Paracoating cheese is a specialized technique used in the dairy industry to enhance the texture, appearance, and shelf life of cheese products. This process involves applying a thin, protective layer of paraffin wax or a similar coating material to the cheese surface, creating a barrier that prevents moisture loss and inhibits mold growth. Commonly used for hard and semi-hard cheeses like Cheddar or Gouda, paracoating not only preserves the cheese’s quality but also ensures a consistent and appealing finish for retail presentation. Understanding the steps and best practices for paracoating is essential for cheese producers aiming to maintain product integrity and meet consumer expectations.

Explore related products

What You'll Learn

- Preparing the Cheese Surface: Clean, dry, and ensure cheese is at room temperature for optimal adhesion

- Mixing Paracoat Ingredients: Combine wax, resin, and additives precisely according to manufacturer instructions for consistency

- Applying the Paracoat: Use a brush or sprayer to evenly coat cheese, avoiding drips or pooling

- Drying and Curing: Allow coated cheese to dry in a controlled environment, ensuring complete curing for protection

- Inspecting the Finish: Check for cracks, bubbles, or imperfections; reapply if necessary for a smooth seal

Preparing the Cheese Surface: Clean, dry, and ensure cheese is at room temperature for optimal adhesion

The success of paracoating cheese hinges on a seemingly mundane yet critical step: preparing the cheese surface. Imagine applying paint to a dusty, damp wall—the result would be uneven, prone to peeling, and aesthetically unappealing. The same principle applies to cheese. Before any coating can adhere properly, the surface must be clean, dry, and at room temperature. This trifecta ensures the paracoating not only sticks but also forms a uniform, protective layer that enhances both appearance and shelf life.

Cleaning the cheese surface is the first non-negotiable step. Residues like dust, mold spores, or natural cheese oils can act as barriers, preventing the paracoating from bonding effectively. Use a food-grade brush or cloth to gently remove any visible debris. For harder cheeses, a light rinse with cold water followed by immediate drying can be effective, but avoid soaking, as excess moisture can compromise adhesion. Soft cheeses, however, should never be rinsed—instead, use a dry brush to avoid altering their texture.

Once cleaned, drying the cheese surface is equally vital. Moisture is the enemy of adhesion, as it creates a barrier between the cheese and the paracoating. Pat the surface dry with a clean, lint-free cloth, ensuring no moisture remains. For larger cheese wheels, consider using a hairdryer on a low, cool setting to speed up the process, but avoid heat, as it can soften the cheese prematurely. The goal is a surface that feels matte and dry to the touch, ready to accept the coating without interference.

Finally, ensuring the cheese is at room temperature is a step often overlooked but crucial for optimal adhesion. Cold cheese causes the paracoating to set too quickly, leading to cracking or uneven coverage. Conversely, warm cheese can become too soft, making application messy and ineffective. Allow the cheese to sit at room temperature for 30–60 minutes before paracoating, depending on its size. This simple step ensures the coating adheres smoothly and sets correctly, creating a professional finish.

In practice, think of this process as preparing a canvas for painting. Just as an artist wouldn’t paint on a dirty, wet surface, a cheesemaker must treat the cheese with the same care. Clean, dry, and temperature-controlled—these three steps are the foundation of a successful paracoating, transforming ordinary cheese into a visually appealing, longer-lasting product. Master this preparation, and the rest of the process becomes significantly easier.

Cheez-It Bowl 2023: Teams, Matchup, and Game Preview

You may want to see also

Mixing Paracoat Ingredients: Combine wax, resin, and additives precisely according to manufacturer instructions for consistency

The precise combination of wax, resin, and additives is the cornerstone of successful paracoating. Deviating from manufacturer instructions, even slightly, can result in a coating that’s too brittle, too soft, or unevenly applied. For instance, a common ratio for cheese paracoating involves 60% wax, 35% resin, and 5% additives, though this varies by product and desired finish. Always measure by weight, not volume, to ensure accuracy, as densities differ between ingredients.

Consider the role of each component: wax provides the protective barrier, resin acts as the binder, and additives (like plasticizers or pigments) enhance flexibility or appearance. Overmixing can degrade the resin’s integrity, while undermixing leads to separation. Use a double boiler or heated mixer to melt wax and resin at their optimal temperatures (typically 140–160°F), then incorporate additives slowly, stirring continuously for 3–5 minutes until fully emulsified. A digital thermometer is essential to monitor temperature, preventing overheating that could alter the mixture’s properties.

Practical tips can streamline the process. For small batches, a handheld immersion blender ensures thorough mixing without clumping. For larger operations, industrial mixers with temperature control are ideal. Always test a small sample before coating an entire batch of cheese. If the mixture appears grainy or separates, reheat gently and remix. Store unused paracoat in airtight containers at room temperature, as refrigeration can cause wax to solidify unevenly, requiring reheating and remixing before reuse.

