After cheese production, whey—a nutrient-rich byproduct—is no longer discarded as waste but is instead transformed into valuable products across various industries. Companies utilize whey in multiple ways: it is processed into whey protein powders for the health and fitness market, incorporated into animal feed as a cost-effective and nutritious supplement, and used as an ingredient in baked goods, beverages, and processed foods to enhance texture and nutritional value. Additionally, whey is increasingly being converted into biofuels and biogas through fermentation, contributing to sustainable energy solutions. These innovative applications not only maximize resource efficiency but also reduce environmental impact, making whey a prime example of circular economy practices in the dairy industry.

| Characteristics | Values |

|---|---|

| Disposal as Waste | Historically, whey was considered a waste product and disposed of, often leading to environmental issues due to its high organic content and pollution potential. |

| Animal Feed | Whey is commonly dried and used as a protein-rich supplement in animal feed, particularly for livestock such as pigs, poultry, and cattle. |

| Human Food Products | Whey is processed into various food products, including whey protein powders, sports supplements, baked goods, and beverages like whey-based drinks. |

| Fermentation | Whey is used as a substrate for fermentation to produce bio-based chemicals, lactic acid, and ethanol, contributing to the bioeconomy. |

| Pharmaceuticals and Nutraceuticals | Whey-derived proteins and bioactive peptides are used in the production of dietary supplements, functional foods, and pharmaceutical products due to their health benefits. |

| Biogas Production | Whey can be anaerobically digested to produce biogas, a renewable energy source, reducing reliance on fossil fuels. |

| Cosmetics and Personal Care | Whey proteins and lactose are used in cosmetics and personal care products for their moisturizing and skin-conditioning properties. |

| Environmental Remediation | Whey can be used in bioremediation processes to treat wastewater and soil contaminated with heavy metals or organic pollutants. |

| Research and Development | Whey is a subject of ongoing research for its potential applications in biotechnology, material science, and sustainable production processes. |

| Export and Trade | Processed whey products, such as whey protein concentrates and isolates, are traded globally, contributing to the dairy industry's economy. |

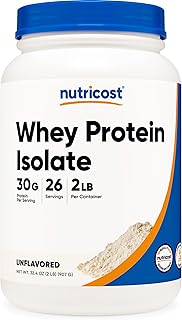

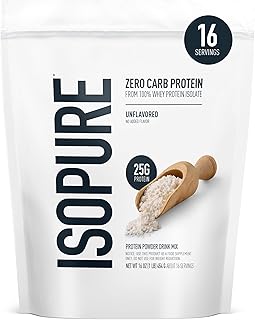

Explore related products

What You'll Learn

- Whey as Animal Feed: Dried whey is a cost-effective, nutrient-rich feed supplement for livestock and pets

- Whey in Food Products: Used in baked goods, protein bars, and beverages for added nutrition and texture

- Whey Protein Production: Processed into powders and supplements for fitness and health-conscious consumers

- Whey in Biogas Generation: Fermented whey produces biogas, a renewable energy source for sustainable practices

- Whey Waste Management: Treatment and disposal methods to minimize environmental impact and comply with regulations

Whey as Animal Feed: Dried whey is a cost-effective, nutrient-rich feed supplement for livestock and pets

Whey, a byproduct of cheese production, is far from waste. Its transformation into dried whey has unlocked a valuable resource for the animal feed industry. This lactose-rich, protein-packed powder offers a cost-effective way to enhance the nutritional profile of livestock and pet diets.

Nutritional Powerhouse: Dried whey boasts a unique composition, typically containing 10-12% protein, 70-80% lactose, and essential vitamins and minerals like calcium and phosphorus. This nutrient density makes it an ideal supplement for young, growing animals, lactating females, and those recovering from illness. For instance, calves fed diets containing 10-20% dried whey show improved growth rates and stronger immune systems.

