Cloth binding cheese is a traditional method of preserving and aging cheese, particularly popular for varieties like cheddar and Cheshire, where the cheese is wrapped in cheesecloth and stored to develop its flavor and texture. This technique not only protects the cheese from external contaminants but also allows it to breathe, promoting the growth of beneficial molds and bacteria that contribute to its unique character. The process involves carefully selecting the right type of cloth, preparing the cheese by trimming and cleaning it, and then tightly wrapping it to ensure even maturation. Proper storage conditions, such as maintaining the correct temperature and humidity, are crucial for achieving the desired results. Cloth binding is a craft that combines precision and patience, offering cheese enthusiasts a rewarding way to enhance the quality and taste of their cheese.

| Characteristics | Values |

|---|---|

| Purpose | To preserve and shape cheese during aging, allowing proper moisture evaporation and mold development. |

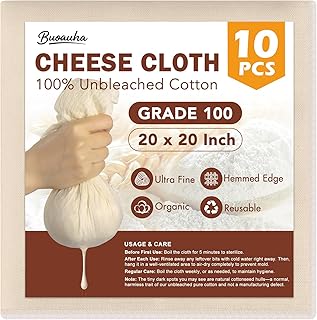

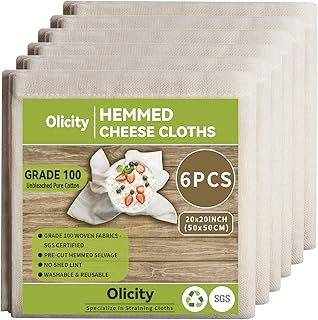

| Materials Needed | Cheese cloth (muslin or butter muslin), cheese, brine (optional), cheese wax (optional). |

| Cheese Types | Hard and semi-hard cheeses (e.g., Cheddar, Gouda, Parmesan). |

| Cloth Preparation | Wash and sterilize cheesecloth; dampen slightly for easier wrapping. |

| Wrapping Technique | Wrap cheese tightly in cloth, ensuring no gaps; secure ends with string or rubber bands. |

| Brining (Optional) | Soak cheese in brine solution before wrapping to enhance flavor and preserve. |

| Aging Conditions | Store in a cool, humid environment (e.g., cheese cave, wine fridge) at 50-55°F (10-13°C) with 80-85% humidity. |

| Aging Duration | Varies by cheese type (e.g., 2-12 months for Cheddar, 1-2 years for Parmesan). |

| Mold Development | Natural molds may form on cloth; wipe gently with brine or vinegar solution if excessive. |

| Turning Frequency | Turn cheese weekly to ensure even moisture distribution and mold growth. |

| Waxing (Optional) | Apply cheese wax after cloth binding for additional protection during long-term aging. |

| Unwrapping | Remove cloth carefully before consuming; trim rind if desired. |

| Benefits | Improves flavor, texture, and shelf life; traditional method for artisanal cheese making. |

| Challenges | Requires precise humidity and temperature control; risk of mold overgrowth if not monitored. |

Explore related products

What You'll Learn

- Prepare Cheese Block: Ensure cheese is dry, cut to size, and at room temperature for binding

- Cut Cloth Material: Measure and cut cheesecloth or muslin to fit the cheese block

- Wrap Cheese Tightly: Encase cheese in cloth, removing wrinkles, and secure with a knot or twist

- Press and Shape: Apply pressure to form the cheese into the desired shape and size

- Hang to Drain: Suspend bound cheese to allow excess whey to drain completely

Prepare Cheese Block: Ensure cheese is dry, cut to size, and at room temperature for binding

Before binding cheese in cloth, the block must be meticulously prepared to ensure a successful outcome. Moisture is the enemy of proper binding, as it can lead to mold or uneven drying. Pat the cheese dry with a clean kitchen towel, removing any surface moisture. For cheeses with a natural rind, consider brushing off excess debris gently. If the cheese is particularly moist, let it air-dry for 30 minutes to an hour in a cool, well-ventilated area. This step is crucial for varieties like cheddar or Gouda, which have a tendency to retain moisture.

