Cheese is a dairy product made from milk. The process of making cheese involves turning milk into a solid by removing water and acidifying the milk. This is done by separating the milk into curds (solids) and whey (liquid). The amount of water removed determines the dryness and hardness of the cheese, with drier cheeses lasting longer. To make cheese, milk is heated gently and cultures (or 'starter cultures') and rennet are added. The cultures are lactic-acid-forming bacteria that turn lactose (milk's natural sugar) into lactic acid, causing the milk to curdle. Rennet is an enzyme that helps coagulate the milk and form curds. While cheese is primarily made by curdling milk, the process of thickening milk is used in cooking to create a variety of dishes, including sauces, soups, and desserts.

Is cheese made by thickening milk?

| Characteristics | Values |

|---|---|

| Thickening milk | Can be done by reducing it over low heat to cause the water content to evaporate |

| Cheese-making process | Milk is separated into solid curds and liquid whey |

| Curds | The solids that are separated from the whey |

| Whey | The liquid that is separated from the curds |

| Starter cultures | Bacteria that are added to the milk to convert lactose into lactic acid |

| Rennet | An enzyme that helps coagulate the milk |

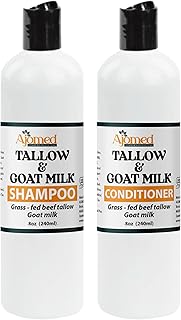

Explore related products

$8.8 $15.99

What You'll Learn

Milk is thickened by removing water content and acidifying it

Milk is composed of about 87% water. Thickening milk is the first step in making cheese. The process involves removing some of the water content and acidifying the milk. The amount of water removed determines how long the cheese will last. Harder cheeses, for example, are drier and therefore keep fresh longer.

To start the cheese-making process, milk is gently heated, and then cultures, or "starter cultures", are added. These cultures are lactic-acid-forming bacteria that convert lactose (milk's natural sugar) into lactic acid. This chemical change causes the milk to curdle. An enzyme called rennet is also added to assist with this process. Rennet joins up the proteins in the milk, allowing it to coagulate and form a firm, jelly-like substance called curd.

Once the curd is set, it is cut into small pieces, allowing the release of more whey (mainly water) from the solid curd. The smaller the curd pieces, the drier the curd becomes, and the harder the final cheese will be. The curd and whey can be further heated to encourage more separation, and the curds are then stacked and allowed to settle so that the whey can be fully drained off.

After the whey is removed, the curd is broken up, and salt is often added for flavour, preservation, and to inhibit the growth of certain bacteria. The curd is then placed into moulds and pressed to form a homogeneous texture in the final cheese. The cheeses are then removed from the moulds and taken to a cool, humid store to mature, resulting in a vast range of cheese types depending on the specific conditions used during the process.

Swiss Cheese Holes: Worm-Made or Not?

You may want to see also

Rennet, an enzyme, helps coagulate milk into a curd

The process of converting liquid milk into a solid mass or "curd" is called coagulation. Coagulation can occur in a few different ways, including enzyme action, acid addition, or a combination of acid and heat. Rennet, a complex set of enzymes, is one of the most important tools in making cheese. It is produced in the stomachs of ruminant mammals and contains chymosin, a protease enzyme that curdles the casein in milk.

Rennet enzymes act like a razor, shaving off the κ-casein hairs. Without these hairs, the micelles can stick together, aggregate, and form the basic structure of cheese. Rennet joins up the proteins in the milk, allowing it to fully coagulate and form a firm, jelly-like substance called curd. The amount of rennet added, the speed of the set, and the level of acidity all determine the style of cheese created.

The curd is then cut into small pieces, releasing whey (mainly water) from the solid curd. The smaller the curd pieces, the drier the final cheese. The curds and whey can be heated to encourage further separation, after which the whey is fully drained off. Salt is often added to the curd for flavour and as a preservative. The curd is then placed into moulds and pressed to form a homogeneous texture.

The coagulation process can also be achieved through acid and heat, as seen in ricotta, mascarpone, and paneer. Acid coagulation results in softer cheeses, as the acid dissolves the calcium "glue" between the casein micelles. Rennet coagulation, on the other hand, refers to the addition of enzymes to make the milk clot and is used in cheeses like cheddar, gouda, and queso fresco.

Bread Cheese: A Simple, Delicious Dairy Delight

You may want to see also

Starter cultures are added to determine flavour and texture

Starter cultures are essential in the process of transforming milk into cheese. They are a group of specific bacteria strains put together to make a specific type of cheese. Starter cultures are added to milk to ferment the lactose (milk's natural sugar) into lactic acid, which raises the acidity of the milk and causes it to curdle and split into curds and whey. Curds are the solid particles that are a crucial ingredient in the production of cheese.

The type of bacteria strains and the ratio of each strain in a cheese culture vary depending on the desired cheese outcome. Different combinations and ratios of bacteria yield different cheeses. For example, Swiss cheese uses one type of culture, while Brie and Blue use others. The texture of the cheese also determines the type of culture needed. For instance, hard cheeses like Swiss cheese, Parmesan, and other hard cheeses typically require a thermophilic starter culture because of their high heat resistance.

