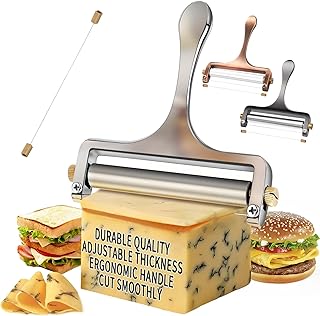

Repairing or tightening the wire on a hand cheese slicer is a straightforward task that can extend the life of your tool and ensure smooth, precise slicing. Over time, the wire may become loose or break due to regular use, but with the right tools and a bit of patience, you can easily restore it to optimal condition. The process typically involves removing the old wire, threading a new one through the slicer’s mechanism, and securing it tightly to maintain proper tension. Whether you’re replacing a broken wire or simply tightening a loose one, understanding the steps and having the necessary materials on hand will make the repair quick and efficient.

| Characteristics | Values |

|---|---|

| Tools Required | Pliers, screwdriver, replacement wire (if needed), wire cutter |

| Steps to Tighten Wire | 1. Locate the tensioning mechanism (usually a screw or knob). 2. Turn the screw clockwise or adjust the knob to tighten the wire. 3. Test the tension by slicing cheese; adjust as needed. |

| Steps to Replace Wire | 1. Remove the old wire by loosening the screws or clamps holding it. 2. Insert the new wire, ensuring it is straight and taut. 3. Secure the wire by tightening the screws or clamps. 4. Adjust the tension as needed. |

| Common Issues | Wire too loose, wire broken, wire misaligned |

| Precautions | Ensure the slicer is clean and dry before repair. Avoid overtightening to prevent wire breakage. Use appropriate tools to avoid damage to the slicer. |

| Replacement Wire Types | Stainless steel wire (most common), durable and rust-resistant |

| Maintenance Tips | Regularly clean the slicer to prevent cheese buildup. Check wire tension periodically to ensure optimal performance. |

| Safety Tips | Handle sharp wires with care to avoid injury. Keep hands clear of the wire during adjustment. |

Explore related products

$8.99 $9.99

What You'll Learn

- Tools Needed: Gather pliers, screwdriver, replacement wire, and cloth for cleaning and adjusting the slicer

- Wire Removal: Loosen screws, detach old wire, and clean wire holders before installing a new one

- Wire Installation: Thread new wire through holders, secure with screws, and ensure even tension

- Tension Adjustment: Tighten screws gradually, test wire tension, and adjust until slicing is smooth

- Maintenance Tips: Regularly clean wire, check screws, and replace wire if frayed or damaged

Tools Needed: Gather pliers, screwdriver, replacement wire, and cloth for cleaning and adjusting the slicer

Repairing or tightening a hand cheese slicer wire begins with assembling the right tools. Pliers are essential for gripping and adjusting the wire, ensuring it’s taut enough to slice through cheese without snapping. A screwdriver, typically a flathead or Phillips depending on your slicer’s design, is needed to access the screws holding the wire in place. Replacement wire is a must-have, as worn or frayed wires compromise slicing efficiency and safety. Lastly, a clean cloth is vital for wiping away grease, debris, or rust that could hinder adjustments or affect the cheese’s quality.

The choice of pliers matters more than you might think. Needle-nose pliers offer precision for delicate adjustments, while standard pliers provide stronger grip for tighter wires. If your slicer’s wire is severely rusted or damaged, consider using cutting pliers to remove the old wire cleanly before installing the replacement. Always test the tension after tightening—a wire that’s too loose will wobble, while one that’s too tight risks breaking under pressure.

Replacement wire isn’t one-size-fits-all. Most cheese slicers use stainless steel wires with a diameter of 0.5 to 0.7 millimeters, but check your slicer’s manual or manufacturer’s website for specifications. If you’re unsure, measure the old wire’s thickness with calipers for accuracy. When installing the new wire, thread it through the slicer’s guides evenly, ensuring it sits flush against the blade for consistent slicing.

Cleaning is often overlooked but critical. Use the cloth to wipe down the slicer’s surface, paying attention to the wire guides and screw threads. For stubborn grime, dampen the cloth with warm, soapy water, but avoid soaking the slicer to prevent rust. After cleaning, dry thoroughly before reassembling. A well-maintained slicer not only performs better but also extends the life of the wire and other components.

