Harden liquid cheese by gradually heating it to a specific temperature, typically around 170°F (77°C), while stirring constantly to prevent scorching. This process, known as thermal coagulation, causes the proteins in the cheese to denature and form a solid mass. Adding acid, such as lemon juice or vinegar, can also help accelerate the hardening process by lowering the pH and encouraging protein aggregation. Additionally, incorporating rennet or other coagulants can further enhance the cheese's texture and firmness. Once the desired consistency is achieved, the cheese can be molded, pressed, or aged to develop its final characteristics.

| Characteristics | Values |

|---|---|

| Method | Heating, Adding Acid (e.g., vinegar, lemon juice), Using Rennet, Draining |

| Temperature Range for Heating | 165–185°F (74–85°C) |

| Acid Quantity | 1–2 tablespoons per cup of liquid cheese |

| Rennet Amount | 1/4–1/2 teaspoon per gallon of liquid cheese |

| Draining Time | 4–24 hours depending on desired hardness |

| Curdling Time | 5–15 minutes after adding acid or rennet |

| Storage for Hardening | Refrigerate at 35–40°F (2–4°C) |

| Common Liquid Cheeses | Ricotta, Cottage Cheese, Whey-Based Cheeses |

| Texture After Hardening | Firm to semi-hard, depending on method and duration |

| Shelf Life After Hardening | 1–2 weeks refrigerated |

| Additional Ingredients | Salt (1–2 teaspoons per cup for flavor and preservation) |

| Equipment Needed | Thermometer, Cheesecloth, Colander, Pot |

| pH Level for Coagulation | 4.6–5.0 (optimal for curdling) |

| Yield | Varies; typically 1–2 cups of hardened cheese per quart of liquid |

| Best Practices | Stir gently during heating, avoid over-stirring after curdling |

Explore related products

What You'll Learn

- Control Temperature: Maintain precise temperatures during curdling and pressing to ensure proper texture

- Add Salt: Incorporate salt to reduce moisture and enhance flavor and preservation

- Use Rennet: Apply rennet to coagulate milk proteins effectively for firmer curds

- Press Firmly: Apply consistent pressure to expel whey and compact the cheese structure

- Age Properly: Allow cheese to age in controlled conditions to harden and develop flavor

Control Temperature: Maintain precise temperatures during curdling and pressing to ensure proper texture

Temperature control is the linchpin of transforming liquid cheese into a firm, sliceable masterpiece. During curdling, a precise temperature range—typically between 85°F and 95°F (29°C and 35°C)—activates enzymes and acids that coagulate milk proteins. Deviations of even 2-3°F can result in a grainy texture or incomplete curd formation. For pressing, cooler temperatures around 50°F to 60°F (10°C to 15°C) slow moisture release, ensuring a dense, even consistency. Without this dual-phase temperature management, your cheese risks becoming either rubbery or crumbly.

Consider the process as a delicate dance: heat too high during curdling, and you’ll scorch the proteins; too low, and curds won’t form. For pressing, warmth accelerates moisture expulsion but can create uneven hardening. A digital thermometer with a probe is your best ally here. Monitor the vat’s temperature constantly, adjusting with warm water baths or ice packs as needed. For small-batch cheesemakers, a sous vide cooker offers unparalleled precision, maintaining temperatures within 0.1°F accuracy—ideal for cheeses like cheddar or mozzarella.

The science behind temperature control lies in its impact on microbial activity and protein structure. During curdling, heat denatures proteins, forcing them to bond and expel whey. Too much heat, however, can kill beneficial bacteria, halting fermentation. During pressing, cooler temperatures slow bacterial metabolism, allowing moisture to escape gradually without compromising texture. For aged cheeses, maintaining a consistent 55°F (13°C) during pressing sets the stage for proper aging, preventing cracks or voids.

Practical tips abound for mastering this technique. For curdling, preheat your milk slowly—no more than 2°F per minute—to avoid shocking the proteins. Use a double boiler or water bath to stabilize heat. During pressing, wrap your cheese in cheesecloth and place it in a cool, draft-free area. If your kitchen runs warm, a mini-fridge set to 50°F works wonders. For hard cheeses like Parmesan, extend pressing time at lower temperatures (45°F to 50°F) to achieve maximum density.

In essence, temperature control isn’t just a step—it’s the backbone of cheese hardening. Ignore it, and you’ll face textural failures; master it, and you’ll craft cheeses with professional-grade consistency. Whether you’re a novice or seasoned cheesemaker, investing in temperature precision pays dividends in every bite.

Cheese and Parasites: Unraveling the Myth of Growth Promotion

You may want to see also

Add Salt: Incorporate salt to reduce moisture and enhance flavor and preservation

Salt is a cornerstone in the transformation of liquid cheese into a firmer, more stable product. Its role extends beyond mere flavor enhancement; it acts as a moisture regulator and a preservative, crucial for achieving the desired texture and extending shelf life. When added to liquid cheese, salt initiates a process known as osmosis, drawing water out of the cheese curds and concentrating the solids. This not only hardens the cheese but also creates an environment less hospitable to bacteria, thereby slowing spoilage.

