Using a cheese wire is a simple yet effective method for achieving clean, precise cuts of cheese, especially for softer varieties like Brie or Camembert. To begin, ensure the cheese wire is taut and securely attached to its handles. Position the wire at the desired cutting point, then apply gentle, even pressure as you pull the wire through the cheese in a smooth, steady motion. Avoid sawing, as this can lead to uneven edges. For harder cheeses, a cheese wire may not be the best tool, and a knife or cheese plane might be more suitable. Always clean the wire after use to prevent bacterial growth and maintain its sharpness for future cuts.

| Characteristics | Values |

|---|---|

| Purpose | Cutting cheese into precise slices or portions |

| Tool | Cheese wire (a thin, flexible wire with handles) |

| Technique | 1. Place cheese on a stable surface. 2. Position wire at desired cutting point. 3. Pull wire through cheese with steady, even pressure. 4. Repeat for additional cuts. |

| Advantages | - Provides clean, straight cuts. - Minimizes crumbling compared to knives. - Ideal for soft to semi-hard cheeses. |

| Limitations | Not suitable for very hard or aged cheeses. Requires practice for consistent results. |

| Maintenance | Wipe wire clean after use. Store in a dry place to prevent rust. |

| Safety | Handle with care to avoid cuts. Ensure wire is taut during use. |

| Alternatives | Cheese knife, cheese slicer, or dental floss for softer cheeses. |

Explore related products

What You'll Learn

- Choosing the Right Cheese Wire: Select a sturdy, sharp wire for clean cuts

- Preparing Cheese for Cutting: Chill cheese to firm it up before slicing

- Proper Handling Techniques: Hold wire taut, apply even pressure for smooth cuts

- Cleaning and Maintenance: Wash wire after use, dry thoroughly to prevent rust

- Safety Tips: Avoid loose clothing, use a stable surface to prevent accidents

Choosing the Right Cheese Wire: Select a sturdy, sharp wire for clean cuts

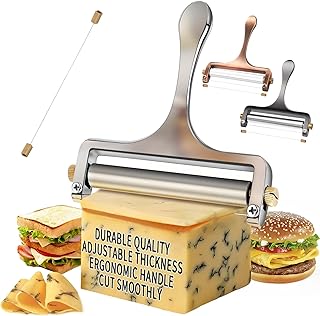

A cheese wire's effectiveness hinges on its material and tension. Stainless steel wires, for instance, resist rust and maintain sharpness longer than cheaper alternatives. When selecting a cheese wire, prioritize durability and edge retention. A flimsy wire will wobble and tear through cheese, leaving jagged edges. Conversely, a sturdy, sharp wire glides through with precision, ensuring clean, even slices every time.

Consider the cheese types you frequently cut. Softer cheeses like Brie or Camembert require a thinner, more flexible wire to avoid crushing. Harder cheeses like Parmesan or aged Gouda demand a thicker, stiffer wire to handle their density. Adjustable tension mechanisms in some cheese wires allow for customization, catering to various cheese textures. This adaptability ensures optimal performance across different varieties.

Proper maintenance extends a cheese wire's lifespan. After each use, hand-wash the wire with mild soap and warm water, avoiding abrasive sponges that could dull the edge. Dry thoroughly to prevent rust, especially in stainless steel models. Regularly inspect the wire for signs of wear or fraying, replacing it immediately if compromised. A well-maintained cheese wire remains sharp and reliable, delivering consistent results.

For those seeking precision, ergonomic handles make a significant difference. Non-slip grips provide control, reducing the risk of accidents during cutting. Some models feature weighted handles for added stability, minimizing hand fatigue during prolonged use. Investing in a cheese wire with these features not only enhances performance but also elevates the overall cheese-cutting experience.

In conclusion, choosing the right cheese wire involves balancing material quality, wire thickness, and ergonomic design. By selecting a sturdy, sharp wire tailored to your cheese preferences and maintaining it properly, you ensure clean cuts every time. This attention to detail transforms a simple kitchen tool into an indispensable asset for cheese enthusiasts.

Mastering Dukino's Mom: Easy Cheese Strategies for Quick Victory

You may want to see also

Preparing Cheese for Cutting: Chill cheese to firm it up before slicing

Chilling cheese before cutting is a simple yet transformative step that elevates the precision and ease of using a cheese wire. Soft to semi-hard cheeses, such as Brie, Camembert, or young Cheddar, benefit most from this technique. When cold, their texture firms up, reducing the likelihood of crumbling or tearing during slicing. Aim to chill the cheese in the refrigerator for at least 30 minutes, or until it feels slightly resistant to the touch. Avoid freezing, as this alters the cheese’s moisture content and flavor profile.

The science behind chilling is straightforward: cold temperatures slow molecular movement, making the cheese more stable. This is particularly crucial when using a cheese wire, which relies on even pressure to achieve clean cuts. Without proper firmness, the wire can drag or compress the cheese, resulting in uneven slices. For best results, wrap the cheese in wax paper or parchment before chilling to prevent it from drying out or absorbing refrigerator odors.

While chilling is essential for softer cheeses, harder varieties like Parmesan or aged Gouda require less attention to temperature. However, even these can benefit from a brief chill to minimize friction and ensure smoother cuts. The key is to strike a balance—firm enough for control, but not so cold that the cheese becomes brittle. A 15-minute chill is often sufficient for harder cheeses, allowing them to retain their natural texture while still cooperating with the wire.

Practical tip: If time is limited, a quick workaround is to place the cheese in the freezer for 10 minutes. This provides a similar firming effect without the risk of over-chilling. Always let the cheese sit at room temperature for a few minutes after cutting to restore its optimal flavor and texture. By mastering this preparatory step, you’ll find that using a cheese wire becomes a seamless, professional-grade experience.

