Creating a cheese board with a tile inset is a unique and stylish way to elevate your entertaining game, but ensuring its longevity requires proper care, such as oiling the wood to protect it from moisture and wear. To oil a cheese board with a tile inset, start by selecting a food-safe mineral oil or cutting board conditioner, ensuring it won’t interfere with the flavors of your cheeses. Clean the wooden surface thoroughly, avoiding the tile inset, and dry it completely before applying the oil. Use a clean cloth or brush to evenly coat the wood, allowing the oil to penetrate and nourish the material. Wipe off any excess to prevent a greasy finish, and let it dry according to the product’s instructions. Regular oiling not only preserves the wood’s natural beauty but also ensures your cheese board remains functional and safe for years to come.

| Characteristics | Values |

|---|---|

| Materials Needed | Wood board, tile inset, food-safe mineral oil, sandpaper, wood glue, clamps, sealant (optional), paintbrush or cloth |

| Tools Required | Saw, drill, router (optional), measuring tape, pencil, safety gear (gloves, goggles) |

| Wood Type | Hardwoods like maple, walnut, or cherry (durable and food-safe) |

| Tile Inset Size | Customizable; common sizes are 4x4 inches or 6x6 inches |

| Tile Type | Ceramic or porcelain tiles (heat-resistant and easy to clean) |

| Oiling Process | Apply food-safe mineral oil evenly with a cloth or brush; let it absorb for 24 hours, then wipe off excess |

| Frequency of Oiling | Reapply oil every 3-6 months to maintain wood condition |

| Sandpaper Grit | Start with 120 grit, finish with 220 grit for smooth surface |

| Drying Time | Allow wood glue and oil to dry for at least 24 hours before use |

| Maintenance | Clean with mild soap and water; avoid harsh chemicals or dishwashers |

| Design Tips | Use contrasting wood and tile colors for aesthetic appeal; add handles or feet for functionality |

| Safety Precautions | Work in a well-ventilated area; wear protective gear when cutting or sanding |

| Cost Estimate | $30-$100 depending on materials and tile choice |

| Time Required | 2-3 days (including drying time) |

| Difficulty Level | Intermediate (basic woodworking skills required) |

Explore related products

What You'll Learn

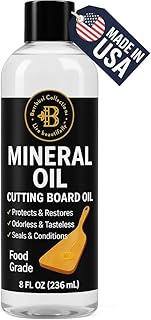

Choosing the Right Oil

Selecting the right oil for your cheese board with a tile inset is crucial for both aesthetics and functionality. The oil must penetrate the wood to protect it from moisture and stains while enhancing its natural grain. Food-safe mineral oil is the gold standard here—it’s odorless, tasteless, and won’t turn rancid over time. Avoid vegetable-based oils like olive or coconut, as they can spoil and leave a residue that affects the cheese’s flavor. Apply mineral oil sparingly; a thin, even coat is sufficient. Wipe off excess after 10–15 minutes to prevent pooling, especially around the tile inset where wood meets ceramic.

Consider the wood type when choosing your oil. Hardwoods like maple or walnut absorb oil differently than softer woods like pine. For denser woods, warm the mineral oil slightly (not hot) to improve absorption. Test a small area first to ensure the oil doesn’t darken the wood more than desired. If you prefer a tinted finish, mix a few drops of food-safe wood stain into the oil, but be cautious—too much can overpower the wood’s natural beauty. Always prioritize oils that maintain the board’s integrity without altering its appearance.

For those seeking eco-friendly options, walnut oil is a viable alternative to mineral oil. While it can impart a slight nutty aroma, it’s safe for food contact and polymerizes to form a protective layer. However, it dries slower and requires more frequent applications. Apply walnut oil in thin layers, allowing each coat to dry for 24 hours before adding another. This method ensures even coverage and minimizes waste. Note that walnut oil is not suitable for individuals with nut allergies, so label your board accordingly if it’s a shared item.

Maintenance is key to prolonging the life of your oiled cheese board. Reapply oil every 3–4 weeks with regular use, or monthly for occasional use. Inspect the board for dry spots, especially around the tile inset, as the wood-tile junction is prone to moisture absorption. If the tile is porous (e.g., unglazed ceramic), seal it separately with a tile-safe sealant before oiling the wood. This prevents liquids from seeping into the grout or tile, ensuring both components remain hygienic and visually appealing.

Finally, avoid over-oiling, as excess can create a slippery surface or attract dust. Use a clean, lint-free cloth to apply and buff the oil, ensuring a smooth finish. Store your board in a cool, dry place to prevent warping, and never submerge it in water. With the right oil and care, your cheese board with tile inset will remain a stunning centerpiece for years, blending functionality and artistry seamlessly.