The use of starter cultures in cheese-making has been carried out for hundreds of years. In recent times, technicians have become adept at selecting and breeding certain strains, creating blends of bacteria designed to acidify milk and give different flavours. Mesophiles, which are used to make most cheeses, perform best at temperatures between 20-30°C. Thermophiles, which are used to make continental cheeses that are supple and sweeter in flavour (e.g. Gruyère, Comté), work best at hotter temperatures, between 45-50°C.

The starter cultures also aid in the development and preservation of the cheese's flavour and texture during the cheese-making process and the subsequent ageing process. The good bacteria in the starter cultures help prevent the growth of bad bacteria, which can spoil the cheese and shorten its shelf life. This is why cheese generally has a longer shelf life than milk.

River Rat Cheese: A Local Delicacy from the Netherlands

You may want to see also

Explore related products

$17.84 $29.99

Salt is added for flavour and to preserve the cheese

The process of making cheese involves turning milk into a solid by removing water and acidifying the milk. Once the curds and whey have been separated, salt is often added to the curds. Salt is added to cheese for flavour and preservation.

Salt is essential to the cheesemaking process. It is added to the cheese at a very early stage – either by adding it into the dry curd mass before it is moulded or by applying it to the outside of the cheese once it has been moulded. Salt is added to cheese to obtain the required flavour and texture, for its preservative properties, and as a taste enhancer. It also helps to control the bacteria that grow inside the cheese, aids texture development, regulates moisture, and helps preserve the cheese as it ages.

Salt contributes to the texture of the final cheese because it affects how the fats and proteins break down within the cheese as it ages. It also enables cheesemakers to encourage certain moulds to dominate. Blue mould, for example, can be encouraged to grow and dominate other moulds by the addition of salt.

Salt also acts as a natural preservative. When ageing cheese, it is important that the moisture within the cheese is ‘bound’ to salt. Salt will help preserve the cheese by preventing spoilage and preventing pathogenic bacteria from growing. This is why cheeses like Feta can be stored unrefrigerated, and other very dry cheeses like Parmesan could technically last forever.

However, salt usage has been opposed by the public and governmental bodies, who have been advised by health authorities that salt should be reduced or avoided in cheese for a healthier diet. Several consumers avoid cheese with high salt content, mainly due to health problems such as hypertension, cardiovascular disease, stroke, and heart attacks.

The Real Ingredients of Nacho Cheese Doritos

You may want to see also

Pressing the curd gives the cheese its final texture

The process of making cheese involves several steps, and pressing the curd is one of the final steps in creating the desired texture. This step is crucial in determining the final texture and quality of the cheese.

Cheese is made by first collecting milk from dairy farms and bringing it to a cheese plant for processing. The milk is then pasteurized to eliminate harmful bacteria and standardized by adding fat, cream, or protein to ensure consistency in cheese production. After pasteurization, "starter cultures" of good bacteria are added to the milk to initiate the process of fermentation, which helps determine the cheese's flavor and texture. Different types of cultures yield different types of cheese.

The addition of rennet, an enzyme, is a critical step as it causes the milk to coagulate and form curds (solids) and whey (liquid). The curds are then cut into small pieces to release more whey, and the smaller the curds, the drier the final cheese will be. The curds and whey are heated to separate them further, and this mixture is cooked to release the whey from the curd.

The pressing of the curd is the final step in creating the desired texture of the cheese. The curds are pressed together, forming a homogeneous texture and removing any remaining whey. The pressing process can last for several days, and the length of pressing time impacts the final texture of the cheese. After pressing, the cheeses are removed from their moulds and taken to a cool, humid store to mature for an extended period.

The process of pressing the curd is a delicate step in cheesemaking, as it is essential in determining the final texture and quality of the cheese. By pressing the curds together, the cheese maker can control the moisture content and create a uniform texture. The length of pressing time and the amount of pressure applied can be adjusted to create a vast range of cheese types, from soft and moist to hard and dry.

The Art of Cheese Flavoring: A Tasty Science

You may want to see also

Frequently asked questions

Cheese is made by turning milk into a solid by removing water and acidifying the milk. This is done by separating the milk into curds (solids) and whey (liquid).

To set the milk into curd, it is gently heated, and then cultures (called ‘starter cultures’) and rennet are added. The cultures added are lactic-acid-forming bacteria that change the lactose (sugar) in milk into lactic acid, causing the milk to curdle. Rennet is an enzyme that joins up the proteins in the milk to allow the milk to coagulate and form the curd (a firm jelly-like substance).

Once the curd is set, it is cut into small pieces, allowing more whey to be released. The smaller the cut pieces, the more whey is released, and the drier the final cheese. The curds and whey can also be heated, and the curd stacked to encourage further separation.

After the curds and whey are fully separated, the curd is broken up, salt is often added, and the cut curd is placed into moulds. The curd is then pressed to push and squash the particles together, forming a homogeneous texture in the final cheese, and removing the last bits of whey.

After pressing, the cheeses are removed from the moulds, cloth-bound, and taken to a cool, humid store to mature. By altering the amount of rennet, the speed of the set, and the nature of acidification, different styles of cheese can be created.

![Artisan Cheese Making at Home: Techniques & Recipes for Mastering World-Class Cheeses [A Cookbook]](https://m.media-amazon.com/images/I/81eH1+cYeZL._AC_UY218_.jpg)