Hardening cheese is a process that involves transforming soft or semi-soft cheeses into a firmer texture, often through methods like aging, pressing, or altering moisture content. This technique not only extends the cheese's shelf life but also enhances its flavor and versatility in cooking. Whether you're working with fresh cheeses like mozzarella or halloumi, understanding the principles of hardening—such as controlling humidity, temperature, and salt levels—can help you achieve the desired consistency. This process is particularly useful for creating cheeses suitable for grilling, slicing, or long-term storage, making it a valuable skill for both home cooks and cheese enthusiasts.

| Characteristics | Values |

|---|---|

| Method | Air-drying, Aging, Salting, Pressing, Heat Treatment |

| Temperature | Cool, dry environment (50-55°F / 10-13°C) |

| Humidity | Low humidity (60-70%) |

| Time | Varies (days to years) depending on desired hardness |

| Cheese Types | Hard cheeses (e.g., Parmesan, Pecorino, Cheddar) |

| Salt Application | Dry salting or brine immersion |

| Mold Control | Regularly wipe or brush molds during aging |

| Storage | Well-ventilated, temperature-controlled environment |

| Texture Change | Becomes firmer, drier, and more crumbly |

| Flavor Development | Intensifies, becoming nuttier and sharper |

| Moisture Loss | Significant reduction in moisture content |

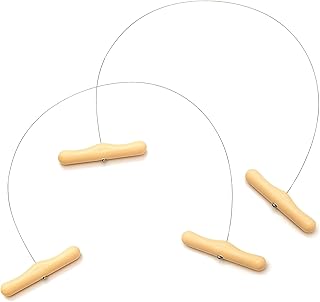

| Equipment | Cheese mats, aging racks, humidity-controlled chambers |

| Common Mistakes | Over-salting, improper humidity, uneven drying |

| Safety | Monitor for spoilage, maintain cleanliness |

Explore related products

What You'll Learn

- Control Moisture Content: Reduce water to increase firmness and extend shelf life effectively

- Adjust Salting Techniques: Apply salt evenly to draw out moisture and enhance flavor

- Optimize Aging Conditions: Maintain specific temperature and humidity for desired texture development

- Use Pressing Methods: Apply pressure to expel whey and compact curds for hardness

- Choose Right Cultures: Select bacteria strains that promote acidity and firm texture formation

Control Moisture Content: Reduce water to increase firmness and extend shelf life effectively

Cheese hardness is inversely proportional to its moisture content. This fundamental principle underpins the art of cheese aging and preservation. By systematically reducing water activity within the cheese matrix, you initiate a cascade of physical and biochemical changes that culminate in a firmer texture and extended shelf life.

Understanding this relationship empowers you to manipulate cheese consistency predictably, transforming a pliable young cheese into a crumbly, aged masterpiece.

Achieving optimal moisture reduction requires a multi-pronged approach. Temperature control is paramount. Lower temperatures slow bacterial activity and enzymatic reactions, minimizing moisture generation. Ideal aging temperatures range from 50°F to 55°F (10°C to 13°C) for most hard cheeses. Humidity management is equally crucial. A controlled environment with relative humidity around 80-85% prevents excessive drying while allowing gradual moisture loss. Salt application plays a dual role: it draws out moisture through osmosis and inhibits bacterial growth, further contributing to firmness. A typical brine solution for hard cheeses contains 20-25% salt.

Air circulation is essential to prevent moisture buildup on the cheese surface, which can lead to mold growth and uneven drying.

The transformation from soft to hard cheese is a gradual process, requiring patience and vigilance. Regular monitoring of moisture content is crucial. A simple method involves weighing the cheese periodically; a consistent weight loss indicates successful moisture reduction. More advanced techniques like refractometry provide precise measurements of water activity. Remember, over-drying can lead to a dry, crumbly texture, so striking the right balance is key.

Experimentation is vital, as different cheese varieties respond uniquely to moisture control techniques.

By mastering the art of moisture control, you unlock the ability to craft cheeses with desired textures and extended shelf lives. This knowledge empowers both home cheesemakers and commercial producers to create a diverse range of hard cheeses, from the sharp bite of aged cheddar to the granular texture of Parmesan. It's a testament to the transformative power of understanding the science behind cheese aging.

Crafting the Perfect Cheese and Cracker Tray: Tips and Ideas

You may want to see also

Adjust Salting Techniques: Apply salt evenly to draw out moisture and enhance flavor

Salt is the unsung hero in the cheese hardening process, acting as both a preservative and a flavor enhancer. Its primary role is to draw out moisture, a crucial step in achieving the desired texture. When applied correctly, salt can transform a soft, pliable cheese into a firm, sliceable delight. This technique is particularly essential for cheeses like cheddar or Gouda, where a harder texture is sought after.