Cheese Cravings and Vitamin D: Unraveling the Surprising Connection

You may want to see also

Preparing the Cheese Board Surface

The surface of your cheese board is the canvas for your culinary masterpiece, and preparing it properly ensures both aesthetics and functionality. Before applying any oil, ensure the wood is clean, dry, and free of rough spots. Sand the surface lightly with 220-grit sandpaper to create a smooth, even texture that will absorb the oil evenly. Pay special attention to the edges and corners, as these areas tend to accumulate more wear and tear. If your board includes a tile inset, mask the edges of the tile with painter’s tape to prevent oil from seeping underneath, which could compromise the adhesive bond.

Analyzing the type of wood is crucial, as different woods absorb oils differently. Hardwoods like maple or walnut are ideal for cheese boards due to their density and natural resistance to moisture. Softer woods, such as pine, may require more frequent oiling and are less suitable for long-term use. For boards with tile insets, consider the contrast between the wood and tile when choosing your oil. A darker oil like walnut oil can enhance the richness of the wood, while mineral oil provides a neutral finish that lets the tile take center stage. Always test the oil on a small, inconspicuous area to ensure it achieves the desired effect.

Persuasive arguments for oiling your cheese board surface go beyond mere aesthetics. Oiling protects the wood from moisture, preventing cracks and warping that can occur when cheese and other foods are served. It also creates a barrier against bacteria, making the board easier to clean and maintain. For boards with tile insets, oiling the wood ensures the entire surface remains hygienic and durable. While some may argue that oiling is unnecessary, the longevity and appearance of your board will significantly benefit from this simple step.

Comparing oiling techniques reveals that the method matters as much as the product. Apply the oil sparingly with a clean cloth, working in the direction of the wood grain. Avoid over-saturating the surface, as excess oil can pool and become sticky. For best results, apply multiple thin coats, allowing each layer to absorb fully before adding the next. This method ensures deep penetration and a smooth finish. If your board includes a tile inset, remove the painter’s tape immediately after oiling to avoid residue. Wipe away any excess oil from the tile surface with a damp cloth to maintain its original appearance.

Descriptively, the final result of a well-prepared cheese board surface is a thing of beauty. The wood grain is enhanced, the tile inset gleams, and the entire board exudes a warm, inviting quality. The oil brings out the natural colors and textures of the materials, creating a harmonious blend of functionality and artistry. Whether you’re serving a simple selection of cheeses or an elaborate charcuterie spread, a properly prepared surface elevates the experience. With regular maintenance, your cheese board will remain a stunning centerpiece for years to come.

Can Cats Eat Cheese? Understanding the Risks and Benefits

You may want to see also

Applying Tile Inset Techniques

Tile insets elevate a simple cheese board from functional to artistic, adding texture, color, and a unique focal point. The key lies in seamless integration, ensuring the tile becomes an organic part of the board, not an afterthought. Begin by selecting a tile that complements the wood’s grain and tone. Porcelain or ceramic tiles work best due to their durability and ease of cleaning. Avoid natural stone tiles, as they may absorb oils or crack under pressure. Measure the desired inset area, typically centered or offset for visual interest, and mark it precisely with a pencil. Use a Forstner bit to drill starter holes along the marked lines, then carefully cut out the wood with a jigsaw, staying just inside the lines to ensure a snug fit.

Once the cavity is prepared, sand the edges smooth to prevent splintering and ensure a flush fit. Apply a thin layer of food-safe epoxy adhesive to the tile’s back, spreading it evenly with a notched trowel. Press the tile firmly into place, using clamps or weights to hold it level while the adhesive cures. Allow at least 24 hours for the epoxy to fully set, depending on the manufacturer’s instructions. After curing, inspect the edges for any gaps. If present, fill them with a color-matched wood filler, sand smooth, and wipe clean. This meticulous process ensures the tile inset is both functional and aesthetically pleasing, ready to withstand the rigors of cheese board use.

The choice of tile pattern and shape can dramatically alter the board’s character. A single, large tile creates a bold statement, while mosaic tiles offer intricate detail. Consider the cheese board’s intended use—a minimalist design suits formal settings, whereas playful patterns thrive in casual environments. For a cohesive look, echo the tile’s colors in the wood finish or accompanying accessories. For instance, a tile with blue accents pairs well with a walnut board stained to enhance its natural warmth. This deliberate coordination transforms the cheese board into a conversation piece, blending utility with artistry.

Maintenance of the tile inset is straightforward but requires attention to detail. Always hand-wash the board with mild soap and warm water, avoiding harsh chemicals that could degrade the epoxy or wood finish. Dry immediately to prevent moisture from seeping into the seams. Periodically apply a food-safe mineral oil to the wood to maintain its luster and protect against drying. The tile itself requires no special care beyond regular cleaning, ensuring its vibrancy endures. With proper care, a tile-inset cheese board becomes a lasting centerpiece, marrying craftsmanship with culinary presentation.

