Changing a cheese wire is a straightforward task that ensures clean and precise cuts when slicing cheese. Over time, cheese wires can become dull or frayed, affecting their efficiency and the quality of the cut. To replace a cheese wire, start by identifying the type of cheese cutter you have, as different models may have varying mechanisms for wire replacement. Typically, you’ll need to locate the wire tensioning system, which often involves loosening a screw or clamp to release the old wire. Carefully remove the worn wire, ensuring not to damage the cutter, and thread the new wire through the guides, securing it tightly to maintain proper tension. Finally, test the wire by making a few cuts to ensure it’s functioning smoothly. Regularly changing the cheese wire not only enhances performance but also prolongs the life of your cheese cutter.

| Characteristics | Values |

|---|---|

| Tool Required | Cheese wire cutter replacement kit, pliers, screwdriver |

| Steps | 1. Remove the old wire by loosening the screws or clips holding it in place. 2. Clean the wire guide and grooves to ensure smooth operation. 3. Insert the new wire, ensuring it is taut and properly aligned. 4. Secure the wire by tightening screws or clips. 5. Test the cutter to ensure the wire moves freely and cuts effectively. |

| Wire Material | Stainless steel (most common for durability and rust resistance) |

| Wire Thickness | Typically 0.5-1 mm, depending on the cutter model |

| Frequency of Replacement | Every 6-12 months or when the wire becomes frayed or dull |

| Safety Tips | Wear gloves to avoid cuts; ensure the wire is securely fastened before use |

| Compatibility | Check the cutter model for specific wire size and replacement kit compatibility |

| Cost | Replacement kits range from $5 to $20, depending on brand and quality |

| DIY vs. Professional | Most replacements can be done at home, but consult a professional if unsure |

Explore related products

$8.99 $9.99

What You'll Learn

- Choosing the Right Wire: Select durable, food-grade stainless steel wire for safe and efficient cheese cutting

- Removing Old Wire: Carefully unwind and detach the worn-out wire from the cutter handle

- Installing New Wire: Thread the new wire through the cutter, ensuring it’s taut and secure

- Testing Wire Tension: Adjust the wire tightness to achieve clean, precise cuts without snapping

- Maintaining the Cutter: Regularly clean and inspect the wire and handle for longevity

Choosing the Right Wire: Select durable, food-grade stainless steel wire for safe and efficient cheese cutting

The wire you choose for cutting cheese is more than a tool—it’s a determinant of both safety and efficiency. Stainless steel, particularly food-grade varieties, stands out for its durability and resistance to corrosion. Unlike galvanized or coated wires, which may leach harmful substances into food, food-grade stainless steel ensures no chemical transfer occurs during use. This material’s strength also prevents breakage, reducing the risk of wire fragments contaminating your cheese. For optimal performance, select a wire with a gauge between 16 and 18, balancing flexibility and rigidity for clean cuts through both soft and hard cheeses.

Consider the wire’s compatibility with your cheese cutter or board. Most cheese wires come in standard lengths (12–16 inches), but ensure it fits snugly within your cutter’s grooves to avoid slippage. If replacing a wire, measure the old one for accuracy. Installation typically involves threading the wire through the cutter’s guides and securing it with tension screws or clamps. Tighten these components firmly but not excessively, as over-tightening can warp the wire or damage the cutter. Regularly inspect the wire for signs of wear, such as kinks or fraying, and replace it every 6–12 months depending on frequency of use.

From a practical standpoint, food-grade stainless steel wire is not only safer but also cost-effective in the long run. Inferior materials may save money upfront but often require frequent replacements due to rust or breakage. Stainless steel’s non-reactive surface resists bacterial growth, making it easier to clean—simply wash with warm, soapy water and dry thoroughly after each use. For added hygiene, periodically sanitize the wire with a food-safe disinfectant, especially if cutting aged or raw-milk cheeses.

Comparing stainless steel to alternatives highlights its superiority. Plastic-coated wires, for instance, may seem convenient but can harbor bacteria in the coating’s crevices. Copper or aluminum wires, while aesthetically pleasing, are prone to oxidation and may impart metallic flavors. Stainless steel’s inert nature eliminates these concerns, ensuring your cheese retains its pure taste. For artisanal cheesemakers or home enthusiasts, investing in high-quality wire translates to consistent, professional-grade results without compromising food safety.

Finally, the choice of wire reflects a broader commitment to culinary precision. A sharp, durable wire ensures even slices, enhancing both presentation and texture. Whether crafting thin wafers of Parmesan or thick wedges of Brie, the right wire transforms the task from laborious to effortless. By prioritizing food-grade stainless steel, you not only safeguard your health but also elevate the art of cheese cutting, proving that even the smallest tool can make a significant difference in the kitchen.

