Blue cheese is a unique variety of cheese with a strong smell and a crumbly texture. It is often blue-veined and made using a specific type of mould. But is it a heterogeneous mixture? A heterogeneous mixture is one in which the composition varies at different points, with ingredients not uniformly distributed. A salad dressing made with oil, vinegar, and blue cheese chunks is a good example of a heterogeneous mixture, as the ingredients can separate and vary in distribution. However, it is unclear whether blue cheese itself falls into this category. While it is made with a variety of ingredients, the process of making blue cheese involves fermentation and inoculation with specific bacteria, resulting in a product with a distinct flavour and texture.

Is Blue Cheese Heterogeneous?

| Characteristics | Values |

|---|---|

| Composition | Not uniform throughout |

| Distribution of Ingredients | Uneven |

| Visual Clarity | Different parts can be seen |

| Texture | Crumbly |

| Odor | Strong and pungent |

| Color | Changes with age |

| Mold | Can develop within days if not stored properly |

Explore related products

What You'll Learn

Blue cheese salad dressing is heterogeneous

Blue cheese salad dressing is a heterogeneous mixture. This is because the ingredients that make up the dressing—in this case, oil, vinegar, and blue cheese—do not have a uniform composition throughout the mixture. In other words, the ingredients are not evenly distributed. For example, one part of the dressing may contain a higher concentration of blue cheese, while another part may be richer in oil or vinegar.

The concept of heterogeneity and homogeneity is a fundamental one in chemistry. A mixture is considered homogeneous when it has a uniform composition throughout, meaning that every part of the mixture has the same taste and appearance. A simple example of a homogeneous mixture is a sports drink, where every sip tastes the same because the ingredients are uniformly mixed.

On the other hand, a heterogeneous mixture does not have a uniform composition and can vary from one part to another. Examples of heterogeneous mixtures include trail mix, where you can visually identify and pick out different nuts, chocolate pieces, and raisins, and vegetable soup, where each spoonful may contain different proportions of vegetables.

Blue cheese itself is created through a two-phase process of culturing suitable spore-rich inocula and fermentation. The first phase involves preparing a Penicillium roqueforti inoculum, which is then added to autoclaved, homogenized milk. Salt, sugar, or both are added to this mixture, which is then incubated for several days. The second phase involves additional fermentation and the addition of modified milk fat, which stimulates the release of free fatty acids essential for the rapid development of blue cheese's distinctive flavor.

Skinny Girl Salad Dressing: Blue Cheese Delight?

You may want to see also

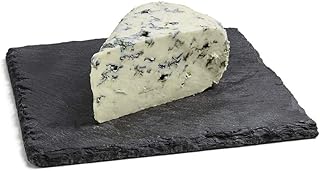

Blue cheese is blue-veined

Blue cheese is a type of cheese that is characterised by its blue veins and crumbly texture. The blue veins in this cheese are a result of the Penicillium roqueforti mould, which is added during the production process. This mould is first prepared as an inoculum, using a freeze-dried Penicillium roqueforti culture. This culture is then sprinkled on top of curds, which are moulded and drained to form the cheese loaves.

The process of making blue cheese is similar to that of other varieties of cheese, consisting of six standard steps. However, additional ingredients and processes are required to create the distinctive blue veins and flavour of blue cheese. One of the key steps in the production of blue cheese is the addition of the Penicillium roqueforti mould. This mould is responsible for the characteristic blue veins that run through the cheese.

The mould is added during the second phase of production, after the milk has been autoclaved, homogenised, and inoculated. The milk is then incubated for several days at a specific temperature range before more salt and/or sugar is added. This process is crucial in developing the unique flavour and texture of blue cheese.

The final step in the production of blue cheese is the ripening process, where the cheese is aged. This step is essential for the development of the blue cheese flavour, as freshly made blue cheese has little to no characteristic flavour. Typically, a fermentation period of 60 to 90 days is required for the cheese to develop its distinct taste and be acceptable for marketing.

In summary, blue cheese is a type of cheese that is distinguished by its blue veins, crumbly texture, and strong flavour. The blue veins are a result of the Penicillium roqueforti mould, which is added during the production process. The process of making blue cheese involves specific steps and ingredients to create its unique characteristics, making it a popular and distinct variety of cheese.

Clam Bellies and Blue Cheese: A Culinary Adventure

You may want to see also

Blue cheese is made with Penicillium Roqueforti

Blue cheese is a beloved delicacy for many, with its pungent aroma and crumbly texture. The unique flavour and colour of blue cheese are largely due to the Penicillium Roqueforti fungus. This fungus is a saprophyte, commonly found in nature, and isolated from soil or decaying organic matter.

Penicillium Roqueforti is a key component in the production of blue-veined cheeses. It is used as a fungal adjunct culture, or secondary starter culture, in the manufacture of blue-veined cheeses such as Roquefort, Gorgonzola, Cabrales, Stilton, and Danablu. The fungus contributes to the distinct flavour and colour of these cheeses. It is well-suited to the conditions of cheese-making, including low oxygen levels and temperatures.