Comparing paracoating to other cheese preservation methods highlights its precision. Unlike brine or vacuum sealing, paracoating demands exact ingredient ratios and application techniques. While brine relies on osmotic pressure, paracoating forms a physical barrier, making consistency in mixing critical. Unlike vacuum sealing, which is forgiving of minor errors, a flawed paracoat can render cheese susceptible to mold or moisture loss. This underscores why adhering to manufacturer guidelines isn’t just recommended—it’s non-negotiable.

Finally, the takeaway is clear: consistency in mixing paracoat ingredients isn’t just about following rules—it’s about understanding the science behind each component. Wax, resin, and additives must work in harmony to create a protective layer that preserves cheese without compromising its flavor or texture. By measuring accurately, controlling temperature, and testing rigorously, you ensure a paracoat that performs as intended, extending the life of your cheese while maintaining its artisanal quality.

Mastering Cheese Storage: Optimal Fridge Tips for Freshness & Flavor

You may want to see also

Applying the Paracoat: Use a brush or sprayer to evenly coat cheese, avoiding drips or pooling

The choice of application tool—brush or sprayer—significantly impacts the paracoating process, each with distinct advantages and challenges. A brush offers precision, allowing you to control the thickness of the coating and navigate the cheese’s contours, particularly useful for irregularly shaped varieties like aged cheddar or gouda. However, brushes can introduce inconsistencies if not used with a steady hand, leading to uneven coverage. Sprayers, on the other hand, provide a uniform application, ideal for large batches or flat surfaces such as wheels of brie or camembert. Yet, sprayers require careful calibration to avoid oversaturation, which can cause pooling or dripping, compromising the cheese’s texture and appearance.

To achieve an even paracoat, start by preparing the cheese surface. Ensure it is dry and free of excess moisture, as dampness can interfere with adhesion. For brush application, dip the bristles into the paracoat solution, then gently tap the brush against the container’s edge to remove excess liquid. Apply in smooth, even strokes, following the natural shape of the cheese. Work systematically, covering one section at a time to maintain consistency. If using a sprayer, hold the nozzle 6–8 inches from the surface and apply in a sweeping motion, overlapping each pass slightly to ensure full coverage. Maintain a steady hand and consistent pressure to prevent drips.

Dosage is critical for both methods. Aim for a thin, uniform layer—typically 1–2 millimeters thick—to preserve the cheese’s flavor and texture while providing adequate protection. Overapplication can lead to a gummy or rubbery coating, while too little may fail to seal the cheese properly. For sprayers, dilute the paracoat solution according to the manufacturer’s instructions, usually a 1:1 ratio with water, to achieve optimal viscosity. Brush applications may require a slightly thicker mixture to ensure even distribution without dripping.

Practical tips can enhance your technique. When brushing, use a silicone or natural bristle brush, as these materials are less likely to shed fibers onto the cheese. For sprayers, opt for a low-pressure model to minimize overspray and waste. Always test your method on a small piece of cheese before coating an entire batch to ensure the desired result. Finally, allow the paracoat to dry completely—typically 2–4 hours at room temperature—before handling or packaging the cheese.

In conclusion, mastering the application of paracoat requires attention to detail and the right tools. Whether you choose a brush or sprayer, the goal is the same: a seamless, protective layer that enhances the cheese’s longevity without compromising its quality. By understanding the nuances of each method and following precise techniques, you can achieve professional results that elevate your cheese to the next level.

Cheesecake Perfection: Is a Water Bath Always Necessary?

You may want to see also

Explore related products

Drying and Curing: Allow coated cheese to dry in a controlled environment, ensuring complete curing for protection

After coating cheese with a protective layer, the drying and curing process is critical to ensure the coating adheres properly and provides the intended protection. This stage requires precision and control to achieve optimal results. The environment in which the cheese dries must be carefully regulated, maintaining a consistent temperature and humidity level to facilitate even curing. For most paraffin or wax coatings, a temperature range of 60-70°F (15-21°C) with humidity around 50-60% is ideal. These conditions prevent the formation of cracks or uneven surfaces, which could compromise the protective barrier.

The duration of the drying and curing process varies depending on the type of cheese and the thickness of the coating. Hard cheeses, such as cheddar or Parmesan, typically require 24-48 hours to cure fully, while softer cheeses may need up to 72 hours. It’s essential to monitor the cheese periodically during this period, checking for signs of incomplete curing, such as tackiness or soft spots. If these issues arise, adjust the environmental conditions or extend the curing time. For example, increasing airflow around the cheese can help accelerate drying without overheating, which could damage the cheese.

