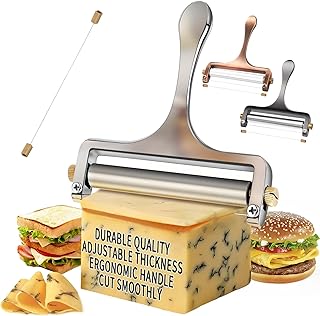

Repairing or tightening a tension-handle cheese slicer is a straightforward task that can extend the life of your kitchen tool and ensure smooth, precise slicing. Over time, the tension mechanism may loosen due to regular use, causing the wire to sag or break. To address this, start by identifying the type of slicer you have, as designs can vary. Typically, you’ll need to locate the tension adjustment screw or knob, often found near the handle or base. Using a screwdriver or your fingers, turn the screw clockwise to tighten the wire, ensuring it’s taut but not overly stretched. If the wire is damaged, carefully replace it with a compatible one, following the manufacturer’s instructions. Regular maintenance, such as cleaning and occasional tightening, will keep your cheese slicer functioning efficiently for years to come.

| Characteristics | Values |

|---|---|

| Tool Required | Screwdriver (usually flathead or Phillips, depending on the slicer) |

| Common Issue | Loose or worn tension spring |

| Solution | Adjust the tension screw located near the blade or spring mechanism |

| Steps | 1. Locate the tension screw (often on the side or back of the slicer). 2. Turn the screw clockwise to tighten the tension. 3. Test the slicer by slicing cheese; adjust further if needed. |

| Additional Tips | - Ensure the slicer is clean and free of debris before adjusting. - If the screw is stripped or damaged, consider replacing the slicer or the screw. - Refer to the manufacturer's manual for model-specific instructions. |

| Safety Precaution | Be cautious when handling the blade to avoid injury. |

| Maintenance | Regularly check the tension and clean the slicer to ensure optimal performance. |

| Replacement Parts | Tension spring or screw (if damaged or worn out) |

| Alternative Method | Some models may require adjusting a locking nut or clamp instead of a screw. |

| Frequency of Adjustment | As needed, depending on usage and wear |

Explore related products

$8.99 $9.99

What You'll Learn

- Adjusting the Tension Screw: Locate and turn the tension screw clockwise to tighten the slicing wire

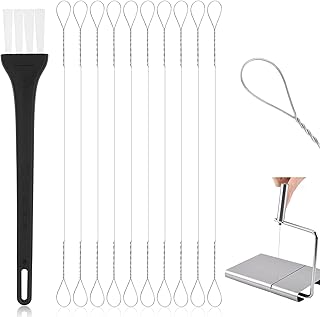

- Replacing the Cutting Wire: Remove old wire, thread new wire, and secure it properly for smooth slicing

- Cleaning and Maintenance: Wipe down the slicer, remove debris, and lubricate moving parts for optimal performance

- Fixing Loose Handles: Tighten handle screws or replace worn-out handles to ensure a firm grip

- Aligning the Wire Frame: Adjust the wire frame to ensure it’s straight and parallel for even slicing

Adjusting the Tension Screw: Locate and turn the tension screw clockwise to tighten the slicing wire

One of the most common issues with a tension-hand cheese slicer is a loose slicing wire, which can lead to uneven cuts or wire breakage. The tension screw, a small but crucial component, is your go-to solution for this problem. Located near the wire attachment point, this screw controls the wire's tautness. Understanding its function is key to maintaining your slicer's performance. By adjusting this screw, you can ensure the wire is tight enough to slice through cheese smoothly but not so tight that it snaps under pressure.

To begin the adjustment process, locate the tension screw, typically found on the side or base of the slicer, close to where the wire is anchored. It’s often a small, slotted screw that can be turned with a flathead screwdriver or even a coin in some models. Once identified, turn the screw clockwise to tighten the wire. This action increases the tension, pulling the wire taut. Be mindful of the force applied; overtightening can cause the wire to break, while undertightening may result in sloppy slicing. A good rule of thumb is to tighten until the wire feels firm but still has a slight give when pressed gently.

The art of adjusting the tension screw lies in finding the perfect balance. Too much tension can strain the wire, leading to premature wear or snapping, especially when slicing harder cheeses like Parmesan. Conversely, too little tension results in a floppy wire that struggles to cut cleanly, often leaving jagged edges or tearing the cheese. For optimal results, test the slicer after each small adjustment. Slice a piece of cheese and observe the wire’s performance. If it cuts smoothly without wobbling or straining, you’ve hit the sweet spot.