Once the cheese is dry, precision in cutting is key. Measure and trim the block to the desired size, ensuring straight edges for even binding. A sharp, clean knife is essential to avoid tearing or crumbling the cheese. For example, a 2-pound block of cheese might be cut into 8-ounce portions for individual binding. The size should align with the intended use—smaller blocks for personal consumption, larger ones for aging or gifting. Remember, the cloth will add a slight bulk, so account for this when determining the final dimensions.

Room temperature is often overlooked but plays a pivotal role in the binding process. Cold cheese can cause the cloth to wrinkle or adhere improperly, while overly warm cheese may become too soft to handle. Aim for a cheese temperature of 65–70°F (18–21°C). Remove the cheese from refrigeration 1–2 hours before binding, allowing it to acclimate gradually. This is especially important for harder cheeses like Parmesan, which can become brittle if not handled at the right temperature.

Finally, inspect the cheese for any imperfections or cracks, as these can compromise the binding. Minor flaws can be trimmed away, while larger issues may require the block to be repurposed. A well-prepared cheese block not only ensures a neat, professional finish but also contributes to the longevity and flavor development of the cheese during aging. By prioritizing dryness, precision in cutting, and proper temperature, you set the stage for a successful cloth-binding process.

Cheese in the Trap: Unraveling the Ending and Its Happiness

You may want to see also

Cut Cloth Material: Measure and cut cheesecloth or muslin to fit the cheese block

The first step in cloth binding cheese is selecting and preparing the right fabric. Cheesecloth or muslin are ideal due to their breathable, lightweight nature, which allows moisture to escape while protecting the cheese. These materials are also easy to clean and reuse, making them cost-effective for repeated use. Before cutting, ensure the fabric is clean and free from any residues that could contaminate the cheese. A quick wash in hot water and air drying will suffice, but avoid using fabric softeners as they can leave behind chemicals.

Measuring the cloth to fit the cheese block requires precision. Lay the cheese block on the fabric and estimate the amount needed by allowing enough material to wrap around the block with a slight overlap. A good rule of thumb is to cut the cloth so it extends 2–3 inches beyond the edges of the cheese on all sides. For a standard 2-pound block of cheese, a square piece of cloth approximately 18 inches by 18 inches often works well. If you’re working with a round cheese, measure the diameter and add 4–6 inches to ensure full coverage.

Cutting the cloth should be done with care to avoid fraying, which can compromise the binding. Use sharp fabric scissors to ensure clean edges. If fraying is a concern, consider folding the edges of the cloth over by half an inch and ironing them down before wrapping the cheese. This not only prevents loose threads from sticking to the cheese but also gives the binding a neater appearance. For those who prefer a more rustic look, leaving the edges raw is acceptable, though it may require more frequent trimming over time.

The choice between cheesecloth and muslin depends on the desired level of breathability and texture. Cheesecloth has a looser weave, making it more breathable but less durable, while muslin’s tighter weave offers better protection but slightly less airflow. For softer cheeses that need more moisture control, cheesecloth is often preferred. Harder cheeses, which require more structural support, benefit from the sturdiness of muslin. Experimenting with both materials will help you determine which works best for your specific cheese type and aging conditions.

Cheese's Journey: The Columbian Exchange's Impact on Dairy Traditions

You may want to see also

Wrap Cheese Tightly: Encase cheese in cloth, removing wrinkles, and secure with a knot or twist

Cloth binding cheese is an age-old technique that not only preserves the cheese but also allows it to breathe, developing its unique flavor and texture. The key to mastering this method lies in the tightness of the wrap. Wrap Cheese Tightly: Encase cheese in cloth, removing wrinkles, and secure with a knot or twist. This step is crucial because a loose wrap can lead to uneven drying or mold growth, while wrinkles can trap moisture, compromising the cheese’s quality. Start by selecting a clean, food-grade cheesecloth or muslin, ensuring it’s free from any detergents or residues. Place the cheese in the center of the cloth, gather the edges, and pull them upward, smoothing the fabric as you go. Twist the cloth at the top to tighten it around the cheese, then secure it with a knot or a twist, ensuring the cheese is fully encased without gaps.

