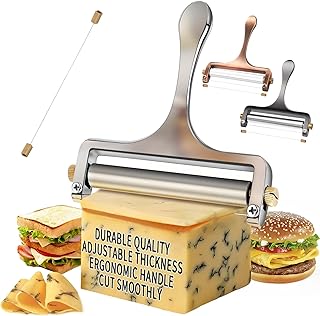

Installing a metal wire on a cheese cutter is a straightforward process that ensures your tool remains functional and efficient for slicing through various types of cheese. To begin, gather the necessary materials, including a replacement wire specifically designed for your cheese cutter model, as well as any tools required for assembly, such as pliers or a screwdriver. Start by removing the old wire, if present, by loosening the tensioning mechanism or screws that hold it in place. Next, thread the new wire through the designated slots or grooves on the cutter, ensuring it is aligned properly and taut. Secure the wire by tightening the tensioning mechanism or screws according to the manufacturer’s instructions, taking care not to overtighten, as this could damage the wire or the cutter. Finally, test the wire’s tension by gently pulling it to ensure it is firmly in place and ready for use. Proper installation not only extends the life of your cheese cutter but also guarantees clean, precise cuts every time.

| Characteristics | Values |

|---|---|

| Tools Required | Wire cutter, pliers, screwdriver (if applicable), replacement wire |

| Wire Type | Stainless steel cheese cutter wire (specific gauge recommended by manufacturer) |

| Wire Length | Varies by cutter model, typically 1-2 inches longer than the cutter's cutting surface |

| Installation Method | 1. Remove old wire (if present) using pliers or screwdriver. 2. Thread new wire through cutter's wire guides/slots. 3. Secure wire ends using tensioning mechanism (screws, clips, or clamps) provided by the cutter. |

| Tension Adjustment | Adjust tension according to manufacturer's instructions to ensure clean cuts without wire breakage |

| Safety Precautions | Wear gloves to protect hands from sharp wire edges. Ensure wire is securely fastened before use. |

| Maintenance | Regularly inspect wire for wear, rust, or damage. Replace wire as needed for optimal performance. |

| Compatibility | Ensure replacement wire is compatible with your specific cheese cutter model. |

| Difficulty Level | Easy to moderate, depending on cutter design and tools required. |

| Time Required | Typically 5-15 minutes for installation and tension adjustment. |

Explore related products

$8.99 $9.99

What You'll Learn

- Gather Tools & Materials: Wire, cutter, pliers, gloves, and safety glasses are essential for the installation process

- Measure & Cut Wire: Determine the required length, then cut the metal wire precisely using wire cutters

- Prepare Cheese Cutter: Clean the cutter and ensure the wire groove is free of debris for smooth installation

- Attach Wire Securely: Insert the wire into the groove, tighten screws, and test tension for even cutting

- Safety & Maintenance: Wear gloves, inspect wire regularly, and replace if frayed to prevent accidents

Gather Tools & Materials: Wire, cutter, pliers, gloves, and safety glasses are essential for the installation process

Before embarking on the task of installing a metal wire on a cheese cutter, it's crucial to assemble the necessary tools and materials. This preparatory step is often overlooked, but it’s the foundation of a successful and safe installation. The core items you’ll need include the wire itself, a cutter, pliers, gloves, and safety glasses. Each of these serves a specific purpose, ensuring precision, protection, and efficiency throughout the process.

The wire is the star of the show, but not all wires are created equal. For cheese cutting, opt for a stainless steel wire with a gauge between 18 and 20. This range strikes the perfect balance between strength and flexibility, allowing it to slice through cheese smoothly without snapping under tension. Ensure the wire is clean and free of burrs to prevent contamination and ensure a clean cut.

Next, the cutter is essential for trimming the wire to the correct length. A pair of diagonal cutters or wire cutters works best, as they provide a clean, angled cut that’s easier to handle during installation. Avoid using dull or damaged cutters, as they can fray the wire ends, compromising its integrity.

Pliers are your go-to tool for manipulating the wire into place. Needle-nose pliers, in particular, offer the precision needed to thread the wire through the cutter’s mechanism. They also help in tightening the wire securely, ensuring it doesn’t slip during use. Keep a firm grip, but avoid over-tightening, as this can deform the wire or damage the cutter.

Safety should never be an afterthought. Gloves protect your hands from sharp wire edges and provide a better grip, reducing the risk of slips. Leather or cut-resistant gloves are ideal. Pair these with safety glasses to shield your eyes from potential wire snaps or debris. Even a small fragment can cause significant injury, so don’t skip this step.

In summary, gathering the right tools and materials is more than a checklist—it’s a strategic move to ensure the installation goes smoothly and safely. Each item plays a unique role, from the wire’s precision to the pliers’ control and the protective gear’s safeguard. By investing time in preparation, you set the stage for a cheese cutter that’s not only functional but also reliable for years to come.