Are Sargento Cheeses Vegetarian? A Comprehensive Guide for Cheese Lovers

You may want to see also

Removing Old Wire: Carefully unwind and detach the worn-out wire from the cutter handle

The first step in changing a cheese wire is often the most overlooked yet crucial: removing the old wire. This process requires precision and care to avoid damaging the cutter handle or injuring yourself. Begin by examining the wire’s attachment points—typically small grooves or slots on either side of the handle. Use a pair of needle-nose pliers or a flathead screwdriver to gently pry the wire out of these grooves, taking care not to force it. If the wire is rusted or stuck, apply a small amount of penetrating oil (like WD-40) and let it sit for 5–10 minutes before attempting removal again.

Analyzing the mechanics of this step reveals why patience is key. Cheese wires are designed to be taut and durable, but over time, they can fray or become embedded in the handle. Forcing the wire out can cause it to snap, leaving fragments lodged in the grooves or, worse, creating sharp edges that could compromise the new wire’s stability. A systematic approach—starting at one end, gradually loosening the wire, and working your way to the other side—minimizes these risks. Think of it as unraveling a knot: slow, deliberate movements yield the best results.

From a practical standpoint, here’s a step-by-step breakdown: First, position the cutter handle on a flat surface to stabilize it. Second, identify the side where the wire is least secure and begin unwinding it counterclockwise (or in the direction opposite to its original winding). Third, as you unwind, gently lift the wire out of the grooves, using a tool only when necessary. Finally, once the wire is free, inspect the grooves for debris or damage. If they’re clogged with cheese residue or rust, clean them with a soft brush and mild detergent before proceeding to the next step.

Comparing this process to other wire-replacement tasks highlights its unique challenges. Unlike changing a guitar string or a lawn trimmer line, cheese wires are often under significant tension and embedded in a compact, handheld tool. This makes precision and control paramount. For instance, while a guitar string can be cut and removed in pieces, a cheese wire must be unwound intact to avoid leaving sharp ends that could snag the new wire. This distinction underscores the importance of treating the removal process as a delicate operation rather than a brute-force task.

In conclusion, removing old cheese wire is a deceptively simple step that demands attention to detail. By approaching it methodically—using the right tools, applying gentle force, and cleaning the handle afterward—you ensure a smooth transition to the next phase of the process. Skipping or rushing this step can lead to frustration, damage, or even safety hazards. Treat it as the foundation of your wire-changing endeavor, and the rest of the task will follow suit with ease.

Converting Cheese Measurements: Ounces in Half a Pound Explained

You may want to see also

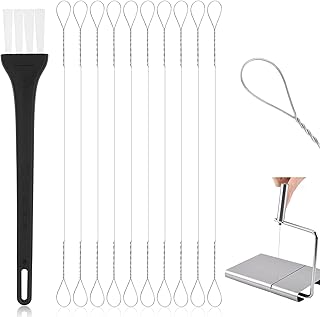

Installing New Wire: Thread the new wire through the cutter, ensuring it’s taut and secure

The success of your cheese wire cutter hinges on the precision of this step: threading the new wire. Imagine a surgeon suturing a delicate incision—the same care and attention to detail are required here. Begin by feeding one end of the wire through the designated channel, ensuring it glides smoothly without snagging. This process demands patience; rushing could lead to tangles or misalignment, compromising the cutter's performance.

Instructively, the technique is straightforward but requires a methodical approach. Hold the wire firmly at the entry point, guiding it along the cutter's path. Each cheese wire cutter may have unique design features, so consult the manufacturer's instructions for specific guidance. Generally, the wire should follow a straight or slightly curved route, depending on the cutter's mechanism. As you thread, maintain constant tension to prevent slack, which could result in uneven cutting.

A comparative analysis reveals that different wire materials and thicknesses can impact this process. For instance, stainless steel wires, known for their durability, might require more force to thread due to their rigidity. On the other hand, thinner wires, while easier to manipulate, may demand extra care to avoid breakage. The key is to strike a balance between tension and gentleness, ensuring the wire is secure without being strained.

Descriptively, the ideal outcome is a wire that sits snugly within the cutter, almost invisible to the naked eye. It should be taut like a guitar string, ready to slice through cheese with precision. Achieving this tension is an art, and practice makes perfect. Over time, you'll develop a feel for the right amount of pull, ensuring the wire is secure without being over-tightened, which could lead to premature wear.

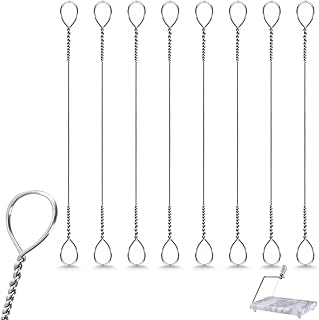

Practically, consider using a pair of needle-nose pliers to assist in feeding the wire through tight spaces, especially in intricate cutter designs. This tool can provide the necessary grip and precision, making the task more manageable. Additionally, always have a spare wire ready, as the threading process may cause minor damage or fraying, rendering the wire less effective for cutting. With these techniques and considerations, you'll master the art of installing new cheese cutter wire, ensuring every slice is a perfect one.

