In 1874, Wisconsin, a state renowned for its dairy heritage, became the birthplace of a distinctive cheese that would leave a lasting legacy in the culinary world. This cheese, known as Brick Cheese, was developed by John Jossi, a Wisconsin cheesemaker of Swiss descent. Inspired by traditional Swiss techniques, Jossi adapted the process to local conditions, using a unique method of pressing the curds with bricks, which gave the cheese its name. Brick Cheese is characterized by its semi-soft texture, mild flavor, and slightly tangy finish, making it a versatile ingredient in both cooking and snacking. Its creation marked a significant milestone in Wisconsin’s dairy history, solidifying the state’s reputation as a leader in cheese innovation.

| Characteristics | Values |

|---|---|

| Name | Brick Cheese |

| Origin | Wisconsin, USA |

| Year Developed | 1874 |

| Creator | John Jossi |

| Milk Type | Cow's milk |

| Texture | Semi-soft |

| Flavor | Mild, slightly tangy, and nutty |

| Color | Pale yellow to golden |

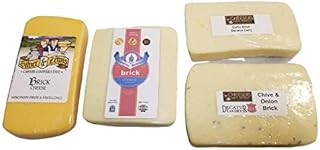

| Shape | Rectangular blocks or bricks |

| Aging Time | 1-3 months |

| Uses | Sandwiches, cheese boards, melting (e.g., burgers, grilled cheese) |

| Distinct Feature | Originally made using the "bricking" process, where heavy bricks were used to press the cheese |

Explore related products

What You'll Learn

Origin of Brick Cheese

In the heart of Wisconsin's dairyland, a cheese with a distinctive flavor and texture emerged in 1874, forever changing the state's culinary landscape. Brick cheese, named for the bricks used to press the curds during production, was first developed by John Jossi, a Swiss immigrant who settled in Green County. Jossi's innovation combined traditional European cheesemaking techniques with the rich milk of Wisconsin's dairy cows, resulting in a semi-soft cheese with a mild, nutty flavor and a slightly tangy finish. This unique cheese quickly gained popularity among local farmers and eventually became a staple in Wisconsin's dairy industry.

To understand the significance of brick cheese, consider the historical context of its creation. In the mid-19th century, Wisconsin experienced a surge in immigration, particularly from European countries with strong dairy traditions. These immigrants brought their cheesemaking expertise, which merged with the abundant milk supply from Wisconsin's growing dairy farms. Jossi's development of brick cheese exemplifies this fusion of old-world craftsmanship and new-world resources. The cheese's production process involves heating the milk, adding rennet to form curds, and then pressing the curds with bricks to remove excess whey. This method not only gives the cheese its name but also contributes to its characteristic texture and flavor.

From a practical standpoint, making brick cheese at home requires specific ingredients and equipment. You'll need high-quality milk, preferably from grass-fed cows, rennet, cheese salt, and a cheese press or heavy objects like bricks wrapped in food-safe material. Begin by heating the milk to around 90°F (32°C), then add the rennet and let the curds form. Cut the curds into small pieces and slowly raise the temperature to 100°F (38°C) to release more whey. After pressing the curds, brine the cheese in a solution of water and salt for several hours, then age it at a cool temperature for at least two weeks. This process allows the cheese to develop its signature flavor and texture, making it ideal for sandwiches, cheese boards, or melting over dishes like burgers and casseroles.

Comparatively, brick cheese stands out from other Wisconsin cheeses like cheddar or Colby due to its unique production method and flavor profile. While cheddar is known for its sharpness and Colby for its mild, creamy texture, brick cheese offers a balance of tanginess and nuttiness that pairs well with both sweet and savory foods. Its semi-soft consistency also makes it versatile in cooking, as it melts smoothly without becoming oily. For instance, brick cheese is a popular choice for the classic Wisconsin dish, the "cheese fry," where it’s melted over a bed of crispy fries and topped with sautéed onions and peppers.

In conclusion, the origin of brick cheese in Wisconsin in 1874 marks a pivotal moment in the state's dairy history. John Jossi's innovation not only created a delicious and versatile cheese but also showcased the potential of combining traditional techniques with local resources. Whether you're a cheese enthusiast looking to explore new flavors or a home cheesemaker eager to try your hand at a historic recipe, brick cheese offers a rich taste of Wisconsin's heritage. Its enduring popularity is a testament to the ingenuity of early dairy pioneers and the timeless appeal of a well-crafted cheese.

Should Grated Pecorino Cheese Be Refrigerated? Storage Tips Revealed

You may want to see also

John Jossi's Role

The cheese developed in Wisconsin in 1874 was Limburger cheese, a pungent, semi-soft cheese with a distinctive aroma. This cheese became a staple in Wisconsin’s dairy industry, shaping its culinary identity. While Limburger’s origins trace back to Europe, its American success story is deeply tied to Wisconsin’s dairy pioneers. Among them, John Jossi played a pivotal role in its development and commercialization.

