Tying cheesecloth cheese is a fundamental technique in the art of cheesemaking, essential for shaping and draining curds during the production process. Cheesecloth, a loosely woven cotton fabric, acts as a porous barrier that allows whey to escape while holding the curds together, helping to form a cohesive cheese mass. Mastering this skill ensures proper moisture removal and even shaping, which are critical for achieving the desired texture and structure of the final product. Whether you're crafting a soft cheese like ricotta or a firmer variety like cheddar, understanding how to tie cheesecloth effectively is a key step in creating high-quality, homemade cheese.

| Characteristics | Values |

|---|---|

| Material Needed | Cheesecloth, cheese curds, salt |

| Cheesecloth Size | Large enough to hold cheese curds and allow for tying |

| Tying Method | Gather corners of cheesecloth and tie securely with kitchen twine or a long strip of cheesecloth |

| Knot Type | Double knot or surgeon's knot for added security |

| Cheese Curd Preparation | Mix cheese curds with salt (optional) before wrapping in cheesecloth |

| Wrapping Technique | Place cheese curds in center of cheesecloth, gather edges, and twist gently to remove excess whey |

| Hanging Time | 1-2 hours or until desired firmness is achieved |

| Hanging Location | Cool, dry place with good air circulation |

| Cheese Types | Suitable for soft cheeses like paneer, ricotta, or farmer's cheese |

| Yield | Depends on amount of cheese curds used |

| Storage | Store wrapped cheese in refrigerator for up to 1 week |

| Alternative Tying Methods | Using a cheese hoop or mold for shaped cheeses |

| Tips | Use a fine-weave cheesecloth for smoother cheese texture |

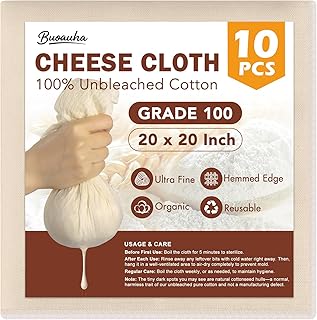

Explore related products

What You'll Learn

- Preparing Cheesecloth: Choose fine-weave, clean cloth; rinse, wring, and lay flat for wrapping cheese curds

- Draining Curds: Wrap curds tightly, place in mold, and apply weight to release whey

- Pressing Cheese: Adjust weight gradually over hours to compact curds into desired shape

- Removing Cloth: Unwrap gently after pressing; ensure cheese holds shape without cloth residue

- Storing Cheese: Air-dry, wrap in fresh cloth or wax paper, and refrigerate for aging

Preparing Cheesecloth: Choose fine-weave, clean cloth; rinse, wring, and lay flat for wrapping cheese curds

The foundation of any successful cheesecloth-wrapped cheese lies in the cloth itself. Opt for a fine-weave, 100% cotton cheesecloth. This tight weave ensures the curds are adequately supported while allowing whey to drain efficiently. Avoid coarse weaves, which can trap curds and hinder drainage, leading to uneven texture and potential spoilage.

Before use, cleanliness is paramount. Rinse the cheesecloth thoroughly under cold water to remove any dust, lint, or manufacturing residues. A quick soak in warm water with a mild, unscented detergent can further ensure hygiene, especially if the cloth is new. Wring out excess water gently—you want the cloth damp, not soaking wet. This moisture helps the cloth conform to the curds without sticking, facilitating even pressing and molding.

Lay the damp cheesecloth flat on a clean surface, smoothing out wrinkles and folds. This step is crucial for achieving a uniform wrap around the cheese curds. A flat, even cloth ensures consistent pressure during the pressing stage, which directly impacts the final cheese’s density and shape. Think of it as preparing a canvas for your cheese masterpiece—the better the preparation, the smoother the outcome.

For those new to cheesemaking, consider this practical tip: cut the cheesecloth slightly larger than needed. This extra material provides flexibility when wrapping irregular curd shapes and allows for secure tying without straining the cloth. Remember, the goal is to create a snug, protective envelope for the curds, not a tight straitjacket. Properly prepared cheesecloth is the unsung hero of the process, quietly ensuring your cheese develops the right texture and flavor.

Milwaukee's Cheese Legacy: Did a Factory Ever Call It Home?

You may want to see also

Draining Curds: Wrap curds tightly, place in mold, and apply weight to release whey

Tying cheesecloth around curds is a critical step in cheesemaking, acting as a bridge between loose curds and a consolidated cheese mass. This process isn't just about containment; it's about controlled drainage. By wrapping curds tightly, you create a uniform pressure that encourages whey expulsion, shaping the curds into a cohesive form. The cheesecloth acts as a filter, allowing whey to escape while retaining the curds, ensuring a firmer texture in the final product.

Think of it as a gentle squeeze, coaxing out excess moisture without damaging the delicate curd structure.