American Cheese in the UK: Unraveling Its British Name Mystery

You may want to see also

Explore related products

Testing Wire Tension: Adjust the wire tightness to achieve clean, precise cuts without snapping

Achieving the right wire tension is critical for clean, precise cheese cuts. Too loose, and the wire drags, tearing the cheese; too tight, and it snaps under pressure, wasting both wire and cheese. The ideal tension varies by cheese type—softer cheeses like Brie require less tension than harder varieties like Parmesan. Start by threading the wire through the cutter and securing it, then gently pull it taut. Avoid over-tightening initially; you can always adjust further.

To test tension, hold the wire cutter handles and apply gradual, even pressure as if cutting. Observe the wire’s behavior: does it glide smoothly through the cheese, or does it resist? A properly tensioned wire should cut effortlessly without wobbling or straining. If the wire leaves jagged edges or crumbles the cheese, it’s likely too loose. Conversely, if it snaps or feels overly rigid, it’s too tight. Adjust in small increments, tightening or loosening the wire’s securing mechanism until the desired balance is achieved.

Comparing wire tension to a guitar string can be helpful. Just as a guitarist tunes strings for optimal sound, you’re tuning the wire for optimal cutting. Too much tension risks breakage, while too little compromises performance. For most cheese wires, aim for a tension that allows the wire to depress slightly under thumb pressure but not sag. This ensures it’s tight enough to cut efficiently without exceeding its breaking point.

Practical tips: Use a tension gauge if available, aiming for a force of 5-10 pounds for medium-hard cheeses. If a gauge isn’t accessible, rely on tactile feedback—the wire should feel firm but not rigid. Always test on a small piece of cheese before attempting a full cut. For adjustable wire cutters, follow the manufacturer’s instructions for tightening mechanisms, typically involving screws or knobs. Regularly inspect the wire for wear and replace it if frayed, as damaged wires are more prone to snapping under tension.

Mastering wire tension transforms cheese cutting from a chore into an art. With practice, you’ll develop a feel for the ideal tightness, ensuring every slice is clean and precise. Remember, the goal isn’t just to cut cheese—it’s to do so with efficiency and elegance, preserving both the tool and the ingredient. Adjust thoughtfully, test frequently, and let the wire’s tension work in harmony with your technique.

Exploring the Cheese Plate: Counting Squares for a Perfect Presentation

You may want to see also

Maintaining the Cutter: Regularly clean and inspect the wire and handle for longevity

A cheese wire's effectiveness hinges on its cleanliness and structural integrity. Neglecting these aspects leads to frayed wires, rusty handles, and compromised cuts. Regular maintenance not only extends the tool's lifespan but also ensures consistent, precise slicing.

Begin by disassembling the cutter, if possible, to access all components. Use warm, soapy water and a soft-bristled brush to remove cheese residue, especially around the wire's anchor points and handle crevices. For stubborn buildup, a 50/50 solution of white vinegar and water dissolves grease without damaging metal. Rinse thoroughly and dry completely to prevent rust. Aim to clean after every 3–5 uses, depending on frequency and cheese type (soft cheeses require more frequent cleaning).

Inspection is equally critical. Examine the wire for kinks, frays, or thinning, which indicate imminent breakage. Test the handle for cracks or loose fittings that could lead to slippage during use. Replace the wire at the first sign of wear—most wires last 6–12 months with moderate use, but this varies based on cheese density and cutting technique. Handles, if made of wood, benefit from occasional mineral oil treatment to prevent drying and splitting.

Comparing this routine to maintaining a kitchen knife highlights its simplicity. While knives require sharpening and honing, cheese wires demand only basic cleaning and visual checks. Yet, the impact on performance is comparable. A well-maintained cutter slices through aged cheddar as effortlessly as a freshly sharpened blade glides through tomatoes.

Incorporating this practice into your cheese-cutting ritual takes minimal effort but yields significant returns. Think of it as preventive care—a few minutes of maintenance today spares you the frustration of a snapped wire tomorrow. By prioritizing cleanliness and inspection, you ensure your cheese wire remains a reliable tool for years, elevating every board or recipe it touches.

American Cheese vs. Velveeta: Unraveling the Melty Mystery

You may want to see also

Frequently asked questions

A cheese wire is a thin, flexible wire used to cut through cheese cleanly. You may need to change it if the wire becomes dull, frayed, or breaks, affecting its cutting efficiency.

Replace your cheese wire if it shows signs of wear, such as fraying, rust, or difficulty cutting through cheese smoothly.

Most cheese wires are designed for easy replacement. You can typically change it yourself by following the manufacturer’s instructions or using a replacement kit.

Replacement cheese wires are available at kitchen supply stores, online retailers, or directly from the manufacturer of your cheese cutter.