Block opening at a cheese plant refers to the process of cutting and handling large blocks of cheese, typically after they have been aged or stored. This critical step involves carefully removing the cheese from its packaging, inspecting it for quality, and preparing it for further processing, such as slicing, shredding, or packaging for distribution. Proper block opening ensures the cheese remains uncontaminated, maintains its texture and flavor, and meets industry standards. The process often requires specialized equipment and trained personnel to handle the cheese efficiently while minimizing waste and ensuring food safety.

Explore related products

What You'll Learn

Safety protocols for block opening

Block opening in a cheese plant involves handling large, heavy blocks of cheese, often weighing hundreds of pounds, which are transported, lifted, and cut into smaller portions. The process demands precision and strength, but it also poses significant safety risks if not managed correctly. Workers must operate heavy machinery, such as forklifts and band saws, while avoiding hazards like sharp blades, slippery surfaces, and awkward lifting positions. Without strict safety protocols, injuries ranging from cuts and strains to more severe accidents can occur.

Step-by-Step Safety Protocols:

- Pre-Operation Inspection: Before starting, inspect all equipment, including forklifts, pallet jacks, and cutting machinery, for defects or malfunctions. Ensure blades are sharp but securely guarded, and hydraulic systems are functioning properly.

- Personal Protective Equipment (PPE): Workers must wear non-slip footwear, cut-resistant gloves, and eye protection. High-visibility vests are recommended in areas with heavy machinery traffic.

- Lifting Techniques: Use mechanical aids like forklifts or hoists to move blocks, avoiding manual lifting whenever possible. If manual handling is necessary, train workers in proper techniques: bend at the knees, keep the back straight, and lift with leg muscles.

- Machine Operation: Only trained and certified operators should use cutting machinery. Establish clear communication protocols, such as hand signals or verbal cues, to coordinate movements around the equipment.

Cautions and Common Pitfalls:

Slippery floors from cheese residue or cleaning solutions are a frequent hazard. Regularly clean and dry work areas, and use non-slip mats in high-risk zones. Overloading forklifts or cutting machines beyond their capacity can lead to equipment failure or accidents. Always adhere to manufacturer guidelines for weight limits and operational speeds.

Comparative Analysis:

Unlike smaller-scale cheese production, industrial block opening requires a higher level of automation and safety oversight. For instance, while a small artisan shop might rely on manual cutting tools, a large plant uses band saws or wire cutters, which demand stricter safety measures. Similarly, the volume of cheese handled in industrial settings necessitates more robust protocols, such as daily safety briefings and regular emergency drills.

Practical Tips for Implementation:

Post safety guidelines in visible areas, such as near machinery or in break rooms. Conduct monthly safety audits to identify and address potential risks. Encourage workers to report near-miss incidents, as these can highlight systemic issues before they cause harm. Finally, invest in ergonomic tools, like adjustable cutting tables, to reduce physical strain and improve efficiency.

By prioritizing these safety protocols, cheese plants can minimize risks, protect workers, and maintain productivity during block opening operations.

Paleo-Friendly Cheese Options: What’s Acceptable on Your Diet?

You may want to see also

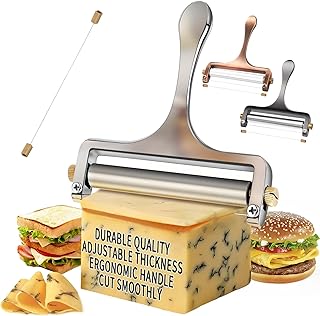

Equipment used in block opening

Block opening in a cheese plant is a critical step that requires precision and efficiency to maintain product quality and safety. The equipment used in this process is designed to handle large, heavy blocks of cheese while ensuring minimal damage and contamination. One of the primary tools is the block opener, a machine that uses sharp, stainless steel blades to split cheese blocks into manageable portions. These blades are often adjustable to accommodate different block sizes, typically ranging from 20 to 60 pounds, and are operated with hydraulic or pneumatic systems for consistent force application. Proper blade maintenance, including regular sharpening and sanitization, is essential to prevent tearing or crumbling of the cheese, which can lead to yield loss.

Another essential piece of equipment is the conveyor system, which transports cheese blocks from storage to the opening station. These conveyors are typically made of food-grade materials like stainless steel or plastic to comply with hygiene standards. Some advanced systems incorporate automated sorting mechanisms that use sensors to detect block size and direct them to the appropriate opening station. For instance, a plant processing both 40-pound and 60-pound blocks might use a conveyor with integrated scales and diverters to streamline workflow. Ensuring the conveyor belts are free of debris and properly tensioned is crucial to avoid block jamming or misalignment during transport.

Once opened, the cheese blocks often undergo a vacuum lifting process to move them safely without manual handling. Vacuum lifters use suction cups or pads to grip the cheese, reducing the risk of contamination from human contact. These devices are particularly useful for softer cheeses that are prone to damage when handled manually. For example, a vacuum lifter with a capacity of 150 pounds can efficiently transfer large blocks to cutting or packaging stations. Operators should be trained to monitor suction levels and inspect the lifters for wear to prevent accidental drops, which can compromise product integrity.