Jossi, a Swiss immigrant, brought expertise in cheese-making to Wisconsin during a time when the state’s dairy industry was burgeoning. His role wasn’t merely that of a craftsman; he was an innovator who adapted European techniques to suit local conditions. Jossi’s mastery of the Limburger-making process—from curdling milk to aging the cheese in damp cellars—ensured consistency and quality. This was critical in a market where consumers were still unfamiliar with such a strongly flavored cheese. His ability to produce Limburger at scale helped it gain traction, particularly among German immigrants who already appreciated its taste.

To replicate Jossi’s success in modern cheese-making, consider these steps: source high-quality, unpasteurized milk (as Jossi would have used), maintain precise temperature control during curdling (around 90°F), and age the cheese in a humid environment for at least 3 months. Jossi’s attention to detail—such as using specific bacterial cultures for fermentation—was key to Limburger’s unique flavor profile. Modern cheese-makers can emulate this by investing in traditional tools like wooden aging racks and monitoring humidity levels (ideally 90-95%).

A cautionary note: Limburger’s strong odor can be polarizing. Jossi’s success relied on targeted marketing, often pairing the cheese with mild accompaniments like rye bread or dark beer to balance its intensity. Today, cheese-makers should consider this lesson by educating consumers on pairing options or offering samples in less intimidating formats, such as spreads or melted dishes.

In conclusion, John Jossi’s role in Wisconsin’s Limburger story was that of a bridge between tradition and innovation. His technical skill and adaptability laid the foundation for a cheese that, while no longer as popular, remains a testament to Wisconsin’s dairy heritage. By studying his methods, modern cheese-makers can honor this legacy while creating products that resonate with contemporary tastes.

Prevent Cheese Mold: Effective Storage Tips to Keep Cheese Fresh

You may want to see also

Unique Production Method

In 1874, Wisconsin became the birthplace of a cheese that would later be celebrated for its distinctive flavor and texture: Brick Cheese. What sets this cheese apart is not just its regional origin but its unique production method, which involves a process known as "bricking." This technique, where the curds are pressed between bricks wrapped in cloth, gives the cheese its name and contributes to its characteristic dense yet creamy texture.

The bricking process begins after the curds have been heated and stirred in a traditional cheesemaking manner. Unlike other cheeses that are pressed using weighted presses or molds, Brick Cheese curds are placed on a draining table and layered between bricks. The weight of the bricks gently presses the curds, expelling whey while maintaining enough moisture to create a semi-soft cheese. This method allows for a slower, more controlled consolidation of the curds, which is crucial for developing the cheese’s smooth mouthfeel and mild, slightly nutty flavor.

One of the key advantages of the bricking method is its simplicity, making it accessible for small-scale producers. However, it requires precision in timing and pressure. Too much pressure can result in a dry, crumbly texture, while too little can leave the cheese overly moist and lacking structure. Cheesemakers often adjust the duration of bricking based on the humidity and temperature of the environment, typically ranging from 12 to 24 hours. This hands-on approach ensures consistency in the final product, a hallmark of Wisconsin’s artisanal cheesemaking tradition.

Comparatively, the bricking method contrasts with the production of cheeses like Cheddar or Swiss, which rely on different pressing techniques and aging processes. Brick Cheese’s shorter aging period, usually 1 to 3 months, further distinguishes it. During this time, the cheese develops a thin, orange rind and a flavor profile that balances sweetness with a hint of tanginess. This unique combination of production and aging makes Brick Cheese a versatile ingredient, ideal for melting in sandwiches or enjoying on its own.

For home cheesemakers or enthusiasts looking to replicate this method, the key is patience and attention to detail. Start by ensuring the curds reach the proper pH (around 6.2) before bricking. Use food-safe bricks or weighted boards wrapped in cheesecloth to apply even pressure. Monitor the process closely, flipping the curds periodically to ensure uniform moisture distribution. While modern equipment can streamline the process, the traditional bricking method remains a testament to the ingenuity of Wisconsin’s early cheesemakers and their commitment to crafting a truly unique cheese.

Can Great Value Milk Be Used for Cheese Making?

You may want to see also

Explore related products

Historical Significance

The year 1874 marked a pivotal moment in Wisconsin’s dairy history with the development of brick cheese, a creation that would cement the state’s reputation as America’s Dairyland. This semi-soft cheese, named for the flat bricks used to press it, emerged from the ingenuity of immigrant cheesemakers adapting European techniques to local resources. Its historical significance lies not just in its creation but in how it symbolized the fusion of cultural heritage and American innovation, setting a precedent for the state’s dairy industry.

Analyzing the context of brick cheese’s development reveals its role as a bridge between old-world traditions and new-world opportunities. Wisconsin’s 19th-century landscape was dotted with small farms, many operated by German and Swiss immigrants who brought their cheesemaking expertise. However, the lack of refrigeration and long distances to markets necessitated a cheese that could withstand aging and transportation. Brick cheese, with its washed-rind method and robust flavor, met this need, becoming a practical solution for farmers and a staple for consumers.

