’s natural qualities in a whole new way.

Creative Ways to Enjoy and Serve Cheese and Potato Pie

You may want to see also

Prepare the Cheese: Cut into desired sizes, ensuring even drying and proper air circulation

Cutting cheese into the right sizes is the first critical step in air drying, as it directly influences both the drying time and the final texture. Larger pieces will dry more slowly and may develop a harder exterior before the interior is fully dried, leading to uneven results. Smaller pieces, on the other hand, dry faster and more uniformly, but they may become too brittle or lose flavor if left unattended. For most cheeses, aim for slices or cubes between ½ to 1 inch thick. This size range strikes a balance, allowing air to circulate effectively while maintaining the cheese’s structural integrity.

Consider the type of cheese when determining the ideal size. Harder cheeses like Parmesan or Pecorino can handle thinner slices, often as thin as ¼ inch, as they are less prone to crumbling. Softer cheeses, such as mozzarella or young cheddar, should be cut into thicker pieces, around ¾ inch, to prevent them from drying out too quickly or losing their shape. Always use a sharp, clean knife to ensure clean cuts, as jagged edges can hinder even drying and create pockets where moisture accumulates.

Proper air circulation is just as vital as the size of the cheese pieces. Overcrowding the drying rack or tray can trap moisture, leading to mold or spoilage. Arrange the cheese in a single layer, leaving at least 1 inch of space between pieces. If using a multi-tiered rack, ensure each level is spaced far enough apart to allow air to flow freely. For optimal results, place the rack in a well-ventilated area with consistent airflow, such as near an open window or a fan set on low. Avoid areas with high humidity, as this will slow the drying process and increase the risk of mold.

A practical tip for ensuring even drying is to flip the cheese pieces halfway through the process. This simple step exposes all sides to air equally, preventing one side from drying faster than the other. For smaller pieces, flipping every 12 hours is sufficient; for larger pieces, every 24 hours works well. Keep a log of flipping times to stay organized, especially if drying multiple batches. This attention to detail will result in uniformly dried cheese with a consistent texture and flavor profile.

Finally, monitor the cheese regularly to catch any issues early. If you notice moisture pooling on the tray or rack, adjust the spacing or wipe it away to prevent mold. Similarly, if the cheese begins to dry too quickly and becomes overly brittle, consider covering it loosely with a cheesecloth to slow the process. By combining precise cutting with mindful arrangement and regular maintenance, you’ll achieve perfectly air-dried cheese tailored to your preferences.

Mastering the Art of Growing Critical X Cheese Candy Feminized

You may want to see also

Set Up Drying Area: Use a clean, well-ventilated space with consistent temperature and low humidity

A clean, well-ventilated drying area is the backbone of successful air-dried cheese. Think of it as a controlled environment where moisture evaporates slowly and evenly, preventing mold growth and encouraging the development of a desirable rind. Imagine a stuffy, humid room – your cheese would sweat, attracting unwanted bacteria and spoiling.

The ideal space mimics the conditions of a natural cave: cool, dry, and with a gentle airflow.

Location Matters: Choose a spot away from direct sunlight, which can cause uneven drying and off-flavors. A pantry, basement, or even a dedicated shelf in a cool room are good options. Ensure the area is free from strong odors, as cheese readily absorbs them.

Airflow is Key: Aim for a consistent, gentle breeze. A small fan on low setting, positioned to create a cross-ventilation effect, works well. Avoid strong drafts that could dry the cheese too quickly, leading to a hard, crumbly texture.

Temperature Control: The sweet spot for air-drying cheese is between 50°F and 60°F (10°C and 15°C). This range slows bacterial growth while allowing moisture to escape gradually. A basement often naturally maintains this temperature, but a cool room with a thermostat can be adjusted accordingly.

Humidity Management: Aim for a relative humidity of around 60-70%. Too high, and mold becomes a risk; too low, and the cheese will dry out excessively. A hygrometer, readily available at hardware stores, is a valuable tool for monitoring humidity levels. If humidity is too high, consider using a dehumidifier or placing a bowl of uncooked rice (a natural desiccant) nearby.

Cleanliness is Paramount: Before placing your cheese, thoroughly clean and sanitize the drying area. Wipe down surfaces with a food-safe disinfectant and allow them to air dry completely. Remember, any dust, dirt, or bacteria present will transfer to your cheese. Regularly clean the area during the drying process, especially if you're drying multiple batches.

Cheese on Tacos: Culinary Delight or Cultural Misstep?

You may want to see also

Explore related products

$12.74 $17.53

$3.69

Monitor Drying Time: Check regularly, flipping cheese to prevent mold and ensure even drying

Air-drying cheese is a delicate balance of patience and vigilance. Neglecting to monitor the process can lead to uneven drying or, worse, mold growth. Regular checks are essential, not just to observe progress but to intervene when necessary. Flipping the cheese at consistent intervals ensures that moisture evaporates uniformly, preventing the formation of hard, dry spots on one side and damp, mold-prone areas on the other. This simple act of turning the cheese can make the difference between a perfectly aged wheel and a ruined batch.