The mold you choose dictates the cheese's final shape and size. For softer cheeses like ricotta or paneer, a simple basket mold lined with cheesecloth suffices. Harder cheeses, like cheddar or gouda, require more robust molds, often made of food-grade plastic or stainless steel. Once the wrapped curds are nestled in the mold, the application of weight becomes crucial. This weight, often in the form of a heavy plate or dedicated cheese press, provides the necessary force to expel whey efficiently. The amount of weight depends on the cheese type; softer cheeses require less pressure, while harder cheeses demand more.

A good rule of thumb is to start with a weight equivalent to 5-10% of the curd mass and adjust as needed.

While the process seems straightforward, there are nuances to consider. Over-tightening the cheesecloth can restrict whey drainage, leading to a dense, rubbery texture. Conversely, too loose a wrap can result in uneven shaping and whey pockets within the cheese. Finding the right balance requires practice and observation. Pay attention to how the curds feel as you wrap them – they should be snug but not compressed.

Additionally, the duration of pressing varies depending on the cheese type and desired moisture content. Softer cheeses may only need a few hours, while harder cheeses can require days or even weeks of pressing.

This seemingly simple act of wrapping, molding, and weighing is a transformative stage in cheesemaking. It's where loose curds evolve into recognizable cheese forms, shedding excess whey and developing their unique textures. Mastering this technique empowers you to craft cheeses with varying degrees of firmness, from creamy spreads to crumbly delights. Remember, patience and attention to detail are key. Observe the curds, adjust the pressure, and let the magic of cheese transformation unfold.

Perfectly Crispy: Reheating Cheese Quesadilla in Air Fryer Tips

You may want to see also

Pressing Cheese: Adjust weight gradually over hours to compact curds into desired shape

The art of pressing cheese is a delicate balance of time, pressure, and patience. Unlike a quick squeeze, this process demands gradual weight adjustments over hours, allowing the curds to knit together into a cohesive, textured wheel. Imagine sculpting with moisture and milk solids – too much force, too soon, and you’ll expel vital whey, leaving a crumbly mess. Too little, and the curds remain loose, lacking the density and structure that define a good cheese.

Mastering this gradual approach is key to achieving the desired texture, from the crumbly bite of a fresh chevre to the firm slice of a cheddar.

Begin with a modest weight, roughly 5-10 pounds, distributed evenly across the wrapped curds. This initial press gently consolidates the curds, encouraging whey expulsion without crushing them. After 30 minutes, assess the progress. Is whey still draining freely? If so, increase the weight by 2-3 pounds, ensuring the pressure remains consistent across the entire surface. Repeat this incremental adjustment every 30-60 minutes, gradually ramping up to 20-30 pounds for harder cheeses like cheddar or Gruyère. Remember, this is a marathon, not a sprint. Rushing the process will only lead to a dense, rubbery texture, devoid of the nuanced crumb and flavor developed through slow, controlled pressing.

For softer cheeses like ricotta or paneer, a lighter touch is required. Aim for a final weight of 10-15 pounds, applied for a shorter duration, typically 1-2 hours.

The type of press used plays a crucial role in this process. A simple, homemade press constructed from two boards and a weight (bricks, canned goods, or even a heavy pot) can be surprisingly effective. For greater control, consider investing in a dedicated cheese press, which allows for precise weight adjustments and even pressure distribution. Regardless of the setup, ensure the pressing surface is clean and food-safe, and that the cheesecloth is securely wrapped around the curds to prevent them from escaping under pressure.

Patience is paramount. Resist the urge to peek constantly, as this can disrupt the delicate pressing process. Instead, focus on the steady drip of whey, a visual cue that the curds are consolidating. As the pressing progresses, the whey will slow to a trickle, and the cheese will firm up, taking on its intended shape. This transformation, from loose curds to a solid wheel, is a testament to the power of gradual pressure and the magic of cheesemaking.

Finally, remember that pressing is just one step in the cheesemaking journey. The duration and intensity of pressing will influence not only the texture but also the flavor and aging potential of the final product. Experimentation is key – adjust weights, timings, and techniques to discover the unique characteristics of each cheese variety. With practice and a keen eye for detail, you’ll master the art of pressing, crafting cheeses that are not only delicious but also a testament to your patience and skill.

Mastering the Art of Squeezing Easy Cheese: Simple Tips and Tricks

You may want to see also

Explore related products

Removing Cloth: Unwrap gently after pressing; ensure cheese holds shape without cloth residue

The moment of truth arrives when you must remove the cheesecloth, revealing the fruit of your labor. This delicate process demands precision and care to preserve the cheese's integrity. Imagine the disappointment of finding cloth fibers embedded in your carefully crafted cheese—a scenario easily avoided with the right technique. Unwrapping is not merely a final step but a critical phase that determines the cheese's presentation and texture.

