The question of whether there is any cheese that is not cultured is an intriguing one, as it delves into the fundamental processes of cheese production. Culturing, which involves the use of bacteria or molds to ferment milk, is a cornerstone of traditional cheese-making, contributing to flavor, texture, and preservation. However, not all cheeses rely on microbial cultures. For instance, fresh cheeses like ricotta and some types of paneer are made by simply curdling milk with acid (such as lemon juice or vinegar) or heat, bypassing the culturing step. These cheeses lack the complex flavors and textures associated with cultured varieties but are prized for their simplicity and versatility. Thus, while culturing is common, it is not a universal requirement in cheese production.

Explore related products

What You'll Learn

- Uncultured Cheese Alternatives: Explore plant-based or synthetic options that mimic cheese without bacterial cultures

- Heat-Treated Cheeses: Some cheeses undergo processes that eliminate live cultures, like pasteurization

- Fresh Cheeses: Certain fresh cheeses, like ricotta, may not require culturing during production

- Processed Cheese Products: Highly processed cheese-like items often lack live cultures due to additives

- Non-Dairy Cultured Products: Fermented nut or seed-based products that avoid dairy culturing entirely

Uncultured Cheese Alternatives: Explore plant-based or synthetic options that mimic cheese without bacterial cultures

Traditional cheese relies on bacterial cultures to transform milk into its signature tangy, textured form. But what if you’re avoiding dairy, intolerant to lactose, or simply curious about alternatives? Enter uncultured cheese—a category of plant-based or synthetic options that mimic cheese without relying on bacterial fermentation. These alternatives leverage innovative techniques and ingredients to replicate the flavor, melt, and mouthfeel of cheese, all while bypassing the culturing process.

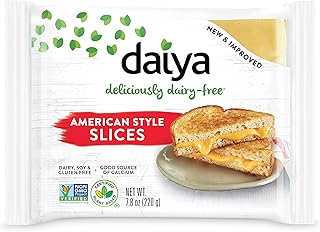

Plant-based cheeses lead the charge in this space, using nuts, seeds, and legumes as their base. For instance, cashew cheese is a popular option, made by blending soaked cashews with nutritional yeast, lemon juice, and salt. The result is a creamy, spreadable product that mimics the richness of dairy cheese. Similarly, coconut milk-based cheeses offer a firmer texture, ideal for slicing or shredding. These options are not only free from bacterial cultures but also from animal products, making them suitable for vegans. To enhance flavor, manufacturers often add enzymes like lipase or microbial transglutaminase, which mimic the effects of culturing without using bacteria directly.

Synthetic cheese alternatives take a more futuristic approach, using precision fermentation or lab-grown proteins to create cheese-like products. Companies like Perfect Day engineer microbial strains to produce whey proteins identical to those found in cow’s milk, then combine them with plant-based fats and natural flavors. These proteins are cultured in bioreactors, not through traditional bacterial fermentation, resulting in a product that melts and stretches like dairy cheese. While still emerging, this technology promises a scalable, sustainable solution for cheese lovers seeking uncultured options.

For those experimenting at home, creating uncultured cheese alternatives is surprisingly accessible. Start with a simple recipe: blend 2 cups of soaked cashews, 2 tablespoons of nutritional yeast, 1 tablespoon of lemon juice, and 1 teaspoon of salt until smooth. Adjust the consistency by adding water or oil for a creamier texture. For a firmer cheese, mix in agar-agar or carrageenan, then chill until set. These DIY methods allow you to control ingredients and avoid additives, making them ideal for dietary restrictions or personal preferences.

While uncultured cheese alternatives offer exciting possibilities, they’re not without limitations. Plant-based options often lack the complexity of aged cheeses, and synthetic versions can be costly. However, as technology advances and consumer demand grows, these alternatives are becoming increasingly sophisticated. Whether you’re vegan, lactose intolerant, or simply curious, uncultured cheese alternatives provide a compelling way to enjoy the flavors and textures of cheese without the bacterial cultures. Experiment with recipes, explore emerging brands, and discover a new world of cheese-like possibilities.

Daemon's Role in Blood and Cheese's Plot to Kill Jaehaerys

You may want to see also

Heat-Treated Cheeses: Some cheeses undergo processes that eliminate live cultures, like pasteurization

Cheese production often involves live cultures, but not all cheeses retain these microorganisms by the time they reach your plate. Heat-treated cheeses, such as those that undergo pasteurization, are prime examples of this phenomenon. During pasteurization, milk is heated to a specific temperature—typically 161°F (72°C) for 15 seconds or 145°F (63°C) for 30 minutes—to destroy harmful bacteria and extend shelf life. This process also eliminates the live cultures that would otherwise ferment the cheese, resulting in a product that is technically "not cultured" in its final state. While pasteurization ensures safety, it alters the cheese’s microbial profile, making it distinct from raw or traditionally cultured varieties.