Is There Wood in Shredded Cheese? Uncovering the Truth Behind the Rumor

You may want to see also

Measure & Cut Wire: Determine the required length, then cut the metal wire precisely using wire cutters

Precision is paramount when measuring and cutting the metal wire for your cheese cutter. A wire that’s too short won’t span the cutter’s frame, rendering it useless, while one that’s too long risks fraying or becoming a safety hazard. Start by examining your cheese cutter’s design. Most models require a wire length that matches the width of the cutting frame plus an additional 1–2 inches on each side for secure attachment. Use a ruler or measuring tape to determine this exact length, ensuring accuracy to the nearest millimeter. This step is non-negotiable—it’s the foundation for a functional and safe cheese cutter.

Once you’ve determined the required length, it’s time to cut the wire. Not all wire cutters are created equal; opt for a pair with sharp, hardened steel blades designed for metalwork. Position the wire firmly against the cutter’s blade, ensuring it doesn’t slip during the cut. Apply steady, even pressure to avoid fraying the wire’s ends, which can complicate the installation process. If your wire has a protective coating, strip a small section at each end to ensure a secure attachment to the cutter’s mechanism. A clean, precise cut here will save you frustration later.

Consider the wire’s gauge as you measure and cut. Thicker wires (lower gauge numbers) are more durable but require greater force to cut, while thinner wires are easier to manipulate but may wear out faster. For most home cheese cutters, a 16–18 gauge wire strikes a balance between strength and ease of use. If you’re unsure, consult the cutter’s manual or manufacturer recommendations. Remember, the goal is to create a wire that’s both functional and long-lasting, so take your time with this step.

A practical tip: mark the wire with a permanent marker or masking tape before cutting to avoid measurement errors. This simple precaution ensures you don’t accidentally cut the wire too short. After cutting, inspect the wire’s ends for burrs or sharp edges, which can be filed down with a metal file or sandpaper for safety. This attention to detail not only improves the wire’s performance but also protects your hands during installation and use.

In conclusion, measuring and cutting the wire is a deceptively simple step that demands focus and precision. By taking the time to measure accurately, use the right tools, and consider the wire’s gauge, you’ll set the stage for a cheese cutter that performs flawlessly. Skimp on this step, and you risk a wire that’s either too short, too long, or prone to failure. Done correctly, it’s a small investment of effort that pays off in smooth, efficient cheese slicing for years to come.

Avoid Garden Cheese: Why Your Dairy Doesn't Belong in the Soil

You may want to see also

Prepare Cheese Cutter: Clean the cutter and ensure the wire groove is free of debris for smooth installation

Before installing a new metal wire on your cheese cutter, a crucial yet often overlooked step is preparing the cutter itself. This involves a thorough cleaning process, ensuring the wire groove is pristine and ready for the new wire. Neglecting this step can lead to a host of problems, from uneven cutting to premature wire breakage.

The Cleaning Process: A Step-by-Step Guide

Begin by disassembling the cheese cutter, if possible, to access all its components. Use a soft-bristled brush or a damp cloth to remove any visible debris, cheese remnants, or dust from the cutter's surface. For stubborn stains or grease buildup, a mild detergent solution (1-2 teaspoons of dish soap per cup of warm water) can be effective. Avoid abrasive cleaners or scouring pads, as these may scratch the cutter's surface. Pay particular attention to the wire groove, using a cotton swab or a small brush to dislodge any trapped particles.

Inspecting the Wire Groove: A Critical Analysis

The wire groove is the heart of the cheese cutter, and its condition directly impacts the wire's performance. Examine the groove for any signs of wear, corrosion, or damage. If the groove is excessively worn or damaged, consider replacing the cutter or having it professionally repaired. For minor imperfections, use a fine-grit sandpaper (400-600 grit) to gently smooth the groove, ensuring a uniform surface for the wire to rest upon.

Practical Tips for Optimal Results

To ensure a smooth installation, dry the cutter thoroughly after cleaning, using a clean cloth or air-drying it for at least 30 minutes. For added protection, apply a small amount of food-safe lubricant (e.g., mineral oil or silicone-based lubricant) to the wire groove, reducing friction and prolonging the wire's lifespan. This step is particularly beneficial for high-volume cheese cutting or when using harder cheeses. By dedicating 10-15 minutes to preparing your cheese cutter, you'll create an ideal environment for the new wire, resulting in cleaner cuts, reduced wire wear, and a more enjoyable cheese-cutting experience.