The dosage of salt is critical to this process. For most liquid cheese recipes, a general guideline is to use 1-2% salt by weight of the cheese. For example, if you have 1 kilogram of liquid cheese, adding 10-20 grams of salt should suffice. However, this can vary depending on the type of cheese and the desired outcome. Soft cheeses may require less salt, while harder varieties benefit from a higher concentration. It’s essential to add salt gradually, tasting as you go, to avoid oversalting, which can overpower the cheese’s natural flavors.

Incorporating salt effectively requires technique. Simply sprinkling salt over liquid cheese won’t yield uniform results. Instead, dissolve the salt in a small amount of warm water or whey first, then stir it gently into the cheese. This ensures even distribution and prevents pockets of high salinity. For best results, allow the salted cheese to rest for several hours or overnight, giving the salt time to penetrate the curds fully and initiate the hardening process.

Beyond texture and preservation, salt plays a subtle yet significant role in flavor development. It enhances the natural umami notes of the cheese while balancing acidity. This is particularly important in liquid cheeses, which often have a milder profile. A well-salted cheese not only feels firmer but also tastes more complex and rounded. For artisanal cheesemakers, this step is an opportunity to refine the sensory experience of the final product.

Practical tips can further optimize the use of salt in hardening liquid cheese. For instance, using fine-grained salt ensures faster dissolution and more even distribution. If you’re working with aged liquid cheese, consider reducing the salt slightly, as aging naturally concentrates flavors. Additionally, monitor the cheese’s moisture content after salting; if it’s still too soft, a second, smaller dose of salt can be applied, but with caution to avoid over-salting. With precision and patience, salt becomes a transformative tool, turning liquid cheese into a hardened, flavorful masterpiece.

Wisconsin: The American State Celebrated as the Cheese Capital

You may want to see also

Use Rennet: Apply rennet to coagulate milk proteins effectively for firmer curds

Rennet is a game-changer for transforming liquid milk into firm, sliceable cheese. This natural enzyme complex, derived from animal sources or produced through microbial fermentation, targets specific milk proteins, triggering a rapid and controlled coagulation process. Unlike acidic methods that yield crumbly textures, rennet creates a strong, elastic curd ideal for harder cheeses like cheddar or Parmesan.

Understanding its mechanism is key: rennet's chymosin enzyme cleaves kappa-casein, a protein stabilizing milk micelles. This cleavage destabilizes the micelles, causing them to aggregate and form a solid mass. The resulting curd's firmness depends on factors like rennet type, dosage, milk temperature, and pH.

Dosage and Application: Precision is paramount. Typical rennet dosages range from 1/8 to 1/4 teaspoon per gallon of milk, but always follow recipe guidelines. Dilute liquid rennet in cool, non-chlorinated water before adding it to milk warmed to the recipe's specified temperature (usually 86-100°F). Stir gently for 30 seconds, then let the milk rest undisturbed for 10-60 minutes, depending on the desired curd set.

For beginners, using rennet tablets or pre-measured liquid drops simplifies the process. Remember, over-coagulation leads to tough, rubbery cheese, while under-coagulation results in a soft, crumbly texture.

Beyond Firmness: Rennet's Impact on Flavor and Texture: Rennet's influence extends beyond curd firmness. It contributes to a cleaner flavor profile compared to acid-coagulated cheeses, which can have a tangy, lactic taste. The elastic curd structure created by rennet allows for stretching and molding, essential for cheeses like mozzarella. Additionally, rennet-coagulated cheeses generally have a longer shelf life due to the firmer texture and reduced whey content.

Troubleshooting: If your curd doesn't set properly, consider these factors: expired rennet, incorrect milk temperature, or high milk acidity. Always use fresh rennet stored according to manufacturer instructions. Ensure your milk is free from antibiotics, which can inhibit rennet activity. If acidity is an issue, consider adding a pinch of calcium chloride to the milk before adding rennet.

Mastering rennet application unlocks a world of cheese-making possibilities. From the sharp bite of aged cheddar to the stretchy delight of mozzarella, this enzyme is the key to achieving the desired texture and flavor in your homemade cheeses. Remember, practice makes perfect, so experiment with different dosages, milk types, and techniques to discover the magic of rennet in your cheese-making journey.