From a practical standpoint, heat-treated cheeses are ideal for certain populations, such as pregnant women, young children, or immunocompromised individuals, who may need to avoid raw dairy products. Examples include pasteurized versions of cheddar, mozzarella, and Swiss cheese. These cheeses still offer the familiar flavors and textures consumers enjoy, but without the potential risks associated with live bacteria. However, it’s worth noting that pasteurization can slightly affect the complexity of flavor, as the absence of live cultures means the cheese will not develop additional nuances over time.

For those interested in making heat-treated cheese at home, the process begins with pasteurizing milk before adding rennet and other coagulants. Heat the milk to 161°F (72°C) for 15 seconds, using a thermometer to ensure accuracy, then cool it to the desired temperature for curdling. This method is particularly useful for beginners, as it reduces the risk of contamination and simplifies the cheesemaking process. However, be cautious not to overheat the milk, as temperatures above 176°F (80°C) can denature proteins and affect curd formation.

Comparatively, heat-treated cheeses differ from their raw or traditionally cultured counterparts in both production and aging potential. While raw-milk cheeses continue to develop flavors and textures as they age due to live cultures, pasteurized cheeses remain static. This makes heat-treated cheeses more consistent in taste and safer for mass production but less dynamic for artisanal cheese enthusiasts. For instance, a pasteurized cheddar will maintain its sharp flavor profile indefinitely, whereas a raw-milk cheddar might evolve over months or years.

In conclusion, heat-treated cheeses offer a safe and accessible alternative to traditionally cultured varieties, particularly for those with specific health considerations. While they lack the microbial activity that drives aging and flavor development, they remain a staple in kitchens worldwide. Whether you’re crafting cheese at home or selecting it at the store, understanding the role of heat treatment can help you make informed choices tailored to your needs and preferences.

Does Arby's Philly Cheesesteak Stack Up to the Original?

You may want to see also

Fresh Cheeses: Certain fresh cheeses, like ricotta, may not require culturing during production

Fresh cheeses, such as ricotta, stand apart in the dairy world because they often bypass the culturing step, relying instead on simple coagulation to transform milk into cheese. Unlike aged cheeses that depend on bacterial cultures to develop flavor and texture over time, ricotta is made by heating whey (a byproduct of other cheese production) until proteins precipitate and form curds. This method, known as heat-acid coagulation, uses acid (like vinegar or lemon juice) and heat to quickly separate curds from whey, resulting in a soft, creamy texture without the need for bacterial fermentation. This process not only preserves the milk’s natural freshness but also makes ricotta a quick and efficient cheese to produce.

From a practical standpoint, making ricotta at home is a straightforward process that requires minimal ingredients and equipment. Start by heating 8 cups of whole milk and 2 cups of whey (or additional milk) in a large pot over medium heat. Once the mixture reaches 180–185°F (82–85°C), add 3–4 tablespoons of distilled white vinegar or fresh lemon juice, stirring gently for 10–15 seconds. Let the mixture rest for 5–10 minutes until curds form, then pour the contents through a cheesecloth-lined strainer. The longer you strain, the firmer the ricotta becomes. This method yields a cheese that’s versatile enough for both sweet and savory dishes, from lasagna to cheesecake.

Comparatively, cultured cheeses like cheddar or gouda undergo a more complex process involving bacterial cultures that acidify the milk and enzymes (like rennet) to coagulate it. These cheeses develop their distinctive flavors and textures through aging, which can take weeks, months, or even years. In contrast, ricotta’s lack of culturing means it retains a mild, milky flavor and a delicate consistency, making it ideal for dishes where the cheese’s freshness is the star. Its simplicity in production also makes it a cost-effective option for both home cooks and commercial producers.

For those with dietary restrictions, ricotta’s production method offers a unique advantage. Since it doesn’t rely on bacterial cultures, it’s often better tolerated by individuals with sensitivities to fermented foods. Additionally, its short production time means fewer additives are needed, making it a purer option for those seeking minimally processed dairy products. However, it’s worth noting that ricotta’s lack of aging limits its shelf life compared to harder, cultured cheeses, so it’s best consumed fresh or stored properly to maintain quality.

In conclusion, fresh cheeses like ricotta demonstrate that not all cheese requires culturing to be delicious and functional. By leveraging heat-acid coagulation, these cheeses offer a quick, simple, and versatile alternative to their aged counterparts. Whether you’re making it at home or purchasing it, understanding ricotta’s unique production process highlights its role as a staple in both traditional and modern cuisine. Its freshness, simplicity, and adaptability make it a standout in the world of cheese.

Cost Breakdown: How Much Does a Pound of Cheese and Meat Tray Really Cost?