Freezing Ham Potato Soup with Cheese: Tips for Perfect Results

You may want to see also

Explore related products

Sealing and Finishing Tips

The final steps of crafting a cheese board with a tile inset are crucial for both aesthetics and durability. Sealing and finishing not only enhance the visual appeal but also protect the wood and tile from moisture, stains, and wear. Here’s how to ensure your project stands the test of time.

Analytical Insight: Before applying any sealant, assess the type of wood and tile you’re working with. Hardwoods like maple or walnut absorb oils differently than softer woods like pine. Porous tiles, such as terracotta, require more thorough sealing than non-porous options like ceramic. Understanding these material properties ensures the sealant penetrates effectively without altering the natural beauty of the wood or tile.

Instructive Steps: Begin by sanding the wood surface to a smooth finish, using 220-grit sandpaper. Wipe away dust with a tack cloth. Apply a food-safe mineral oil or tung oil in thin, even coats, allowing each layer to dry for 4–6 hours. For the tile inset, use a silicone-based sealant along the edges to prevent moisture from seeping beneath the tile. Avoid over-applying oil near the tile, as excess can pool and discolor grout lines.

Comparative Cautions: While mineral oil is cost-effective and easy to apply, it requires more frequent reapplication. Tung oil, though pricier, provides a harder, more durable finish and enhances the wood’s natural grain. For tiles, epoxy-based sealants offer superior protection but can be messy and require precise application. Silicone sealants are user-friendly but may not bond as strongly with certain tile materials.

Descriptive Takeaway: Imagine your cheese board gleaming under soft lighting, the wood grain deepened by oil, the tile inset seamlessly integrated. Proper sealing and finishing transform a functional piece into a work of art. Regular maintenance—reapplying oil every 3–6 months and inspecting the tile sealant annually—ensures your board remains a centerpiece for years to come. With these tips, you’ll achieve a balance of beauty and practicality that elevates every gathering.

Do Fried Wontons from Chinese Restaurants Contain Cheese?

You may want to see also

Maintaining the Cheese Board Longevity

Regular oiling is crucial for preserving the integrity of your cheese board with tile inset, but it’s only one piece of the longevity puzzle. The wood and tile materials react differently to moisture, temperature, and wear, requiring a tailored maintenance approach. Wood, being porous, absorbs oils to prevent drying and cracking, while tile needs protection from stains and grout erosion. Start by selecting a food-safe mineral oil or beeswax-based conditioner, applying a thin, even coat every 3–4 weeks with a soft cloth. Focus on the wood surfaces, avoiding excessive oil on the tile to prevent a slippery residue.

Environmental factors play a significant role in your cheese board’s lifespan. Prolonged exposure to direct sunlight can fade both wood and tile, while humidity fluctuations cause wood to warp or crack. Store the board in a cool, dry place, away from windows or heat sources. After use, clean the tile inset with a mild detergent and dry immediately to prevent water from seeping into the grout. For the wood, wipe gently with a damp cloth, avoiding soaking, and reapply oil after cleaning to replenish moisture lost during washing.

Grout maintenance is often overlooked but critical for both aesthetics and hygiene. Over time, grout can discolor or crack, compromising the board’s appearance and structural integrity. Inspect the grout lines monthly for signs of wear or staining. For minor stains, scrub with a soft-bristled brush and a paste of baking soda and water. For deeper issues, consider resealing the grout with a food-safe sealant annually. This not only preserves the tile inset but also prevents bacteria from accumulating in cracks.

Finally, mindful usage extends your cheese board’s life significantly. Avoid cutting directly on the tile surface, as it can dull knives and chip the edges. Use separate cutting boards for slicing and reserve the cheese board for serving. Limit exposure to acidic foods like citrus or vinegar-based dips, which can etch tile and discolor wood. For outdoor use, apply a UV-protective wood finish annually to shield against sun damage. With these practices, your cheese board with tile inset will remain a functional and elegant centerpiece for years to come.

Stop the Whine: Turning Complaints into Cheese-Worthy Achievements

You may want to see also

Frequently asked questions

Use food-safe mineral oil or butcher block oil, as they are non-toxic and ideal for surfaces that come into contact with food. Avoid using vegetable oils or tung oil, as they can go rancid over time.

Apply the oil carefully with a clean cloth or brush, ensuring it only touches the wood. Use painter’s tape or masking tape to cover the edges of the tile before oiling to prevent any oil from seeping underneath or staining the tile.

Reapply oil every 3–6 months, depending on usage. Inspect the wood regularly for dryness or dullness. The tile inset does not require oiling, so focus solely on maintaining the wooden portions of the board.