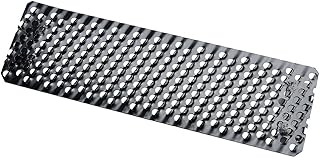

The question of whether a drywall rasp is the same as a cheese grater often arises due to their similar appearances and abrasive surfaces. While both tools feature rough, textured edges designed for material removal, their purposes and designs differ significantly. A drywall rasp is specifically engineered for shaping and smoothing drywall, offering a coarse surface ideal for working with rigid, fibrous materials. In contrast, a cheese grater is a kitchen utensil with finer, sharper edges optimized for breaking down soft, edible items like cheese or vegetables. Despite superficial similarities, their distinct functionalities and intended uses make them unsuitable for interchangeable applications.

| Characteristics | Values |

|---|---|

| Primary Use | Drywall rasp: Shaping and smoothing drywall; Cheese grater: Grating cheese and other foods |

| Material | Drywall rasp: Typically made of hardened steel; Cheese grater: Often made of stainless steel or aluminum |

| Blade Design | Drywall rasp: Coarse, sharp teeth for aggressive material removal; Cheese grater: Fine, sharp holes or blades for grating food |

| Handle | Drywall rasp: Ergonomic, often rubberized for grip during construction work; Cheese grater: May have a simple handle or none, designed for kitchen use |

| Size | Drywall rasp: Larger and bulkier for handling drywall; Cheese grater: Compact and lightweight for kitchen tasks |

| Safety | Drywall rasp: Designed for durability and safety in construction; Cheese grater: Focused on preventing food contamination and ease of cleaning |

| Versatility | Drywall rasp: Limited to construction tasks; Cheese grater: Can be used for various foods like cheese, vegetables, and chocolate |

| Maintenance | Drywall rasp: Requires occasional sharpening or replacement of worn teeth; Cheese grater: Needs regular cleaning to prevent food buildup |

| Cost | Drywall rasp: Generally more expensive due to specialized design; Cheese grater: Affordable and widely available |

| Environment | Drywall rasp: Used in construction settings; Cheese grater: Used in kitchens and culinary environments |

Explore related products

What You'll Learn

- Tool Design Differences: Drywall rasps have coarse teeth; cheese graters have finer, sharper edges for food

- Material Usage: Rasps shape drywall; graters shred cheese, reflecting distinct purposes and durability needs

- Safety Concerns: Drywall rasps may have sharper edges, posing risks if used for food

- Surface Impact: Rasps roughen surfaces; graters create fine shreds, showing functional contrasts

- Cleaning Challenges: Drywall residue clogs rasps; graters are easier to clean for food use

Tool Design Differences: Drywall rasps have coarse teeth; cheese graters have finer, sharper edges for food

Drywall rasps and cheese graters may appear similar at first glance, but their teeth tell a different story. The former boasts coarse, rugged teeth designed to aggressively remove material from drywall, smoothing rough edges and shaping surfaces. These teeth are spaced widely apart to prevent clogging from dust and debris, ensuring efficient work. In contrast, cheese graters feature finer, sharper edges that effortlessly slice through food items like cheese, vegetables, or citrus zest. This precision is crucial for culinary tasks, where consistency and texture matter.

Consider the materials these tools handle. Drywall is a dense, fibrous material that requires robust abrasion, hence the need for coarse teeth. Cheese, on the other hand, is softer and more delicate, demanding a gentler yet effective cutting mechanism. The finer edges of a cheese grater minimize waste and maintain the integrity of the food, while a drywall rasp’s aggressive design would shred cheese into unusable pieces. This fundamental difference in tooth structure highlights how each tool is optimized for its specific purpose.

For those looking to use these tools effectively, understanding their design is key. When working with drywall, apply moderate pressure and use long, even strokes to avoid over-sanding. Always wear a dust mask to protect against fine particles. With cheese graters, hold the tool firmly and use controlled, downward motions to achieve uniform shreds or slices. Clean the grater immediately after use to prevent food particles from hardening in the narrow spaces between the blades.

A practical tip for DIY enthusiasts: never substitute one tool for the other. Attempting to use a cheese grater on drywall will yield poor results and dull the grater’s edges, while a drywall rasp will ruin food and pose a hygiene risk. Investing in the right tool for the job not only ensures efficiency but also prolongs the lifespan of your equipment. This distinction in design is a testament to how small details in tool engineering cater to vastly different applications.

Cheese Making: How It Compares to Other Fermentation Processes

You may want to see also

Material Usage: Rasps shape drywall; graters shred cheese, reflecting distinct purposes and durability needs

A drywall rasp and a cheese grater, though superficially similar in their abrasive surfaces, serve fundamentally different purposes shaped by the materials they interact with. Drywall rasps are designed to shape and smooth gypsum-based drywall, a task requiring durability and precision. Their coarse, rugged teeth are engineered to withstand the abrasive nature of drywall without dulling quickly, ensuring longevity in demanding construction environments. Cheese graters, on the other hand, are crafted to shred softer, more pliable materials like cheese or vegetables. Their finer, sharper edges prioritize efficiency and ease of use in a kitchen setting, where durability is secondary to the ability to produce consistent, fine shreds.