You may want to see also

Explore related products

Processed Cheese Products: Highly processed cheese-like items often lack live cultures due to additives

Processed cheese products, often found in slices, spreads, or blocks, are engineered for convenience and longevity, not microbial vitality. Unlike traditional cheeses that rely on live cultures for flavor development and preservation, these items are formulated with additives like emulsifiers, stabilizers, and artificial flavors to achieve a uniform texture and extended shelf life. The pasteurization and melting processes used in their production eliminate any live cultures, resulting in a product that is technically "cheese-like" but devoid of the microbial activity found in cultured varieties.

Consider the ingredient list of a typical processed cheese slice: milk, whey, milk protein concentrate, sodium citrate, and artificial color. These components are combined under high heat and pressure, creating a homogeneous mixture that resists spoilage but sacrifices the complex flavors and health benefits associated with live cultures. For instance, sodium phosphate, a common additive, acts as an emulsifier to prevent separation but does nothing to support microbial life. This contrasts sharply with aged cheddar or Gouda, where live cultures continue to work, enhancing flavor and texture over time.

From a health perspective, the absence of live cultures in processed cheese products means they lack probiotics, beneficial bacteria that support gut health. While not all cheeses are probiotic powerhouses, even mild varieties like mozzarella contain trace amounts of live cultures. Processed cheese, however, is a sterile product, stripped of any microbial activity. For those seeking the health benefits of cultured foods, opting for natural cheeses or fermented dairy alternatives like kefir is a more effective choice.

Practical tip: If you’re using processed cheese for its meltability (e.g., in grilled cheese sandwiches or sauces), consider blending it with small amounts of cultured cheese like sharp cheddar or Gruyère. This not only introduces live cultures but also enhances flavor complexity. For example, a 50/50 mix of processed American cheese and shredded cheddar can improve both nutritional value and taste without sacrificing texture.

In summary, processed cheese products are a testament to food science’s ability to prioritize convenience over biological integrity. While they serve a purpose in certain applications, their lack of live cultures makes them a poor substitute for traditional cheeses in terms of flavor, nutrition, and microbial activity. Understanding this distinction empowers consumers to make informed choices, balancing convenience with the benefits of cultured foods.

Carl's Jr. Chili Cheese Fries: Are They on the Menu?

You may want to see also

Non-Dairy Cultured Products: Fermented nut or seed-based products that avoid dairy culturing entirely

While traditional cheese relies heavily on dairy culturing, a burgeoning category of non-dairy alternatives challenges this norm. These products, crafted from fermented nuts and seeds, offer a compelling solution for those seeking cheese-like experiences without dairy or its associated culturing processes. This innovation isn't merely about substitution; it's a redefinition of what "cheese" can be, leveraging the transformative power of fermentation to create complex flavors and textures from plant-based sources.

Examples abound: cashew-based camembert-style wheels, almond feta crumbles, and sunflower seed cheddar shreds. Each utilizes specific strains of cultures to achieve distinct profiles, from tangy and sharp to creamy and mild.

Creating these products involves a precise fermentation process. Key steps include: 1) Soaking: Nuts or seeds are soaked to soften and activate enzymes, aiding in fermentation. 2) Blending: Soaked ingredients are blended with water, cultures (often probiotic strains), and sometimes nutritional yeast for cheesy flavor. 3) Fermentation: The mixture is left to ferment at controlled temperatures, allowing cultures to transform sugars into lactic acid, creating tanginess and preserving the product. 4) Shaping & Aging: The fermented mixture is shaped, often with molds or presses, and aged to develop deeper flavors and firmer textures.

Caution: Fermentation times vary depending on the desired outcome, ranging from 12 hours for a fresh cheese-like spread to several weeks for aged, harder varieties.

The appeal of these products extends beyond dietary restrictions. They offer a sustainable alternative to dairy, requiring significantly less water and land resources. Nutritionally, they can be rich in healthy fats, protein, and probiotics, contributing to gut health. However, it's crucial to note that not all non-dairy cheeses are created equal. Some rely heavily on additives and stabilizers, diluting their health benefits. Look for products with minimal ingredients, focusing on whole foods and live cultures.

This burgeoning category is more than a trend; it's a testament to the ingenuity of food science and the growing demand for diverse, sustainable, and delicious alternatives. As fermentation techniques continue to evolve, we can expect even more sophisticated and convincing non-dairy cheese experiences, challenging the very definition of this beloved food.

Mastering Vacuum-Sealed Cheese Aging: Techniques for Perfectly Matured Flavors

You may want to see also

Frequently asked questions

No, all cheese is cultured. Culturing is a necessary step in cheese-making where bacteria or molds are added to milk to ferment it, creating the texture and flavor characteristic of cheese.

No, cheese cannot be made without bacteria or mold. These microorganisms are essential for coagulating milk and developing the cheese’s unique properties, even if they are present in very small amounts.

Yes, some plant-based cheese alternatives are not cultured. These products are typically made from nuts, soy, or coconut and may use ingredients like oils, starches, and natural flavors to mimic cheese without the culturing process.