Preventing mold growth during cheese aging is crucial for ensuring the safety, quality, and consistency of the final product. While some molds are intentionally introduced to create specific cheese varieties, uncontrolled or undesirable mold growth can lead to off-flavors, spoilage, or health risks. Key strategies to mitigate unwanted mold include maintaining optimal humidity and temperature levels in the aging environment, ensuring proper airflow, and regularly cleaning and sanitizing aging surfaces and equipment. Additionally, using appropriate salt concentrations, controlling moisture content in the cheese, and employing protective coatings or natural antimicrobials can further inhibit mold proliferation. Vigilant monitoring and adherence to best practices in hygiene and storage conditions are essential for successful cheese aging.

| Characteristics | Values |

|---|---|

| Optimal Humidity Control | Maintain relative humidity between 80-90% to discourage unwanted mold growth. |

| Temperature Regulation | Keep aging room temperature consistent, typically between 50-55°F (10-13°C). |

| Air Circulation | Ensure proper airflow to prevent stagnant air and moisture buildup. |

| Sanitation Practices | Regularly clean aging surfaces, tools, and equipment to eliminate spores. |

| Salt Application | Use salt as a natural preservative to inhibit mold growth on cheese surfaces. |

| pH Control | Maintain a low pH (below 5.0) to create an unfavorable environment for mold. |

| Use of Antimicrobial Agents | Apply food-grade antimicrobial solutions or molds (e.g., Penicillium candidum) to control unwanted molds. |

| Proper Wrapping/Coating | Use breathable materials like cheese paper or wax coatings to regulate moisture. |

| Regular Turning | Flip cheese regularly to prevent moisture accumulation on one side. |

| Monitoring and Inspection | Frequently inspect cheese for early signs of unwanted mold and address promptly. |

| Aging Environment | Use dedicated aging rooms or caves with controlled conditions. |

| Avoid Cross-Contamination | Isolate cheeses with different molds to prevent unwanted spore transfer. |

| Use of Beneficial Molds | Introduce specific molds (e.g., Penicillium camemberti) to outcompete unwanted molds. |

| Moisture Management | Control moisture levels by adjusting humidity or using dehumidifiers. |

| Time-Based Aging | Follow specific aging timelines to minimize mold risks during critical stages. |

Explore related products

What You'll Learn

- Control Humidity Levels: Maintain optimal humidity (85-95%) to discourage mold without drying cheese

- Proper Air Circulation: Ensure adequate airflow to prevent moisture buildup and mold formation

- Sanitize Equipment: Regularly clean and sanitize aging tools to eliminate mold spores

- Monitor Temperature: Keep consistent temperatures (50-55°F) to slow unwanted mold growth

- Use Protective Coatings: Apply wax or natural coatings to shield cheese from mold

Control Humidity Levels: Maintain optimal humidity (85-95%) to discourage mold without drying cheese

Maintaining the right humidity is a delicate balancing act in cheese aging. Too much moisture, and you’re inviting mold to take over; too little, and your cheese dries out, losing texture and flavor. The sweet spot lies between 85% and 95% humidity, a range that discourages unwanted mold growth while keeping the cheese adequately moist. This isn’t guesswork—it’s science. Mold spores thrive in environments above 95% humidity, where condensation forms and provides the water they need to multiply. Below 85%, the cheese’s surface dries, creating a barrier that traps moisture internally, leading to cracks or uneven aging.

To achieve this balance, invest in a hygrometer to monitor humidity levels accurately. Place it near the cheese, ensuring it’s not directly above or below the aging surface, as this can skew readings. If humidity drops below 85%, introduce a water source, such as a tray of water or damp cloth, into the aging environment. For excess moisture, use a dehumidifier or improve air circulation with a small fan. Be cautious with fans, though—direct airflow can dry out the cheese’s surface, defeating the purpose.

Consider the cheese type when adjusting humidity. Hard cheeses like Parmesan tolerate slightly lower humidity (around 85%) because their dense structure retains moisture better. Soft cheeses, such as Brie, require closer to 95% to maintain their creamy texture. Experimentation is key—start at the midpoint (90%) and adjust based on visual cues. If mold appears, reduce humidity; if the cheese feels dry or cracks, increase it.