One practical tip is to use wire racks or mesh trays to allow air circulation around the entire surface of the cheese. This setup prevents the cheese from sweating or developing moisture pockets, which can lead to mold or spoilage. Additionally, rotating the cheese periodically ensures uniform curing, especially for larger wheels. For commercial operations, investing in a climate-controlled drying room with adjustable humidity and temperature settings can streamline the process and improve consistency.

Comparing traditional methods to modern techniques highlights the advantages of controlled environments. Historically, cheese was cured in natural settings, relying on ambient conditions, which often led to inconsistent results. Today, technology allows for precise control, reducing waste and improving product quality. For instance, using dehumidifiers or humidifiers can fine-tune moisture levels, while digital thermostats ensure temperature stability. This level of control is particularly beneficial for artisanal cheesemakers aiming for premium, consistent products.

In conclusion, drying and curing coated cheese is a meticulous process that demands attention to detail. By maintaining a controlled environment, monitoring progress, and employing practical techniques, cheesemakers can ensure the coating cures completely, providing robust protection. Whether for small-scale production or large operations, mastering this step is essential for preserving the quality and longevity of the cheese.

Amul Cheese Slices vs. Cubes: A Taste Comparison

You may want to see also

Inspecting the Finish: Check for cracks, bubbles, or imperfections; reapply if necessary for a smooth seal

A flawless paracoat finish is the hallmark of a well-preserved cheese, acting as a protective barrier against mold and moisture loss. However, achieving this smooth seal requires meticulous inspection. After applying the paracoat, allow it to dry completely, typically 24-48 hours depending on humidity and cheese size. Once dry, examine the surface under bright, indirect light. Run your fingertips gently over the coating, feeling for any irregularities.

Even the slightest crack or bubble compromises the seal, allowing air and contaminants to reach the cheese.

Cracks, often resembling fine lines, can result from uneven application, insufficient coating thickness, or rapid drying. Bubbles, appearing as raised pockets, indicate trapped air or improper mixing of the paracoat solution. Imperfections like streaks or rough patches may stem from debris on the cheese surface or an uneven application technique. Addressing these issues promptly is crucial. A compromised seal can lead to mold growth, off-flavors, and accelerated drying, ultimately affecting the cheese's quality and shelf life.

Remember, a smooth, uniform finish is not merely aesthetic; it's essential for optimal cheese preservation.

Reapplication is necessary if imperfections are detected. Lightly sand the affected area with fine-grit sandpaper to create a smooth base for the new coat. Ensure the cheese surface is clean and dry before reapplying the paracoat. Follow the recommended dosage and application instructions for your chosen paracoat product, typically a thin, even layer applied with a brush or sponge. Allow the new coat to dry completely before inspecting again. Patience is key; rushing the process can lead to further imperfections.

Think of it as an artist perfecting a painting, each layer building upon the last to achieve a flawless finish.

For larger cheeses or those with intricate shapes, consider using a spray applicator for a more even coat. Experiment with different application techniques to find what works best for your specific cheese variety and desired finish. Remember, the goal is not just to cover the cheese but to create a seamless, protective barrier that enhances its longevity and flavor. With careful inspection and meticulous reapplication when needed, you can achieve a paracoat finish that rivals the artistry of the cheese itself.

Mastering Karstaag: Cheesing Strategies for Skyrim's Toughest Dragon Priest

You may want to see also

Frequently asked questions

Paracoating cheese is a process of applying a thin layer of wax or a similar coating to the surface of cheese to preserve it, prevent mold growth, and extend its shelf life.

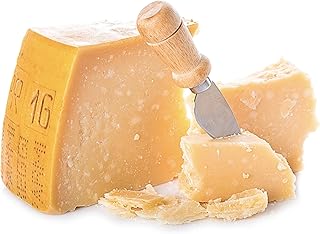

Hard and semi-hard cheeses like Cheddar, Gouda, and Parmesan are ideal for paracoating due to their lower moisture content, which allows the coating to adhere better and provides longer-lasting protection.

You will need food-grade wax (such as cheese wax or paraffin wax), a double boiler or melting pot, a brush or spatula for application, and a clean, dry surface for the cheese to cool on after coating.

Melt the wax in a double boiler, ensuring it doesn’t overheat. Brush or pour the melted wax evenly over the cheese, covering all surfaces. Allow the first coat to dry, then apply a second coat for better protection. Let the cheese cool completely before storing.

When properly paracoated, cheese can last 6 months to 2 years, depending on the type of cheese, storage conditions, and the thickness of the coating. Store in a cool, dry place away from direct sunlight.