Consider the material properties each tool must handle. Drywall is a dense, fibrous material that generates significant friction during shaping, necessitating a rasp made from hardened steel or carbide. This ensures the tool remains effective over repeated use, even when subjected to the coarse texture of drywall. Cheese, in contrast, is softer and less abrasive, allowing graters to be made from stainless steel or even plastic, materials that balance sharpness with affordability. The distinct material demands of drywall and cheese directly influence the design and composition of their respective tools, highlighting the importance of purpose-driven engineering.

From a practical standpoint, using a drywall rasp for grating cheese or a cheese grater for shaping drywall would yield unsatisfactory results. A drywall rasp’s coarse teeth would tear cheese unevenly, while a cheese grater’s fine edges would quickly dull or break when applied to drywall. This incompatibility underscores the specialized nature of each tool. For instance, a professional drywall installer might use a rasp with a 6-8 teeth-per-inch (TPI) rating for precise edge smoothing, whereas a home cook would opt for a grater with a 12-14 TPI for fine cheese shredding. Understanding these specifications ensures the right tool is used for the right task.

The durability requirements of rasps and graters further reflect their distinct purposes. Drywall rasps are often subjected to heavy use on construction sites, where they must resist wear and maintain sharpness over time. Cheese graters, while used frequently in kitchens, face less abrasive conditions and can be replaced more affordably if they dull or damage. This divergence in durability needs is evident in their construction: rasps are typically thicker and more robust, while graters prioritize lightweight design for ease of handling. By aligning material usage with intended function, both tools optimize performance in their respective domains.

In essence, the material usage of drywall rasps and cheese graters is a testament to the principle of form following function. Rasps are built to endure the rigors of shaping drywall, while graters are tailored to efficiently shred softer materials like cheese. Recognizing these distinctions not only ensures the right tool is used for the right job but also prolongs the life of each tool. Whether smoothing drywall edges or preparing ingredients for a recipe, understanding the purpose-driven design of these tools enhances both efficiency and effectiveness in any task.

Shredded vs Grated Cheese: Understanding the Key Differences

You may want to see also

Safety Concerns: Drywall rasps may have sharper edges, posing risks if used for food

Drywall rasps and cheese graters may appear similar at first glance, but their intended uses dictate vastly different designs, particularly in edge sharpness. While a cheese grater’s blades are sharp enough to cut through soft foods like cheese or vegetables, they are typically designed with safety in mind, featuring rounded edges or protective coatings to minimize injury during kitchen use. In contrast, drywall rasps are engineered for aggressive material removal, often featuring razor-sharp, jagged edges that can easily tear through drywall, wood, or plaster. This fundamental difference in sharpness makes drywall rasps inherently dangerous when repurposed for food preparation.

Consider the potential risks if a drywall rasp were used to grate cheese. The ultra-sharp edges, designed to shred tough construction materials, could easily introduce microscopic metal particles into the food. Ingesting these particles poses serious health risks, including gastrointestinal irritation or, in extreme cases, internal lacerations. Additionally, the rough surface of a drywall rasp is difficult to clean thoroughly, increasing the likelihood of bacterial contamination from trapped food particles. These hazards underscore the importance of using tools only for their intended purposes.

From a practical standpoint, the ergonomic design of drywall rasps further exacerbates their unsuitability for food preparation. Unlike cheese graters, which often feature handles or guards to protect hands from blades, drywall rasps are built for durability and force, not precision or safety. Their rigid, unforgiving structure increases the risk of accidental cuts or injuries during use, particularly when handling slippery food items. Even if one were to attempt using a drywall rasp for grating, the lack of control and safety features would make it a hazardous endeavor.

To mitigate these risks, it’s essential to adhere to tool-specific guidelines. For food preparation, always use kitchen-grade tools like cheese graters, microplanes, or box graters, which are designed with food safety and user protection in mind. If a drywall rasp is the only tool available, it’s safer to opt for pre-shredded cheese or alternative methods rather than risk contamination or injury. For those working in construction or DIY projects, store drywall rasps separately from kitchen utensils to avoid accidental misuse. Prioritizing tool specificity not only ensures efficiency but also safeguards health and well-being.

Cheese Steak Shop Steak Portions: Ounces Explained and Tips

You may want to see also

Explore related products

$27.32 $29.95

Surface Impact: Rasps roughen surfaces; graters create fine shreds, showing functional contrasts

A drywall rasp and a cheese grater may appear similar at first glance, but their surface impact reveals distinct functional contrasts. Rasps are designed to roughen surfaces, effectively removing material to create texture or smooth out imperfections. In contrast, graters are engineered to produce fine, uniform shreds, ideal for culinary applications. This fundamental difference in purpose dictates their design, material, and usage, making them specialized tools for specific tasks.

