Ireland is home to a variety of goat's cheese producers, including St. Tola and Corleggy. While some Irish goat's cheeses are made using raw milk, others are made with pasteurised milk. For example, the Tom and Ollie Irish Goats Boilie Log from County Tyrone and Tesco British Goats Cheese are both made with pasteurised goat's milk. Raw milk has been a controversial topic in Ireland, with debates surrounding the health risks and benefits of consuming unpasteurised products.

Is goat's cheese pasteurised in Ireland?

| Characteristics | Values |

|---|---|

| Pasteurisation of goat's cheese in Ireland | Not all goat's cheese in Ireland is pasteurised. Raw milk is commonly used in the production of Irish farmhouse cheeses. |

| Examples of pasteurised goat's cheese | Ferme Chevre, Tesco British Goats Cheese, Tom and Ollie's Irish Goats Boilie Log |

| Examples of unpasteurised goat's cheese | Ardsallagh Goat Products, St. Tola |

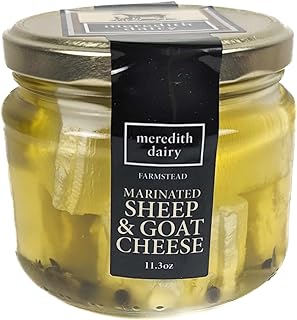

Explore related products

What You'll Learn

Irish goat cheese producers like St. Tola and Ardsallagh

St. Tola and Ardsallagh are two of the most well-known Irish goat cheese producers. St. Tola, founded by former schoolteacher-turned-cheesemaker Siobhán Ní Gháirbhith, is located in the town of Inagh, just south of The Burren in County Clare. Their cheese is made with fresh goat's milk from the farm's herd of Saanen and Toggenburg goats, and it has a mild and creamy texture when young, becoming firmer and more pungent as it ages. St. Tola's cheese is internationally recognized and can be found in specialty cheese shops like Neal's Yard Dairy in London, which has been selling Irish cheeses since the 1980s.

Ardsallagh, on the other hand, is a family-owned business in East Cork that has been making high-quality, handmade, natural goat cheese for over 20 years. They use traditional handmade production methods and fresh goat's milk from their own herd and other local Irish goat farms to create their award-winning cheeses. Ardsallagh's products are available throughout Ireland in small independent shops, national supermarket chains, and the menus of many restaurants. Their soft goat cheese is gently pasteurized and has a creamy texture and a gentle flavor.

Both St. Tola and Ardsallagh prioritize the health and well-being of their goats, and their commitment to quality and sustainability has earned them recognition and awards. These two producers exemplify the dedication and craftsmanship that go into Irish goat cheese, contributing to the growing reputation of Irish cheeses on the international stage.

Goat Cheese: Stinky or Not?

You may want to see also

Pasteurised vs raw milk in goat cheese

Pasteurisation is a process that effectively kills pathogens in raw milk that can cause diseases. Goat cheese made from pasteurised milk tends to have a smooth, tangy flavour with hints of caramel and gentle, subtle goaty notes. Pasteurised goat milk cheese is matured for several weeks to allow the cheese to develop its mould-ripened rind and distinctive flavour.

On the other hand, raw milk can contain disease-causing pathogens, as demonstrated by numerous scientific studies. These studies, along with outbreaks of foodborne illnesses, clearly show the health risks associated with consuming raw milk. However, some people prefer raw milk because they believe it has higher nutritional quality than pasteurised milk.

For example, vitamin C levels in raw goat milk have been recorded at 23.3 mg/litre, while pasteurisation at 72°C/16s reduced vitamin C levels by 16.6%. It's important to note that substantial vitamin loss only occurs after very high-temperature heating for a prolonged period. For instance, heating raw milk at 90°C for 10 minutes can result in a 70% reduction in vitamin C content.

Some sources indicate that vitamin C retention during storage is better in heated milk (72°C/15s, 75°C/15s, 80°C/15s) than in raw milk. This suggests that the benefits of pasteurisation in terms of food safety may outweigh the potential loss of certain nutrients.

In Ireland, goat cheese is commonly made with pasteurised milk, as seen with products like Tesco British Goats Cheese, which is produced in the UK and sold in Ireland. This ensures that consumers can enjoy the flavour and health benefits of goat cheese while minimising the risk of foodborne illnesses associated with raw milk.

Goat Cheese: Pasteurization Process and Benefits Explained

You may want to see also

Health risks of pasteurised and raw goat cheese

Goat cheese is a nutritious dairy product with many health benefits. It is packed with vitamins, minerals, protein, and healthy fats. It is also a good source of calcium, which is essential for healthy bones and teeth. Goat cheese can be high in fat, so it should be consumed in moderation to avoid weight gain.

