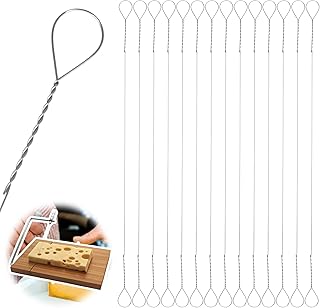

Changing the wire on a wood cheese board is a straightforward task that can extend the life of your board and ensure it remains functional for slicing and serving. Over time, the wire may become dull or break, making it necessary to replace it to maintain the board’s efficiency. To begin, you’ll need a replacement wire specifically designed for cheese boards, which can typically be found at kitchen supply stores or online. The process involves removing the old wire by loosening the screws or mechanisms that hold it in place, carefully threading the new wire through the board’s grooves, and securing it tightly to ensure smooth cutting. With the right tools and a bit of patience, you can easily restore your cheese board to its original condition.

| Characteristics | Values |

|---|---|

| Tools Required | Pliers, wire cutter, screwdriver, replacement wire (specific gauge for cheese board), sandpaper (optional) |

| Difficulty Level | Moderate |

| Time Required | 15-30 minutes |

| Steps | 1. Remove the old wire by loosening the screws holding it in place. 2. Cut the new wire to the appropriate length, allowing extra for securing. 3. Thread the new wire through the existing holes in the board. 4. Tighten the screws to secure the wire firmly. 5. Test the wire tension by slicing cheese to ensure it cuts smoothly. |

| Wire Gauge | Typically 12-14 gauge, depending on the board design |

| Maintenance Tip | Regularly check wire tension and replace if it becomes frayed or loose. |

| Safety Precaution | Wear gloves when handling wire to avoid cuts. |

| Cost of Replacement Wire | $5-$10, depending on length and quality |

| Alternative Method | Some boards use a replaceable wire cartridge, simplifying the process. |

| Environmental Impact | Replacing the wire extends the life of the board, reducing waste. |

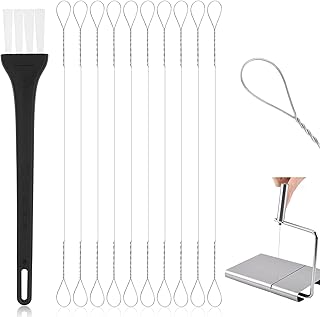

Explore related products

$8.99 $9.99

What You'll Learn

- Gather Tools: Wire cutter, pliers, screwdriver, replacement wire, and safety gloves

- Remove Old Wire: Loosen screws, cut wire, and detach it carefully from the board

- Measure New Wire: Ensure the replacement wire matches the original length and thickness

- Install Wire: Thread new wire through holes, secure with screws, and tighten firmly

- Test & Adjust: Check wire tension, ensure smooth slicing, and make final adjustments

Gather Tools: Wire cutter, pliers, screwdriver, replacement wire, and safety gloves

Before embarking on the task of replacing the wire on your wooden cheese board, it's essential to assemble the right tools. A wire cutter, pliers, screwdriver, replacement wire, and safety gloves are the backbone of this operation. Each tool plays a specific role, and their collective presence ensures a smooth, efficient, and safe process. The wire cutter is your primary weapon for removing the old wire, while the pliers provide the necessary grip and manipulation for handling the wire ends. A screwdriver, often overlooked, is crucial for accessing hidden screws that may secure the wire in place. The replacement wire, of course, is the star of the show, breathing new life into your cheese board. Lastly, safety gloves are non-negotiable, protecting your hands from sharp wire edges and potential slips.

Consider the wire cutter as the precision instrument in this toolkit. Its primary function is to sever the old wire cleanly, without damaging the wooden board. When selecting a wire cutter, opt for one with a comfortable grip and sharp blades. Dull blades can lead to frayed wire ends, complicating the removal process. For those dealing with thicker wires, a heavy-duty cutter is advisable. The pliers, on the other hand, are your go-to tool for bending and twisting wire ends. Needle-nose pliers, with their slender design, offer better access to tight spaces, making them ideal for this task. If your cheese board has screws holding the wire in place, a screwdriver becomes indispensable. Match the screwdriver type to the screw head – Phillips, flathead, or Allen – to avoid stripping the screws.

The replacement wire is where your creativity can shine. Cheese board wires typically come in various materials, such as stainless steel or galvanized steel, each with its own aesthetic and durability. Measure the length of the old wire to ensure the replacement fits perfectly. If you're feeling adventurous, consider a wire with a unique finish or texture to add a personal touch to your board. However, always prioritize functionality over style, ensuring the wire is sturdy enough to support the weight of the cheese and handle. Safety gloves, while seemingly mundane, are a critical component of this toolkit. They provide a barrier against sharp wire edges and prevent slips that could lead to injuries. Opt for gloves with a good grip, such as nitrile or leather, to maintain dexterity while working.

