Hi-temp cheese, also known as heat-stable cheese, is a specially formulated dairy product designed to withstand high cooking temperatures without melting, separating, or losing its texture. Unlike traditional cheeses that can become oily or clump when exposed to heat, hi-temp cheese maintains its consistency and flavor, making it ideal for applications like pizza, baked dishes, and sauces. Developed through advanced processing techniques, it combines natural cheese with emulsifiers and stabilizers to ensure it performs well under prolonged heat, offering both convenience and versatility for chefs and food manufacturers alike.

| Characteristics | Values |

|---|---|

| Definition | High-temperature (Hi-Temp) cheese is a type of processed cheese designed to remain stable and not separate when exposed to high cooking temperatures, typically above 170°F (77°C). |

| Primary Use | Ideal for dishes like pizzas, burgers, sauces, and baked casseroles where cheese needs to melt smoothly without oiling out or burning. |

| Key Ingredients | Cheese (Cheddar, Mozzarella, etc.), emulsifying salts (e.g., sodium citrate), stabilizers, and sometimes additional milk solids or whey. |

| Melting Point | Higher than natural cheese, typically above 170°F (77°C), ensuring it melts evenly without separating. |

| Texture | Smooth, creamy, and consistent when melted, without graininess or oil separation. |

| Shelf Life | Longer than natural cheese due to processing and added preservatives, often several months when refrigerated. |

| Flavor | Mild to medium, depending on the base cheese used, with a focus on functionality over complex flavor profiles. |

| Appearance | Uniform color and texture, often in blocks, slices, or shredded forms. |

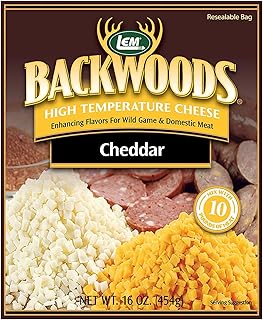

| Common Brands | Examples include Sargento Hi-Temp Cheese, Leprino Foods' pizza cheese, and some Kraft processed cheese variants. |

| Applications | Pizza, grilled cheese sandwiches, sauces, baked dishes, and fast-food items requiring consistent meltability. |

| Nutritional Profile | Higher in sodium and fat compared to natural cheese due to processing and added ingredients. |

| Storage | Refrigerated, with some varieties available in shelf-stable formats for commercial use. |

Explore related products

What You'll Learn

- Definition: High-temp cheese melts smoothly at elevated temperatures, ideal for cooking and baking

- Common Types: Cheddar, mozzarella, and provolone are popular high-temp cheese varieties

- Applications: Used in pizzas, grilled cheese, sauces, and baked dishes for consistent melt

- Production Process: Made with specific cultures and aging to enhance heat stability

- Benefits: Resists oil separation and maintains texture under prolonged heat exposure

Definition: High-temp cheese melts smoothly at elevated temperatures, ideal for cooking and baking

High-temp cheese, also known as heat-stable or heat-resistant cheese, is a game-changer for chefs and home cooks alike. Unlike traditional cheeses that can become greasy, stringy, or separate when exposed to heat, high-temp varieties maintain their texture and melt smoothly even at elevated temperatures. This makes them ideal for applications like pizza, grilled cheese sandwiches, and baked casseroles, where consistent melting and even distribution are crucial. For instance, mozzarella, a classic high-temp cheese, holds its structure in a wood-fired pizza oven, creating that perfect, stretchy bite without burning or clumping.

When selecting high-temp cheese, consider the specific cooking method and desired outcome. For example, cheddar is excellent for sauces and dips because it melts evenly at temperatures between 130°F and 150°F (54°C–65°C), while provolone performs well in high-heat grilling, maintaining its integrity up to 160°F (71°C). Pairing cheeses with complementary melting points can also enhance dishes—combining mozzarella (melts at 155°F/68°C) with parmesan (melts at 160°F/71°C) in a lasagna ensures a creamy yet structured texture. Always shred or grate the cheese yourself for better meltability, as pre-shredded varieties often contain anti-caking agents that hinder smooth melting.