Practical Application: Incorporating dried whey into animal feed requires careful consideration. For livestock, it’s commonly blended into rations at 5-15% of the total feed, depending on the animal’s age, weight, and nutritional needs. Pets, particularly dogs and cats, benefit from smaller doses, often added to commercial pet foods or treats. However, its high lactose content necessitates caution for animals with lactose intolerance, where alternatives like whey protein concentrate might be more suitable.

Economic and Environmental Benefits: Beyond its nutritional value, dried whey offers economic advantages. Its affordability compared to traditional protein sources like soybean meal makes it an attractive option for farmers. Additionally, repurposing whey reduces waste from cheese production, aligning with sustainable agricultural practices. This dual benefit—cost savings and environmental responsibility—positions dried whey as a smart choice for modern feed formulations.

Best Practices: To maximize the benefits of dried whey, store it in a cool, dry place to prevent clumping and spoilage. Gradually introduce it into animal diets to monitor tolerance, especially in pets. For livestock, consult a nutritionist to tailor the inclusion rate to specific herd or flock requirements. With proper usage, dried whey can significantly improve animal health, productivity, and overall farm efficiency.

Perfect Ham and Cheese Hot Pocket: Cooking Time Guide

You may want to see also

Whey in Food Products: Used in baked goods, protein bars, and beverages for added nutrition and texture

Whey, a byproduct of cheese production, is no longer destined for waste streams. Instead, it’s repurposed into a versatile ingredient that enhances food products across categories. In baked goods, whey proteins act as natural emulsifiers, improving dough elasticity and crumb structure. For instance, adding 5–10% whey powder to bread recipes can increase loaf volume by up to 15%, while reducing staling rates by 20%. This makes whey a functional and cost-effective alternative to synthetic additives.

Protein bars, a staple in the health and wellness market, rely on whey for both nutritional value and texture. Whey protein isolate, containing over 90% protein by weight, is often the primary ingredient in these bars. Its fast-digesting nature makes it ideal for post-workout recovery, particularly for adults aged 18–45 who prioritize muscle repair. Manufacturers typically blend 20–30 grams of whey protein per 60-gram bar, ensuring it meets daily protein intake recommendations. The protein’s ability to bind moisture also prevents bars from becoming dry or crumbly, extending shelf life.

Beverages represent another frontier for whey utilization, particularly in smoothies, protein shakes, and fortified dairy drinks. Whey protein hydrolysate, a pre-digested form, is often added to sports drinks at concentrations of 3–5% to enhance absorption and reduce muscle soreness. For children and older adults, whey-fortified milk or juices provide an accessible way to meet daily protein needs without altering taste significantly. A single 250ml serving of whey-enriched juice can deliver 10–15 grams of protein, making it a convenient option for those with dietary restrictions or limited appetites.

Incorporating whey into these products requires careful formulation to avoid off-flavors or grittiness. For baked goods, combining whey with fats or sugars masks its natural tanginess, while in beverages, homogenization ensures smooth texture. Protein bars benefit from the addition of gums or fibers to balance whey’s moisture-binding properties. By leveraging whey’s functional and nutritional benefits, companies not only reduce waste but also create products that cater to diverse consumer needs—from athletes seeking recovery aids to families prioritizing balanced diets.

Understanding Cheese Portions: How Many Slices in 30 Grams?

You may want to see also

Whey Protein Production: Processed into powders and supplements for fitness and health-conscious consumers

Whey, a byproduct of cheese production, was once considered waste, often discarded or used as animal feed. Today, it’s a cornerstone of the multi-billion-dollar health and fitness industry, transformed into high-value protein powders and supplements. This shift isn’t just about recycling waste—it’s a strategic move to meet the growing demand for convenient, nutrient-dense products among fitness enthusiasts and health-conscious consumers.

