Goat's cheese is a versatile ingredient that can be used in a variety of dishes, from salads to tarts and pizzas. It has a tangy flavour and a creamy texture that makes it a popular choice for many. Making goat's cheese at home is a simple and cost-effective process that only requires a few basic ingredients and kitchen equipment. The maturation process for goat's cheese can vary, with some cheeses being aged for 3 to 6 months to develop a more complex flavour and texture. In this article, we will explore the different methods for maturing goat's cheese and provide tips on how to incorporate it into your cooking.

How to Mature Goats Cheese

| Characteristics | Values |

|---|---|

| Ingredients | Goat's milk, cheese salt (kosher salt), cheesecloth, thermometer |

| Milk Type | Full-fat, pasteurized goat milk (not ultra-pasteurized) |

| Flavouring | Herbs (chives, thyme, rosemary, dill), dried herbs and spice blends (tarragon, za'atar, basil), chopped nuts |

| Moulding | Logs/disks, covered in wax paper or clingfilm |

| Draining | Cheesecloth inside a sieve for an hour, or bundle up cheesecloth and hang from faucet |

| Storage Temperature | Cool (8-15ºC), damp environment like a cellar or fridge |

| Storage Duration | Up to one month of additional ageing recommended |

| Serving Suggestions | Salads, vegetable tarts, soups, risottos, sourdough toast, puff pastry, pizza, omelettes |

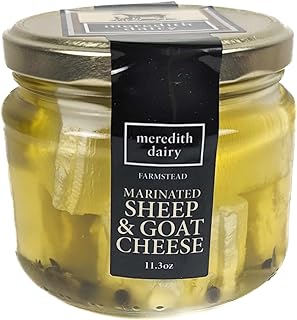

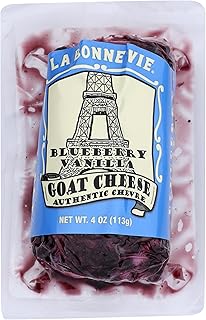

Explore related products

What You'll Learn

Making goat's cheese at home

Ingredients and Tools:

- Goat's milk: Use full-fat goat's milk, preferably pasteurized, as ultra-pasteurized milk won't curdle the same way. You can also use raw goat's milk if available.

- Citric acid or lemon juice and vinegar: Citric acid can be combined with water and added to the milk. Alternatively, use fresh lemon juice and vinegar for a similar effect.

- Cheesecloth: You'll need a fine cheesecloth to line your colander and strain the cheese.

- Thermometer: A thermometer is useful to monitor the temperature of the milk as it heats up.

- Colander: You will need a colander to strain the cheese.

- Large, non-reactive pot: Use a pot made from a non-reactive metal, such as cast iron or stainless steel, that can hold at least half a gallon of liquid.

Instructions:

- Line a colander with two or three layers of fine cheesecloth.

- Slowly heat the goat's milk in the pot over medium heat until it reaches 185°F (85°C). Stir frequently to ensure even heating.

- If using citric acid, combine it with water and add it to the milk, stirring gently. If using lemon juice and vinegar, remove the milk from the heat and add the lemon juice, stirring a couple of times. Then, add the vinegar and briefly stir.

- Allow the mixture to sit for about 30 minutes. The curds will be like tiny specks, not large clumps.

- Slowly ladle the mixture into the cheesecloth-lined colander.

- Add salt and any desired spices or herbs to the cheese. Stir lightly to combine.

- Gather the ends of the cheesecloth and tie them together. Hang the cheesecloth and allow the cheese to drain for about an hour.

- Place the cheese on a cutting board and shape it as desired. You can roll it into a log or form it into a wheel.

Your homemade goat's cheese is now ready to be enjoyed! It will last for about one to two weeks in the fridge, so it's best to use it within a week. You can serve it on toast, bagels, crackers, or use it in salads, pasta, or tarts.

Folding Goat Cheese into Soda Bread: Perfect Timing

You may want to see also

Flavouring goat's cheese

Goat's cheese is incredibly versatile and can be flavoured in many ways. Its creamy texture and tanginess make it a good pairing with wine, especially Sauvignon Blanc from Sancerre.

Goat's cheese can be used in both sweet and savoury dishes. For a savoury option, it can be crumbled over a salad with roasted tomatoes and red peppers, or stuffed into a chicken breast with tarragon, lemon zest, and seasoning, wrapped in bacon, and baked. It can also be spread on toast and drizzled with honey, or paired with apples and honey in a tart or sandwich. The creaminess and acidity of goat's cheese also make it a good match with fruit, such as roasted figs, cherries, apricots, or peaches.

Goat's cheese can also be used as a filling or sauce for pasta dishes. It can be combined with Parmesan, milk, and pasta cooking water for a simple, no-cook sauce. It can also be added to a cream sauce with lemon zest, or used as a filling with spinach, butternut squash, or pine nuts.

For a more unusual option, goat's cheese can be grilled in corn husks and served with a corn relish. It can also be used to make a creamy dressing for a salad of warm roasted beets, carrots, and beet greens.

