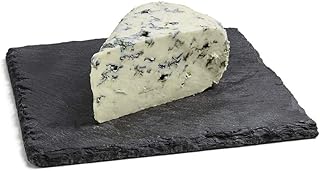

Blue cheese is a general classification of cheeses that have had cultures of the mold Penicillium added so that the final product is spotted or veined throughout with blue, or blue-grey mold and carries a distinct smell. The mold on blue cheese is from the same family of spores used to make penicillin. The distinctive flavor and aroma of blue cheese arise from methyl ketones, which are a metabolic product of Penicillium roqueforti. The mold makes the cheese creamy, particularly near where the amino acids are most active — the gray, blue veins. The blue mold will also soften the cheese a bit, but it's not a massive difference. One user describes blue cheese without mold as tasting like feta without brine.

Characteristics of Blue Cheese without Mold

| Characteristics | Values |

|---|---|

| Taste | Mild, creamy, nutty, sharp, tangy, salty, sweet |

| Texture | Soft, crumbly, creamy, smooth, moist, velvety |

| Colour | White, pale ivory |

| Smell | Distinct |

| Type of milk | Cow's, goat's, sheep's |

| Penicillium | Roqueforti, Glaucum |

| Health hazards | Unlikely |

Explore related products

What You'll Learn

- Blue cheese is made with mould spores of the Penicillium genus

- The mould is added to the curds, and the cheese is pierced to expose it to oxygen

- Blue cheese is safe to eat because the mould does not produce toxins

- The mould accelerates the biochemical processes that give blue cheese its unique characteristics

- Blue cheese without mould would taste like cream cheese or feta without brine

Blue cheese is made with mould spores of the Penicillium genus

Penicillium roqueforti is added to the cheese-making process by sprinkling the inoculum on top of the curds along with Brevibacterium linens. The curds are then knit in moulds to form cheese loaves with a relatively open texture. To create the blue veins characteristic of blue cheese, the aged curds are pierced, forming air tunnels in the cheese. When given oxygen, the mould is able to grow along the surface of the curd-air interface, creating the blue veins and developing flavour as it ages. The veins along the blue cheese are also responsible for the aroma of blue cheese.

Penicillium roqueforti produces several mycotoxins, including roquefortine, isofumigaclavine A, mycophenolic acid, and ferrichrome, which are present in the cheese at low levels. However, the instability of some of these mycotoxins and the lack of optimal environmental conditions for their production mean that health hazards due to Penicillium roqueforti metabolites are considered unlikely. The distinctive flavour and aroma of blue cheese are a result of methyl ketones, which are metabolic products of Penicillium roqueforti.

The appearance of blue cheese can be altered by using different strains of Penicillium roqueforti with different spore colours. For example, a mutant strain of Penicillium roqueforti that did not turn blue was created by exposing the mould to UV lights. This mutant strain produced a cheese that was flavourful like blue cheese but lacked the blue colour.

Blue Cheese's Best Cracker Companion: A Tasty Guide

You may want to see also

The mould is added to the curds, and the cheese is pierced to expose it to oxygen

Blue cheese is made from cow, goat, sheep, or even buffalo milk, which may be raw or pasteurized. The milk is then curdled, and the curds are ladled into containers to be drained and formed into a full wheel of cheese. The mould, usually Penicillium roqueforti inoculum, is then sprinkled on top of the curds. The curds are then knit in moulds to form cheese loaves with a relatively open texture. This open texture is important as it allows for air gaps between the curds, which will later facilitate piercing and oxygen exposure.

After the mould is added, whey drainage continues for 10 to 48 hours with no pressure applied. Instead, the moulds are inverted frequently to promote whey drainage. Salt is then added to provide flavour and act as a preservative, and the cheese is brine or dry-salted for 24 to 48 hours.

The final step is ripening the cheese by ageing it. When the cheese is freshly made, there is little to no blue cheese flavour development. To facilitate flavour development, the cheese is pierced with thin needles or skewers to expose the mould to oxygen. The blue mould then matures inside the air tunnels, developing flavour as it ages. Usually, a fermentation period of 60 to 90 days is needed before the flavour of the cheese is typical and acceptable for marketing.

Blu Cheese and Keto: A Match Made in Heaven?

You may want to see also

Blue cheese is safe to eat because the mould does not produce toxins

Blue cheese is a type of cheese characterised by its blue veins, which are caused by the growth of the mould Penicillium roqueforti. This mould is responsible for the distinct taste, smell, and appearance of blue cheese.

Despite being mouldy, blue cheese is safe to eat because the mould does not produce toxins. The types of Penicillium used to produce blue cheese, such as Penicillium roqueforti and Penicillium glaucum, do not produce toxins by themselves and are not dangerous to humans. In fact, Penicillium roqueforti is in the same family of spores as the one used to make the antibiotic penicillin.