The Art of Even Salting:

Imagine a cheese's surface as a canvas, and salt as the artist's brushstroke. The goal is to create a uniform masterpiece. Uneven salting can lead to pockets of high salt concentration, resulting in an unpleasant, overly salty bite. To avoid this, follow a precise method: after cutting the cheese to the desired shape, sprinkle salt evenly across all surfaces. Use a fine-grained salt, such as kosher or cheese salt, as it adheres better and dissolves more readily. A general guideline is to use 2-3% of the cheese's weight in salt, but this can vary based on the cheese variety and desired hardness.

Technique and Timing:

The salting process is a delicate dance. After applying the salt, gently rub it into the cheese's surface, ensuring every nook and cranny is covered. Then, let the cheese rest. This waiting period is critical, as it allows the salt to penetrate and work its magic. For smaller cheeses, a few hours might suffice, but larger wheels may require a day or more. The key is to monitor the cheese's moisture loss; you want it to firm up but not become dry and crumbly.

A Word of Caution:

While salt is a powerful tool, it must be wielded with care. Over-salting can ruin the cheese's flavor and texture. Always err on the side of caution and taste as you go. If you're new to cheese making, start with smaller batches to perfect your salting technique. Additionally, consider the cheese's intended use. A cheese for melting might require less hardening, while a cheese for grating benefits from a firmer texture.

In the quest for the perfect hardened cheese, salting is a critical step that demands attention to detail. It's a process that combines science and art, where precision and patience yield delicious results. By mastering this technique, cheese enthusiasts can elevate their craft, creating cheeses with the ideal texture and flavor profile. Remember, the journey to cheese perfection is a salty one, but the rewards are well worth the effort.

Discover the Delights of an Authentic Italian Meat and Cheese Tray

You may want to see also

Optimize Aging Conditions: Maintain specific temperature and humidity for desired texture development

Cheese hardening is a delicate dance of temperature and humidity, where precision dictates texture. Ideal aging conditions vary by cheese type, but the principle remains: control the environment, control the outcome. For instance, Parmigiano-Reggiano thrives in a cool, dry setting—around 50-59°F (10-15°C) with 60-85% humidity—to develop its signature granular hardness over 12-36 months. In contrast, a semi-hard cheese like Cheddar requires slightly warmer temperatures (50-55°F or 10-13°C) and higher humidity (80-85%) to achieve its firm yet sliceable texture in 3-12 months. Understanding these nuances is the first step in mastering cheese aging.

To optimize aging conditions, invest in tools that monitor and regulate temperature and humidity with precision. A digital hygrometer-thermometer is essential for tracking environmental conditions, while a dehumidifier or humidifier can help maintain the desired levels. For small-scale aging, a wine fridge modified with a humidity tray (filled with water or a saturated brine solution) can create a stable microclimate. Larger operations may require climate-controlled rooms with automated systems. Consistency is key—fluctuations can stall or ruin the hardening process, so regular monitoring and adjustments are crucial.

The science behind hardening lies in moisture loss and microbial activity, both of which are accelerated or slowed by temperature and humidity. Lower humidity encourages moisture evaporation, hardening the cheese, while higher humidity slows this process, allowing for slower texture development. Temperature affects enzyme activity and microbial growth, which break down proteins and fats. For example, aging Gruyère at 46-54°F (8-12°C) with 85-95% humidity fosters the growth of propionic bacteria, creating its distinctive eyes and complex flavor. Balancing these factors requires experimentation and patience, but the payoff is a cheese with the exact texture and character you desire.

Practical tips can make the difference between success and failure. Always age cheese on racks or mats to allow air circulation, preventing mold growth on the surface. Rotate cheeses periodically to ensure even exposure to the environment. For harder cheeses, consider wrapping them in cheesecloth or wax paper to control moisture loss without suffocating the rind. If humidity drops too low, mist the cheese lightly with water or place a damp cloth nearby. Conversely, if mold appears due to excess moisture, reduce humidity and gently brush the surface with vinegar before rewrapping. These small interventions can salvage months of work and elevate your cheese to its full potential.

Quickly Defrost Ricotta Cheese in the Microwave: Simple Steps

You may want to see also

Explore related products

Use Pressing Methods: Apply pressure to expel whey and compact curds for hardness

Pressing cheese is a transformative step in the cheesemaking process, turning soft, delicate curds into a firmer, more structured product. By applying controlled pressure, you expel excess whey and compact the curds, creating a denser texture that ranges from semi-soft to hard. This method is essential for cheeses like Cheddar, Parmesan, and Gouda, where texture and longevity are key. The degree of pressure and duration depend on the desired outcome—gentler pressing for semi-soft cheeses, heavier weights for harder varieties.