The science behind high-temp cheese lies in its lower moisture content and pH levels, which prevent it from becoming oily or separating under heat. For instance, cheeses like Gruyère and Emmental have a pH of around 5.5, allowing them to melt uniformly without breaking down. When using high-temp cheese in baking, preheat your oven to 350°F (175°C) and monitor the dish closely—overheating can cause even heat-stable cheeses to toughen. For sauces, maintain a low simmer (around 180°F/82°C) to preserve the cheese’s smooth consistency without scorching.

Finally, high-temp cheese isn’t just for savory dishes—it’s a secret weapon in desserts too. Cheesecakes, for example, rely on cream cheese (a high-temp variety) to achieve a rich, velvety texture without curdling. When making cheesecake, ensure your cream cheese is at room temperature (68°F–72°F/20°C–22°C) before mixing to avoid lumps. For a decadent twist, incorporate shredded high-temp cheeses like sharp cheddar into brownie batters for a savory-sweet surprise that melts seamlessly during baking. With its versatility and reliability, high-temp cheese is an indispensable ingredient for any culinary endeavor.

What Does 'Cheese It' Mean? Unraveling the Slang Mystery

You may want to see also

Common Types: Cheddar, mozzarella, and provolone are popular high-temp cheese varieties

High-temp cheese, designed to withstand elevated cooking temperatures without melting excessively or losing texture, is a staple in kitchens where durability meets flavor. Among the most popular varieties are Cheddar, Mozzarella, and Provolone, each bringing unique qualities to dishes that require heat resistance. Cheddar, with its sharp tang and firm texture, holds up well in sauces and baked dishes, making it a go-to for casseroles and macaroni recipes. Mozzarella, known for its stretchy consistency, performs admirably in pizzas and grilled sandwiches, where it melts just enough to bind ingredients without becoming oily. Provolone, with its smoky flavor and semi-hard structure, excels in high-heat applications like paninis and stuffed dishes, adding depth without disintegrating.

Consider the application when choosing among these cheeses. For instance, if you’re crafting a grilled cheese sandwich, opt for a young, mild Cheddar, which melts smoothly while retaining its bite. In contrast, aged Cheddar is better suited for toppings or crumbles where its crumbly texture shines. Mozzarella’s moisture content varies by type—fresh mozzarella is too wet for high-heat cooking, while low-moisture or part-skim varieties are ideal for pizzas and baked pastas. Provolone’s versatility lies in its ability to balance flavor and structure; use smoked Provolone for a bold kick in hot sandwiches or unsmoked varieties for subtler dishes like stuffed peppers.

Practical tips can elevate your use of these cheeses. When grating Cheddar for sauces, freeze it briefly to prevent clumping and ensure even melting. For Mozzarella, pair it with drier cheeses like Parmesan in recipes to control moisture and enhance flavor complexity. Provolone’s thin slices work best in layered dishes, while thicker cuts are perfect for grilling. Always preheat your cooking surface gradually to avoid shocking the cheese, which can cause uneven melting or oil separation.

A comparative analysis reveals why these cheeses dominate high-temp applications. Cheddar’s acidity and protein structure allow it to melt smoothly without breaking, making it superior to softer cheeses like Brie or Camembert. Mozzarella’s pH level and moisture balance give it elasticity under heat, outperforming cheeses like Swiss that tend to separate. Provolone’s lower moisture content and firmer texture make it more heat-resistant than Gouda or Edam, which can become greasy. Understanding these properties ensures you select the right cheese for the right job.

Finally, experimentation is key to mastering high-temp cheese. Combine Cheddar and Mozzarella for a creamy yet structured pizza topping, or blend Provolone with Gruyère for a rich, melt-friendly fondue. Test small batches in your recipes to observe how each cheese behaves under specific temperatures and cooking methods. By leveraging the strengths of Cheddar, Mozzarella, and Provolone, you’ll create dishes that not only withstand heat but also deliver exceptional flavor and texture.