The process of tightly wrapping cheese in cloth is both an art and a science. Analytically, the tightness of the wrap affects the cheese’s moisture content and aging process. Too tight, and the cheese may dry out too quickly; too loose, and it risks retaining excess moisture, leading to spoilage. The goal is to create a snug fit that allows air circulation while preventing the cheese from becoming desiccated. For semi-hard cheeses like Cheddar or Gouda, a firmer wrap is ideal, while softer cheeses like Brie may require a looser approach to accommodate their higher moisture levels. Practically, this means adjusting the tension based on the cheese type and desired outcome.

From a comparative perspective, cloth binding stands out against modern methods like plastic wrapping or vacuum sealing. While plastic creates a barrier that traps moisture, cloth allows the cheese to breathe, fostering the growth of beneficial molds and bacteria that enhance flavor. However, cloth binding requires more attention to detail. For instance, the cloth must be changed periodically to prevent mold buildup, and the cheese should be monitored for signs of over-drying. In contrast, plastic wrapping is low-maintenance but often results in a less complex flavor profile. Cloth binding, when done correctly, offers a superior sensory experience but demands precision in execution.

Instructively, here’s a step-by-step guide to achieving the perfect wrap: First, cut a square of cheesecloth large enough to fully cover the cheese with extra fabric for twisting. Lay the cloth flat and place the cheese in the center. Gather the edges of the cloth, ensuring the cheese is centered, and begin smoothing out wrinkles as you pull the fabric upward. Twist the gathered cloth tightly at the top, creating a taut seal around the cheese. Secure the twist with a knot or a rubber band, ensuring no part of the cheese is exposed. For larger cheeses, consider using multiple layers of cloth or a double-wrap technique to maintain even pressure.

Finally, descriptively, imagine the cheese nestled in its cloth cocoon, the fabric’s natural fibers cradling it like a protective blanket. The twist at the top resembles a neatly tied package, a testament to the care taken in preserving the cheese. Over time, the cloth will absorb excess moisture, leaving the cheese firm yet supple, its aroma deepening with each passing day. This method is not just functional but also evocative of traditional craftsmanship, connecting the cheesemaker to centuries of culinary heritage. By mastering the art of tightly wrapping cheese in cloth, you’re not just preserving food—you’re honoring a timeless tradition.

Master Cold Smoking Cheese in Your Pellet Smoker: Easy Steps

You may want to see also

Explore related products

Press and Shape: Apply pressure to form the cheese into the desired shape and size

Applying pressure to shape cheese is a critical step in cloth binding, transforming a soft, formless curd into a structured, presentable wheel. This process not only defines the cheese’s final appearance but also influences its texture and density. The amount of pressure applied depends on the cheese type: softer cheeses like Brie require gentle handling to maintain their creamy interior, while harder varieties such as Cheddar benefit from firmer pressure to expel excess whey and create a compact structure. Use a cheese press or improvise with weighted objects, ensuring even distribution to avoid uneven shaping.

The shaping phase is where artistry meets technique. After pressing, the cheese should be wrapped in cheesecloth, which acts as a moldable exterior. For round cheeses, place the curd in a hoop lined with cloth, folding the excess fabric over the top before applying weight. Rectangular or cylindrical shapes require careful folding and tucking of the cloth to maintain sharp edges. Remember, the cloth’s tension affects the final form, so adjust it periodically as the cheese settles.