When it comes to the health risks of pasteurised and raw goat cheese, it is important to consider the presence of harmful bacteria. Unpasteurised goat cheese poses a higher risk of carrying Listeria and other food-related illnesses, which can be dangerous during pregnancy. Therefore, it is recommended that pregnant women only consume goat cheese made from pasteurised milk to protect both themselves and their babies from potential complications. However, even when pasteurised, it should be consumed in moderation due to its high fat content.

On the other hand, raw goat cheese has its own set of benefits. It contains beneficial bacteria called probiotics, which can improve digestive health, reduce inflammation, and boost immunity. Raw goat cheese may also be easier on the digestive system for some people, as goat milk products have a different protein structure and lower levels of lactose compared to cow's milk.

Overall, both pasteurised and raw goat cheese have their own advantages and potential risks. Pasteurised goat cheese reduces the risk of harmful bacteria but may still contribute to weight gain if consumed in excess. Raw goat cheese offers probiotic benefits and improved digestibility but carries a higher risk of bacterial infections, especially for individuals with compromised immune systems or pregnant women. It is always recommended to consult a healthcare professional for specific dietary advice and to check the labels of goat cheese products to ensure informed choices.

Goat Cheese: A Healthy, Less Fattening Alternative to Hard Cheeses?

You may want to see also

Explore related products

Grilled goat cheese in salads and tarts

Grilled goat's cheese is a popular ingredient in salads and tarts. It can be grilled on bread and served with salad, or grilled on its own and placed on top of a salad.

Grilled goat's cheese salad

A classic French bistro starter, Salade de Chèvre Chaud, is a warm goat's cheese salad. This can be made with a ripened goat's cheese with a rind, or with fresh goat's cheese. If using a ripened goat's cheese, it can be pan-fried. If using fresh goat's cheese, spread it on bread and grill it. The bread can be a baguette or crostini, and the salad can be made with all sorts of lettuce, such as oak lettuce or bibb lettuce. The lettuce should be left in larger pieces so that you can cut it while eating. Other ingredients in the salad can include beetroot, onion, pecans or other nuts, and herbs.

For a goat's cheese salad with honey dressing, brush one side of the bread with olive oil and grill it for 1-2 minutes. Turn the slices over and top with a slice of goat's cheese, then season with crushed pepper. Grill for another 1-2 minutes until the cheese is bubbling and golden. Toss the salad leaves, herbs, pickled onion slices, and pecans in a mixing bowl, then divide between plates. Top with the cheese toasts and drizzle with warm honey.

Grilled goat's cheese tarts

Ferme Chevre, a French goat's pasteurised milk cheese, is ideal for grilling and can be used in tarts and salads.

Goat Cheese: Is Aging Necessary?

You may want to see also

Global requirements for pasteurisation in goat cheese production

Pasteurisation is a process that involves heating milk to a specific temperature and time to eliminate harmful bacteria and microorganisms that can cause spoilage or disease. This process is widely used to improve food preservation and promote food safety. While some countries, like Canada, mandate the pasteurisation of goat milk, the practice of pasteurising goat milk and cheese varies globally.

In Canada, for instance, goat milk must be pasteurised unless the cheese is aged for more than 60 days. In this case, raw milk can be used for hard cheeses with an ageing process of at least four months. Pasteurisation is done by heating the milk to 63°C for 30 minutes to ensure it is safe for consumption.

On the other hand, some sources mention that goat milk can be pasteurised using the vat pasteurisation method, heating the milk to at least 145°F for 30 minutes. This method is considered the traditional way of pasteurising milk and has gained popularity among smaller milk processors. However, it may alter protein structure and taste due to longer holding times.

Another pasteurisation technique is flash pasteurisation or High Temperature Short Time (HTST), where milk is heated to 161°F for 15 seconds. This method is used by some goat dairy companies and is believed to have minimal impact on taste and quality while being safer and more environmentally friendly.

While pasteurisation improves food safety and prolongs shelf life, it can also affect other components in the milk. For example, vitamins and enzymes can be damaged during the heating process, which is a concern for consumers who use goat milk for cheese-making and other cultured products. Therefore, different regions and companies may have varying requirements and preferences regarding pasteurisation in goat cheese production.

Goat Cheese and GERD: Friend or Foe?

You may want to see also

Frequently asked questions

No, there are some raw goat cheeses produced in Ireland.

Raw milk is milk that has not been pasteurised.

Pasteurisation is a process that kills harmful bacteria such as listeria, E. coli, and salmonella, which can be present in the gut and faeces of healthy cows.

Raw milk cheese has a depth of flavour that pasteurised cheeses cannot replicate. This is due to the complex mix of naturally occurring organisms in raw milk.

You can buy pasteurised goat cheese from various retailers in Ireland, including Tesco and Tom and Ollie.