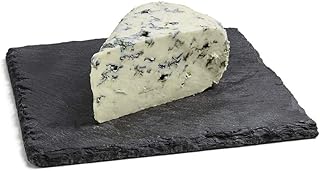

Gorgonzola cheese, a renowned Italian blue cheese, owes its distinctive flavor, aroma, and appearance to the presence of specific molds. The class of mold found in Gorgonzola is *Penicillium*, specifically *Penicillium roqueforti*. This mold species is responsible for the characteristic blue-green veins that develop throughout the cheese during the aging process. *Penicillium roqueforti* not only contributes to the cheese's unique visual appeal but also plays a crucial role in developing its complex, tangy, and slightly spicy flavor profile. The mold's enzymatic activity breaks down the cheese's proteins and fats, enhancing its texture and taste, making Gorgonzola a beloved staple in culinary traditions worldwide.

| Characteristics | Values |

|---|---|

| Mold Class | Penicillium |

| Species | Penicillium roqueforti |

| Appearance | Blue-green veins throughout the cheese |

| Texture | Soft, crumbly |

| Flavor Contribution | Sharp, tangy, earthy |

| Growth Conditions | Requires specific humidity and temperature (around 7-12°C) |

| Role in Cheese Making | Responsible for the characteristic flavor, aroma, and appearance |

| Safety | Generally recognized as safe (GRAS) for consumption |

| Other Cheeses with Same Mold | Roquefort, Stilton, Danish Blue |

| Sporulation | Produces spores under optimal conditions |

| Metabolism | Aerobic, requiring oxygen for growth |

| pH Preference | Thrives in slightly acidic environments (pH 5-6) |

| Antibiotic Production | Known to produce penicillin and other bioactive compounds |

| Allergenic Potential | Can cause allergic reactions in sensitive individuals |

| Industrial Use | Used in controlled environments for cheese production |

Explore related products

$17.97

What You'll Learn

- Penicillium Roqueforti: The primary mold class responsible for Gorgonzola's distinctive blue veins and flavor

- Mold Cultivation: Penicillium Roqueforti is intentionally introduced during cheese production for controlled growth

- Health Safety: This mold class is safe for consumption, adding unique taste and texture to the cheese

- Flavor Development: Penicillium Roqueforti contributes to Gorgonzola's pungent, earthy, and slightly spicy characteristics

- Aging Process: The mold thrives during aging, breaking down fats and proteins to enhance flavor complexity

Penicillium Roqueforti: The primary mold class responsible for Gorgonzola's distinctive blue veins and flavor

Gorgonzola cheese owes its signature blue veins and complex flavor profile to *Penicillium roqueforti*, a mold class specifically cultivated for its transformative properties. Unlike molds that signify spoilage, *P. roqueforti* is intentionally introduced during the cheesemaking process, typically by piercing the curd with stainless steel rods or injecting spores directly into the cheese. This controlled inoculation allows the mold to grow internally, creating the characteristic veining while breaking down fats and proteins into compounds that contribute to Gorgonzola’s tangy, earthy, and slightly spicy taste.

Analyzing the role of *P. roqueforti* reveals its dual function as both a flavor enhancer and a preservative. As the mold grows, it produces enzymes that hydrolyze milk fats and proteins, releasing free fatty acids and amino acids. These compounds are responsible for the cheese’s pungent aroma and sharp flavor. Additionally, the mold’s growth inhibits the proliferation of harmful bacteria, extending the cheese’s shelf life. This symbiotic relationship between mold and cheese is a testament to the precision of traditional cheesemaking techniques, where even microbial activity is carefully managed.

For home cheesemakers or enthusiasts, understanding *P. roqueforti* is key to replicating Gorgonzola’s unique qualities. The mold is commercially available as a spore suspension, which should be added at a precise dosage—typically 0.05% to 0.1% of the milk weight—during the cheesemaking process. Maintaining a humid environment (around 85-90% humidity) and a temperature of 50-54°F (10-12°C) during aging is critical for optimal mold growth. Regularly turning the cheese ensures even veining, while monitoring for unwanted molds is essential to prevent contamination.