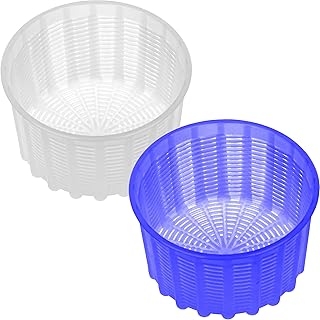

Practical tips can make this process smoother. For small-scale aging, a wine fridge with humidity control works well. If using a DIY setup, line the container with salt-resistant materials like stainless steel or food-grade plastic to prevent corrosion. Regularly clean the aging space to remove mold spores and maintain a sterile environment. Remember, consistency is crucial—fluctuations in humidity can stress the cheese, leading to uneven aging or off-flavors.

In essence, controlling humidity isn’t just about preventing mold; it’s about creating the ideal environment for cheese to develop its unique character. By staying within the 85-95% range and tailoring adjustments to the cheese type, you’ll foster a healthy aging process that highlights flavor, texture, and aroma. It’s a precision task, but the payoff—a perfectly aged wheel—is well worth the effort.

Deli Cheese Slices: Understanding the Ounce Measurement for Perfect Portions

You may want to see also

Proper Air Circulation: Ensure adequate airflow to prevent moisture buildup and mold formation

Mold thrives in stagnant, humid environments, making proper air circulation a critical factor in cheese aging. Without adequate airflow, moisture accumulates on the cheese's surface, creating the perfect breeding ground for unwanted molds. This not only compromises the cheese's appearance but can also lead to off-flavors and even spoilage.

Imagine a stuffy, poorly ventilated room – the air feels heavy, and surfaces feel damp. This is akin to the environment mold relishes. Conversely, a well-ventilated space promotes evaporation, keeping surfaces dry and inhospitable to mold growth.

Achieving optimal airflow requires a multi-pronged approach. Firstly, consider the aging environment itself. A dedicated aging room with controlled temperature and humidity is ideal. Aim for a temperature range of 50-55°F (10-13°C) and a relative humidity of 80-85%. Incorporate a ventilation system that allows for air exchange, ensuring fresh air circulates while maintaining the desired temperature and humidity levels. This could involve a simple exhaust fan or a more sophisticated system with air filters.

For smaller-scale operations or home cheesemakers, utilizing a wine fridge or a cool, dry basement can be suitable. In these cases, strategically placing a small fan to promote air movement around the cheese is crucial. Avoid direct airflow onto the cheese, as this can dry it out excessively.

The cheese's placement within the aging environment also plays a role. Avoid overcrowding the aging space. Leave sufficient space between cheeses to allow air to circulate freely around each wheel or block. This prevents the formation of stagnant pockets of air where moisture can accumulate. Consider using shelving or racks that allow for airflow beneath and around the cheese.

Finally, remember that proper air circulation is an ongoing process. Regularly monitor the aging environment, checking for any signs of condensation or mold growth. Adjust ventilation and airflow as needed to maintain optimal conditions. By prioritizing adequate airflow, you create an environment that discourages mold growth, allowing your cheese to develop its unique character and flavor profile without unwanted interruptions.

Can Dogs Eat Cheese? Understanding the Risks and Benefits for Your Pet

You may want to see also

Sanitize Equipment: Regularly clean and sanitize aging tools to eliminate mold spores

Mold spores are ubiquitous, lurking in the air and on surfaces, ready to colonize your carefully crafted cheese. While some molds are desirable in cheese aging, uncontrolled growth can ruin your batch. This is where sanitizing your equipment becomes a critical line of defense.

Every tool that comes into contact with your cheese, from aging mats to brushes and even your hands, can harbor spores. A single overlooked spore can multiply rapidly in the warm, humid environment of a cheese cave, leading to unwanted mold growth and potentially spoiling your cheese.

Think of sanitizing as a two-pronged attack. First, cleaning removes visible dirt, debris, and the majority of mold spores. Use hot water and a mild, food-safe detergent, scrubbing thoroughly to dislodge any clinging particles. Rinse meticulously to avoid leaving behind soap residue, which can taint the cheese's flavor.

Second, sanitizing kills any remaining spores. Food-grade sanitizers like vinegar solutions (1 part vinegar to 4 parts water) or commercial sanitizing solutions specifically designed for food contact surfaces are effective options. Follow the manufacturer's instructions for dilution ratios and contact times to ensure complete disinfection.