The Art of Unwrapping: Begin by gently loosening the cheesecloth from the cheese's surface. Think of it as peeling back the layers of a precious gift, where haste can lead to damage. Start at one corner, slowly working your way around the cheese. If the cloth resists, refrain from tugging forcefully. Instead, consider the cheese's moisture level; a slightly drier surface might make the cloth more adherent. In such cases, a light mist of water can ease the process, but use this trick sparingly to avoid altering the cheese's texture.

A common mistake is rushing this step, leading to torn cheesecloth and a messy outcome. Take your time, especially with softer cheeses, as they are more prone to deformation. For harder varieties, a thin, flexible spatula can assist in gently prying the cloth away from the cheese's edges. The goal is to maintain the cheese's shape and structure, ensuring it stands proudly without any cloth remnants.

Mastering the Technique: Here's a step-by-step guide to ensure success:

- Prepare the Cheese: Before unwrapping, ensure the cheese is at room temperature. Cold cheese can become brittle, making it susceptible to cracking during the unwrapping process.

- Gently Does It: Begin unwrapping from the least adhered side, gradually working towards the more stubborn areas. This approach minimizes the risk of tearing the cheesecloth or damaging the cheese.

- Inspect and Adjust: As you unwrap, periodically check for any cloth fibers left on the cheese. If you spot any, carefully remove them with a clean pair of tweezers or a small brush.

- Final Touches: Once unwrapped, inspect the cheese's surface. If needed, use a clean, dry cloth to gently pat and smooth any minor imperfections, ensuring a flawless finish.

In the world of cheese making, the devil is in the details, and the unwrapping process is no exception. By approaching this step with patience and precision, you'll ensure your cheese not only tastes exceptional but also presents beautifully, free from any unwanted cloth residue. This technique is a testament to the craftsmanship involved in cheese making, where every step contributes to the final masterpiece.

Cheese and Gut Health: Boosting Your Microbiome with Fermented Dairy

You may want to see also

Storing Cheese: Air-dry, wrap in fresh cloth or wax paper, and refrigerate for aging

Proper storage is crucial for preserving the flavor, texture, and longevity of cheese, especially when using cheesecloth as part of the process. After air-drying the cheese to remove excess moisture, the next steps involve wrapping it in fresh cloth or wax paper before refrigerating for aging. This method balances humidity control and protection, allowing the cheese to mature gracefully. Air-drying prevents mold growth by minimizing surface moisture, while the breathable nature of cheesecloth or wax paper ensures the cheese doesn’t suffocate or become too dry.

When wrapping cheese in cheesecloth, ensure the cloth is clean and free of any residual odors. Gently enclose the cheese, avoiding tight knots that could restrict airflow. For wax paper, cut a piece large enough to fully cover the cheese, then secure it with a loose twist or a small piece of tape. Both materials allow the cheese to breathe, a critical factor for aging, as they permit the exchange of air while retaining enough moisture to prevent desiccation. This step is particularly vital for semi-hard and hard cheeses, which benefit from slow, controlled aging.

Refrigeration is the final, non-negotiable step in this process. Store the wrapped cheese in the coolest part of the refrigerator, ideally at 35–38°F (2–3°C), to slow bacterial activity while allowing enzymes to work. Place the cheese on a shelf rather than in a crisper drawer to maintain consistent airflow. For optimal aging, check the cheese weekly, rewrapping it in fresh cloth or paper if any moisture accumulates. This routine ensures the cheese develops its intended flavor profile without spoiling.

Comparing cheesecloth to wax paper reveals subtle differences in their effects on aging. Cheesecloth is ideal for cheeses that require more humidity, such as cheddar or gouda, as it allows slightly more moisture retention. Wax paper, on the other hand, is better suited for drier cheeses like parmesan, as it reduces moisture contact. Understanding these nuances helps tailor the storage method to the specific cheese type, maximizing its potential during the aging process.

In practice, this storage technique is both simple and effective, requiring minimal tools and effort. For home cheesemakers or enthusiasts, it offers a reliable way to age cheese without specialized equipment. The key takeaway is consistency: regular monitoring, proper wrapping, and stable refrigeration temperatures are essential. By mastering these steps, you can transform a fresh cheese into a complex, flavorful masterpiece, proving that sometimes, the simplest methods yield the best results.

Are Cheese Slices Buggy? Uncovering the Truth About Insects in Cheese

You may want to see also

Frequently asked questions

Securely wrap the cheesecloth around the curds, gathering the corners and edges together, and tie it tightly with kitchen twine or a rubber band to ensure it stays in place during draining.

Use 2-3 layers of cheesecloth to provide adequate strength and filtration while allowing whey to drain properly.

Yes, cheesecloth can be reused after washing it thoroughly with hot, soapy water and ensuring it’s fully dried before the next use.