In Australia, it is illegal to sell unpasteurised cow's milk for human consumption. However, there are a few unpasteurised hard or semi-hard cheeses imported into the country, such as Emmental, Gruyere, and Roquefort. These cheeses must be labelled as not being pasteurised. While some sources claim that all commercial cheeses made in Australia are pasteurised, others state that soft cheeses, such as feta and mozzarella, are safe to consume during pregnancy when made from pasteurised milk.

| Characteristics | Values |

|---|---|

| Commercially available goat's cheese in Australia | Pasteurised |

| Soft goat's cheese in Australia | Should be avoided by pregnant women |

| Soft goat's cheese in Australia | Should be consumed cooked if consumed by pregnant women |

| Soft goat's cheese in Australia | Should be avoided by people with reduced immune systems, the elderly or young children |

| Commercially available goat's cheese in Australia | Made from pasteurised milk |

| Commercially available cow's milk in Australia | Made from pasteurised milk |

| Unpasteurised cow's milk in Australia | Illegal to sell for human consumption |

| Unpasteurised milk in Australia | Should not be consumed |

| Unpasteurised milk or cheese in Australia | Can cause serious illness in vulnerable people if contaminated |

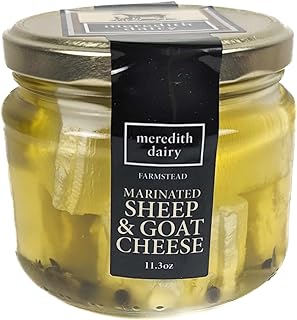

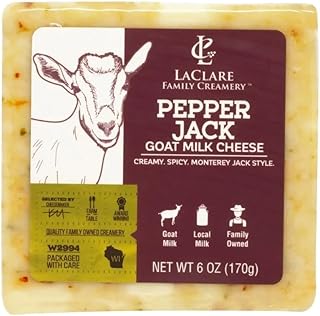

Explore related products

What You'll Learn

Australian-made goat's cheese is pasteurised

Australian guidelines recommend that pregnant women avoid eating soft cheeses, including goat's cheese, as they are more likely to be made from unpasteurized milk, which can cause food poisoning and serious illness. However, it is important to note that in Australia, all commercial cheeses, including goat's cheese, are made from pasteurized milk due to strict food safety regulations.

When it comes to Australian-made goat's cheese, it is safe to say that it is pasteurized. The country has strict laws prohibiting the sale of unpasteurized cow's milk for human consumption, and similar regulations apply to goat's milk and cheese. Australian-made goat's cheese sold in supermarkets and produced by commercial manufacturers is safe to consume, as it adheres to these stringent standards.

To ensure the safety of Australian-made goat's cheese, there are strict production processes and testing procedures in place. These regulations are designed to protect consumers, especially those who are more vulnerable to foodborne illnesses, such as pregnant women, individuals with weakened immune systems, the elderly, and young children. It is important to note that these vulnerable groups should still exercise caution and avoid consuming raw milk or cheese made from unpasteurized milk.

While Australian-made goat's cheese is typically pasteurized, it is always a good idea to read the labels and check the ingredients list. Some cheeses may be labeled as "made from pasteurized milk" or specifically mention "pasteurized" in the ingredients list. This information is usually found on the packaging or on the manufacturer's website. By checking the labels, consumers can make informed choices, especially those with specific dietary restrictions or preferences.

In summary, when it comes to Australian-made goat's cheese, it is safe to assume that it has been pasteurized due to the country's stringent food safety regulations. However, it is always recommended to check the labels and ingredients to confirm, especially for those with specific dietary needs or concerns.

Goat Cheese: A High-Fiber Superfood?

You may want to see also

Imported goat's cheese may be unpasteurised

It is illegal to sell unpasteurised cow's milk in Australia for human consumption. However, some unpasteurised hard or semi-hard cheeses, such as extra-hard parmesan-type cheeses, Swiss cheeses like Emmental, Gruyere, and Sbrinz, and Roquefort cheese, are imported into the country. These cheeses must undergo strict production processes and testing and be labelled as not being pasteurised.

Pregnant women in Australia are advised to avoid soft cheeses, including ricotta, feta, and blue cheese, unless they are fully cooked. This is because soft cheeses may be made from unpasteurised milk, which poses a risk of food poisoning. However, some sources indicate that soft cheeses made from pasteurised milk are safe to consume during pregnancy.

It is important to note that listeria, a potential risk associated with unpasteurised cheese, is rare in Australia. Nonetheless, vulnerable individuals such as pregnant women, people with weakened immune systems, the elderly, or young children, should exercise caution when consuming unpasteurised products.

When purchasing goat's cheese in Australia, it is essential to check the label to determine whether it is pasteurised or not. Commercially packaged goat's cheese sold in supermarkets is safe to consume, as all cheese produced in Australia must be made from pasteurised milk. However, some imported goat's cheese varieties may be unpasteurised, and it is crucial to verify the product's origin and labelling before consumption.