One common mistake is rushing the pressing process, which can lead to cracks or uneven density. Allow the cheese to rest under pressure for 12–24 hours, depending on its size and moisture content. Smaller cheeses (e.g., 1–2 lbs) may require 10–15 lbs of weight, while larger wheels (5+ lbs) may need 30–50 lbs. Monitor the whey drainage; insufficient pressing leaves the cheese too moist, while over-pressing can make it dry and crumbly.

For aged cheeses, pressing is a precursor to aging, as it establishes the foundation for flavor and texture development. Soft, fresh cheeses like chèvre, however, may only need light pressing to retain their spreadable consistency. Experiment with pressure levels to achieve the desired outcome, and always refer to specific recipes for guidance. With practice, pressing and shaping become intuitive, allowing you to craft cheeses that are as visually appealing as they are delicious.

Anchovy, Extra Cheese, Pepperoni, Pineapple: Pizza Perfection or Chaos?

You may want to see also

Hang to Drain: Suspend bound cheese to allow excess whey to drain completely

Suspending bound cheese to drain is a critical step often overlooked by novice cheesemakers, yet it profoundly impacts texture and flavor. When cheese is first pressed, it retains excess whey—a liquid byproduct of curdling milk. This whey, if not removed, can lead to a soggy, underdeveloped final product. Hanging the cheese allows gravity to assist in drainage, ensuring a firmer, more cohesive structure. For example, a 2-pound wheel of cheddar, when hung for 24 hours, can lose up to 8 ounces of whey, resulting in a denser, more mature cheese.

To execute this technique effectively, follow these steps: First, ensure the cheese is securely wrapped in cheesecloth, tying the ends tightly to create a sturdy bundle. Use a clean, food-safe string or twine to suspend the cheese in a cool, well-ventilated area, such as a pantry or cellar. The ideal temperature range is 50–60°F (10–15°C), as higher temperatures can encourage spoilage. Hang the cheese at least 6 inches above a drip tray to catch the whey, and check periodically to ensure the cloth isn’t straining under the weight. For smaller cheeses (under 1 pound), 12–18 hours of hanging time suffices, while larger wheels may require up to 48 hours.

A common mistake is rushing this process or using inadequate materials. Cheesecloth with a tight weave is essential to prevent curds from escaping, and the hanging area must be free from pests or contaminants. For added protection, place a fine mesh cover over the cheese. If you notice the cloth becoming saturated, gently replace it to avoid mold growth. This step is particularly crucial for hard cheeses like Parmesan or Gouda, where proper drainage determines the final hardness and aging potential.

Comparatively, draining cheese in a mold relies on pressure alone, which can compress curds unevenly. Hanging, however, allows for uniform drainage, preserving the cheese’s natural shape and texture. Think of it as the difference between squeezing a sponge and letting it air-dry—one is forceful, the other patient and natural. This method is especially advantageous for cheeses intended for long aging, as it minimizes moisture pockets that could foster bacterial growth.

In practice, hanging to drain is a testament to the cheesemaker’s patience and precision. It’s a simple yet transformative step that bridges the gap between fresh curds and a refined cheese. By mastering this technique, you not only improve the quality of your cheese but also deepen your understanding of the craft. Remember, the goal isn’t just to remove whey—it’s to create a foundation for flavor and texture that will evolve over weeks or months.

Understanding Cheese Brick Weights: How Many Grams Are in One?

You may want to see also

Frequently asked questions

Cloth binding cheese is a traditional method of wrapping cheese in cheesecloth or muslin to allow it to breathe and age properly. It helps regulate moisture, prevents mold growth, and supports the development of a natural rind, enhancing flavor and texture.

Use food-grade cheesecloth or muslin that is clean, unbleached, and free from any chemicals. Ensure the cloth is breathable to allow air circulation, which is essential for proper aging.

Regularly inspect the cloth for mold or excessive moisture. Gently wipe the cloth with a brine solution or salt water to keep it clean and dry. Replace the cloth if it becomes soiled or damaged during the aging process.