While some types of mould produce chemicals called mycotoxins that are harmful to humans, the mould used to make blue cheese does not produce any harmful substances. Mycotoxins are toxic compounds that can suppress immune function, cause digestive distress, and even contribute to cancer. However, the mould in blue cheese does not produce mycotoxins at levels that are harmful to humans, and large quantities of cheese are rarely consumed, further reducing the risk of health hazards.

Blue cheese is made by adding the mould culture to the cheese milk or sprinkling it on top of the curds after they have been drained and formed into wheels. The cheese is then left to age for 2-3 months, during which time the mould grows and develops flavour. The blue mould matures inside the air tunnels, creating the characteristic blue veins and developing flavour as it ages.

Proper storage and food safety practices are important to prevent negative side effects and enjoy blue cheese safely. Blue cheese should be tightly wrapped and stored in the refrigerator. It should be discarded if there are any changes in its appearance or smell, as consuming spoiled blue cheese can cause food poisoning.

Blue Cheese and Penicillin: What's the Connection?

You may want to see also

Explore related products

The mould accelerates the biochemical processes that give blue cheese its unique characteristics

Blue cheese is made using milk from cows, goats, or sheep. The process of making blue cheese consists of six standard steps, but additional ingredients and processes are required to give this blue-veined cheese its particular properties.

The mould that gives blue cheese its distinctive characteristics is called Penicillium roqueforti. According to legend, one of the first blue cheeses, Roquefort, was discovered when a young boy, eating bread and ewes' milk cheese, left his meal in a cave after seeing a beautiful girl in the distance. When he returned months later, the cheese had become infested with Penicillium roqueforti, a mould that was growing in the cave.

Penicillium roqueforti is responsible for the greenish-blue mouldy aspect of blue cheese. It produces several mycotoxins, including roquefortine, isofumigaclavine A, mycophenolic acid, and ferrichrome. Importantly, these mycotoxins are present at low levels, and the large quantities of cheese consumed suggest that health hazards due to Penicillium roqueforti metabolites are unlikely.

Penicillium roqueforti produces enzymes that release amino acids, which quickly break down the cheese's proteins (casein). This process, called proteolysis, makes the cheese creamy, particularly near where the amino acids are most active—the grey, blue veins. In addition, Penicillium roqueforti also triggers another biochemical event called lipolysis, which catalyses enzymes that lead to the creation of free fatty acids and the release of methyl ketone. This gives the cheese its distinct blue look, odd smell, and sharp flavour.

The mould in blue cheese accelerates the biochemical processes that give blue cheese its unique characteristics. Without the mould, blue cheese would not have its distinctive sharp flavour, creamy texture, or blue veins.

Blue Cheese vs Gorgonzola: What's the Taste Difference?

You may want to see also

Blue cheese without mould would taste like cream cheese or feta without brine

Blue cheese is made using milk from cows, goats, or sheep. The process of making blue cheese consists of six standard steps, but additional ingredients and processes are required to give this blue-veined cheese its particular properties. After the curds have been ladled into containers to be drained and formed into a wheel of cheese, the Penicillium roqueforti inoculum is sprinkled on top of the curds along with Brevibacterium linens. The mould then matures inside the air tunnels, developing flavour as it ages.

The distinctive flavour and aroma of blue cheese come from methyl ketones, which are a metabolic product of Penicillium roqueforti. The mould is responsible for the greenish-blue, mouldy aspect of blue cheese. The mould also produces several mycotoxins, including roquefortine, isofumigaclavine A, mycophenolic acid, and ferrichrome. However, these are present at low levels, and the large quantities of cheese consumed suggest that health hazards due to Penicillium roqueforti metabolites are unlikely.

According to some sources, blue cheese without mould would taste like cream cheese or feta without brine. One source mentions that they tried blue cheese without the Penicillium added, and it tasted like feta without brine. Another source mentions that blue cheese without mould is cream cheese. However, it is important to note that the mould in blue cheese does affect its taste and texture. The mould makes the cheese sharper and softer. Therefore, blue cheese without mould may have a milder flavour and a firmer texture.

Additionally, when choosing a replacement for blue cheese, it is essential to consider the characteristics the cheese is meant to add to a recipe. For example, in salads and pastas, gorgonzola or Roquefort are common blue cheese choices. Feta is a great mould-free replacement for gorgonzola, as it has a similar texture and a mild flavour. On the other hand, Roquefort has a tangy, peppery, sharper flavour and a creamy texture, so a moist yet strongly-flavoured goat cheese could be a suitable alternative.

Blue Cheese Dressing: Acidic or Not?

You may want to see also

Frequently asked questions

Blue cheese without mold is cream cheese. The mold in blue cheese is what gives it its distinct look, texture, and taste.

The mold in blue cheese is called Penicillium. More specifically, the molds used are Penicillium roqueforti and Penicillium glaucum.

Blue cheese is made by adding the mold Penicillium roqueforti to cheese milk. The cheese is then pierced with needles or skewers to expose it to oxygen, which helps the mold grow and develop flavor. Salt is added to preserve the cheese, and then it is aged for several weeks or months.