Goat Cheese and Lactose Intolerance: Friend or Foe?

You may want to see also

Pregnant women are advised to avoid unpasteurised cheese

In Australia, it is illegal to sell unpasteurised cow's milk for human consumption. However, there are some unpasteurised hard or semi-hard cheeses imported into the country, such as Parmesan, Emmental, Gruyere, and Roquefort. These cheeses must be labelled as unpasteurised and are not recommended for vulnerable people, including pregnant women.

Listeria bacteria can be found in raw, unpasteurised milk and certain other foods, and pregnant women are about ten times more likely than other adults to develop listeriosis, a serious infection caused by the bacteria. Listeria can also be present in soft cheeses, whether pasteurised or unpasteurised, as they have higher moisture content, providing a more suitable environment for bacterial growth. Even when pasteurised, cheese can become contaminated with Listeria or other pathogens after production, through secondary contamination down the supply chain.

To minimise the risk of foodborne illnesses, pregnant women are advised to stick to pasteurised cheeses and carefully read the labels of any cheese they plan to consume. Soft cheeses, whether made from pasteurised or unpasteurised milk, should be cooked to a high heat to reduce the risk of bacterial contamination.

Goat and Sheep Cheese: Delicious or Disgusting?

You may want to see also

Explore related products

Listeria is rare in Australia

While listeria can cause serious illness and even death, it is rare in Australia. The last recorded listeria outbreak in the country was in rockmelons. Listeria is a bacteria that can cause serious illness and, in some cases, death, particularly in vulnerable people. In Australia, around 100 people are hospitalised with listeriosis each year, and about 15 people die.

People at greater risk from listeriosis include pregnant women, their unborn and newborn babies, the elderly, and those with weakened immune systems. This includes cancer patients, organ transplant recipients, and people on drugs like cortisone. Eating foods contaminated with listeria is the most common way of contracting the illness. Listeria is common in the environment and can contaminate different types of food, even if it is stored in the refrigerator as the bacteria is tolerant of low temperatures.

To avoid listeria, those who are pregnant or have a weakened immune system are advised to eat freshly cooked or freshly prepared food. They should also avoid foods with a higher risk of listeria contamination, such as cold meats from delicatessens and sandwich bars, packaged sliced ready-to-eat meats, cold cooked chicken, chilled seafood, and smoked or cooked ready-to-eat prawns.

In Australia, it is illegal to sell unpasteurised cow's milk for human consumption, and vulnerable people are advised to avoid raw milk or raw milk cheeses. All cheeses in Australia are made from pasteurised milk, although there are a few exceptions with imported hard or semi-hard cheeses, which must be labelled as unpasteurised.

Goat Cheese vs Goat Milk: Which is Healthier?

You may want to see also

Soft goat's cheese is safe if pasteurised

Soft goat cheese can be a delicious treat, but it's important to ensure it's safe to eat, especially for vulnerable people like pregnant women, the elderly, young children, or those with weakened immune systems. In Australia, it is illegal to sell unpasteurised cow's milk for human consumption, and the same caution applies to goat cheese.

When it comes to soft goat cheese, it is generally safe to consume if it has been pasteurised. Pasteurisation is a process that kills harmful bacteria, such as Listeria, which can cause foodborne illnesses. Listeria is rare in Australia, but it's still important to take precautions. Soft goat cheese that is pasteurised can be a good source of calcium and protein, which are essential for both maternal and fetal health.

However, it's important to be cautious with artisanal or imported goat cheeses, as these are more likely to be unpasteurised. Always check the labels to ensure the cheese has been pasteurised, and if you're dining out or ordering dishes with goat cheese, don't be afraid to ask the server about the pasteurisation process. If in doubt, cooking the cheese thoroughly until it's steaming hot can kill any harmful bacteria and make it safe to consume.

In summary, soft goat cheese can be enjoyed safely during pregnancy and by vulnerable individuals as long as it has been pasteurised or cooked thoroughly. It's always a good idea to err on the side of caution and consult your healthcare provider if you have any concerns or questions about your diet.

Goat Cheese: Healthy Option or Unhealthy Indulgence?

You may want to see also

Frequently asked questions

It is recommended that pregnant women do not consume soft cheeses, including goat's cheese, unless they are cooked to a high heat. This is because soft cheeses are often made from unpasteurised milk, which can cause food poisoning and lead to serious illness.

If a cheese is unpasteurised, it must be labelled as such in Australia. Therefore, any cheese that does not say "unpasteurised" on the label is safe to consume.

Yes, there are a few unpasteurised hard and semi-hard cheeses imported into Australia, including some extra hard cheeses (parmesan types), Swiss cheeses (Emmental, Gruyere and Sbrinz), and Roquefort cheese. However, these cheeses must undergo strict production processes and testing and are not suitable for vulnerable people, including pregnant women.