Consider the environment in which the cheese is drying. Humidity levels, temperature, and airflow all influence drying time. In humid conditions, mold can develop rapidly, often within 24 to 48 hours. Flipping the cheese daily in such environments is critical. Conversely, in drier climates, flipping every other day may suffice. Use a hygrometer to monitor humidity, aiming for levels between 60% and 70% for optimal drying. If mold appears despite regular flipping, trim the affected area immediately and adjust the drying conditions.

The frequency of flipping also depends on the cheese variety and its stage in the drying process. Hard cheeses like Parmesan or Pecorino require less frequent flipping as they dry, while softer cheeses like halloumi or feta need more attention. For the first week, flip the cheese twice daily to establish a consistent drying pattern. After the initial phase, reduce this to once daily or every other day, depending on the cheese’s texture and the environment. Always inspect the cheese for signs of moisture accumulation or mold, adjusting your routine as needed.

Practical tools can streamline the monitoring process. Cheese mats or racks with breathable surfaces allow air to circulate evenly, reducing the risk of moisture buildup. Keep a drying log to record flipping times, environmental conditions, and observations. This log becomes a valuable reference for future batches, helping you refine your technique. For example, if mold appeared after five days in a previous batch, you’ll know to increase flipping frequency or adjust humidity levels in subsequent attempts.

Ultimately, monitoring drying time is an art as much as a science. It requires observation, adaptability, and a willingness to learn from each batch. Flipping the cheese regularly is a small but crucial step that ensures even drying and prevents mold. By staying attentive and responsive to the cheese’s needs, you’ll master the air-drying process and produce cheeses with the desired texture and flavor. Remember, consistency in monitoring is key—it’s the difference between a mediocre result and a masterpiece.

Exploring Cheese's Organic Macromolecules: Proteins, Fats, Carbs, and More

You may want to see also

Store Properly: Once dry, wrap in wax paper or store in airtight containers for longevity

Proper storage is the unsung hero of air-drying cheese, ensuring your efforts don’t go to waste. Once your cheese has reached the desired dryness, the next step is critical: wrap it in wax paper or place it in an airtight container. Wax paper allows the cheese to breathe slightly, preventing moisture buildup while still protecting it from external contaminants. Airtight containers, on the other hand, create a sealed environment that locks in flavor and texture, ideal for harder cheeses like Parmesan or aged cheddar. The choice depends on the cheese type and your intended use—wax paper for semi-soft varieties, containers for longer-term preservation.

Consider the environment where you store your cheese. A cool, dark place like a pantry or cellar is best, as fluctuations in temperature and light can degrade quality. Avoid refrigerators unless necessary, as the humidity can rehydrate the cheese, undoing your drying efforts. For optimal longevity, label your storage with the date and type of cheese. This simple step ensures you use older batches first and helps track aging progress.

Airtight containers come in various materials, but glass or food-grade plastic are preferred for their non-reactive properties. Avoid metal containers, as they can impart unwanted flavors. If using wax paper, secure it tightly with twine or tape, ensuring no air gaps. For added protection, place a silica gel packet inside the container to absorb any residual moisture. This small detail can extend shelf life by months, especially in humid climates.

Finally, inspect your stored cheese periodically. Even with proper storage, mold or off-odors can develop. If you notice any signs of spoilage, discard the cheese immediately to prevent contamination of other batches. Regularly rotating your stock and maintaining cleanliness in storage areas are simple practices that pay dividends in preserving the quality of your air-dried cheese. With these steps, your cheese will remain a testament to your craftsmanship, ready to be enjoyed whenever the craving strikes.

Protein Content in a Cheeseburger: How Many Grams Are There?

You may want to see also

Frequently asked questions

Air drying cheese is a process where cheese is exposed to air at controlled temperatures and humidity levels to reduce moisture content. It is done to concentrate flavor, improve texture, and extend shelf life.

Hard and semi-hard cheeses like Parmesan, Pecorino, or aged cheddar are ideal for air drying due to their lower moisture content and ability to harden further.

The time varies depending on the cheese type and desired dryness, but it typically ranges from a few days to several weeks. Harder cheeses may take longer than softer varieties.

Optimal conditions include a cool, well-ventilated area with temperatures between 50–60°F (10–15°C) and humidity around 60–70%. Avoid direct sunlight and ensure good air circulation.

Yes, you can air dry cheese at home. Basic equipment includes a drying rack, cheesecloth or mats, and a cool, dry space. A dehumidifier or fan can help control humidity and airflow.