Comparatively, *P. roqueforti* distinguishes Gorgonzola from other blue cheeses like Roquefort or Stilton, each of which uses the same mold class but with regional variations in technique and aging. While Roquefort is aged in specific caves in France, Gorgonzola’s production is more versatile, often aged in controlled environments worldwide. This adaptability highlights the mold’s resilience and the cheesemaker’s ability to manipulate its growth to achieve distinct regional flavors.

In conclusion, *Penicillium roqueforti* is not merely a mold but the architect of Gorgonzola’s identity. Its role in creating the cheese’s texture, flavor, and appearance underscores the intersection of science and art in cheesemaking. Whether you’re a producer or a connoisseur, appreciating *P. roqueforti*’s contribution deepens your understanding of this iconic cheese and the meticulous craftsmanship behind it.

Nacho Cheese Shelf Life: How Long Does Opened Nacho Cheese Last?

You may want to see also

Mold Cultivation: Penicillium Roqueforti is intentionally introduced during cheese production for controlled growth

Penicillium roqueforti, a mold belonging to the Ascomycota phylum, is the star player in the production of Gorgonzola cheese, as well as other blue-veined cheeses like Roquefort and Stilton. This mold is intentionally introduced during the cheese-making process, a practice that dates back centuries. The mold spores are typically added to the milk or sprinkled on the curds, with a dosage of around 10^6 to 10^8 spores per milliliter of milk. This precise introduction is crucial, as it ensures the mold's controlled growth, which in turn imparts the distinctive flavor, aroma, and appearance that define these cheeses.

The cultivation of Penicillium roqueforti requires specific conditions to thrive. The mold prefers a temperature range of 7-12°C (45-54°F) and a relative humidity of 85-95%. These conditions are meticulously maintained in aging cellars or caves, where the cheeses are stored for a period of 2-4 months. During this time, the mold grows and produces proteolytic and lipolytic enzymes, which break down the cheese's proteins and fats, resulting in the characteristic creamy texture and pungent flavor. It's essential to monitor the mold's growth, as excessive or insufficient development can negatively impact the cheese's quality.

To ensure optimal mold growth, cheese makers follow a series of steps. First, they select high-quality milk, typically from cow's or sheep's milk, which is then pasteurized or thermized to reduce competing bacteria. Next, the milk is coagulated using rennet or other clotting agents, and the resulting curds are cut, stirred, and drained. The Penicillium roqueforti spores are then added, either by spraying or mixing them into the curds. After salting and molding, the cheeses are pierced with needles to create air channels, allowing the mold to grow and spread throughout the cheese. This process requires precision and attention to detail, as any deviation can lead to off-flavors or textures.

One of the key challenges in cultivating Penicillium roqueforti is preventing the growth of unwanted bacteria and molds. To mitigate this risk, cheese makers employ various techniques, such as using starter cultures to acidify the milk and create an environment hostile to competing microorganisms. Additionally, they maintain strict hygiene practices, regularly cleaning and sanitizing equipment and facilities. For home cheese makers, it's crucial to source high-quality Penicillium roqueforti spores from reputable suppliers and follow established recipes and guidelines. With proper care and attention, even novice cheese makers can successfully cultivate this mold and produce delicious blue-veined cheeses.

The intentional introduction of Penicillium roqueforti during cheese production highlights the delicate balance between art and science in traditional cheese making. By understanding the mold's requirements and implementing precise techniques, cheese makers can harness its unique properties to create complex, flavorful cheeses. As consumers, we can appreciate the skill and craftsmanship that goes into producing these cheeses, and perhaps even try our hand at cultivating Penicillium roqueforti in our own kitchens. With its distinct flavor and texture, Gorgonzola cheese is a testament to the transformative power of mold cultivation, inviting us to explore the fascinating world of microbial fermentation.

