Cheese is a dairy product made primarily from milk. The process of making cheese involves heating milk and adding a coagulant to separate the milk into solid curds and liquid whey. The type of milk used in cheesemaking can vary, with cow's milk being the most common due to its wide availability and optimal fat and protein content. Other types of milk used include sheep's milk, goat's milk, and buffalo milk, each contributing distinct flavours and textures to the final product. The process of cheesemaking also involves adding starter cultures, which contain bacteria that aid in fermentation and flavour development. The addition of salt helps preserve the cheese and enhances its flavour. The specific steps and ingredients used in cheesemaking vary globally, resulting in a diverse range of cheeses with unique characteristics.

| Characteristics | Values |

|---|---|

| Main Ingredient | Milk |

| Other Ingredients | Cultures, coagulants, salt, spices, herbs, wine |

| Milk Type | Cow's milk, sheep's milk, goat's milk, buffalo milk, camel's milk, horse milk, yak's milk |

| Milk Composition | 80-90% water, fat, protein, sugar, minerals |

| Pasteurization | Heat-treated or "pasteurized" to kill pathogens |

| Coagulant | Rennet, an enzyme complex |

| Rennet | Replicates rennin, an enzyme produced in the stomachs of calves and other mammals to digest milk |

| Starter Culture | Contains living bacteria that convert lactose sugar in milk into lactic acid |

| Bacteria Types | Mesophiles, thermophiles, lactic acid bacteria, secondary cultures |

| Curds | Solid clumps of milk |

| Whey | Liquid separated from curds |

| Salt | Enhances flavour, regulates moisture, preserves cheese, controls bacteria growth |

| Ripening/Aging | Affects flavour, texture, and preservation |

Explore related products

What You'll Learn

Milk types: cow, sheep, goat, buffalo, camel, horse, yak

Cheese is made from milk, and different types of milk produce different flavours and textures of cheese. Here are some of the milk types used in cheese-making and the characteristics of the cheese produced:

Cow Milk Cheese

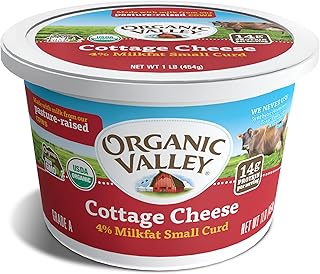

Cow milk is commonly used in cheese-making. It contains about 3.25% fat. Cow milk cheeses tend to be more piquant and animal-flavoured than goat milk cheeses. Examples of cow milk cheeses include:

- Cheddar

- Mozzarella

- Cottage cheese

- Cream cheese

- Manchego

- Gouda

Sheep Milk Cheese

Sheep milk contains more fat, solids, and minerals than cow milk, making it ideal for the cheese-making process. It also has a higher calcium content, which helps resist contamination during cooling. Sheep milk cheese typically takes longer to ripen, ranging from two weeks to two years. Examples of sheep milk cheeses include:

- Feta

- Roquefort

- Manchego

- Pecorino Romano

- Ricotta

- Halloumi

Goat Milk Cheese

Goat milk is similar to cow milk in overall fat content, with goat milk containing slightly more fat at 3.5%. However, goat milk contains more fatty acids, giving it a characteristic tart flavour. Goat milk cheeses tend to become more approachable with age, developing buttery and mellow flavours. Examples of goat milk cheeses include:

- Chèvre

- Bûcheron

- Caprino

- Crottin de Chavignol

- Feta

- Montrachet

Buffalo Milk Cheese

Buffalo milk is one of the rarest types of milk used in cheese-making. It has an extremely high fat content of almost 10%, making it ideal for semi-soft and soft cheeses. Examples of buffalo milk cheeses include:

- Burrata di Bufala

- Caciotta

- Casatica

- Dangke

- Stracciatella di Bufala

- Surti paneer

Other Milk Types

In addition to the above, there are a few other types of milk that are used to make cheese, although they are less common. These include:

- Horse milk: Horse milk cheese has a unique, slightly flowery taste similar to semi-hard cheese.

