Blue cheese is a generic term for cheese made with cultures of edible moulds, which create blue-green spots or veins throughout the cheese. It is typically made from pasteurized cow's, sheep's, or goat's milk. Blue cheese is believed to have been discovered by accident when cheeses were stored in caves with naturally controlled temperature and moisture levels, creating an environment favourable to the growth of harmless mould. The process of making blue cheese consists of six standard steps, with additional ingredients and processes required to give it its distinctive properties. Processed cheese, on the other hand, is a product made from a blend of natural cheeses, typically Colby and Cheddar, mixed with other ingredients such as vegetable oils, unfermented dairy, salt, food colouring, or sugar. It was first developed in Switzerland in 1911 by adding sodium citrate to melted Emmentaler cheese. So, is blue cheese a processed cheese?

Explore related products

What You'll Learn

- Blue cheese is made with the addition of cultures of edible moulds, which create blue-green spots or veins

- Blue cheese is ripened with cultures of the mould Penicillium roqueforti

- Blue cheese is made from pasteurized cow's, sheep's, or goat's milk

- Blue cheese is often relatively low in fat but has a high sodium content

- Blue cheese is believed to have been discovered by accident when cheeses were stored in caves with naturally controlled temperature and moisture levels

Blue cheese is made with the addition of cultures of edible moulds, which create blue-green spots or veins

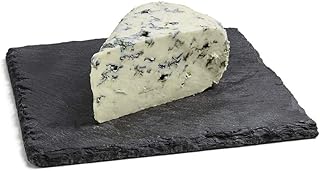

Blue cheese is ripened with cultures of edible mould called Penicillium roqueforti. This mould is responsible for the distinct taste, smell, and appearance of blue cheese. The mould is added after the curds have been drained and formed into wheels or loaves. The curds are then punctured to create small openings for air to penetrate and support the growth of the mould, resulting in the formation of blue-green spots or veins.

The process of making blue cheese is similar to that of other cheeses, but with additional ingredients and processes to create its unique characteristics. Firstly, the Penicillium roqueforti inoculum is prepared. This involves washing the mould from pure culture agar plates and then freeze-drying it. Salt, sugar, or both are then added to homogenized milk via a sterile solution. This mixture is then inoculated with the mould and incubated for three to four days at 21–25 °C (70–77 °F). More salt and/or sugar is added, and aerobic incubation is continued for another one to two days.

The curds are then ladled into containers to drain and form into wheels or loaves. At this stage, the Penicillium roqueforti inoculum is sprinkled on top of the curds, along with Brevibacterium linens, which contributes to the distinctive smell of blue cheese. The curds are then knit in moulds to form loaves with an open texture. Whey drainage is continued for 10–48 hours without applying pressure, but the moulds are inverted frequently.

Salt is added to the cheese to enhance flavour and act as a preservative. This process, known as brine salting or dry salting, takes 24–48 hours. Finally, the cheese is ripened and aged. The temperature and humidity of the ageing room are carefully monitored to ensure optimal flavour and texture development. The ripening process takes around 60–90 days for the cheese to develop its typical flavour and aroma. During this time, the Penicillium roqueforti mould grows and creates the blue-green veins or spots characteristic of blue cheese.

Blue Cheese: Friend or Foe of Testosterone?

You may want to see also

Blue cheese is ripened with cultures of the mould Penicillium roqueforti

The mould Penicillium roqueforti plays a critical role in the production of interior mould-ripened blue cheeses such as Gorgonzola, Roquefort, and Stilton. The growth of the fungus results in the development of flavour and texture through its enzymatic activity. The fungus also produces volatile and non-volatile flavour components and changes the texture of the cheese due to its metabolic action.

To make blue cheese, a Penicillium roqueforti inoculum is prepared and sprinkled on top of the curds, along with Brevibacterium linens. The curds are then knit in moulds to form cheese loaves with an open texture. Whey drainage is continued for 10-48 hours without applying pressure, and the moulds are frequently inverted to promote this process. Salt is added to enhance flavour and act as a preservative through brine salting or dry salting for 24-48 hours.

During the ripening process, the temperature and humidity of the room are carefully monitored to ensure the cheese does not spoil and maintains its optimal flavour and texture. The ripening temperature is typically around 8-10°C with a relative humidity of 85-95%. The cheese loaves are also punctured to create small openings for air to penetrate, encouraging the growth of the aerobic Penicillium roqueforti cultures and the formation of blue veins.

The distinctive flavour and aroma of blue cheese are a result of methyl ketones, which are metabolic products of Penicillium roqueforti. This process of ripening with mould cultures transforms the cheese, giving it its characteristic blue-green veins, flavour, and texture.

Removing Blue Cheese Stains from Clothes: Effective Methods

You may want to see also

Blue cheese is made from pasteurized cow's, sheep's, or goat's milk

One of the oldest known blue cheeses is Gorgonzola, which is said to have been created around AD 879. Other well-known varieties include Stilton, which became popular in the early 1700s, and Roquefort, a French sheep milk blue cheese from southern France. The legend of Roquefort's discovery involves a youth who, distracted by a beautiful girl, left his ewes' milk cheese in a nearby cave, only to return a few months later and find it transformed by mold (Penicillium roqueforti) into the distinctive blue cheese.

