When you pull the plug on Easy Cheese, the iconic aerosol cheese product, the immediate effect is the cessation of its pressurized dispensing mechanism, which relies on nitrous oxide to propel the cheese out of the can. Without this pressure, the cheese remains trapped inside, rendering the product unusable in its intended form. Over time, the cheese may spoil due to exposure to air, as the airtight seal is broken, leading to potential bacterial growth and off flavors. Additionally, the environmental impact of disposing of an unused aerosol can becomes a concern, as it contains materials that require proper recycling or disposal. This scenario highlights the importance of responsible consumption and the limitations of convenience-driven food products.

| Characteristics | Values |

|---|---|

| Physical State | Easy Cheese becomes a runny, liquid-like substance when the plug is pulled, as the pressurized gas is released. |

| Texture | Loses its smooth, spreadable texture and turns into a thin, pourable consistency. |

| Taste | Flavor remains largely unchanged, but the lack of aeration may slightly alter the mouthfeel. |

| Shelf Life | Once opened and exposed to air, Easy Cheese spoils faster, typically within 2-3 days if not refrigerated. |

| Packaging | The can loses its pressure, rendering the nozzle ineffective for controlled dispensing. |

| Usage | No longer suitable for precise application; best used as a sauce or melted topping. |

| Appearance | Loses its fluffy, aerated look and becomes more like a liquid cheese product. |

| Storage | Must be refrigerated after opening to slow spoilage, unlike the original pressurized can. |

| Environmental Impact | Increased waste if not consumed quickly, as the product cannot be resealed effectively. |

Explore related products

What You'll Learn

- Gas Release Mechanism: How propellant gases escape rapidly when the seal is broken

- Oxidation Process: Exposure to air causes cheese to spoil quickly

- Texture Changes: Cheese hardens or becomes runny without preservatives

- Microbial Growth: Bacteria thrive, leading to mold and decay

- Environmental Impact: Aerosol can disposal affects waste management systems

Gas Release Mechanism: How propellant gases escape rapidly when the seal is broken

The moment you break the seal on a can of Easy Cheese, a dramatic release of propellant gases occurs, driven by the sudden drop in pressure. These gases, typically a blend of nitrous oxide and carbon dioxide, are compressed under high pressure to keep the cheese product smooth and dispensable. When the seal is broken, the gases rapidly expand, escaping through the nozzle in a burst of force. This mechanism is not unlike the principle behind aerosol sprays, where propellants are used to expel the product from the container. Understanding this process is key to appreciating the physics behind the convenience of aerosolized cheese.

To visualize this, imagine a balloon filled with air and then suddenly popped. The air rushes out in an instant, creating a loud noise and a brief gust of wind. Similarly, the propellant gases in Easy Cheese are under significant pressure, waiting for the seal to be broken. The speed and force of this release are directly proportional to the pressure differential between the inside of the can and the external atmosphere. This rapid escape of gases not only propels the cheese out of the can but also creates the distinctive "whoosh" sound that signals the product is ready to use.

From a practical standpoint, this gas release mechanism has implications for how you handle and store Easy Cheese. For instance, shaking the can before use can increase the pressure inside, leading to a more forceful release when the seal is broken. However, excessive shaking or exposure to heat can cause the propellants to expand dangerously, potentially leading to can rupture. Manufacturers recommend storing Easy Cheese at room temperature and avoiding puncturing the can, as this can disrupt the delicate balance of pressure and propellant.

A comparative analysis reveals that the gas release mechanism in Easy Cheese is more efficient than traditional cheese dispensing methods, such as squeezing cheese from a tube. The propellant system ensures a consistent texture and easy application, making it a favorite for quick snacks or garnishes. However, it also highlights the importance of responsible disposal, as the pressurized nature of the can poses environmental and safety risks if not handled properly. Recycling programs often require cans to be completely empty, so it’s advisable to dispense all the cheese before disposal.

In conclusion, the gas release mechanism in Easy Cheese is a fascinating interplay of physics and chemistry, designed to deliver convenience with every pull of the plug. By understanding how propellant gases escape rapidly when the seal is broken, users can better appreciate the product’s functionality while adhering to safety and storage guidelines. Whether you’re a casual user or a curious enthusiast, this knowledge ensures a safer and more enjoyable experience with this iconic snack.

Why Woodlice Are Nicknamed Cheese Logs: Unraveling the Quirky Moniker

You may want to see also

Oxidation Process: Exposure to air causes cheese to spoil quickly

The moment you puncture the seal on a can of Easy Cheese, the clock starts ticking. Exposure to air initiates a rapid oxidation process, a chemical reaction where oxygen molecules interact with the cheese’s fats and proteins. This reaction breaks down the cheese’s structure, leading to off-flavors, discoloration, and a texture that shifts from creamy to grainy. Think of it as leaving a slice of cheddar on the counter—but accelerated. The airtight canning preserves Easy Cheese’s shelf life, but once opened, it becomes vulnerable to this natural spoilage mechanism.