Now, let's talk about the sequence of tool usage. Begin by using the screwdriver to remove any screws securing the wire. Once the screws are out, employ the wire cutter to sever the old wire, taking care not to damage the wooden board. With the old wire removed, use the pliers to straighten and prepare the ends of the replacement wire. Insert the new wire, ensuring it’s securely anchored, and reattach any screws. Throughout this process, keep your safety gloves on to protect your hands. This methodical approach not only ensures efficiency but also minimizes the risk of errors or accidents.

In conclusion, gathering the right tools is the first step toward successfully replacing the wire on your wooden cheese board. Each tool – wire cutter, pliers, screwdriver, replacement wire, and safety gloves – serves a distinct purpose, contributing to a seamless and safe repair. By understanding the role of each tool and following a structured approach, you can breathe new life into your cheese board, ensuring it remains a functional and stylish centerpiece for your culinary creations.

Should Vegan Nut Cheese Be Refrigerated? Storage Tips Revealed

You may want to see also

Remove Old Wire: Loosen screws, cut wire, and detach it carefully from the board

The first step in replacing the wire on a wooden cheese board is to remove the old one, a process that requires precision and care to avoid damaging the board. Begin by locating the screws that secure the wire to the board. These are typically found at the ends of the wire, where it is anchored to the wooden frame. Using a screwdriver that matches the screw head (usually a Phillips or flathead), turn the screws counterclockwise to loosen them. Be cautious not to strip the screws, as this can complicate the removal process. If the screws are rusted or difficult to turn, apply a small amount of penetrating oil and allow it to sit for a few minutes before attempting again.

Once the screws are loosened, the next step is to cut the wire. Position the wire cutters or pliers near the screw but far enough away to avoid damaging the board. Ensure the cutting tool is sharp to achieve a clean cut. After cutting, gently pull the wire away from the board, taking care not to force it, as this could splinter the wood. If the wire is tightly wound or stuck, use a pair of needle-nose pliers to carefully unwind or extract it. This step demands patience, as rushing can lead to unnecessary damage to the cheese board’s surface.

Detaching the wire from the board is the final phase of this process. With the screws removed and the wire cut, the remaining task is to lift the wire off the board. Inspect the area where the wire was attached for any residual adhesive or debris. If present, use a soft cloth or fine-grit sandpaper to gently clean the surface, ensuring it is smooth and ready for the new wire. Avoid using harsh chemicals or abrasive tools, as these can harm the wood’s finish. Properly preparing the board at this stage ensures a secure and professional-looking installation of the replacement wire.

A practical tip for this process is to work in a well-lit area to clearly see the screws and wire. Additionally, laying down a soft cloth or towel beneath the board can prevent scratches or dents to the workspace. For those new to this task, practicing on a scrap piece of wood or an old board can build confidence before tackling the actual cheese board. By following these steps methodically, you can remove the old wire efficiently, setting the stage for a successful replacement that extends the life of your wooden cheese board.

Does Kerrygold Dubliner Cheese Require Refrigeration? Storage Tips Revealed

You may want to see also

Measure New Wire: Ensure the replacement wire matches the original length and thickness

The integrity of your cheese board hinges on the wire’s precise fit. A mismatch in length or thickness can compromise both functionality and aesthetics. Before purchasing a replacement, measure the original wire meticulously. Use a flexible measuring tape to capture the full length, accounting for any curves or bends. Note the thickness with calipers for accuracy, as even a millimeter discrepancy can affect tension and cutting performance.

Consider the wire’s material and tensile strength as well. Stainless steel is a common choice for its durability and rust resistance, but ensure the gauge matches the original. For example, a 12-gauge wire is thicker and sturdier than 14-gauge, which may be more flexible but less robust. If the original wire is unavailable for comparison, consult the cheese board’s manual or manufacturer for specifications.

Practical tip: If the original wire is frayed but intact, lay it flat on a surface and trace its outline onto paper. This creates a template for comparing lengths and shapes when shopping for replacements. Alternatively, take the wire to a hardware store for a side-by-side comparison. Avoid eyeballing measurements, as visual estimates often lead to errors.

A cautionary note: Using a wire that’s too short will result in inadequate tension, causing it to slip or break under pressure. Conversely, a wire that’s too long or thick may warp the board’s frame or require excessive force to cut. These issues not only diminish the board’s performance but can also damage the wood over time.

In conclusion, precision in measuring the replacement wire is non-negotiable. It ensures seamless functionality, preserves the board’s lifespan, and maintains its elegant appearance. Invest time in accurate measurements—it’s a small step that yields significant returns in both performance and longevity.