Does Vegan Cheese Need Refrigeration? Storage Tips for Plant-Based Cheese

You may want to see also

Health Safety: This mold class is safe for consumption, adding unique taste and texture to the cheese

The mold found in Gorgonzola cheese belongs to the *Penicillium* class, specifically *Penicillium roqueforti*. This mold is not only safe for consumption but is also a cornerstone of the cheese's distinctive flavor and texture. Unlike harmful molds that can cause illness, *Penicillium roqueforti* is deliberately introduced during the cheese-making process to create the characteristic blue veins and creamy consistency. Its safety is well-documented, with centuries of culinary tradition and modern scientific research supporting its use.

From a health perspective, *Penicillium roqueforti* is non-toxic and plays a beneficial role in fermentation. It produces enzymes that break down milk proteins and fats, contributing to the cheese’s rich, tangy profile. Additionally, this mold inhibits the growth of harmful bacteria, acting as a natural preservative. For individuals concerned about mold allergies, it’s important to note that the mold in Gorgonzola is present in controlled amounts and is typically well-tolerated. However, those with severe mold sensitivities should exercise caution and consult a healthcare provider before consuming it.

The unique taste and texture of Gorgonzola are directly tied to the activity of *Penicillium roqueforti*. As the mold grows, it releases compounds that impart earthy, nutty, and slightly spicy notes. The veins themselves create pockets of creaminess within the cheese’s firmer structure, making it a versatile ingredient in cooking and pairing. For optimal enjoyment, serve Gorgonzola at room temperature to allow its flavors to fully develop. Pair it with sweet fruits like pears or honey to balance its sharpness, or use it in recipes like risotto or salads for a decadent touch.

Practical tips for handling Gorgonzola include proper storage to maintain its quality and safety. Wrap the cheese in wax or parchment paper, then store it in the refrigerator at 35–40°F (2–4°C). Avoid plastic wrap, as it can trap moisture and encourage unwanted bacterial growth. Gorgonzola can last up to four weeks when stored correctly, but always inspect it for any signs of spoilage, such as off-odors or discoloration unrelated to the blue veins. For those new to this cheese, start with small portions to appreciate its bold flavor without overwhelming your palate.

In summary, the *Penicillium* mold in Gorgonzola is not only safe but essential to its culinary appeal. Its role in fermentation enhances both taste and texture while ensuring the cheese remains free from harmful pathogens. By understanding its properties and following simple storage guidelines, anyone can confidently enjoy Gorgonzola as part of a balanced diet. Whether savored on its own or incorporated into dishes, this cheese is a testament to the harmonious relationship between microbiology and gastronomy.

Quick Tips for Safely Bringing Cold Milk and Cheese to Room Temperature

You may want to see also

Explore related products

Flavor Development: Penicillium Roqueforti contributes to Gorgonzola's pungent, earthy, and slightly spicy characteristics

Penicillium roqueforti, the mold class found in Gorgonzola cheese, is the architect of its distinctive flavor profile. This mold, also used in blue cheeses like Roquefort and Stilton, produces a complex array of enzymes and metabolites during fermentation. These compounds break down fats and proteins in the cheese, releasing volatile compounds responsible for its pungent, earthy, and slightly spicy characteristics. The intensity of these flavors depends on factors like mold concentration, aging time, and production techniques.

Analytical:

The pungency in Gorgonzola arises from methyl ketones, particularly 2-heptanone and 2-nonanone, produced by P. roqueforti. These compounds, detectable at concentrations as low as 0.5 ppm, contribute a sharp, penetrating aroma. The earthy notes are attributed to geosmin, a metabolite produced by the mold, while the slight spiciness can be linked to the presence of benzaldehyde, a compound also found in cinnamon and cloves.

Instructive:

To enhance the flavor development of Gorgonzola, consider these practical tips:

- Mold Inoculation: Aim for a uniform distribution of P. roqueforti spores throughout the curd. A dosage of 10^6 to 10^7 spores per gram of curd is typical, but adjust based on desired flavor intensity.

- Aging Temperature: Maintain a consistent temperature between 8-12°C (46-54°F) during aging. Higher temperatures accelerate mold growth and flavor development, but can lead to excessive bitterness.