Hold the Cheese: Decoding the Meaning Behind This Popular Phrase

You may want to see also

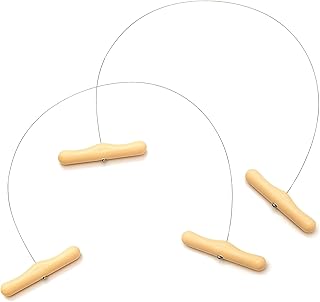

Explore related products

Press Firmly: Apply consistent pressure to expel whey and compact the cheese structure

Applying firm, consistent pressure is a cornerstone technique for transforming liquid cheese into a solid, sliceable form. This process, known as pressing, serves a dual purpose: expelling excess whey and compacting the curds into a cohesive structure. Whey, the liquid byproduct of curdling milk, must be removed to concentrate the solids and achieve the desired texture. Without adequate pressure, the cheese remains soft and crumbly, lacking the density and firmness associated with harder varieties like cheddar or Parmesan.

The art of pressing requires precision and patience. Begin by placing the drained curds in a mold lined with cheesecloth. Gradually increase the pressure using a follower (a flat, weighted plate) and a press. Start with lighter pressure (around 5-10 pounds) for the first hour to allow the curds to settle and release whey gently. Gradually increase the weight in increments, reaching up to 50 pounds or more for harder cheeses, over the course of several hours or even days. Consistency is key; uneven pressure can lead to cracks or uneven texture.

Consider the type of cheese you’re making when determining pressing time and weight. Softer cheeses like paneer require minimal pressing (15-30 minutes), while semi-hard cheeses like Monterey Jack may need 6-12 hours. Hard cheeses like cheddar or Gruyère demand extended pressing times, often 12-24 hours, with heavier weights applied progressively. Always refer to specific recipes for guidance, as variations in milk type, acidity, and desired texture influence pressing requirements.

Practical tips can enhance your pressing success. Ensure the cheesecloth is clean and free of debris to prevent contamination. Periodically flip the cheese in the mold to promote even moisture distribution and prevent sticking. Monitor the whey expulsion; if it slows significantly, increase the pressure slightly. Finally, maintain a cool environment (around 50-55°F) during pressing to prevent bacterial growth and encourage proper moisture loss.

Mastering the art of firm pressing is transformative, turning a liquid mixture into a culinary staple with distinct character. By understanding the mechanics of whey expulsion and curd compaction, you gain control over texture, flavor concentration, and overall quality. Whether crafting a delicate halloumi or a robust Parmesan, consistent pressure is the linchpin that bridges the gap between liquid and solid, amateur and artisan.

Expired Cheese: Safe to Eat if No Mold is Visible?

You may want to see also

Age Properly: Allow cheese to age in controlled conditions to harden and develop flavor

Aging is the alchemist's touch that transforms soft, liquid curds into the complex, hardened cheeses we covet. This process, far from passive, demands precision and patience. Imagine a humid cave, its walls breathing with the scent of earth and time. Here, cheese wheels rest on shelves, their surfaces slowly drying, their interiors firming, their flavors deepening. This is the magic of controlled aging, a delicate dance of temperature, humidity, and time.

Aging cheese isn't merely about hardening; it's about crafting flavor. Think of a young cheddar, mild and pliable, compared to its aged counterpart, sharp and crumbly. The longer the cheese ages, the more moisture evaporates, concentrating flavors and allowing complex compounds to develop. A 6-month aged Gruyère boasts nutty notes, while a 2-year-old Parmesan explodes with umami and crystallized tyrosine.

To age cheese properly, you become a maestro of microclimates. Ideal temperatures range from 50-55°F (10-13°C), mimicking the coolness of a natural cave. Humidity levels hover around 85-90%, preventing excessive drying while allowing for gradual moisture loss. Air circulation is crucial, preventing mold growth and ensuring even aging. Think of it as creating a spa for your cheese, where every element is meticulously calibrated for its transformation.

Regular flipping and brushing of the cheese wheels are essential. This prevents moisture buildup on one side and encourages even mold growth, desirable in some cheeses like Brie. The aging time varies drastically depending on the desired cheese type. A young Gouda might age for 4 weeks, while a vintage Gouda can mature for over a year.

Remember, aging cheese is an art, not an exact science. Experimentation and observation are key. Keep detailed notes on temperature, humidity, and the cheese's appearance and aroma. Embrace the unexpected – a touch of blue mold might be a delightful surprise in a hard cheese. With patience, precision, and a touch of whimsy, you can unlock the full potential of your liquid curds, transforming them into hardened masterpieces that sing with flavor.

Unlocking the Cheese Vault Code in Cookie Run Kingdom

You may want to see also

Frequently asked questions

Hardening liquid cheese involves transforming it from a soft, pourable state into a firmer texture, often for use in cooking, baking, or as a spread. This process can improve its versatility, shelf life, and structural integrity in recipes.

Common methods include heating the cheese gently to evaporate moisture, adding thickeners like cornstarch or flour, or incorporating firmer cheeses or melting agents like sodium citrate. Refrigeration or aging can also help solidify the cheese.

Yes, by using gentle methods like slow heating or refrigeration, you can preserve the flavor and achieve a firmer texture without compromising quality. Avoid overcooking or adding too much thickener, as this can alter the taste and consistency.