Instructively, the process of making brick cheese highlights the resourcefulness of early Wisconsin cheesemakers. Unlike cheddar or Swiss, brick cheese is surface-ripened, with the curds washed in a brine solution to create a distinctive tangy flavor and orange rind. This method, borrowed from European techniques but adapted to local conditions, allowed for a cheese that could be produced year-round, even in the harsh Wisconsin winters. For modern cheesemakers, replicating this process offers a direct link to the past, preserving a craft that shaped the industry.

Persuasively, brick cheese’s legacy extends beyond its taste or production method; it embodies the spirit of Wisconsin’s dairy pioneers. Its development spurred the growth of cooperative creameries, which pooled milk from multiple farms to produce cheese efficiently. This model not only boosted the state’s economy but also fostered a sense of community among farmers. Today, as artisanal cheesemaking experiences a renaissance, brick cheese serves as a reminder of the enduring value of tradition and collaboration in food production.

Comparatively, while cheeses like cheddar and Gouda have global recognition, brick cheese remains a distinctly American creation with deep regional roots. Its historical significance lies in its ability to tell a story of adaptation, resilience, and cultural exchange. Unlike mass-produced cheeses, brick cheese carries the imprint of its time and place, making it a living artifact of Wisconsin’s dairy heritage. For historians and food enthusiasts alike, it offers a tangible connection to the past, proving that even a humble cheese can carry profound historical weight.

Exploring Cheese in the Trap Webtoon: Seasons Count and Storyline

You may want to see also

Modern Popularity

The cheese developed in Wisconsin in 1874 was Colby cheese, a creation of Joseph Steinwand in Clark County. Today, its modern popularity is a testament to how tradition can evolve to meet contemporary tastes. Unlike its cousin, cheddar, Colby has maintained a softer texture and milder flavor, making it a versatile ingredient in both home kitchens and artisanal cheese boards. Its adaptability is key to its resurgence, as modern consumers seek cheeses that pair well with a variety of foods without overpowering them.

Analyzing its appeal, Colby’s modern popularity is driven by its role in cheese blends. It’s a staple in pre-shredded cheese mixes, often combined with Monterey Jack or cheddar, which are marketed for tacos, casseroles, and sandwiches. This blending not only extends its shelf life but also introduces it to a broader audience. For instance, a 2022 report by the Wisconsin Cheese Makers Association noted that Colby-based blends accounted for 15% of all shredded cheese sales in the U.S., a 7% increase from 2018. This data underscores its growing presence in everyday meals.

Instructively, pairing Colby with modern culinary trends can elevate its appeal. For charcuterie boards, slice it thinly and pair with tart apple wedges or honey-drizzled walnuts to balance its creaminess. For melting applications, such as grilled cheese or macaroni, use a 2:1 ratio of Colby to sharp cheddar to achieve a smooth texture without sacrificing flavor depth. Its low moisture content also makes it ideal for aging experiments—try wrapping a block in wax and aging it for 6 months to develop a nuttier profile.

Persuasively, Colby’s sustainability story adds to its modern allure. Wisconsin’s dairy farms, where 90% of Colby is still produced, have adopted eco-friendly practices like methane digesters and rotational grazing. This aligns with consumer demand for ethically sourced products. A 2023 survey by the International Dairy Foods Association found that 62% of millennials are willing to pay more for cheese from sustainable farms. By choosing Colby, consumers support both heritage and innovation in agriculture.

Comparatively, while cheddar dominates global markets, Colby’s niche lies in its regional authenticity. Craft cheesemakers in Wisconsin are experimenting with smoked and spiced Colby varieties, such as jalapeño-infused or beer-washed versions, to attract younger, adventurous palates. These innovations differentiate it from mass-produced cheeses and position it as a premium yet approachable option. For instance, a smoked Colby from Hook’s Cheese Company won Best of Class at the 2021 World Championship Cheese Contest, proving its potential beyond traditional forms.

In conclusion, Colby’s modern popularity is no accident—it’s the result of strategic blending, culinary adaptability, sustainability, and innovation. Whether in a family recipe or a gourmet dish, this 149-year-old cheese continues to carve out its place in today’s food landscape.

Creative Ways to Enjoy Baked Lemon Ricotta Cheese Deliciously

You may want to see also

Frequently asked questions

Brick cheese was developed in Wisconsin in 1874.

Brick cheese was created by John Jossi, a Wisconsin cheesemaker, in 1874.

It is called Brick cheese because bricks were originally used to weigh down the curds during the cheese-making process in 1874.

Brick cheese has a mild, tangy flavor and a semi-soft texture, and its development in Wisconsin in 1874 marked an important milestone in American cheesemaking history.