Comparative Analysis: The Consequences of Neglect

Failing to prepare the cheese cutter can lead to a range of issues, from minor inconveniences to significant problems. A dirty or debris-filled wire groove can cause the wire to kink, fray, or break prematurely, resulting in wasted wire and inconsistent cuts. Moreover, trapped debris can harbor bacteria, compromising food safety and potentially causing health issues, especially for individuals with weakened immune systems or allergies. By contrast, a well-prepared cheese cutter not only ensures optimal performance but also promotes food safety and hygiene, making it a vital step in the wire installation process.

Perfect Cheese Portions: How Much for 23 Sandwiches?

You may want to see also

Explore related products

$5.95 $6.95

Attach Wire Securely: Insert the wire into the groove, tighten screws, and test tension for even cutting

The groove on your cheese cutter is the unsung hero of this process, a small but critical channel designed to hold the wire in place. Its depth and width are engineered to accommodate standard cheese cutter wires, typically 0.5mm to 0.7mm in diameter. Before inserting the wire, inspect the groove for any debris or burrs that could hinder smooth wire movement. A clean groove ensures the wire glides effortlessly during cutting, reducing friction and extending its lifespan.

Inserting the wire requires precision and patience. Begin by threading one end of the wire into the groove at the starting point, usually near the cutter’s handle. Gently guide the wire along the entire length of the groove, ensuring it sits flush against the bottom. Avoid forcing the wire, as this can cause kinks or damage. Once the wire is in place, secure the opposite end in the designated anchor point, often a small notch or screw mechanism. This step lays the foundation for a taut, functional wire.

Tightening the screws is where control meets craftsmanship. Most cheese cutters feature adjustable screws on either side of the wire to regulate tension. Start by tightening one screw slightly, then alternate to the other side, incrementally increasing tension with each turn. Aim for a balance—too loose, and the wire will sag; too tight, and it risks snapping under pressure. A well-tightened wire should feel firm but not rigid, with minimal give when pressed gently.

Testing tension is the final litmus test for a job well done. Hold a block of firm cheese (like cheddar or gouda) against the wire and apply downward pressure. The wire should slice through cleanly, without wobbling or leaving jagged edges. If the cut is uneven, adjust the screws in small increments and retest. For softer cheeses, slightly reduce tension to prevent tearing. This step ensures your cheese cutter performs consistently, whether you’re slicing for a charcuterie board or a grilled cheese sandwich.

Practical tip: Keep a spare wire handy, as even the most securely attached wire will eventually wear out. Replace the wire every 3–6 months, depending on frequency of use. For added longevity, lubricate the groove with a food-safe mineral oil periodically to reduce friction. With proper installation and maintenance, your cheese cutter will deliver precise, effortless cuts every time.

White Castle Cheese Sliders: Ingredients, Toppings, and Melty Magic Revealed

You may want to see also

Safety & Maintenance: Wear gloves, inspect wire regularly, and replace if frayed to prevent accidents

Installing a metal wire on a cheese cutter is a straightforward task, but it’s the ongoing care that ensures longevity and safety. Gloves are your first line of defense. Stainless steel wires, while durable, can have sharp edges or burrs, especially after cutting through hard cheeses like Parmesan. Nitrile or leather gloves provide a protective barrier, reducing the risk of cuts during installation and maintenance. Skip thin latex gloves, as they offer minimal protection against sharp metal.

Regular inspection is the backbone of maintenance. Aim to examine the wire before and after each use. Look for signs of fraying, kinking, or rust, which compromise both cutting efficiency and safety. A frayed wire can snap unexpectedly, sending sharp fragments flying. Rust, though less common with stainless steel, indicates moisture exposure and potential weakening. If you notice any damage, replace the wire immediately—a small investment to avoid accidents.

The frequency of replacement depends on usage. For home cooks using the cutter 2–3 times weekly, inspect the wire monthly and replace it every 6–12 months. Commercial settings or heavy users should replace wires every 3–6 months. Keep spare wires on hand to avoid delays or the temptation to use a compromised wire. Proper tension is also critical; a loose wire can slip during cutting, while an overly tight one may snap under pressure.

Beyond the wire, maintain the cutter itself. Wipe down the frame after each use to remove cheese residue and moisture, which can accelerate rust or bacterial growth. Store the cutter in a dry, cool place, and avoid stacking heavy objects on top, which could misalign the wire. By integrating these practices, you not only extend the life of your cheese cutter but also create a safer kitchen environment.

American Cheese Protein Content: Grams of Protein Per Serving

You may want to see also

Frequently asked questions

You will need a new metal wire specifically designed for cheese cutters, pliers or wire cutters, and possibly a screwdriver if your cutter requires disassembly.

First, remove the old wire by loosening the tension screws or clamps holding it in place. Thread the new wire through the cutter’s guides, ensuring it’s taut and evenly aligned. Secure it by tightening the screws or clamps, then test the tension before use.

It’s not recommended to reuse old wires, as they can become dull or damaged over time, affecting cutting performance. Always use a new wire designed for cheese cutters for the best results.