Practical tips can further enhance your adjustment process. For instance, if your slicer has a wire replacement feature, ensure the new wire is properly seated before tightening the screw. Additionally, regular maintenance, such as cleaning the slicer and checking the wire’s tension monthly, can prevent issues before they arise. For older models or those with stubborn screws, applying a small amount of food-safe lubricant can ease the turning process. Always refer to your slicer’s manual for model-specific guidance, as some designs may vary in their tension adjustment mechanisms.

In conclusion, adjusting the tension screw is a straightforward yet essential task for maintaining your cheese slicer’s functionality. By understanding its role, using the right technique, and applying practical tips, you can ensure your slicer performs reliably for years to come. Whether you’re a casual cheese enthusiast or a professional chef, mastering this simple adjustment will save you time, frustration, and the cost of frequent replacements.

Exploring Cheese Caves: Unveiling the Pounds of Cheese Within

You may want to see also

Replacing the Cutting Wire: Remove old wire, thread new wire, and secure it properly for smooth slicing

One of the most common issues with a tension-hand cheese slicer is a worn or broken cutting wire, which can lead to uneven slices or complete failure. Replacing the wire is a straightforward process that restores the slicer’s functionality. Begin by carefully removing the old wire, taking note of how it’s threaded through the slicer’s mechanism. Most models have a small screw or clamp that holds the wire in place; loosen this to release the tension and slide the wire out. Be cautious not to damage the slicer’s components during this step, as precision is key to ensuring the new wire fits correctly.

Threading the new wire requires attention to detail. Start by feeding one end of the wire through the designated hole or channel, pulling it taut as you go. Ensure the wire is aligned properly with the slicer’s cutting edge to guarantee smooth, even slices. Once the wire is in place, secure it by tightening the screw or clamp, but avoid over-tightening, as this can cause the wire to snap prematurely. A good rule of thumb is to tighten until the wire feels firm but still has a slight give when pressed gently.

The quality of the replacement wire matters significantly. Opt for a wire specifically designed for cheese slicers, typically made of stainless steel for durability and rust resistance. Avoid using makeshift wires, such as fishing line or dental floss, as these lack the strength and sharpness required for efficient slicing. A high-quality wire not only ensures longevity but also enhances the slicer’s performance, making it easier to achieve thin, consistent slices.

After securing the new wire, test the slicer with a block of firm cheese to ensure it operates smoothly. If the wire feels too loose or too tight, adjust the tension accordingly. Regular maintenance, such as cleaning the wire and checking for wear, can extend its lifespan and keep the slicer in optimal condition. By mastering this simple repair, you’ll save money on replacements and enjoy perfectly sliced cheese for years to come.

Mastering Gouda Care: Tips for Perfect Storage and Freshness

You may want to see also

Cleaning and Maintenance: Wipe down the slicer, remove debris, and lubricate moving parts for optimal performance

Regular cleaning and maintenance are essential to keep your tension-hand cheese slicer in top condition, ensuring smooth operation and prolonging its lifespan. Start by wiping down the slicer with a damp cloth to remove any surface residue or grease. Avoid using harsh chemicals or abrasive sponges, as these can damage the slicer’s finish and components. For stubborn stains, a mild dish soap solution can be effective, but always dry the slicer thoroughly afterward to prevent rust or corrosion.

Debris buildup is a common issue that can hinder the slicer’s performance. Pay close attention to the blade area, where small cheese particles often accumulate. Use a soft brush or a toothpick to carefully dislodge any trapped debris, ensuring the blade moves freely. For hard-to-reach areas, compressed air can be a useful tool to blow out hidden particles. Regularly inspect the slicer’s tension mechanism for any obstructions, as even minor blockages can affect slicing precision.

Lubrication is a critical step often overlooked in cheese slicer maintenance. Apply a food-safe lubricant, such as mineral oil, to the moving parts of the slicer, including the blade hinge and tension spring. Use a small brush or cotton swab to ensure even coverage, avoiding excess that could attract dust or cheese particles. Lubricate the slicer every 3–6 months, depending on usage frequency, to maintain optimal performance and reduce wear on mechanical components.

Comparing a well-maintained slicer to a neglected one highlights the importance of this routine. A slicer with clean, lubricated parts glides effortlessly through cheese, producing consistent slices with minimal effort. In contrast, a slicer clogged with debris or lacking lubrication may struggle, leading to uneven cuts or even breakage. By investing just a few minutes in cleaning and maintenance, you can ensure your cheese slicer remains a reliable kitchen tool for years to come.

Mastering the Art of Slicing Frozen Cheese Without Crumbling

You may want to see also

Explore related products

Fixing Loose Handles: Tighten handle screws or replace worn-out handles to ensure a firm grip

A loose handle on your tension-hand cheese slicer can turn a simple task into a frustrating ordeal, compromising both efficiency and safety. The culprit is often as straightforward as a loose screw or a handle that has seen better days. Addressing this issue not only restores functionality but also extends the life of your slicer, ensuring it remains a reliable kitchen tool.