Can Dogs Eat McDonald's Cheeseburgers? Vet-Approved Advice for Pet Owners

You may want to see also

Proper Handling Techniques: Hold wire taut, apply even pressure for smooth cuts

A cheese wire's effectiveness hinges on tension. Imagine slicing through a ripe Brie with a slack wire – it would tear, not cut, leaving a jagged mess. Holding the wire taut, like a guitar string ready to play a clear note, ensures a clean, precise slice. This tension distributes the cutting force evenly, preventing the wire from wobbling or snagging, which can lead to uneven cuts and wasted cheese.

Think of it as a surgeon's scalpel – precision requires a steady hand and a taut blade.

Achieving this tension is surprisingly simple. Most cheese wires feature handles with adjustable grips. Secure the wire firmly between the handles, ensuring no slack remains. Picture pulling a bowstring back before releasing an arrow – that's the level of tautness you're aiming for. This initial setup is crucial; a poorly tensioned wire will frustrate even the most skilled cheese enthusiast.

For softer cheeses like Camembert or fresh mozzarella, a slightly looser tension might be preferable to avoid crushing the delicate texture.

Now, the cut. Don't saw back and forth like a lumberjack. Apply steady, even pressure, guiding the wire through the cheese in one smooth motion. Think of it as drawing a straight line with a pen – slow, deliberate, and controlled. This technique minimizes friction, preventing the wire from heating up and sticking to the cheese, which can lead to uneven slices and a gummy texture.

The beauty of a properly handled cheese wire lies in its versatility. From crumbling aged cheddar to slicing through semi-hard Gruyère, the taut wire and even pressure technique ensures clean cuts every time. It's a simple principle, but one that elevates cheese presentation and enhances the overall tasting experience. Remember, a well-executed cut not only looks appealing but also allows the cheese's full flavor and texture to shine through.

Does Arby's Philly Cheesesteak Stack Up to the Original?

You may want to see also

Explore related products

$6.25 $6.95

Cleaning and Maintenance: Wash wire after use, dry thoroughly to prevent rust

A cheese wire's longevity hinges on proper care, and rust is its arch-nemesis. Think of it as a delicate yet durable tool – strong enough to slice through aged cheddar, but susceptible to corrosion if neglected. After each use, a simple yet crucial ritual is paramount: washing and thorough drying.

Residue from cheese, especially softer varieties, can trap moisture and accelerate rust formation. A quick rinse under warm water, followed by a gentle scrub with a soft brush or sponge, removes these remnants. Avoid harsh detergents or abrasive scrubbers, as they can damage the wire's finish.

The drying stage is equally vital. Air drying alone might not suffice, especially in humid environments. Pat the wire dry with a clean cloth, ensuring no water droplets remain. For added protection, consider a light coating of food-safe mineral oil. This creates a barrier against moisture, further safeguarding against rust.

Think of it as giving your cheese wire a spa treatment – a little pampering goes a long way in preserving its sharpness and longevity.

While the process seems straightforward, consistency is key. Neglecting this routine even once can lead to rust spots, compromising the wire's performance and potentially rendering it unusable. Remember, a well-maintained cheese wire is an investment in your cheese-cutting experience, ensuring clean, precise slices for years to come.

Cheese Rolling Wins: What Do Participants Actually Take Home?

You may want to see also

Safety Tips: Avoid loose clothing, use a stable surface to prevent accidents

Loose clothing can easily get caught in a cheese wire, turning a simple task into a dangerous one. Imagine a sleeve snagging mid-slice, pulling your hand toward the wire with unexpected force. To prevent this, opt for fitted attire or roll up sleeves and secure long hair. This small adjustment significantly reduces the risk of entanglement, ensuring your focus remains on the cheese, not your clothing.

A stable surface is the unsung hero of cheese wire safety. Cutting on a wobbly board or uneven countertop increases the likelihood of the wire slipping or the cheese shifting, leading to uneven slices or, worse, injury. Use a flat, non-slip cutting board or a sturdy countertop. For added stability, place a damp cloth underneath the board to keep it firmly in place. This simple setup transforms a precarious task into a controlled, efficient process.

Consider the ergonomics of your setup. Position the cheese so it’s within easy reach, reducing the need to stretch or lean, which can destabilize your grip. Hold the wire firmly with both hands, applying even pressure to avoid jerky movements that could cause the wire to snap or the cheese to topple. Smooth, deliberate motions not only yield cleaner slices but also minimize the risk of accidents.

Finally, always inspect your cheese wire before use. A frayed or damaged wire is an accident waiting to happen. If you notice any wear, replace it immediately. Pair this with the right clothing and a stable surface, and you’ve created a safe, efficient environment for slicing cheese. These precautions may seem minor, but they’re the difference between a seamless task and a trip to the first-aid kit.

Are Cheese Hot Pockets Vegetarian? Unraveling the Ingredients and Facts

You may want to see also

Frequently asked questions

A cheese wire is a thin, flexible wire with handles on both ends, designed to cut through cheese with precision. To use it, place the wire at the desired cutting point, pull the handles in opposite directions to slice through the cheese, and repeat for additional cuts.

Yes, a cheese wire can be used for hard cheeses, but it may require more effort. Ensure the wire is taut and apply steady pressure to achieve clean cuts.

Clean the cheese wire by wiping it with a damp cloth or washing it with warm, soapy water after each use. Dry it thoroughly to prevent rust, and store it in a dry place.

A cheese wire is ideal for soft to semi-hard cheeses as it provides clean, even cuts without squishing the cheese. Knives are better suited for harder cheeses or when more control is needed for shaping.