Ham and Cheese Sandwich: Uncovering Its Kilojoule Content and Nutritional Value

You may want to see also

Explore related products

Install Wire: Thread new wire through holes, secure with screws, and tighten firmly

The process of installing a new wire on a wooden cheese board is a straightforward task that requires attention to detail and a few basic tools. Begin by selecting a wire that matches the original in terms of gauge and length, typically ranging from 18 to 20 gauge for most cheese boards. This ensures the wire is sturdy enough to support the weight of the cheese and the cutting pressure applied during use. Once you have the appropriate wire, the installation process can commence.

Thread the new wire through the pre-drilled holes on the cheese board, ensuring it follows the same path as the original wire. This step demands patience, as the wire must be guided carefully to avoid kinking or twisting, which could compromise its strength and appearance. A helpful tip is to attach a small weight, like a washer or a nut, to the end of the wire to aid in pulling it through the holes smoothly. This technique is particularly useful for cheese boards with intricate designs or multiple wire strands.

Securing the wire is the next critical step. Position the wire so that it is taut but not overly tight, as this could cause the wood to crack under pressure. Use screws, typically provided with the cheese board or available at hardware stores, to fasten the wire ends. These screws should be tightened firmly, but not excessively, to prevent stripping the wood threads. A good practice is to use a screwdriver with a torque-limiting setting or to tighten the screws by hand initially, then give them a final firm turn with a tool.

The art of tightening the wire securely lies in finding the right balance. Over-tightening can lead to wire breakage or damage to the wood, while under-tightening may result in a loose wire that affects the cheese-cutting experience. A practical approach is to tighten the screws until you feel a slight resistance, indicating the wire is secure, and then test the tension by gently pulling on the wire. If it holds firmly without any give, you've achieved the ideal tightness. This step ensures the wire can withstand regular use and provides a smooth cutting surface for your cheese board.

In summary, installing a new wire on a wooden cheese board involves a precise process of threading, securing, and tightening. By following these steps and paying attention to the wire's tension and the screws' firmness, you can ensure a durable and functional cheese board. This simple maintenance task allows you to extend the life of your cheese board and continue enjoying its use for many gatherings and cheese-tasting sessions to come.

Vacuum-Sealed Gouda: Refrigeration Required or Shelf-Stable?

You may want to see also

Test & Adjust: Check wire tension, ensure smooth slicing, and make final adjustments

Once the new wire is in place, the real test begins. Proper tension is critical—too loose, and the wire won’t slice cleanly; too tight, and it risks snapping under pressure. Use a tension gauge if available, aiming for a reading between 10-15 pounds of force. If a gauge isn’t handy, a practical method is to pluck the wire like a guitar string, listening for a consistent, resonant hum. Adjust the tension screws incrementally, turning them no more than a quarter-turn at a time to avoid over-tightening.

Smooth slicing is the ultimate goal, and it’s achieved through precision. Test the wire by slicing a firm cheese like cheddar or gouda. If the wire catches or tears the cheese, it’s either too loose or misaligned. Re-check the tension and ensure the wire is seated evenly in the grooves. For softer cheeses, like brie, a slightly looser tension may be preferable to prevent crushing. Observe the wire’s path—it should cut in a straight line without wobbling, which indicates uneven tension or a bent wire.

Final adjustments are where craftsmanship meets practicality. If the wire still isn’t performing optimally, consider the board’s condition. Warped wood can throw off alignment, so place the board on a flat surface during testing. For stubborn issues, lightly sand the grooves to remove burrs or debris that might hinder wire movement. Once satisfied, secure the screws with a thread-locking adhesive to prevent loosening over time.

The takeaway is patience. Testing and adjusting aren’t one-off steps but an iterative process. Each cheese board is unique, and what works for one may not work for another. Keep a small notebook to record tension settings and adjustments for future reference. With practice, you’ll develop an instinct for the perfect tension, ensuring your cheese board remains both functional and elegant.

Mixing Egg with Ricotta Cheese: Lasagna Perfection or Unnecessary Step?

You may want to see also

Frequently asked questions

To remove the old wire, locate the metal pegs or screws holding the wire in place. Use pliers to grip the wire and pull it out gently. If the wire is stuck, twist it back and forth while pulling to loosen it.

You’ll need pliers to remove the old wire, a new cheese board wire (available at kitchen supply stores), and possibly a screwdriver if the wire is held by screws. Ensure the new wire fits the board’s size.

Thread the new wire through the holes or pegs on the board, ensuring it’s taut but not overly tight. Secure it by wrapping the ends around the pegs or tightening the screws. Test the wire to ensure it cuts cheese smoothly.