A cheese wire is a specialized kitchen tool designed specifically for cutting cheese with precision and ease. Typically consisting of a thin, taut wire stretched between two handles, it allows users to slice through both hard and soft cheeses cleanly, minimizing crumbling and ensuring even portions. Unlike traditional knives, which can compress or tear cheese, a cheese wire maintains the integrity of the cheese's texture and shape, making it a favorite among cheese enthusiasts and professionals alike. Its simplicity and effectiveness have cemented its place as an essential utensil in cheese boards, charcuterie setups, and culinary environments.

| Characteristics | Values |

|---|---|

| Definition | A cheese wire is a kitchen tool specifically designed for cutting cheese into precise slices or portions. |

| Material | Typically made of stainless steel or coated metal for durability and rust resistance. |

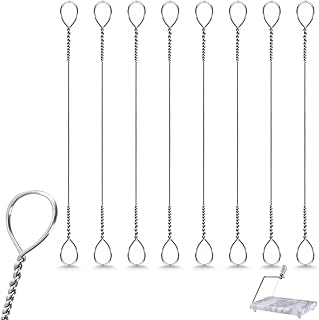

| Design | Consists of a thin, taut wire stretched between two handles or a frame. |

| Purpose | Used to slice both hard and soft cheeses cleanly without crumbling or squashing. |

| Types | Handheld cheese wires, cheese wire cutters with adjustable frames, and integrated cheese boards with wires. |

| Ease of Use | Simple to operate; requires minimal effort to achieve clean cuts. |

| Maintenance | Easy to clean; dishwasher-safe in most cases, depending on the model. |

| Portability | Compact and lightweight, making it easy to store and transport. |

| Versatility | Can be used for other soft foods like cakes or pastries, though primarily designed for cheese. |

| Price Range | Generally affordable, ranging from $5 to $30 depending on brand and features. |

Explore related products

$8.99

What You'll Learn

- Definition: A cheese wire is a thin, sharp wire used for cutting cheese into slices

- Material: Typically made of stainless steel for durability and rust resistance

- Design: Features a handle and taut wire for precise, effortless cutting

- Uses: Ideal for soft to semi-hard cheeses, ensuring clean, even slices

- Alternatives: Cheese knives or planes are common substitutes for harder cheeses

Definition: A cheese wire is a thin, sharp wire used for cutting cheese into slices

A cheese wire is a specialized tool designed for precision in the kitchen, particularly when it comes to slicing cheese. Unlike traditional knives, which can crush or tear the cheese, a cheese wire’s thin, sharp edge glides through both hard and soft varieties with minimal friction. This ensures clean, even slices, preserving the cheese’s texture and appearance. For example, when cutting a delicate Brie or a firm Cheddar, the wire’s efficiency becomes evident, making it a favorite among cheesemongers and home cooks alike.

To use a cheese wire effectively, follow these steps: first, position the wire taut across the cheese at the desired slicing point. Then, apply gentle, even pressure downward, allowing the wire to do the work. Avoid sawing motions, as these can damage the cheese. For harder cheeses, consider chilling them slightly to reduce crumbling. Soft cheeses, on the other hand, may require a quicker, more decisive cut. Always clean the wire immediately after use to prevent residue buildup, which can affect future slices.

The design of a cheese wire often includes handles on either end, providing stability and control during cutting. Some models feature adjustable wires to accommodate cheeses of varying heights, while others are fixed for simplicity. When selecting a cheese wire, consider the types of cheese you frequently slice. For instance, a heavy-duty wire is ideal for aged cheeses, whereas a finer wire may be better suited for softer, creamier options.

One of the key advantages of a cheese wire is its versatility. Beyond slicing cheese, it can be used to portion dough, cut pastries, or even divide delicate desserts like cakes and cheesecakes. This dual functionality makes it a valuable addition to any kitchen toolkit. However, it’s important to handle the wire with care, as its sharpness poses a risk of injury if misused. Always store it in a secure place, away from children and pets.

In comparison to other cheese-cutting tools, the cheese wire stands out for its simplicity and effectiveness. Knives, while versatile, often lack the precision needed for uniform slices. Cheese planes, though useful for hard cheeses, can struggle with softer varieties. The cheese wire bridges this gap, offering a single solution for a wide range of cheeses. Its minimalist design also ensures ease of maintenance, requiring only occasional tightening of the wire to maintain optimal performance.

Tillamook Cheese Factory Memorial Day Hours: Is It Open?

You may want to see also

Material: Typically made of stainless steel for durability and rust resistance

Stainless steel stands as the material of choice for cheese wires, and for good reason. Its inherent properties make it ideal for the task of slicing through cheese with precision and ease. The alloy's composition, typically a blend of iron, chromium, and nickel, provides exceptional strength and resistance to corrosion, ensuring the wire remains sharp and functional even after repeated use. This durability is particularly important in a kitchen tool that often encounters the acidity and moisture present in various cheese types.