The process begins with filtration, where whey is separated into its primary components: protein, lactose, and minerals. Advanced techniques like microfiltration and ultrafiltration isolate whey protein concentrate (WPC) and whey protein isolate (WPI), the latter containing up to 95% protein. These forms are then spray-dried into powders, preserving their nutritional profile while extending shelf life. For example, a single scoop (30g) of whey protein powder typically delivers 20–25g of protein, making it an efficient way to meet daily protein goals.

Incorporating whey protein into a fitness regimen requires precision. For muscle recovery and growth, consume 20–40g of whey protein post-workout, ideally within 30–60 minutes. Older adults, particularly those over 65, can benefit from higher doses (30–40g per serving) to combat age-related muscle loss (sarcopenia). However, it’s crucial to balance whey intake with whole food sources to avoid over-reliance on supplements.

Not all whey proteins are created equal. Whey isolate is ideal for those monitoring calorie or lactose intake, while hydrolyzed whey, pre-digested for faster absorption, suits athletes needing rapid recovery. Blends with added BCAAs (branched-chain amino acids) or enzymes can enhance muscle repair and digestion. Always check labels for added sugars or artificial sweeteners, especially if you’re calorie-conscious.

The rise of whey protein supplements reflects a broader trend: the intersection of sustainability and consumer health. By repurposing whey, companies not only reduce waste but also tap into a lucrative market. For consumers, whey protein offers a practical, science-backed solution to support fitness goals, from muscle building to weight management. It’s a win-win—turning what was once waste into a powerhouse of nutrition.

Do Crab Cheese Wontons Contain Real Crab? The Truth Revealed

You may want to see also

Explore related products

Whey in Biogas Generation: Fermented whey produces biogas, a renewable energy source for sustainable practices

Whey, a byproduct of cheese production, has long been a challenge for dairy companies due to its high organic content and disposal costs. However, innovative solutions have transformed this waste into a valuable resource, particularly in biogas generation. Fermented whey, when processed in anaerobic digesters, produces biogas—a mixture of methane and carbon dioxide—that can be harnessed as a renewable energy source. This approach not only addresses waste management but also contributes to sustainable energy practices, aligning with global efforts to reduce reliance on fossil fuels.

The process begins with the collection of whey from cheese production facilities. Instead of discarding it, the whey is directed to anaerobic digesters, where microorganisms break down its organic matter in the absence of oxygen. This fermentation process releases biogas, which can be captured and utilized for electricity generation, heating, or even as a vehicle fuel. For instance, a medium-sized dairy plant producing 10,000 liters of whey daily can generate approximately 500–700 cubic meters of biogas per day, depending on the organic load and digester efficiency. This biogas can power the plant’s operations or be fed into the grid, offsetting carbon emissions and reducing energy costs.

One notable example is the collaboration between dairy companies and biogas plants in Europe, where fermented whey is a key feedstock for anaerobic digestion. In Germany, for instance, dairy producers supply whey to local biogas facilities, which convert it into energy and organic fertilizer. This symbiotic relationship not only minimizes whey disposal costs but also provides a steady supply of renewable energy to the community. Similarly, in the United States, companies like Vermont Energy Investment Corporation have implemented whey-to-energy projects, showcasing the scalability and feasibility of this approach.

Implementing whey-based biogas systems requires careful planning and investment. Dairy companies must ensure proper pretreatment of whey to optimize biogas yield, such as adjusting pH levels and removing impurities. Additionally, integrating biogas production with existing operations demands technical expertise and infrastructure, including digesters, gas purification systems, and energy conversion equipment. However, the long-term benefits—reduced waste, lower energy costs, and enhanced sustainability credentials—make this a compelling strategy for forward-thinking businesses.

In conclusion, fermented whey’s role in biogas generation exemplifies how waste can be repurposed into a sustainable energy solution. By adopting this practice, dairy companies not only mitigate environmental impact but also unlock new revenue streams and strengthen their commitment to green initiatives. As the demand for renewable energy grows, whey-derived biogas stands out as a practical, scalable, and eco-friendly option for the dairy industry and beyond.