- Aging Time: Allow for a minimum of 2-3 months of aging for a balanced flavor profile. Longer aging (up to 6 months) intensifies pungency and complexity.

Comparative:

Compared to other blue cheeses, Gorgonzola's flavor profile is more nuanced due to the specific strains of P. roqueforti used and the production methods employed. For instance, Roquefort's sharper, saltier flavor stems from its longer aging period and the unique microflora of its aging caves. Stilton, on the other hand, exhibits a creamier texture and milder flavor due to a different P. roqueforti strain and shorter aging time.

Descriptive:

Imagine biting into a wedge of Gorgonzola: the initial creaminess gives way to a burst of pungent aroma, reminiscent of a damp forest floor after rain. A subtle warmth, like a whisper of black pepper, lingers on the tongue, balanced by a hint of nuttiness from the aged milk. This symphony of flavors, orchestrated by P. roqueforti, is what makes Gorgonzola a truly unique and captivating cheese.

Cheese Quesadilla Weight Watchers Points: A Simple Guide

You may want to see also

Aging Process: The mold thrives during aging, breaking down fats and proteins to enhance flavor complexity

The mold found in Gorgonzola cheese, *Penicillium roqueforti*, is a star player in the aging process, transforming a simple cheese into a complex, flavorful masterpiece. This mold thrives in the cool, humid environment of aging caves, where it slowly breaks down the cheese’s fats and proteins. As it grows, it releases enzymes that act like culinary alchemists, converting dense, creamy textures into a crumbly, marbled interior. This enzymatic activity is the secret behind Gorgonzola’s signature tanginess and depth, making it a favorite among cheese connoisseurs.

To understand the aging process, imagine it as a slow dance between the mold and the cheese. Over weeks to months, *P. roqueforti* penetrates the cheese, creating veins of blue-green mold. During this time, the mold’s enzymes target lipids and proteins, breaking them into smaller molecules like free fatty acids and amino acids. These compounds are responsible for the cheese’s nutty, spicy, and slightly sweet notes. For optimal flavor development, Gorgonzola is typically aged for 2 to 4 months, though some artisanal varieties may extend this to 6 months for a more intense profile.

Practical tips for appreciating this process include storing Gorgonzola at 4–8°C (39–46°F) to mimic the aging cave environment and allow the mold to continue its work. Wrap the cheese in wax or parchment paper, not plastic, to maintain humidity without trapping excess moisture. When serving, let the cheese come to room temperature to fully experience its nuanced flavors. Pair it with honey, walnuts, or a full-bodied red wine to complement its complexity.

Comparatively, other blue cheeses like Roquefort and Stilton also use *P. roqueforti*, but Gorgonzola’s aging process is unique due to its Italian origins and specific production techniques. While Roquefort is aged in natural limestone caves, Gorgonzola’s aging often involves controlled environments, allowing for consistency in flavor and texture. This distinction highlights how the same mold can produce vastly different results based on regional practices and aging conditions.

In conclusion, the aging process of Gorgonzola is a testament to the transformative power of *Penicillium roqueforti*. By breaking down fats and proteins, this mold elevates the cheese’s flavor complexity, turning it into a culinary treasure. Whether you’re a cheese enthusiast or a curious cook, understanding this process deepens your appreciation for the art and science behind one of Italy’s most iconic cheeses.

Carb Count in String Cheese: Uncovering the Nutritional Facts

You may want to see also

Frequently asked questions

Gorgonzola cheese contains molds from the *Penicillium* genus, specifically *Penicillium roqueforti*.

Yes, the *Penicillium roqueforti* mold in Gorgonzola cheese is safe to consume and is intentionally added during the cheese-making process to create its distinctive flavor and texture.

The mold in Gorgonzola (*Penicillium roqueforti*) is a controlled, food-grade strain used in cheese production, whereas harmful molds, such as *Aspergillus* or *Fusarium*, are not intentionally added and can produce toxins if present in food.