To slow oxidation, limit air exposure. Transfer unused Easy Cheese to an airtight container, pressing plastic wrap directly onto the surface to minimize contact with oxygen. Refrigeration is non-negotiable, as lower temperatures decelerate the reaction rate. For optimal preservation, consume the product within 3–5 days of opening. If you’re a sporadic user, consider portioning the cheese into smaller, sealed containers to reduce repeated exposure during use.

Comparatively, traditional cheeses spoil via mold growth, a biological process fueled by moisture and air. Easy Cheese, however, is formulated with emulsifiers and preservatives to resist mold, making oxidation its primary enemy. This distinction highlights why sealing and refrigeration are more critical for aerosol cheeses than their natural counterparts. While mold is visible, oxidation’s effects are subtler but equally detrimental, manifesting as a rancid taste and unappetizing texture.

A practical tip: if you notice Easy Cheese developing a yellowish tint or a sharp, unpleasant odor, discard it immediately. These are telltale signs of advanced oxidation. For those experimenting with cheese preservation, vacuum sealing or using inert gases like nitrogen can further extend freshness, though such methods are overkill for casual use. Ultimately, the key to combating oxidation is vigilance—treat Easy Cheese like fresh produce, not a pantry staple.

Why Fans Throw Cheese at Football Games: A Tasty Tradition Explained

You may want to see also

Texture Changes: Cheese hardens or becomes runny without preservatives

Preservatives in processed cheese products like Easy Cheese play a critical role in maintaining their signature smooth, spreadable texture. Without these additives, the cheese’s structure begins to break down. Sodium phosphates, typically added to stabilize moisture and prevent separation, are absent in their natural state, allowing fats and proteins to migrate. This migration results in either a hardened, crumbly mass or a greasy, runny liquid, depending on storage conditions. Refrigerated cheese may dry out and solidify as moisture evaporates, while room-temperature cheese can separate into oily pools and solid curds.

To observe this transformation firsthand, conduct a simple experiment: divide a batch of homemade cheese sauce (without preservatives) into two containers. Store one in the refrigerator and the other at room temperature. Within 48 hours, the refrigerated sample will likely develop a tough, rubbery exterior, while the room-temperature sample will separate into a layer of whey and a clump of coagulated fat. This demonstrates how preservatives act as a scaffold, holding the cheese’s components in equilibrium. Without them, the natural tendency of fats and liquids to separate dominates, altering texture dramatically.

From a culinary perspective, understanding this texture shift is essential for anyone attempting to replicate processed cheese at home. To mitigate hardening, incorporate a small amount of sodium citrate (1-2% by weight) into your recipe, which binds calcium and prevents protein aggregation. For a runnier consistency, add 10-15% whey powder to stabilize moisture without relying on artificial preservatives. However, note that these solutions only approximate the texture of preserved cheese—natural versions will still degrade faster. Store homemade cheese in airtight containers and consume within 3-5 days to minimize textural changes.

Comparatively, artisanal cheeses like cheddar or gouda undergo controlled aging, where texture changes are intentional and desirable. In contrast, the hardening or liquefaction of Easy Cheese without preservatives is a sign of unintended decay. While some may argue this highlights the "unnatural" nature of processed cheese, it underscores the science behind its consistency. Preservatives aren’t merely additives; they’re tools that manipulate chemistry to create a stable, shelf-stable product. Removing them reveals the delicate balance required to maintain texture—a balance that, once disrupted, cannot be easily restored.

For practical application, if you’ve accidentally left Easy Cheese unrefrigerated or are working with a preservative-free alternative, there’s a quick fix to salvage texture. For hardened cheese, gently reheat it in a double boiler with a splash of milk, stirring until smooth. For runny cheese, strain off excess liquid and blend the solids with a pinch of xanthan gum (0.1% by weight) to rebind the mixture. These methods won’t fully replicate the original texture but can make the cheese usable again. Ultimately, the lesson is clear: preservatives aren’t just for longevity—they’re the backbone of texture in processed foods.

American Cheese Abroad: Exploring Its Global Presence and Variations

You may want to see also

Explore related products

Microbial Growth: Bacteria thrive, leading to mold and decay

Once the seal is broken on a can of Easy Cheese, the clock starts ticking for microbial growth. The product’s shelf-stable nature relies on an airtight environment, but exposure to air introduces bacteria, yeast, and mold spores. Within 24 to 48 hours, these microorganisms begin to multiply, particularly if the cheese is stored at room temperature. Refrigeration slows this process but doesn’t halt it entirely. The cheese’s high moisture content and nutrient-rich composition create an ideal breeding ground, accelerating decay.

Consider the role of oxygen in this process. Unlike anaerobic bacteria, which thrive without oxygen, the microbes most likely to colonize Easy Cheese are aerobic, meaning they require oxygen to grow. When the can is opened, oxygen floods in, providing the energy source these organisms need to reproduce. This is why mold often appears as a fuzzy layer on the surface first—it’s the most oxygen-rich area. Over time, the mold penetrates deeper, breaking down the cheese’s structure and releasing enzymes that further degrade it.