Finally, sanitation equipment plays a vital role in maintaining the cleanliness of block-opening machinery. High-pressure washers and sanitizing sprayers are used to clean blades, conveyors, and lifters between batches to prevent cross-contamination. Automated cleaning systems, such as CIP (Clean-in-Place) units, are increasingly popular for their efficiency and thoroughness. These systems use heated cleaning solutions at specific concentrations (e.g., 1-2% sanitizing solution) to remove residue and pathogens. Regular audits of cleaning protocols and equipment functionality are necessary to meet regulatory standards and ensure food safety.

In summary, the equipment used in block opening at a cheese plant is specialized to handle the unique challenges of processing large cheese blocks. From precision-cutting blades to automated conveyors and vacuum lifters, each tool plays a distinct role in optimizing efficiency and maintaining quality. Proper maintenance and sanitation of these machines are non-negotiable, as they directly impact yield, safety, and compliance. By investing in the right equipment and adhering to best practices, cheese plants can streamline their operations and deliver consistent, high-quality products.

Mastering the Art of Ordering Taco Bell's Chili Cheese Burrito

You may want to see also

Steps to open cheese blocks

Block opening at a cheese plant is a critical step in the production process, ensuring that large cheese blocks are safely and efficiently prepared for further handling, cutting, or packaging. This procedure requires precision, adherence to safety protocols, and the use of specialized equipment to maintain product quality and worker safety. Here’s a detailed guide to the steps involved in opening cheese blocks effectively.

Step 1: Inspect and Prepare the Block

Begin by visually inspecting the cheese block for any signs of damage, contamination, or improper sealing. Ensure the block is at the optimal temperature (typically 4–8°C) to maintain structural integrity during handling. Use a food-grade brush or cloth to remove any surface debris or packaging residue. For wax-coated blocks, carefully trim the wax layer with a sterile knife, avoiding deep cuts into the cheese itself. This preparatory step is crucial for preventing contamination and ensuring a clean cut in the subsequent stages.

Step 2: Position and Secure the Block

Place the cheese block on a dedicated cutting table or conveyor system, ensuring it is stable and securely positioned. Use non-slip mats or clamps to prevent movement during the opening process. For larger blocks (e.g., 20–40 kg), consider using a hydraulic lift or trolley to minimize manual strain. Align the block so that the intended cutting plane is perpendicular to the blade, reducing the risk of uneven cuts or equipment damage.

Step 3: Execute the Initial Cut

Using a band saw, wire cutter, or guillotine-style cheese cutter, make the initial cut along the designated line. For semi-hard to hard cheeses, set the blade speed to 10–15 meters per second to ensure a clean, precise cut. Apply consistent pressure and avoid forcing the blade to prevent cracking or crumbling. In automated systems, program the machine to follow pre-set dimensions (e.g., 5 cm slices) for uniformity. Always wear protective gear, including gloves and eye protection, during this step.

Step 4: Separate and Inspect the Sections

Carefully separate the cut sections, using spatulas or lifters to avoid direct hand contact with the cheese. Inspect each piece for quality, discarding any portions with defects or foreign matter. For aged cheeses, check for the presence of undesirable mold or excessive moisture. If the block is to be further processed (e.g., shredded or melted), ensure the sections are uniform in size to facilitate consistent downstream handling.

Step 5: Clean and Sanitize Equipment

After completing the block opening, thoroughly clean all equipment with food-grade sanitizers to prevent cross-contamination. Pay special attention to blades, cutting surfaces, and conveyor belts. Follow HACCP (Hazard Analysis and Critical Control Points) guidelines to maintain hygiene standards. Regularly inspect equipment for wear and tear, replacing blades or components as needed to ensure continued precision and safety.

By following these steps, cheese plants can streamline the block opening process, enhance product quality, and uphold safety standards. Attention to detail at each stage ensures that the final product meets consumer expectations while minimizing waste and operational risks.

Tom and Jerry's Cheese Chase: A Hilarious Pursuit or Just a Myth?

You may want to see also

Explore related products

Quality checks during block opening

Block opening at a cheese plant is a critical step where large cheese blocks are prepared for further processing, such as slicing, shredding, or packaging. This stage demands meticulous quality checks to ensure the final product meets safety, texture, and flavor standards. Overlooking these checks can lead to costly recalls, customer dissatisfaction, or regulatory penalties.

Visual Inspection: The First Line of Defense

Begin with a thorough visual examination of the block’s exterior. Look for discoloration, mold growth, or unusual texture—signs of improper storage or bacterial contamination. For example, a greenish tint on cheddar could indicate the presence of *Penicillium* species, while a slimy surface may suggest *Listeria* contamination. Use a magnifying glass or UV light to detect subtle defects. Document findings immediately, as even minor issues can escalate during processing.