In summary, gathering the right tools—pliers, screwdriver, replacement wire, and cloth—transforms a frustrating repair into a straightforward task. Each tool plays a specific role, from tightening the wire to ensuring cleanliness, ultimately restoring your cheese slicer to optimal functionality. With these essentials in hand, you’re equipped to tackle the job efficiently and effectively.

Mastering Cheese Measurements: Calculating the Volume of a Cheese Wedge

You may want to see also

Wire Removal: Loosen screws, detach old wire, and clean wire holders before installing a new one

The first step in replacing a worn-out cheese slicer wire is to access the wire holders, which typically involves loosening screws. Most hand cheese slicers have two screws, one on each side, securing the wire in place. Use a screwdriver that matches the screw head type (usually Phillips or flathead) to avoid stripping. Turn the screws counterclockwise, but don’t remove them entirely unless necessary; partially loosening them often provides enough slack to detach the wire. Be cautious not to overtighten later, as this can warp the slicer’s frame or damage the new wire.

Once the screws are loosened, carefully detach the old wire by pulling it out of the holders. Some slicers have a tensioning mechanism that may need to be released first. Inspect the wire for fraying or breakage to confirm replacement is necessary. If the wire is merely loose, you might opt to retighten it instead. However, if it’s damaged or excessively worn, proceed with removal. Dispose of the old wire responsibly, as sharp edges can pose a hazard.

Before installing a new wire, clean the wire holders to ensure optimal performance. Over time, grease, cheese residue, and debris can accumulate, hindering smooth operation. Use a damp cloth or a soft brush to remove buildup, and dry thoroughly to prevent rust. For stubborn grime, a mild detergent or vinegar solution can be effective. Ensure the holders are completely clean and dry before proceeding, as moisture can compromise the slicer’s longevity.

With the holders clean, prepare to install the new wire. Cut the replacement wire to the appropriate length, typically matching the old wire’s dimensions. Insert one end into a holder, pull it taut, and secure it by tightening the screw clockwise. Repeat on the opposite side, ensuring even tension. Test the wire by gently pressing down to ensure it’s stable and functional. Proper tension is key—too loose, and it won’t slice effectively; too tight, and it risks snapping under pressure.

Finally, reassemble any additional components if applicable, such as a blade guard or handle. Test the slicer with a block of cheese to verify smooth operation. Regular maintenance, including periodic cleaning and tension checks, can extend the life of both the wire and the slicer. By following these steps, you’ll restore your cheese slicer to its original efficiency, ensuring clean, precise cuts every time.

Does Jimmy John's Offer Pepper Jack Cheese? A Menu Breakdown

You may want to see also

Wire Installation: Thread new wire through holders, secure with screws, and ensure even tension

A frayed or loose wire on your hand cheese slicer doesn't mean it's destined for the trash. Replacing the wire is a straightforward fix that restores your slicer's functionality. The key to success lies in proper wire installation, ensuring a taut and secure cutting edge.

Here's a breakdown of the process: thread the new wire through the holders, secure it with screws, and achieve even tension for optimal slicing.

Begin by sourcing the correct replacement wire, typically stainless steel, designed for cheese slicers. Most slicers use a specific gauge wire, so consult your model's manual or the manufacturer's website for specifications. Once you have the wire, locate the wire holders on your slicer. These are usually small metal components with holes or grooves designed to anchor the wire.

Thread the wire through these holders, ensuring it follows the original path. This often involves feeding the wire from one end of the slicer, across the cutting surface, and out the other end.

With the wire threaded, secure it in place using the provided screws. Tighten the screws firmly, but be careful not to overtighten, as this can damage the wire or the slicer's components. Aim for a snug fit that holds the wire securely without causing undue stress.

The final, crucial step is achieving even tension across the wire. Uneven tension will result in uneven slicing and potential wire breakage. Gently pull the wire from both ends, distributing the tension evenly. Some slicers have built-in tensioning mechanisms; consult your manual for specific instructions. If not, carefully adjust the wire's position within the holders until the tension feels uniform.

Test the slicer by gently slicing a piece of cheese. If the wire cuts smoothly and evenly, you've successfully installed the new wire. If not, recheck the tension and adjust as needed.