The manufacturing process of stainless steel cheese wires involves a careful balance of elements. Chromium, for instance, is added to the alloy to form a protective oxide layer on the surface, preventing rust and maintaining the wire's integrity. This is crucial, as rust can not only compromise the wire's cutting ability but also pose health risks if it comes into contact with food. A typical stainless steel cheese wire contains around 10.5% chromium, ensuring optimal corrosion resistance without sacrificing flexibility.

##

When selecting a cheese wire, consider the gauge of the stainless steel. A higher gauge number indicates a thinner wire, which is ideal for slicing softer cheeses like Brie or Camembert. For harder varieties such as Cheddar or Parmesan, a lower gauge (thicker) wire provides the necessary strength to cut through without breaking. This simple adjustment in material thickness demonstrates how stainless steel's versatility caters to the diverse needs of cheese enthusiasts.

The maintenance of stainless steel cheese wires is relatively straightforward, further adding to their appeal. Regular cleaning with mild detergent and warm water is sufficient to keep the wire in top condition. It's advisable to dry the wire thoroughly after each use to prevent water spots and maintain its sleek appearance. Unlike some other materials, stainless steel does not require special oils or treatments, making it a low-maintenance option for both professional chefs and home cooks.

In the world of cheese accessories, the choice of material is not merely a matter of aesthetics but a critical factor in performance and longevity. Stainless steel's dominance in cheese wire construction is a testament to its ability to meet the specific demands of this culinary task. Its durability, rust resistance, and adaptability to different cheese types make it an indispensable tool for anyone looking to elevate their cheese presentation and enjoyment. With proper care, a stainless steel cheese wire can become a trusted companion in the kitchen, ensuring every cheese board is a masterpiece.

Understanding the Idiom 'Have All the Cheese': Origins and Modern Usage

You may want to see also

Design: Features a handle and taut wire for precise, effortless cutting

A cheese wire's design is deceptively simple yet brilliantly effective. At its core, it consists of a taut wire stretched between two handles, a configuration that prioritizes precision and ease of use. This minimalist design ensures that the tool is lightweight and easy to maneuver, making it ideal for both professional chefs and home cooks. The taut wire, often made of stainless steel, is thin enough to slice through cheese with minimal friction, reducing waste and ensuring clean cuts every time.

To use a cheese wire effectively, start by positioning the wire at the desired cutting point. Apply gentle, even pressure on both handles, pulling them apart in a smooth, steady motion. This technique allows the wire to glide through the cheese effortlessly, creating uniform slices without crumbling or tearing. For harder cheeses like Parmesan or aged Gouda, ensure the wire is fully taut to maintain control and precision. Softer cheeses, such as Brie or Camembert, may require a slightly looser grip to avoid squashing the cheese.

One of the standout features of a cheese wire is its versatility. Unlike traditional knives, which can push or drag cheese, the wire’s thin profile minimizes contact with the cheese, preserving its texture and shape. This makes it particularly useful for cutting semi-soft to hard cheeses into thin, even slices, perfect for charcuterie boards or sandwiches. Additionally, the wire’s design reduces the risk of injury compared to sharp blades, making it a safer option for users of all ages.

When selecting a cheese wire, consider the handle design for comfort and control. Ergonomic handles with non-slip grips enhance usability, especially during prolonged use. Some models feature adjustable wires, allowing you to customize tension for different cheese types. Maintenance is straightforward: simply hand-wash the wire and handles with warm, soapy water after each use to prevent residue buildup. Avoid dishwashers, as high temperatures can damage the wire’s tension.

In comparison to other cheese-cutting tools, the cheese wire stands out for its simplicity and efficiency. While cheese knives and planes excel in specific tasks, the wire’s design offers a universal solution for clean, precise cuts across a wide range of cheeses. Its compact size and affordability make it a practical addition to any kitchen, whether you’re a cheese enthusiast or a casual consumer. By mastering its use, you’ll elevate your cheese presentation and enjoy a more seamless cutting experience.

Discovering Neufchatel Cheese: A French Delight and Creamy Classic

You may want to see also

Explore related products

Uses: Ideal for soft to semi-hard cheeses, ensuring clean, even slices

A cheese wire is a specialized tool designed to slice through soft to semi-hard cheeses with precision and ease. Its primary function is to ensure clean, even slices, making it an essential utensil for cheese enthusiasts and professionals alike. Unlike traditional knives, which can crush or tear the cheese, a cheese wire maintains the integrity of the cheese’s texture, delivering consistent results every time. This tool is particularly useful for cheeses like Brie, Camembert, Cheddar, and Gouda, where a smooth cut enhances both presentation and taste.