Temperature and pH Verification: Preventing Spoilage

Before opening, verify the block’s core temperature and pH level. Ideal temperatures range between 2–4°C (36–39°F) for most cheeses, while pH should align with product specifications (e.g., 5.0–5.5 for cheddar). Deviations can signal spoilage or improper curing. Use a calibrated digital thermometer and pH meter for accuracy. If readings fall outside acceptable ranges, isolate the block for further testing or discard it to prevent cross-contamination.

Texture and Aroma Assessment: Ensuring Consistency

Once the block is opened, evaluate its internal texture and aroma. A crumbly texture in a typically smooth cheese like mozzarella or an off-putting ammonia smell in Parmesan could indicate over-aging or improper handling. Train staff to recognize benchmark aromas and textures for each cheese variety. For instance, Gouda should have a nutty, buttery aroma, while Brie should exhibit a creamy interior with a mild fungal scent.

Microbial Testing: The Final Safeguard

While time-consuming, microbial testing is non-negotiable. Collect samples from the block’s interior and exterior for lab analysis. Test for pathogens like *Salmonella*, *E. coli*, and *Listeria monocytogenes*. Rapid methods, such as PCR or ATP bioluminescence, can provide results within hours. Establish a threshold for acceptable microbial counts (e.g., <100 CFU/g for *Listeria*) and reject blocks exceeding limits. Regularly audit testing protocols to align with FDA or EU regulations.

Practical Tips for Streamlining Checks

Integrate quality checks into the workflow without slowing production. Use color-coded tools for different testing stages to avoid cross-contamination. Train operators to recognize defects through hands-on workshops, and maintain a logbook for traceability. Invest in automated systems, such as vision inspection machines or inline pH sensors, to enhance efficiency. Finally, conduct weekly audits to ensure compliance and identify areas for improvement.

By prioritizing these quality checks during block opening, cheese plants can safeguard product integrity, reduce waste, and uphold consumer trust. Each step, from visual inspection to microbial testing, plays a vital role in delivering cheese that is not only delicious but also safe.

Cheese vs. Eggs: Which Food is Kinder to Your Prostate?

You may want to see also

Common issues in block opening

Block opening at a cheese plant involves breaking down large cheese blocks into smaller, manageable pieces for further processing or packaging. While seemingly straightforward, this step is fraught with challenges that can compromise efficiency, quality, and safety. One common issue is blade dullness, which leads to uneven cuts, increased friction, and potential contamination from metal particles. Blades should be sharpened or replaced after every 200–300 blocks, depending on hardness and moisture content of the cheese. For example, harder cheeses like cheddar require more frequent blade maintenance compared to softer varieties like mozzarella.

Another recurring problem is temperature mismanagement. Cheese blocks must be at the optimal temperature (typically 4–8°C) before opening to ensure clean cuts and structural integrity. If too warm, the cheese becomes sticky, causing it to cling to equipment and tear rather than slice. Conversely, overly cold blocks can crack or shatter, leading to waste. A practical tip is to allow blocks to temper in a controlled environment for 12–24 hours before processing, ensuring uniformity throughout the block.

Cross-contamination is a critical concern, especially in plants handling multiple cheese types or allergens. Residual cheese particles on equipment can transfer flavors or allergens between batches, risking product recalls. To mitigate this, use dedicated tools for each cheese type and implement a rigorous cleaning protocol with food-safe sanitizers. For instance, a 200 ppm chlorine solution is effective for most surfaces but should be followed by a thorough rinse to avoid chemical residue.

Lastly, operator error often exacerbates block opening issues. Inconsistent pressure, incorrect blade alignment, or rushed handling can result in jagged edges, uneven portions, or damaged product. Training staff on proper techniques and providing ergonomic tools can reduce mistakes. For example, hydraulic cutting machines with pre-set pressure levels (e.g., 50–70 psi for semi-hard cheeses) ensure uniformity while minimizing physical strain on workers.

Addressing these issues requires a combination of proactive maintenance, precise control, and standardized practices. By focusing on blade sharpness, temperature management, sanitation, and operator training, cheese plants can streamline block opening, enhance product quality, and maintain safety standards.

Philly Cheese Steak Seasoning Secrets: What's on the Meat?

You may want to see also

Frequently asked questions

Block opening is the process of cutting and preparing large blocks of cheese for further processing, packaging, or distribution.

Block opening is necessary to break down large cheese blocks into manageable sizes for slicing, shredding, or portioning, ensuring consistency and efficiency in the final product.

Specialized equipment such as cheese cutters, band saws, or automated block-opening machines are used to safely and precisely cut the cheese blocks.

Yes, safety is critical during block opening. Workers must follow protocols, use protective gear, and ensure machinery is properly maintained to prevent injuries and maintain hygiene standards.