Don't underestimate the importance of frequency. Sanitizing should be a regular ritual, not a sporadic event. Aim to sanitize your equipment before and after each use, and consider additional sanitizing sessions if your cheese cave experiences high humidity or if you notice any signs of mold growth.

Remember, consistency is key. By diligently sanitizing your equipment, you create a hostile environment for unwanted mold, allowing your desired molds to flourish and your cheese to age beautifully.

Cheesing Glory in Destiny 2: Unlocking Easy Triumphs and Strategies

You may want to see also

Explore related products

Monitor Temperature: Keep consistent temperatures (50-55°F) to slow unwanted mold growth

Maintaining a consistent temperature between 50°F and 55°F is critical for slowing unwanted mold growth during cheese aging. This range creates an environment that discourages the proliferation of undesirable molds while allowing beneficial bacteria to thrive. Fluctuations outside this zone can accelerate mold growth, compromise flavor, and even render the cheese unsafe for consumption.

To achieve this, invest in a reliable refrigeration unit or aging cave equipped with a thermostat capable of precise temperature control. Avoid placing cheese near doors, windows, or vents, as these areas are prone to temperature swings. For home cheesemakers, a wine fridge or a converted refrigerator with a temperature controller can be an affordable and effective solution. Regularly calibrate your thermometer to ensure accuracy, as even a slight deviation can impact mold development.

Comparatively, higher temperatures (above 60°F) create ideal conditions for mold spores to germinate and spread rapidly. Conversely, temperatures below 45°F can halt the aging process entirely, stunting flavor development. The 50-55°F sweet spot strikes a balance, slowing unwanted mold growth without sacrificing the cheese’s intended character.

A practical tip for monitoring temperature is to use a data logger, which records temperature fluctuations over time. This tool helps identify patterns and potential issues before they become problematic. Additionally, rotate cheeses periodically within the aging space to ensure even exposure to the controlled environment. By meticulously maintaining this temperature range, you create a stable habitat that favors the desired microbial activity while minimizing the risk of unwanted mold contamination.

Exploring Cheese Diversity: Origins of Unique Flavors and Textures

You may want to see also

Use Protective Coatings: Apply wax or natural coatings to shield cheese from mold

Protective coatings act as a barrier, sealing cheese from the moisture and oxygen that mold thrives on. Wax, the most common option, creates a physical shield, while natural coatings like lard or butter introduce antimicrobial properties. This dual approach not only prevents mold growth but also influences flavor development, making it a crucial technique in cheese aging.

Waxing cheese is a straightforward process. Melt food-grade wax to around 150°F (65°C) and brush or dip the cheese, ensuring complete coverage. Allow each layer to cool before applying the next, aiming for a thickness of 1/8 inch. Natural coatings, like lard or butter, require a different approach. Gently rub a thin, even layer onto the cheese surface, taking care not to leave gaps. Reapply every few weeks to maintain the barrier.

While effective, protective coatings aren't foolproof. Wax can crack if the cheese is handled roughly or experiences temperature fluctuations. Natural coatings, though antimicrobial, can spoil themselves if not stored properly. Regularly inspect coated cheeses for any signs of mold growth, especially around the edges. If mold appears, remove the affected area and reapply the coating.

Remember, the type of cheese dictates the best coating. Hard cheeses like Cheddar benefit from wax's durability, while softer cheeses like Brie may prefer the breathability of natural coatings. Experimentation and careful observation are key to mastering this mold-prevention technique.

Is Hardee's Hot Ham and Cheese Still on the Menu?

You may want to see also

Frequently asked questions

Maintain a temperature between 50°F and 55°F (10°C and 13°C) and relative humidity around 85-90% to discourage unwanted mold growth while promoting proper cheese aging.

Turn or flip the cheese every 3-7 days to ensure even moisture distribution and prevent mold from settling on one side.

Yes, good airflow helps regulate humidity and prevents stagnant conditions that encourage mold. Use shelves or racks to allow air circulation around the cheese.

Wrapping cheese in breathable materials like cheesecloth or waxed paper can help control moisture while still allowing it to breathe, reducing mold risk.

Regularly clean and sanitize the aging space, including shelves and tools, to eliminate mold spores and bacteria that could contaminate the cheese.