Daemon's Role in Blood and Cheese's Plot to Kill Jaehaerys

You may want to see also

Whey Waste Management: Treatment and disposal methods to minimize environmental impact and comply with regulations

Cheese production generates vast quantities of whey, a byproduct that poses significant environmental challenges if not managed properly. Whey contains high levels of organic matter, primarily lactose and proteins, which can deplete oxygen levels in water bodies if discharged untreated, leading to aquatic ecosystem disruption. Regulatory bodies worldwide enforce strict guidelines on whey disposal to mitigate these risks, pushing companies to adopt sustainable treatment and disposal methods.

Treatment Methods: Transforming Waste into Resource

One effective approach is anaerobic digestion, where whey is treated in bioreactors to break down organic matter into biogas (primarily methane) and nutrient-rich digestate. This process not only reduces the biochemical oxygen demand (BOD) by up to 90% but also produces renewable energy. For instance, a dairy plant in Wisconsin processes 100,000 gallons of whey daily, generating enough biogas to power 20% of its operations. Alternatively, membrane filtration and evaporation techniques concentrate whey into valuable products like whey protein isolate or lactose, diverting waste from disposal streams.

Disposal Strategies: Compliance and Caution

When treatment isn’t feasible, regulated land application offers a compliant disposal method. Whey can be spread on agricultural land as a fertilizer substitute, provided it meets application rate limits (typically 5,000–10,000 gallons per acre annually) to prevent soil and groundwater contamination. However, this method requires careful monitoring of nutrient levels, particularly phosphorus, to avoid runoff into nearby water bodies. Direct discharge into municipal wastewater systems is another option but necessitates pre-treatment to meet BOD limits (usually <300 mg/L) to prevent overloading treatment plants.

Innovative Solutions: Closing the Loop

Forward-thinking companies are exploring circular economy models to maximize whey’s value. For example, whey permeate is increasingly used in animal feed, while lactose is extracted for pharmaceutical applications. In Europe, some dairies collaborate with breweries to ferment whey into craft beers, combining waste streams for novel products. These approaches not only minimize environmental impact but also create additional revenue streams, aligning with sustainability goals.

Regulatory Compliance: Navigating the Landscape

Compliance with local and international regulations is non-negotiable. In the U.S., the EPA’s Clean Water Act mandates permits for whey discharge, while the EU’s Water Framework Directive sets stringent limits on pollutant levels. Companies must conduct regular water quality testing and maintain detailed records to avoid penalties. Investing in advanced treatment technologies, such as reverse osmosis or integrated membrane systems, ensures adherence to these standards while future-proofing operations against tightening regulations.

Practical Tips for Implementation

Start by auditing your whey output and assessing local regulatory requirements. Pilot small-scale treatment systems, such as compact anaerobic digesters, to gauge feasibility before full-scale implementation. Partner with research institutions or technology providers to access grants or subsidies for sustainable projects. Finally, engage stakeholders, from farmers to consumers, to build support for innovative whey management practices, turning a waste challenge into a shared sustainability success.

Bleached vs. Unbleached Cheesecloth: Which is Best for Dyeing?

You may want to see also

Frequently asked questions

Whey is the liquid byproduct of cheese production, separated from the curds during the coagulation process. It contains proteins, lactose, vitamins, and minerals, making it a valuable resource rather than waste.

Companies often process whey through filtration, evaporation, and drying to create whey protein concentrates, isolates, or powders. It can also be fermented to produce lactose or used as animal feed.

Yes, whey is widely used in the food industry as an ingredient in protein supplements, baked goods, beverages, and processed foods due to its nutritional value and functional properties.

Yes, whey is utilized in pharmaceuticals, cosmetics, and biotechnology. Its proteins and bioactive compounds are incorporated into products like skincare items and medicinal formulations.

Utilizing whey reduces waste, lowers the environmental impact of cheese production, and creates a sustainable resource. It also minimizes pollution from disposal and maximizes the value of milk used in cheese making.