To use a cheese wire effectively, start by positioning the wire at the desired cutting point. Apply gentle, even pressure as you pull the wire through the cheese, ensuring a straight and controlled motion. For softer cheeses, chilling them slightly before slicing can improve the wire’s performance, reducing the risk of the cheese sticking or deforming. Semi-hard cheeses, on the other hand, may require a slightly firmer grip to achieve a clean cut. Always clean the wire immediately after use to prevent residue buildup, which can affect future slicing.

One of the standout advantages of a cheese wire is its ability to minimize waste. Traditional knives often leave uneven edges or crumbs, but a wire’s thin profile ensures that every slice is maximized. This is especially valuable when working with expensive or artisanal cheeses, where every gram counts. Additionally, the wire’s design allows for adjustable tension, catering to different cheese densities and user preferences. For instance, a tighter tension works well for semi-hard cheeses, while a looser setting is ideal for softer varieties.

When comparing a cheese wire to other slicing tools, its efficiency becomes evident. Knives, while versatile, often require more effort and skill to achieve similar results. Cheese planes, though effective for harder cheeses, can struggle with softer textures. A cheese wire bridges this gap, offering a universal solution for a wide range of cheeses. Its simplicity and effectiveness make it a favorite in both home kitchens and professional settings, where consistency and precision are paramount.

Incorporating a cheese wire into your culinary toolkit can elevate your cheese-serving experience. Whether preparing a charcuterie board, crafting sandwiches, or simply enjoying a slice, the tool ensures that each piece is visually appealing and easy to handle. For those who take their cheese seriously, investing in a high-quality cheese wire is a decision that pays dividends in both functionality and finesse. With proper care, this unassuming tool can become a trusted companion for years to come.

Is Cheese a Proper Noun? Exploring Grammar and Dairy Delights

You may want to see also

Alternatives: Cheese knives or planes are common substitutes for harder cheeses

Cheese wires are ideal for soft to semi-hard cheeses, but harder varieties like Parmesan or aged Gouda demand a different approach. Here, cheese knives and planes step in as reliable substitutes, offering precision and control. Cheese knives, with their sharp, thin blades, are designed to slice through dense cheeses without crumbling them. For optimal results, apply gentle, even pressure and use a rocking motion to maintain the integrity of the cheese. Planes, on the other hand, excel at creating thin, even slices or shavings, perfect for garnishes or melting. When using a plane, ensure the cheese is chilled but not brittle, as this allows for smoother, more consistent results.

While both tools are effective, their suitability depends on the desired outcome. Cheese knives are versatile and handle a wider range of textures, making them a go-to for both cutting and serving. Planes, however, are specialized for harder cheeses and are particularly useful when presentation matters. For instance, a plane can transform a block of aged cheddar into delicate shavings that melt effortlessly over a dish, whereas a knife would produce thicker slices better suited for a cheese board. Understanding these nuances ensures you select the right tool for the task at hand.

For those new to handling harder cheeses, start by practicing with a cheese knife on a moderately hard variety like Gruyère. Hold the knife at a slight angle and slice with a smooth, continuous motion. Avoid sawing, as this can create uneven edges and waste cheese. When transitioning to a plane, begin with a well-chilled block and apply minimal pressure, allowing the tool to glide across the surface. Over time, you’ll develop a feel for the optimal pressure and angle needed for different cheeses. Remember, the goal is to enhance the cheese’s natural qualities, not force it into submission.

One practical tip is to keep your tools sharp and clean. A dull blade can crush rather than cut harder cheeses, compromising both texture and appearance. After each use, wash your knife or plane with warm, soapy water and dry it immediately to prevent rust. For added longevity, store these tools separately from other utensils to avoid dulling the edges. By maintaining your equipment, you ensure consistent performance and extend its lifespan, making every cheese-cutting experience seamless.

In conclusion, while cheese wires are indispensable for softer varieties, harder cheeses require the precision of knives or the finesse of planes. Each tool offers unique advantages, and mastering their use elevates both preparation and presentation. Whether you’re crafting a gourmet platter or adding a finishing touch to a dish, choosing the right alternative ensures your cheese shines in every slice or shaving. With practice and care, these substitutes become invaluable additions to any cheese enthusiast’s toolkit.

Does Cheese Boost Estrogen Levels? Unraveling the Dairy Hormone Myth

You may want to see also

Frequently asked questions

A cheese wire is a kitchen tool specifically designed for cutting cheese into thin, even slices. It consists of a taut wire stretched between two handles, allowing for precise and effortless cutting.

A cheese wire works by pulling the taut wire through the cheese, creating a clean cut. The wire’s thin profile minimizes resistance, making it ideal for soft to semi-hard cheeses without crushing or crumbling them.

A cheese wire is best suited for soft to semi-hard cheeses like Brie, Camembert, Cheddar, and Gouda. It is less effective for very hard cheeses like Parmesan, which require a heavier knife.

While primarily designed for cheese, a cheese wire can also be used to slice other soft foods like cakes, pastries, or even soap. However, it’s most effective and commonly used for cheese.