Brie is a soft cow's-milk cheese named after the French region of Brie, where it originated. It has a pale colour with a slight greyish tinge and a rind of white mould, which is typically eaten. The cheese is made with just a few simple ingredients, including milk, cream, salt and microbial enzymes. Brie is distinguished by the addition of extra cream, which can be labelled as double cream or triple cream. The cheese is then salted, inoculated with cheese culture and aged in a controlled environment for at least four to five weeks.

| Characteristics | Values |

|---|---|

| Main Ingredients | Cow's milk, salt, microbial enzymes, cream, rennet |

| Cheese Culture | Penicillium camemberti or Brevibacterium linens |

| Region | Northern France |

| Texture | Soft, creamy |

| Colour | Pale with a slight greyish tinge under a white rind |

| Taste | Buttery, mushroomy, nutty, fruity, earthy |

| Fat Content | 60% to 75% butterfat |

| Protein Content | 5 to 6 grams of protein per serving |

| Vitamin Content | Good source of vitamin B12 and vitamin B2 |

| Calories | 100 kilocalories per 30-gram serving |

| Fat Content | 8.4 grams of fat, including 5.26 grams of saturated fat per 30-gram serving |

| Storage | Refrigerated at 4°C or lower in a sealed container |

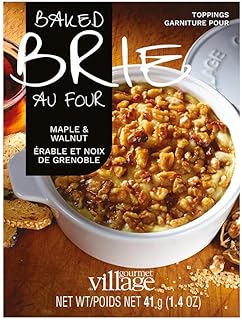

| Serving Suggestions | Baked, grilled, melted, paired with honey and nuts, or used in sandwiches, pasta, or mac and cheese |

Explore related products

What You'll Learn

Brie is made from cow's milk

Brie is a soft cow's-milk cheese named after the region in which it originated, Brie, in northern France. Brie is typically made from whole or semi-skimmed cow's milk, although the type of milk used can vary depending on the region and the cheesemaker. The curd is obtained by adding rennet to raw milk and warming it to a maximum temperature of 37°C (98.6°F).

In the United States, Brie is often made with pasteurized milk due to regulations surrounding raw milk products. The FDA requires any cheese made with raw milk to be aged for at least 60 days before being sold, while traditional Brie is typically aged for less than 40-45 days. As a result, most Brie available in the US is made with pasteurized milk, which can affect its flavour and texture.

The process of making Brie involves heating the milk and cream to 90°F (32°C). The milk is then removed from the heat and inoculated with a cheese culture, such as Penicillium camemberti or Brevibacterium linens. The cheese is then salted and aged in a controlled environment for at least four to five weeks. If left to mature for longer, the cheese becomes stronger in flavour and the rind becomes darker and crumbly, becoming what is known as Brie noir (black Brie).

Brie is known for its creamy texture and mild, buttery flavour, with hints of sweetness and mushrooms. It is a versatile cheese that can be enjoyed on its own or used in recipes such as grilled cheese sandwiches, pasta dishes, or melted over roasted vegetables.

The Crafting of Gran Milano Cheese

You may want to see also

It's a soft cheese

Brie is a soft cow's-milk cheese, named after the region in northern France where it originated. It has a creamy texture and a mild, buttery flavour. It is distinguished by the addition of extra cream, which can be labelled as "double cream" or "triple cream".

Brie is typically made from raw cow's milk, although some varieties are made with pasteurised milk. The curd is obtained by adding rennet to milk and warming it to a maximum temperature of 37°C. The cheese is then removed from the moulds, salted, and inoculated with a cheese culture (Penicillium camemberti or Brevibacterium linens). It is then aged in a controlled environment for at least four to five weeks. If left to mature for longer, the cheese becomes stronger in flavour and the rind becomes darker and crumbly, and it is called Brie noir.

Brie is a good source of protein, providing 5 to 6 grams per 30-gram serving. It also contains vitamins B12 and B2. The cheese is typically ready to eat when the outside is firm and the inside is slightly bouncy and resilient. The rind, which is typically eaten, has a white mould and its flavour depends on the ingredients used and the manufacturing environment.

Brie is often served as part of a cheese course, accompanied by crackers, hard bread, or fruit. It can also be used as a salad garnish or in the construction of canapés. When baked, it makes an excellent gooey centrepiece for a cheese board.

The Best Places to Buy NH-Made Cheese

You may want to see also

It's named after the French region it originated from

Brie is a soft cow's-milk cheese named after the Brie region (from the Gaulish "briga", meaning "hill" or "height") in the north of France where it originated. Brie de Meaux, one of the two types of Brie protected under Appellation d'Origine Contrôlée (AOC) guidelines, has been manufactured in the town of Meaux in the Brie region since the 8th century. It was originally known as the "Queen's Cheese" or the "Queen of Cheeses" and was eaten by all social classes. The other type of Brie protected under AOC guidelines is Brie de Melun, which is produced in the town of Melun and has a stronger flavour and a more pungent smell.