To make blue cheese, the milk is typically combined with a Penicillium roqueforti inoculum, which can be prepared through freeze-drying or purchased commercially. Salt, sugar, or both are added to the milk, which is then inoculated with the Penicillium roqueforti culture. This mixture is incubated for several days at a controlled temperature before being mixed with curds and allowed to drain and form into a wheel of cheese. The cheese is then salted and aged, with the temperature and humidity carefully monitored to ensure optimal flavor and texture development.

The unique flavor and aroma of blue cheese are due to the presence of methyl ketones, which are metabolic products of the Penicillium roqueforti culture. The aging process, typically lasting 60-90 days, is crucial for the development of the characteristic blue cheese flavor. During this time, the cheese loaves are punctured to create openings for air penetration, promoting the growth of the Penicillium roqueforti cultures and the formation of blue veins.

Blue Cheese: Delicious or Disgusting?

You may want to see also

Explore related products

Blue cheese is often relatively low in fat but has a high sodium content

Blue cheese is a generic term for cheese produced with pasteurized cow's, sheep's, or goat's milk and ripened with cultures of the mold penicillium. It is often relatively low in fat but has a high sodium content.

Blue cheese is made by first pasteurizing raw milk. Then, a starter culture is added to convert lactose to lactic acid, changing the milk from liquid to solid. Rennet is added to help coagulate the milk, and the curds are cut to release the whey. In the first phase of production, a Penicillium roqueforti inoculum is prepared. After the curds have been ladled into containers to be drained and formed into a full wheel of cheese, the Penicillium roqueforti inoculum is sprinkled on top of the curds along with Brevibacterium linens. The curds are then knit into molds to form cheese loaves with a relatively open texture. Whey drainage continues for 10–48 hours with no pressure applied, but the molds are inverted frequently to promote this process.

Salt is then added to provide flavor and act as a preservative so that the cheese does not spoil. This process of brine salting or dry salting lasts for 24–48 hours. The final step is ripening the cheese by aging it. When the cheese is freshly made, there is little to no blue cheese flavor development. Usually, a fermentation period of 60–90 days is needed before the flavor of the cheese is typical and acceptable for marketing. During this ripening period, the temperature and humidity in the room are monitored to ensure the cheese does not spoil or lose its optimal flavor and texture. The ripening temperature is generally around eight to ten degrees Celsius with a relative humidity of 85–95%. At the beginning of this process, the cheese loaves are punctured to create small openings to allow air to penetrate and support the growth of the Penicillium roqueforti cultures, thus encouraging the formation of blue veins.

Blue cheese is a good source of protein, calcium, and phosphorous. It is also high in calcium, a nutrient necessary for optimal bone health. However, because blue cheese is high in sodium, it may not be suitable for those on a low-sodium diet.

Blue Cheese: A Dog Owner's Concern?

You may want to see also

Blue cheese is believed to have been discovered by accident when cheeses were stored in caves with naturally controlled temperature and moisture levels

Blue cheese is ripened with cultures of the mould Penicillium. It is a generic term used to describe cheese produced with pasteurised cow's, sheep's, or goat's milk. The mould used in blue cheese is not the same as the one that can spoil other foods. Penicillium roqueforti, the mould in blue cheese, helps inhibit the growth of harmful bacteria and contributes to the unique flavour and texture of the cheese.

Blue cheese is made by first curdling the milk using rennet or other coagulating agents, then cutting the curds and separating them from the whey. The curds are then ladled into containers to be drained and formed into a full wheel of cheese. At this point, the mould is added, and the curds are knit into moulds to form cheese loaves with a relatively open texture. Whey drainage continues for 10–48 hours, with no pressure applied, and the moulds are inverted frequently to promote this process.

Salt is then added to the cheese as a preservative, and the cheese is brine salted or dry salted for 24–48 hours. The final step is ripening the cheese by ageing it. The temperature and humidity of the room are monitored to ensure the cheese does not spoil or lose its optimal flavour and texture. The ripening temperature is usually around eight to ten degrees Celsius, with a relative humidity of 85–95%. The cheese loaves are also punctured to create small openings to allow air to penetrate and support the growth of the mould.

McDonald's and Blue Cheese: A Surprising Combination

You may want to see also

Frequently asked questions

Blue cheese is a generic term for cheese produced with pasteurized cow's, sheep's, or goat's milk and ripened with cultures of the mold Penicillium. It has a salty, sharp flavor and a pungent aroma.

Blue cheese is made by adding a Penicillium roqueforti inoculum to curds and draining them into containers to be formed into a full wheel of cheese. Salt is then added for flavor and as a preservative. The final step is ripening the cheese by aging it for 2-3 months.

Processed cheese is a product made from a blend of natural cheeses, most often Colby and cheddar, mixed with other ingredients. It was first developed in Switzerland in 1911 by Walter Gerber and Fritz Stettler, who were seeking a cheese with a longer shelf life.

Yes, blue cheese is a type of processed cheese. Other examples of processed cheese include Brie, Camembert, Brick, Muenster, Stilton, Mozzarella, Swiss, Parmesan, and Gorgonzola.

Blue cheese is a good source of protein, calcium, and phosphorous.