When it comes to flavouring goat's cheese itself, there are many options. Fresh herbs such as rosemary, lavender, and garlic can be sprinkled over the cheese and left to absorb the flavours overnight. Cracked pepper and orange zest can also be added for a surprising and delicious combination. Honey can be drizzled over the cheese just before serving, and it can be shaped into a log and coated with toppings such as toasted walnuts and honey, lemon zest and cracked pepper, or strawberry rosemary sea salt.

Goat Cheese Magic: Celebrity Cranberry Cinnamon Creations

You may want to see also

Draining goat's cheese

Draining is an essential step in the goat cheese-making process. It involves separating the curds (which will become the cheese) from the whey (a byproduct with many uses). The amount of time needed for draining depends on the desired characteristics of the cheese. Less time results in a sweeter and moister cheese, while more time leads to a drier and tangier cheese. The draining period can range from a few hours to 20 hours, and the optimal period for a particular cheese depends on various factors, including the type of cheese and the configuration adopted (pressed or not).

To drain goat cheese, you will need cheesecloth and a sieve. First, place the cheesecloth inside the sieve. If you don't have a sieve, you can bundle up the cheesecloth and hang it from a faucet. Pour the goat's milk into the cheesecloth-lined sieve and allow it to drain for around an hour. You can collect the leftover whey in a bowl underneath the sieve and use it in other recipes.

The pH of the curd before and during draining is crucial, as it influences the composition, yield, and textural properties of the final product. For example, a rapid curd formation at a fairly low pH improves whey expulsion and results in a lower moisture content in the cheese. Additionally, the temperature during draining is essential. Higher temperatures promote excessive moisture loss, while lower temperatures inhibit whey drainage and produce a very moist cheese with a short shelf life.

After draining, it is time to flavour and mould the cheese. Add salt to the drained cheese and mix well. You can also add fresh herbs or spices at this stage. Then, form the cheese into a log or place it in a mould. Finally, refrigerate the cheese to slow down bacterial activity and prolong its shelf life.

Goat Cheese and Chicken: A Match Made in Heaven?

You may want to see also

Explore related products

Storing goat's cheese

Storing goat cheese

Goat cheese is a versatile and tasty ingredient, but it needs to be stored correctly to keep it fresh and tasty. Goat cheese is more delicate than other cheeses, so once opened, it has a shorter shelf life.

Fresh, unopened goat cheese can be stored in the fridge for up to two months. It should be vacuum-sealed or wrapped in wax or parchment paper and kept in the refrigerator. The vegetable drawer is a good location, as the temperature is normally between 8°C and 10°C, which is similar to a cave—the perfect environment for storing cheese. If you are keeping well-aged goat cheese, this can be stored in the middle of the fridge at a slightly cooler temperature of 4°C to 6°C. To stop the ripening process of fresh cheese, store it at the top of the fridge, where it is coldest, between 0°C and 4°C.

Once opened, the cheese should be removed from its original packaging and stored in a lidded glass or plastic container in the refrigerator. You can also wrap the cheese first in wax or parchment paper and then in plastic wrap. This creates a layer of breathability, which is important as cheese needs some humidity and room to breathe. You can also place the wrapped cheese in an airtight glass container for extra protection.

If you are not planning to use the cheese within 3 to 4 days of opening, you can freeze it. Cut the cheese into rounds, separate each round with a piece of patty paper, and stack them in a container or sandwich bag. Then, break off chunks as needed, defrosting them in the fridge or microwave.

Aged goat cheese should be brought to room temperature for at least 30 minutes before serving to allow the milk fat to soften and ensure maximum flavour.

Goat Cheese and FODMAP: What You Need to Know

You may want to see also

Goat's cheese maturation times

The maturation time for goat's cheese varies depending on the desired flavour and texture. Goat's cheese can be aged for as little as a few months or for several years.

Young goat's cheese is known for its intense, tangy, and earthy flavours. As the cheese matures, these flavours develop and become more subtle, giving way to hints of rural mushroom and rich cream. The texture also changes during maturation, going from soft and spreadable to firm and crumbly.

The minimum maturation time for goat's cheese is typically around three months. For example, the Ribblesdale Cheese Co.'s Goatisan, a mature goat's cheese, is aged for three to five months, resulting in a firm texture and strong flavour.

Some goat's cheeses are matured for much longer periods. The Dutch Cheeseman's Aged Goat's Cheese, for instance, is matured for a minimum of 18 months, resulting in a rich, full-flavoured cheese with a slightly crumbly texture. Even longer maturation times are possible, with Lively Run Goat Dairy's Finger Lakes Gold requiring several years of ageing to reach its desired state.

The maturation time will depend on the specific type of goat's cheese being produced and the desired flavour profile and texture. Proper care during maturation is essential to ensure the cheese develops correctly and to prevent the growth of unwanted moulds and the presence of cheese mites.

Goat Cheese's Pungent Odor: Why So Stinky?

You may want to see also

Frequently asked questions

The maturation time for goat's cheese varies depending on the desired flavour and texture. Some goat's cheeses are matured for around 3 months, while others can be aged for up to 6 months or more.

You will need cheesecloth, a thermometer, and a cool storage space, such as a cellar or fridge.

First, combine goat's milk with heat and acid to coagulate the milk. Then, drain the mixture through cheesecloth and add salt to flavour. Finally, form the cheese into a mould or roll it into a log and wrap it for storage.