- Camel milk: Camel milk is used in some parts of the world, such as the Middle East, to make soft, white, salty cheese.

- Yak milk: Although limited information is available, yak milk is used in some regions, such as Nepal and Tibet, to make traditional cheese.

Belgioioso Cheese: A Taste of Italy Made in America

You may want to see also

Milk preparation: pasteurisation, skimming, warming

Milk is the star ingredient in cheese. The type of milk used varies, with cow's milk being the most common due to its wide availability and optimal fat and protein content. Sheep's milk, goat's milk, and buffalo milk are also used to make cheese, with each type of milk lending a distinctive flavour to the final product. Even more obscure types of milk, such as camel's, horse's, or yak's milk, are used to make regional specialty cheeses.

Before milk can be used to make cheese, it often undergoes a process of pasteurisation. Pasteurisation is a technique that heats milk to a high temperature for a short period to destroy any harmful bacteria and microorganisms, extending its shelf life. The most common method of pasteurisation is High Temperature Short Time (HTST), which heats milk to at least 72°C for at least 15 seconds, followed by rapid cooling. Another method is Low Temperature Long Time (LTLT), which is recommended for cheesemaking as it heats milk to 63°C for 30 minutes, reducing the risk of accidental overheating.

Skimming is another step in milk preparation. Skimming involves removing some or all of the cream from the milk to make reduced-fat, low-fat, or skim milk. This process helps standardise the composition of milk and make it consistent across different seasons and breeds of cows. Skim milk solids can be added back to improve taste, texture, and increase nutrients like protein and calcium.

Warming milk is an important step in the cheese-making process. During warming, milk is typically heated to around 30°C to facilitate the addition of starter cultures and coagulants. Starter cultures are added to introduce bacteria that aid in the transformation of milk to cheese. The bacteria feed on the lactose sugar in milk, producing lactic acid, which helps with curdling, preservation, and flavour development. Coagulants, such as rennet, are also added during this stage to help the milk thicken and separate into curds and whey.

Dragon Cheese: Where is This Mythical Treat Made?

You may want to see also

Coagulation: rennet, acids, starter cultures

Milk is the primary ingredient in cheese. However, it needs to undergo a transformation to become cheese. This process involves coagulation, which is the separation of milk into solid curds and liquid whey. There are different methods of coagulation, including the use of rennet, acids, and starter cultures.

Rennet is an enzyme complex that causes the milk to coagulate and thicken, separating it into curds and whey. Rennet is traditionally sourced from rennin, an enzyme produced in the stomachs of calves and other mammals to help them digest milk. Today, rennet is often genetically engineered through microbial bioprocessing. When rennet is added to milk, it forms a strong and rubbery gel. The curds are then separated from the whey through cutting, stirring, heating, and draining.

Acids, such as vinegar, can also be used for coagulation in certain types of cheese like paneer and queso fresco. However, this method produces more fragile curds compared to rennet.

Starter cultures play a crucial role in the coagulation process by initiating the fermentation of lactose (milk sugars) into lactic acid, thereby lowering the pH of the milk. These cultures contain living bacteria, with the most common types being mesophiles and thermophiles. Mesophilic cultures are best suited for most cheeses as they thrive at lower to moderate temperatures. On the other hand, thermophilic starter bacteria, such as Lactobacilli or Streptococci, are used in hard cheeses that require higher temperatures, altering the taste and affecting the bacterial culture and milk chemistry.

The type of coagulation method, the amount of time the culture is left to acidify the milk, and the size of the resulting curds all contribute to the distinctive characteristics of different cheeses.

The Story Behind Alpine Lace Cheese: A Tasty Tour

You may want to see also

Explore related products

Curds and whey: separation, cutting, heating, draining

Cheese is indeed made from milk! The process of making cheese involves several steps, including curdling, cutting, heating, and draining the curds and whey.