To press cheese effectively, start by placing the drained curds in a mold lined with cheesecloth. Gradually increase the weight, beginning with lighter pressure (around 5-10 pounds) for the first hour to allow whey to escape without crushing the curds. For harder cheeses, incrementally add weight (up to 50 pounds or more) over several hours or overnight. Use a cheese press or improvise with weights like bricks or heavy cans, ensuring even distribution. Monitor the process, flipping the cheese occasionally to promote uniform compaction.

While pressing is straightforward, precision matters. Over-pressing can lead to a dry, crumbly texture, while under-pressing may leave the cheese too moist and prone to spoilage. Temperature also plays a role—press in a cool environment (around 50-60°F) to slow bacterial activity and prevent the curds from becoming too soft. For aged cheeses, pressing is just the beginning; the wheels will continue to firm up during the aging process as moisture evaporates.

Comparing pressing methods reveals their impact on flavor and texture. Cold pressing, where curds are pressed at lower temperatures, preserves more of the milk’s natural sweetness, while warmer pressing can enhance sharpness. Mechanical presses offer consistency, but DIY methods with household items are equally effective for small batches. The key is patience—rushing the process risks uneven results.

In practice, pressing is both art and science. Experiment with weights and durations to achieve your desired hardness, and don’t be afraid to adjust based on visual and tactile cues. A well-pressed cheese should feel firm but yield slightly to pressure, with minimal whey seepage. Master this technique, and you’ll unlock the ability to craft cheeses with the perfect balance of density and flavor.

Exploring the Origins of Empanadas, Guava Cheese, and Guava

You may want to see also

Choose Right Cultures: Select bacteria strains that promote acidity and firm texture formation

The bacteria you choose are the architects of your cheese’s destiny. Among their many roles, certain strains excel at producing lactic acid, a key driver of acidity and moisture expulsion, both essential for a firm texture. Think of them as microscopic builders, constructing a dense, hardened matrix through their metabolic activity. *Lactococcus lactis* subsp. *lactis* biovar *diacetylactis*, for instance, is a workhorse in cheddar production, known for its rapid acidification and flavor contributions. Selecting such strains isn’t just guesswork—it’s a calculated decision that shapes the final product’s structure and mouthfeel.

To harness this power, consider the dosage and timing of your culture addition. A typical mesophilic starter culture might be added at a rate of 1–2% of the milk weight, but this varies based on the strain’s potency and the desired acidity level. For harder cheeses like Parmesan, thermophilic cultures such as *Streptococcus thermophilus* and *Lactobacillus helveticus* are preferred, as they thrive at higher temperatures (around 45–50°C) and produce a more pronounced acidification. These cultures not only firm up the curd but also contribute to the cheese’s longevity by inhibiting spoilage organisms. Precision in culture selection and application is non-negotiable—a slight miscalculation can lead to a rubbery or crumbly texture instead of the desired hardness.

Let’s compare two scenarios to illustrate the impact of culture choice. In a batch of Gouda, using a mixed-strain mesophilic culture with *Lactococcus lactis* and *Leuconostoc mesenteroides* results in a semi-hard cheese with a slightly springy texture. Swap this for a single-strain *Lactococcus lactis* subsp. *cremoris* culture, and you’ll achieve a denser, harder curd due to its higher acid production and faster moisture expulsion. The takeaway? The right bacteria aren’t just participants in the process—they’re the directors, dictating the pace and outcome of hardening.

Practical tip: Always source cultures from reputable suppliers and store them according to manufacturer guidelines (often at -18°C) to maintain viability. When experimenting with new strains, start with small batches to observe their effects on acidity and texture. For example, if you’re aiming for a harder cheese, monitor the pH drop during the first 24 hours of fermentation—a steeper decline indicates more aggressive acidification, a sign your chosen culture is on the right track. Remember, the goal isn’t just hardness but a harmonious balance of texture, flavor, and shelf life, all of which hinge on the bacteria you select.

Mastering Bell GW2: Easy Cheese Strategies for Quick Wins

You may want to see also

Frequently asked questions

Hardening cheese refers to the process of transforming a softer cheese into a harder, drier, and more aged variety through controlled drying, aging, and curing techniques.

To harden cheese at home, start by pressing the curds to remove excess whey, then salt the cheese to draw out moisture, and finally age it in a cool, humid environment while regularly flipping and monitoring it.

The time to harden cheese varies depending on the type, but it typically ranges from several weeks to several months, with harder cheeses like Parmesan taking up to a year or more.

The ideal conditions for hardening cheese are a temperature between 50-55°F (10-13°C) and a humidity level of 80-85% to ensure proper drying and aging without mold growth.

Not all cheeses can be hardened; it’s best to start with varieties like cheddar, Gouda, or Swiss, which are naturally suited for aging and hardening due to their curd structure and moisture content.