Analytical Insight: The handle of a tension-hand cheese slicer is a critical component, acting as the lever that applies pressure to the blade. Over time, repeated use can cause the screws securing the handle to loosen, or the handle material itself may degrade, leading to a wobbly grip. This instability not only makes slicing difficult but also increases the risk of the handle breaking mid-use, potentially causing injury. By systematically inspecting the handle and its fasteners, you can identify the root cause and apply the appropriate fix.

Instructive Steps: Begin by laying the cheese slicer on a flat surface and examining the handle for visible signs of wear or damage. If the handle appears intact, locate the screws that attach it to the slicer’s frame. Using a screwdriver that matches the screw head (typically Phillips or flathead), tighten each screw in a clockwise direction. Apply firm, even pressure, but avoid over-tightening, as this can strip the threads or damage the handle. If the screws are already tight but the handle still feels loose, consider disassembling the handle to inspect the internal mechanism for wear or debris.

Comparative Perspective: While tightening screws is often sufficient, some handles may be beyond repair due to cracks, warping, or material fatigue. In such cases, replacing the handle is the more practical solution. Compare the original handle with replacement options, ensuring compatibility in terms of size, shape, and attachment mechanism. Many manufacturers offer replacement parts, but third-party handles can also work if they match the slicer’s specifications. A new handle not only restores grip but can also introduce ergonomic improvements, such as textured surfaces or contoured designs.

Practical Tips: To prevent future issues, periodically check the handle screws for tightness, especially if the slicer is used frequently. Apply a small amount of thread-locking adhesive (like Loctite Blue 242) to the screws during reassembly to secure them in place without permanent bonding. For wooden handles, consider sanding rough spots and applying food-safe mineral oil to maintain the material’s integrity. Always test the slicer’s tension and handle stability before use, ensuring it operates smoothly and safely.

Mastering the Art of Cutting Large Cheese Blocks: Tips and Techniques

You may want to see also

Aligning the Wire Frame: Adjust the wire frame to ensure it’s straight and parallel for even slicing

A misaligned wire frame is a common culprit behind uneven slices and premature wire breakage in tension-hand cheese slicers. Even a slight tilt or twist can cause the wire to cut at an angle, leading to jagged edges and inconsistent thickness. This not only ruins the presentation of your cheese but also puts unnecessary strain on the wire, shortening its lifespan.

Aligning the wire frame is a straightforward process that requires minimal tools and a keen eye for detail. Most slicers feature adjustable screws or bolts located near the wire frame's mounting points. These screws allow for fine-tuning of the frame's position, ensuring it sits perfectly straight and parallel to the base.

To begin, loosen the screws securing the wire frame. This will allow you to gently manipulate the frame into the correct position. Hold a straight edge, such as a ruler or a thin piece of wood, against the base of the slicer. Align the wire frame so that it runs parallel to this straight edge, ensuring it's neither tilted upwards nor downwards. Once aligned, tighten the screws securely, but be careful not to overtighten, as this can damage the threads or warp the frame.

A helpful tip is to use a level to ensure the base of the slicer itself is sitting on a flat surface before attempting to align the wire frame. This eliminates any external factors that could contribute to misalignment. Additionally, some slicers may have specific instructions for wire frame alignment in their user manuals, so consulting the manufacturer's guidelines is always recommended.

Regularly checking and adjusting the wire frame's alignment is crucial for maintaining the slicer's performance and prolonging the life of the cutting wire. By taking a few minutes to ensure the frame is straight and parallel, you'll enjoy consistently perfect cheese slices and avoid the frustration of dealing with a malfunctioning slicer. Remember, a well-aligned wire frame is the foundation for smooth, effortless slicing.

Is Jung from Cheese in the Trap a Sociopath?

You may want to see also

Frequently asked questions

Locate the tension adjustment screw or knob on your slicer, typically near the blade. Use a screwdriver or turn the knob clockwise to tighten the tension until the blade moves smoothly without excessive play.

Ensure the wire is properly seated in the grooves and the tension is not too tight. Replace the wire with a compatible replacement, and avoid cutting hard cheeses that may strain the wire.

Check for loose screws or bolts in the handle assembly. Tighten them using a screwdriver or wrench. If the handle is damaged, consider replacing it with a compatible part.

Dull or misaligned blades can cause uneven cutting. Sharpen the blade using a fine-grit sandpaper or a blade sharpener. Ensure the blade is securely attached and properly aligned with the slicer frame.