Separation

The first step in cheese production is coagulation, or curdling, which occurs when milk is mixed with an acid like lemon juice or vinegar. The increase in acidity causes milk proteins to tangle together into solid masses, or curds, and a liquid called whey. This process can also occur naturally if milk is left out to sour.

Cutting

Once the curds have formed, they are cut into smaller pieces. It is important to cut the curds as evenly as possible to ensure uniform moisture distribution in the final product. Larger curds will hold excess moisture, while smaller ones will be too dry.

Heating

After cutting, the curds are heated, or cooked. The temperature and duration of heating will vary depending on the type of cheese being made. If the curds are heated too quickly, they will develop a skin that traps the whey inside, preventing proper drainage and affecting the moisture content of the final cheese.

Draining

Finally, the curds and whey are drained. The whey, the liquid byproduct of cheesemaking, is drained away, and the curds are pressed and drained further before different ingredients are added, depending on the type of cheese being made. The curds can be drained using a cheesecloth-lined strainer, and the whey can be saved to make other products like ricotta cheese or bread.

Vegan Delicacy: Follow Your Heart Cheese Ingredients Explained

You may want to see also

Flavour and preservation: salt, bacteria, ageing

Salt, bacteria, and ageing are key factors in the flavour and preservation of cheese. Salt is added to most cheeses to enhance their flavour and regulate moisture content, which affects their texture. It also controls bacterial growth and helps preserve the cheese. The type of salt used matters—cheesemakers typically use non-iodized salt or cheese salt. Iodine can affect the cheese's flavour and texture. Salt helps drain the residual whey, enhances the aroma profile, and regulates the final pH and water activity. It also affects microbial growth, modulating the activity of starter and non-starter lactic acid bacteria (NSLAB) during cheese manufacturing and ripening, influencing the shelf life.

Some cheeses need the addition of bacteria to start the transformation from milk to cheese, so cheesemakers add starter cultures to the milk. A starter culture contains living bacteria that eat the lactose sugar in milk, turning it into lactic acid. As more lactic acid develops, the cheese's acidity rises, helping with curdling, preservation, and flavour development. The two most common types of starter cultures are mesophiles and thermophiles. Mesophilic cultures are best for most cheeses as they thrive at lower to moderate temperatures.

The ageing process is also important—even cheeses with identical ingredients will differ based on different ageing processes. As cheese ages, moisture content decreases, and this concentration of flavours and the transformation of texture are vital to the development of a cheese's character. Different cheese types require various ageing conditions in terms of temperature, humidity, and time. For example, fresh cheeses like mozzarella are typically consumed shortly after production, while hard cheeses like Parmigiano-Reggiano may age for several years, resulting in a complex and crystalline texture with rich, nutty flavours.

Cheese fermentation and flavour formation are the result of complex biochemical reactions driven by the activity of multiple microorganisms.

Sargento Cheese: Crafted with Quality Ingredients

You may want to see also

Frequently asked questions

Yes, milk is the primary ingredient in cheese.

Cheese is usually made with cow's milk, but it can also be made with sheep's milk, goat's milk, buffalo milk, camel's milk, horse milk, or yak's milk.

In addition to milk, most cheeses contain cultures, coagulants, and salt. Other ingredients like spices, herbs, and wine can be added for flavor.

The process of making cheese involves separating the solids from the liquids in milk, which is called coagulation. Milk is warmed up and a starter culture blend is added to start the fermentation process. Then, a coagulant like rennet is added to help the milk turn into curds. The curds are then separated from the whey (liquid) and cut into smaller pieces. Salt is added to preserve the cheese and regulate moisture content. Finally, the cheese is aged or ripened.

There are many types of cheese because the process of making cheese can be varied in several ways. This includes the type of milk and culture used, the size of the curds, whether the curds are heated or washed, and the amount of salt added.