Properly Storing Mascarpone Cheese: Tips for Freshness and Longevity

You may want to see also

Applications: Used in pizzas, grilled cheese, sauces, and baked dishes for consistent melt

High-temp cheese, designed to withstand elevated cooking temperatures without separating or becoming oily, is a game-changer for culinary consistency. Its ability to maintain a smooth, even melt makes it indispensable in dishes where texture and appearance are paramount. For instance, in pizzas, high-temp cheese blends like mozzarella and provolone ensure a gooey, stretchy topping that browns perfectly without burning. This reliability eliminates the guesswork, allowing chefs to focus on flavor combinations rather than worrying about cheese performance.

Consider the grilled cheese sandwich, a classic comfort food elevated by high-temp cheese. Traditional cheeses often ooze out or clump unevenly, but high-temp varieties distribute heat evenly, creating a uniform melt that adheres to the bread. For best results, use a blend of cheddar and Monterey Jack, and cook over medium heat for 3–4 minutes per side. This ensures a golden crust and a creamy interior without the mess. The same principle applies to baked dishes like lasagna or casseroles, where high-temp cheese prevents oil pooling and maintains a cohesive texture.

Sauces, too, benefit from the stability of high-temp cheese. When making a cheese sauce for macaroni or vegetables, incorporate high-temp varieties like Gruyère or processed American cheese to avoid graininess or separation. Heat the sauce gradually, stirring constantly, and maintain a temperature below 170°F (77°C) to preserve the smooth consistency. This technique is especially useful in commercial kitchens, where large batches require precise control to ensure uniformity across servings.

For baked dishes, high-temp cheese shines in its ability to withstand prolonged exposure to heat without compromising quality. In dishes like stuffed peppers or cheese-topped chicken, it retains its meltiness and flavor, even after 30–40 minutes in a 375°F (190°C) oven. To maximize its potential, shred or grate the cheese finely to increase surface area, promoting even melting. Avoid overpacking the dish, as excessive cheese can lead to oil release, despite the high-temp properties.

In summary, high-temp cheese is a versatile ingredient that ensures consistent results across a variety of applications. Whether crafting a perfect pizza, a flawless grilled cheese, a silky sauce, or a robust baked dish, its heat resistance and melting properties make it an essential tool for both home cooks and professional chefs. By understanding its strengths and limitations, you can elevate your dishes with confidence, knowing the cheese will perform exactly as needed.

Mastering the Art of Presenting a Perfect Cheese Board

You may want to see also

Explore related products

Production Process: Made with specific cultures and aging to enhance heat stability

High-temperature cheese, or hi-temp cheese, is engineered to withstand heat without melting or separating, making it ideal for cooking applications like pizzas, baked dishes, and sauces. Central to its production is the strategic use of specific cultures and controlled aging processes, which enhance its heat stability. Unlike traditional cheeses, which rely on general lactic acid bacteria, hi-temp varieties incorporate thermophilic cultures such as *Lactobacillus helveticus* and *Streptococcus thermophilus*. These cultures thrive at higher temperatures (50–55°C) and produce a unique metabolic profile, including increased levels of peptides and calcium complexes, which strengthen the protein matrix and reduce moisture content. This microbial selection is the first critical step in ensuring the cheese retains its structure under heat.

The aging process further refines the cheese’s heat resistance. Typically aged for 3–6 months, hi-temp cheeses undergo a slower, more controlled maturation compared to their conventional counterparts. During this period, proteolytic enzymes break down proteins into smaller peptides, reducing moisture and tightening the protein network. Humidity levels in aging rooms are maintained at 85–90%, while temperatures hover around 10–12°C to prevent excessive drying. This deliberate aging not only enhances heat stability but also develops a sharper, more complex flavor profile. For example, mozzarella used in pizza production often undergoes a 4-month aging process to achieve optimal stretch and melt resistance at temperatures exceeding 200°C.

Producers must balance culture dosage and aging duration to avoid undesirable outcomes. Over-culturing can lead to excessive acidity, while insufficient aging results in inadequate moisture reduction. A common practice is to inoculate milk with 0.02–0.05% culture by weight, followed by a pH target of 5.2–5.4 before pressing. During aging, regular pH and moisture checks ensure the cheese reaches the desired parameters. For instance, a 20% moisture content is ideal for hi-temp cheddar, compared to 35–40% in regular cheddar. This precision in production is what distinguishes hi-temp cheese from standard varieties.