To mitigate microbial growth, follow these practical steps: store opened Easy Cheese in the refrigerator, use a clean utensil to avoid cross-contamination, and consume it within 3 to 5 days. If you notice any off odors, discoloration, or visible mold, discard it immediately—even if the mold is only on the surface, toxins may have spread throughout. For those experimenting with homemade cheese spreads, adding preservatives like sodium benzoate (0.1% by weight) or potassium sorbate (0.2% by weight) can inhibit microbial activity, though these are not typically used in aerosol products like Easy Cheese.

Comparing Easy Cheese to natural cheeses highlights the impact of processing on microbial growth. Natural cheeses often contain live cultures that compete with harmful bacteria, slowing spoilage. Easy Cheese, however, is pasteurized and homogenized, eliminating beneficial microbes while still remaining susceptible to contamination once opened. This underscores the importance of proper storage and handling, as processed foods lack the protective mechanisms of their natural counterparts.

Finally, understanding the science behind microbial growth can shift your perspective on food waste. Mold and decay aren’t just unsightly—they’re signs of complex biological processes at work. By respecting expiration dates and storage guidelines, you’re not just preserving flavor but also preventing the proliferation of pathogens. In the case of Easy Cheese, pulling the plug means embracing the inevitability of spoilage while taking steps to delay it, ensuring each spray remains safe and enjoyable until the last drop.

Wrapping Credelio in Cheese: Safe or Risky for Your Pet?

You may want to see also

Environmental Impact: Aerosol can disposal affects waste management systems

Aerosol cans, like those used for Easy Cheese, are pressurized containers that pose unique challenges for waste management systems. When disposed of improperly, these cans can rupture, releasing their contents and propellants into the environment. This not only contaminates soil and water but also contributes to air pollution, as propellants like propane and butane are often greenhouse gases. Understanding the proper disposal methods is crucial to mitigating these risks.

Steps for Safe Disposal:

- Empty the Can Completely: Before disposal, ensure the can is fully depleted of its contents. For products like Easy Cheese, this might mean using it until nothing remains, even if it requires creative culinary solutions.

- Recycle Responsibly: Check local recycling guidelines. Many municipalities accept aerosol cans in curbside recycling programs, but only if they are empty. Some facilities require cans to be punctured to release residual pressure, though this should only be done by professionals or at designated hazardous waste sites.

- Avoid Trash Bins: Never throw aerosol cans in regular trash. Landfill compaction can cause them to explode, releasing harmful chemicals and creating safety hazards for waste workers.

Cautions and Misconceptions:

A common mistake is assuming that aerosol cans are safe to toss once empty. However, residual propellants and pressure remain, making them hazardous. Additionally, not all recycling programs accept aerosol cans due to their complex composition, which includes metal, plastic, and chemical propellants. Always verify with local waste management authorities to avoid contamination of recycling streams.

Comparative Impact:

The environmental impact of aerosol can disposal pales in comparison to larger waste issues like plastic pollution, but its localized effects are significant. For instance, a single ruptured can in a landfill can release up to 100 grams of greenhouse gases, contributing to climate change. Multiply this by millions of cans disposed of annually, and the cumulative effect becomes alarming. Proper disposal, therefore, is a small but impactful action individuals can take to reduce their environmental footprint.

Practical Tips for Consumers:

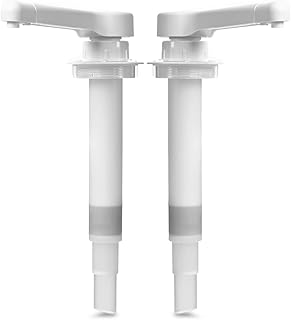

- Opt for non-aerosol alternatives when possible, such as pump sprays or manual dispensers.

- Store aerosol cans in a cool, dry place to prevent accidental rupture.

- Educate household members on proper disposal methods to ensure consistency.

By addressing aerosol can disposal thoughtfully, consumers can play a direct role in protecting waste management systems and the environment. Small changes in behavior can lead to substantial collective benefits, proving that even the act of "pulling the plug" on products like Easy Cheese has broader implications worth considering.

PMMA and Cheese: What You Need to Know Post-Procedure

You may want to see also

Frequently asked questions

Pulling the plug on Easy Cheese refers to discontinuing or stopping the use or supply of something that has been consistently relied upon, much like stopping the flow of cheese from a can. It often results in a sudden lack of convenience or resource.

No, it’s a metaphorical phrase. Easy Cheese comes in an aerosol can, so there’s no actual plug to pull. The phrase is used to describe ending something abruptly.

Consequences depend on the context. If it’s about a product, it could mean shortages or discontinuation. If it’s metaphorical, it might lead to inconvenience, frustration, or the need to find alternatives.

In a literal sense, once a product is discontinued, it’s often irreversible. Metaphorically, reversing the decision depends on the situation, such as reintroducing a resource or restarting a process.

Reasons could include cost-cutting, low demand, or shifting priorities. Metaphorically, it might be done to force change, eliminate dependency, or address a problem caused by over-reliance on something.