How String Cheese Affects Your Body: Nutrition, Digestion, and Health Benefits

You may want to see also

Explore related products

Tension Adjustment: Tighten screws gradually, test wire tension, and adjust until slicing is smooth

A loose wire on your cheese slicer doesn't mean it's destined for the trash. Often, a simple tension adjustment is all that's needed to restore smooth, effortless slicing. The key lies in a gradual, methodical approach, treating the wire like a finely tuned instrument.

Imagine a guitar string – too loose, it produces a dull thud; too tight, it snaps. Your cheese slicer wire operates on a similar principle.

Steps to Tension Perfection:

- Locate the Adjustment Screws: Most cheese slicers have two screws, one on each side of the wire. These screws control the tension.

- Gradual Tightening: Using a screwdriver, turn each screw clockwise a quarter turn at a time. Over-tightening can damage the wire, so patience is key.

- Test After Each Adjustment: After each quarter turn, gently slice a piece of cheese. The wire should feel taut but not overly resistant. You're aiming for a smooth, clean cut without excessive force.

- Fine-Tuning: If the wire feels too loose, tighten the screws a little more. If it's too tight, loosen them slightly. Repeat this process until you achieve the desired tension.

Pro Tip: Mark the initial screw positions with a small dot of paint or a permanent marker. This provides a reference point if you need to make future adjustments.

Caution: Avoid using excessive force when tightening the screws. Over-tightening can stretch or break the wire. If the screws feel unusually tight, stop and reassess – you may need to loosen them slightly and try again.

The Reward: A properly tensioned wire will glide through cheese with minimal effort, producing thin, even slices every time. This simple adjustment extends the life of your cheese slicer and elevates your cheese-cutting experience.

Is Brie Cheese High in Sodium? Uncovering the Truth

You may want to see also

Maintenance Tips: Regularly clean wire, check screws, and replace wire if frayed or damaged

A well-maintained cheese slicer wire is crucial for achieving clean, precise cuts and prolonging the life of your tool. Over time, cheese residue, grease, and debris can accumulate on the wire, affecting its performance and hygiene. Regular cleaning is the first line of defense. Use a soft brush or cloth dampened with warm, soapy water to gently remove buildup. Avoid abrasive materials that could damage the wire’s surface. For stubborn residue, a mild vinegar solution can be effective, but rinse thoroughly afterward to prevent corrosion. Aim to clean the wire after every use, especially when slicing soft or oily cheeses, to maintain optimal functionality.

While cleaning addresses surface issues, checking the screws ensures the wire remains taut and secure. Loose screws are a common culprit for wire slack, which can lead to uneven slicing or wire breakage. Inspect the screws holding the wire in place monthly, or more frequently if you use the slicer daily. Use the appropriate screwdriver to tighten them gently—overtightening can strip the threads or damage the slicer’s frame. If the screws feel unusually tight or resist turning, apply a small amount of food-safe lubricant to the threads to ease movement. This simple step can prevent wire misalignment and ensure consistent slicing pressure.

Despite diligent care, cheese slicer wires are consumable parts that will eventually wear out. Replacing the wire is necessary if it becomes frayed, kinked, or visibly damaged. Frayed wires not only produce jagged cuts but also pose a safety risk, as broken strands can end up in your food. Most hand cheese slicers are designed for easy wire replacement, often requiring only a screwdriver to remove the old wire and install a new one. Replacement wires are affordable and widely available, typically costing between $5 and $15. Always opt for wires compatible with your slicer model to ensure proper fit and tension.

Comparing the cost of regular maintenance to the expense of replacing an entire slicer highlights the value of these practices. A new cheese slicer can range from $20 to $100, depending on quality and features, while routine care requires minimal investment. By cleaning the wire, checking screws, and replacing it when necessary, you can extend the slicer’s lifespan by years. This not only saves money but also reduces waste, aligning with sustainable kitchen practices. Think of maintenance as an act of preservation—for both your tool and the precision of your cheese slices.

Sargento String Cheese Protein Content: A Nutritional Breakdown

You may want to see also

Frequently asked questions

Locate the adjustment screw or knob on your cheese slicer, typically found near the wire. Turn it clockwise to tighten the wire, ensuring it’s taut but not overly stretched to avoid breakage.

Replace the wire with a compatible replacement wire designed for your slicer model. Follow the manufacturer’s instructions for installation, ensuring the wire is securely attached and properly tensioned.

If the wire is slightly bent, gently straighten it using pliers or your fingers. If it’s severely damaged or misaligned, it’s best to replace the wire entirely to ensure safe and effective slicing.