Consider the mechanics of each tool. A drywall rasp features coarse, sharp teeth arranged in a pattern that aggressively bites into surfaces like wood, drywall, or plaster. This action is intentional, as the goal is to alter the surface texture rapidly. On the other hand, a cheese grater’s teeth are finer and more closely spaced, often with different sides offering varying degrees of coarseness. This design allows for controlled shredding, ensuring consistency in the size and shape of the grated material, whether it’s cheese, vegetables, or citrus zest.

From a practical standpoint, using a rasp on cheese or a grater on drywall would yield unsatisfactory results. Attempting to grate cheese with a rasp would likely crush it rather than produce delicate shreds, while using a grater on drywall would be inefficient and ineffective for material removal. For instance, a drywall rasp can remove up to 1/16 inch of material in a single pass, whereas a grater’s fine teeth are incapable of such aggressive action. This highlights the importance of selecting the right tool for the task at hand.

To illustrate further, imagine preparing a dish requiring finely grated Parmesan. A cheese grater’s fine teeth ensure the cheese melts seamlessly into a sauce or tops a dish with elegance. Conversely, a drywall rasp, with its aggressive teeth, would turn the cheese into a crumbly mess, unsuitable for culinary use. Similarly, when smoothing drywall joints, a rasp’s coarse action levels high spots and blends seams, a task a grater could never accomplish efficiently.

In conclusion, while a drywall rasp and a cheese grater may share a superficial resemblance, their surface impact underscores their unique functions. Rasps excel at roughening and shaping surfaces, while graters specialize in creating fine, consistent shreds. Understanding these differences ensures optimal tool selection, whether in a kitchen or a workshop, maximizing efficiency and achieving desired results. Always match the tool to the task for the best outcome.

Decoding Cheese Expiration Dates: A Guide to Freshness and Safety

You may want to see also

Cleaning Challenges: Drywall residue clogs rasps; graters are easier to clean for food use

Drywall residue is the bane of any rasp used for construction. Unlike cheese, which leaves behind soft, water-soluble particles, drywall creates a fine, powdery dust that hardens into a stubborn paste when mixed with sweat or moisture. This residue clogs the rasp’s teeth, dulling its edge and making it less effective for shaping or smoothing surfaces. Over time, the buildup can render the tool nearly unusable, requiring aggressive cleaning or even replacement. In contrast, cheese graters primarily deal with organic matter that rinses away easily, leaving no long-term damage.

To clean a drywall rasp, start by knocking off excess dust with a hammer or hard object. Follow this by soaking the tool in a mixture of warm water and white vinegar (1:1 ratio) for 30 minutes to loosen the residue. Use a stiff-bristled brush or an old toothbrush to scrub between the teeth, ensuring all particles are removed. For stubborn clogs, a wire brush or dental pick can be effective, but be cautious not to damage the rasp’s surface. Finish by drying the tool thoroughly to prevent rust. This process is time-consuming and labor-intensive, unlike cleaning a cheese grater, which typically requires only a quick rinse under hot water and a swipe with a sponge.

The design of drywall rasps and cheese graters also contributes to their cleaning challenges. Rasps often have finer, more intricate teeth designed to catch and shape drywall, which makes them more prone to clogging. Cheese graters, on the other hand, have larger, more spaced-out holes or blades that allow food particles to pass through easily. Additionally, graters are often made with non-stick coatings or stainless steel, which resist buildup, while rasps are usually uncoated and more susceptible to residue adhesion. This fundamental difference in design explains why graters remain functional after minimal cleaning, while rasps demand meticulous maintenance.

For those tempted to use a cheese grater as a drywall rasp (or vice versa), reconsider. While both tools have abrasive surfaces, their intended uses dictate their durability and cleaning requirements. A cheese grater used on drywall will quickly become clogged and damaged, as its teeth are not designed for such abrasive material. Similarly, a drywall rasp used for food would be unhygienic due to the difficulty of removing drywall residue completely. Stick to the tool’s intended purpose to avoid frustration and ensure longevity. In the end, the cleaning challenges of drywall rasps highlight why they are not interchangeable with cheese graters—and why proper tool care is essential.

Creating the Perfect Environment for Aging Cheese: Tips and Tricks

You may want to see also

Frequently asked questions

No, a drywall rasp and a cheese grater are not the same. A drywall rasp is a coarse tool designed for shaping and smoothing drywall, while a cheese grater is a kitchen utensil used for shredding cheese or other foods.

While both tools have abrasive surfaces, a cheese grater is not suitable for drywall work. Its design and material are optimized for food, not construction, and it may not provide the necessary durability or precision for drywall tasks.

The materials can vary. Drywall rasps are typically made of durable metals like steel for heavy-duty use, while cheese graters are often made of stainless steel or plastic, prioritizing food safety and ease of cleaning.