Practical tips for manufacturers include monitoring salt levels, as higher salt concentrations can inhibit culture activity but also improve shelf stability. Additionally, using closed aging systems with controlled airflow minimizes mold growth and ensures uniform moisture loss. For home cooks experimenting with hi-temp cheese, pre-shredding and freezing the cheese before cooking can further enhance its heat resistance, as freezing reduces the risk of oil separation. Understanding these production nuances not only highlights the science behind hi-temp cheese but also empowers both producers and consumers to maximize its potential in culinary applications.

Exploring Cheese Prices in Pakistan: Costs and Market Trends

You may want to see also

Benefits: Resists oil separation and maintains texture under prolonged heat exposure

High-temperature cheese, or hi-temp cheese, is a game-changer for chefs and food manufacturers alike, particularly when it comes to resisting oil separation and maintaining texture under prolonged heat exposure. This unique property stems from its specialized production process, which involves adding heat-stable emulsifiers like sodium citrate or phosphates. These additives create a uniform matrix that locks in moisture and fat, preventing the cheese from becoming greasy or breaking down when exposed to high temperatures. For instance, in a pizza application, hi-temp cheese remains smooth and stretchy even after 20 minutes in a 450°F oven, whereas traditional cheese would separate and lose its appeal.

From a practical standpoint, incorporating hi-temp cheese into recipes requires minimal adjustments. For baked dishes like lasagna or casseroles, use it as a 1:1 replacement for standard cheese, ensuring even distribution for optimal melt. In fried applications, such as stuffed peppers or cheese-topped burgers, its resistance to oil separation prevents unsightly grease pooling, enhancing both presentation and texture. A pro tip: when using hi-temp cheese in sauces, heat it gradually over medium heat, stirring constantly, to avoid clumping and achieve a silky consistency.

The analytical perspective reveals why this benefit matters: oil separation in cheese not only detracts from visual appeal but also alters the flavor profile, making dishes taste heavier and less balanced. Hi-temp cheese’s ability to maintain its structure under heat ensures consistent sensory experiences across servings. For example, in a commercial setting, a batch of grilled cheese sandwiches made with hi-temp cheese will look and taste identical, even if prepared hours apart, thanks to its stable composition.

Persuasively, the cost-effectiveness of hi-temp cheese cannot be overstated. By reducing waste from texture degradation and oil separation, it offers long-term savings for both home cooks and businesses. Imagine a food truck selling cheese-laden nachos at a festival—using hi-temp cheese ensures the product remains appetizing throughout the day, maximizing sales and customer satisfaction. Its reliability under stress makes it an indispensable ingredient in high-volume, fast-paced environments.

Finally, a comparative analysis highlights the versatility of hi-temp cheese. Unlike traditional cheeses, which require precise timing and temperature control to avoid separation, hi-temp cheese allows for experimentation in the kitchen. Whether crafting a slow-cooked dip or a quick panini, its stability under heat opens doors to creative culinary possibilities. For instance, a chef could confidently incorporate it into a sous-vide recipe, knowing it will retain its texture even after hours at 185°F. This adaptability sets hi-temp cheese apart as a modern essential in any kitchen arsenal.

Is Ricotta Cheese Dairy? Understanding Its Classification and Ingredients

You may want to see also

Frequently asked questions

Hi temp cheese, also known as heat-stable cheese, is a type of cheese specifically designed to withstand high temperatures without melting, separating, or losing its texture. It is commonly used in cooking and food processing.

Hi temp cheese is made by modifying the cheese's protein structure through processes like adding emulsifying salts or using specific cultures and enzymes. This ensures it remains stable and retains its shape when exposed to heat.

Hi temp cheese is often used in dishes like pizza, burgers, and baked casseroles, where it needs to hold its shape and texture despite being exposed to high cooking temperatures.

No, hi temp cheese is not the same as regular cheese. While regular cheese melts and changes texture when heated, hi temp cheese is formulated to remain intact and stable under high temperatures.