The process of making blue cheese with Penicillium Roqueforti involves complex fermentation and maturation processes, primarily driven by lactic acid bacteria and fungi. This fungus is responsible for the ripening of the cheese, producing both proteolytic and lipolytic enzymes. The proteolytic enzymes soften the curd and create the desired body and texture in the cheese. Penicillium Roqueforti also produces volatile and non-volatile aroma compounds, with methylketones being the most abundant.

Additionally, blue cheese makers can cultivate their own Penicillium Roqueforti cultures at home. This traditional method involves growing blue mould spores by leaving a piece of sourdough bread with a pea-sized piece of ripe blue cheese in an airtight container for two weeks. Once the bread is consumed by the blue-green mould, it is dried and stored in an airtight jar. These spores can then be used to inoculate milk and begin the process of making blue cheese.

Blue Cheese's Unspoken Etiquette: A Guide to the Do's and Don'ts

You may want to see also

Explore related products

Blue cheese has a pungent odour

Blue cheese is known for its pungent odour, a characteristic feature resulting from the presence of mould cultures. This strong smell can be off-putting to some, but it is an indication of the cheese's unique flavour and maturity. The mould Penicillium roqueforti, for instance, is responsible for the distinct aroma and taste of Roquefort, one of the first blue cheeses, as well as other varieties.

The mould cultures used in blue cheese production are carefully cultivated to create the desired flavour profile. The process begins with the preparation of a Penicillium roqueforti inoculum, which can be achieved through various methods. This mould is naturally occurring, but commercial cheese producers typically use a freeze-dried culture to ensure consistency. The inoculum is then added to milk, along with salt and sugar, and incubated for several days to allow the mould to grow and develop flavour.

The pungent odour of blue cheese is a result of the metabolic activities of these mould cultures. During the ageing process, the mould breaks down the cheese's components, releasing volatile compounds that contribute to its distinctive smell. This process is similar to the ripening of other cheeses, where bacteria or moulds are used to develop flavour, but the types of compounds produced by blue cheese mould give it a sharper, more intense aroma.

Additionally, the crumbly texture and blue veins characteristic of blue cheese also influence its odour. The open texture allows for better air circulation, providing oxygen for the mould to grow and release aromatic compounds. The veins, formed by the mould's growth, not only contribute to the visual appeal but also enhance the overall aroma by providing pathways for the diffusion of these compounds throughout the cheese.

While the pungent odour of blue cheese may be polarising, it serves as a testament to the complex flavour development that occurs during production. The combination of specific mould cultures, ageing processes, and unique textures results in a cheese variety that is prized by many for its strong and distinctive characteristics. Proper storage in a refrigerator is essential to slow down mould growth and maintain the optimal flavour and aroma profile.

Blue Cheese Nightmares: Fact or Fiction?

You may want to see also

Blue cheese has a crumbly texture

Blue cheese is known for its distinctive blue veins, pungent odour, and crumbly texture. This texture is a result of the cheese's production process, which involves the culturing of suitable spore-rich inocula and fermentation to achieve maximum flavour. The first step in creating blue cheese is preparing an inoculum of Penicillium roqueforti, which is then sprinkled on top of curds along with Brevibacterium linens. The curds are then moulded into cheese loaves with a relatively open texture.

The unique texture of blue cheese is further developed through the process of whey drainage, which continues for 10 to 48 hours without the application of pressure. During this time, the moulds are inverted frequently to promote drainage. Salt is then added to enhance flavour and act as a preservative, preventing spoilage during the brine salting or dry salting process, which can last for up to 48 hours.

The final step in the production of blue cheese is ripening, which involves ageing the cheese. Initially, freshly made blue cheese has little to no characteristic flavour. It is only after a fermentation period of 60 to 90 days that the flavour becomes typical and acceptable for marketing. This ageing process contributes to the crumbly texture of blue cheese, as it allows for the development of the distinct blue veins and the maturation of the cheese's flavour and texture.

The crumbly texture of blue cheese is a defining characteristic that sets it apart from other types of cheese. This texture is a result of the combination of specific ingredients, careful culturing, and controlled fermentation processes. The ageing process further refines the texture, resulting in the unique characteristics of blue cheese that are beloved by many.

Blu Cheese and Keto: A Match Made in Heaven?

You may want to see also

Frequently asked questions

Yes, blue cheese is a heterogeneous mixture. This is because it is not a uniform composition, and its ingredients are not evenly distributed.

A heterogeneous mixture is when the composition varies at different points. This is because the ingredients are not evenly distributed.

A salad dressing made with oil, vinegar, and blue cheese chunks is a heterogeneous mixture. This is because the ingredients are not evenly mixed, and the composition varies from one part to another.

Blue cheese is a type of cheese that is often blue-veined and has a crumbly texture. It is made with the addition of Penicillium roqueforti, a type of mould.

Blue cheese is made by first preparing a Penicillium roqueforti inoculum. Salt, sugar, or both are then added to autoclaved, homogenized milk. This mixture is then inoculated with Penicillium roqueforti and incubated for three to four days.