The name "Brie" is not protected in itself, although some regional Bries are. This means that, while anyone can use the name "Brie" for a cheese, only cheese made in the designated regions of Brie de Meaux and Brie de Melun following specific methods can be called by those names.

Brie is traditionally made with raw cow's milk, although some varieties are made with pasteurized milk. It is distinguished by the addition of extra cream, and it can be labelled "double cream" or "triple cream". Brie is traditionally produced in large wheels, 23 to 37 cm in diameter, and ripened slowly. The rind is typically eaten and its flavour depends on the ingredients used and the manufacturing environment.

Merkts Cheese: A Wisconsin Original

You may want to see also

Explore related products

It's usually white with a slight greyish tinge

Brie is a soft cow's-milk cheese named after the region in northern France from which it originated. It is typically white with a slight greyish tinge under a rind of white mould. The mould is usually eaten and its flavour depends on the ingredients used and the manufacturing environment. The cheese is ready to eat when the outside is firm and the inside is slightly bouncy and resilient.

The colour of Brie is largely due to the fact that it is made from cow's milk. The cheese-making process involves adding rennet to raw milk and warming it to a maximum temperature of 37°C (98.6°F). The curd is then taken out of the moulds, salted, inoculated with cheese culture (Penicillium camemberti or Brevibacterium linens), and aged in a controlled environment for at least four to five weeks. If the cheese is left to mature for longer, the pâte becomes drier and darker, and the rind becomes darker and crumbly. This type of Brie is called Brie noir (French for 'black brie').

The white colour of Brie is also due to the fact that it is typically made with pasteurized milk, which is milk that has been heated to a certain temperature to kill harmful bacteria. In the United States, commercially available milk and cheese go through the pasteurization process. However, traditional French Brie is made with raw milk, which is illegal in the US. This means that most of the Brie available in the US is made with pasteurized milk, which contributes to its white colour.

The slight greyish tinge of Brie can be attributed to the ageing process. As Brie ages, it develops a natural rind called a bloomy rind. This rind is a result of the Penicillium camemberti mould that is added during the cheese-making process. The mould initially appears white, but as the cheese ages, it can develop a slight greyish tinge. This mould is safe to eat and is a signature characteristic of Brie cheese.

The white colour of Brie, with its slight greyish tinge, is thus a result of the combination of cow's milk, pasteurization processes, and ageing techniques used in the cheese-making process.

The Science Behind Cheese: Bacteria's Role

You may want to see also

It's mild with a buttery, creamy flavour

Brie is a soft cow's milk cheese, typically made in France, with a mild, buttery, creamy flavour. It is named after the region of Brie in northern France, where it originated. The cheese is made with a few simple ingredients, including milk, cream, salt, and microbial enzymes. It is then inoculated with a cheese culture, typically Penicillium camemberti or Brevibacterium linens, and aged in a controlled environment for at least four to five weeks. The longer the cheese is left to mature, the stronger its flavour becomes.

The distinctive flavour of Brie is due in part to the extra cream that is added during the cheese-making process. It can be labelled as ""double cream" or "triple cream", with higher fat content than similar cheeses like Camembert. Brie typically contains between 60% and 75% butterfat, contributing to its rich, creamy texture and mild flavour.

The traditional French method of making Brie involves using raw milk, which is not allowed in the United States due to regulations surrounding raw milk products. As a result, most Brie cheese available in the US is made with pasteurized milk, which has a milder flavour than its raw milk counterpart. The process of pasteurization kills bacteria in the milk, making it safe for consumption but also altering the flavour and texture of the final product.

The mild, buttery flavour of Brie is often described as tasting mushroomy, eggy, garlicky, nutty, milky, grassy, or fruity. It pairs well with both sweet and savoury accompaniments, such as honey, nuts, crackers, bread, or fruit. When baked, Brie becomes gooey and can be used as a centerpiece for a cheese board or added to dishes like pasta or sandwiches.

Overall, the mild, buttery, and creamy flavour of Brie is a result of the combination of high-fat milk, extra cream, and traditional cheese-making techniques. Its versatility in both flavour and use makes it a popular choice for cheese lovers around the world.

President Feta Cheese: Goat Milk's Delight

You may want to see also

Frequently asked questions

Brie is a soft cow's-milk cheese. It is made with authentic cultures and aged slowly to develop its familiar flavour profile.

Brie and Camembert are both made from cow's milk and are soft-ripened and creamy in texture. However, Brie is distinguished by the addition of extra cream and can be labelled "double cream" or "triple cream". Camembert is not enriched.

All bries, whether 'real' or 'fake', must be eaten when ripe. Ripe Brie is indicated by a firm exterior and a bouncy interior. If eaten too soon, the rind will be stiff, and if overripe, the Brie loses its shape and becomes runny.