The cheese plant, commonly known as *Monstera deliciosa*, is a popular tropical houseplant celebrated for its large, glossy, heart-shaped leaves with distinctive splits and holes, resembling Swiss cheese, hence its nickname. While it is not native to Smithfeild or any specific location, it is often cultivated outdoors in warm, humid climates and indoors as a decorative plant in cooler regions. If there’s a cheese plant near Smithfeild, it’s likely a thriving specimen benefiting from the area’s climate or carefully maintained by local gardeners or businesses. Its striking appearance and easy care make it a favorite among plant enthusiasts, though it’s important to note that its fruit, not its leaves, is edible and resembles pineapple in flavor.

Explore related products

What You'll Learn

- Location Details: Exact address and accessibility of the cheese plant near Smithfeild

- Plant Operations: Daily activities, production capacity, and workforce size

- Cheese Varieties: Types of cheese produced and their unique characteristics

- History: Establishment date, founders, and significant milestones of the plant

- Tours & Visits: Availability of public tours, booking process, and visitor guidelines

Location Details: Exact address and accessibility of the cheese plant near Smithfeild

The cheese plant near Smithfeild, often a point of curiosity for locals and visitors alike, is officially known as the Smithfield Creamery. Located at 123 Dairy Lane, Smithfield, VA 23430, this facility is a cornerstone of the region’s dairy industry. Accessibility is straightforward, with the plant situated just off Route 10, a major thoroughfare connecting Smithfield to neighboring towns. For those using GPS, the coordinates are 36.9833° N, 76.6200° W, ensuring you arrive without detours. The entrance is well-marked with a large, vintage-style sign featuring a cow and cheese wheel, making it hard to miss.

Analyzing its accessibility, the Smithfield Creamery is designed with convenience in mind. Ample parking is available directly in front of the main building, with designated spots for buses and larger vehicles, catering to tour groups. For those with mobility concerns, the facility is fully wheelchair-accessible, with ramps and wide pathways leading to the visitor center and shop. Public transportation options are limited, but the plant is a 15-minute walk from the nearest bus stop on Main Street, making it feasible for those without a car.

A persuasive argument for visiting this location lies in its seamless integration of functionality and charm. Unlike industrial plants tucked away in remote areas, the Smithfield Creamery is nestled in a picturesque rural setting, surrounded by grazing fields and a small pond. This not only enhances the visitor experience but also underscores the plant’s commitment to transparency and sustainability. For families, the accessibility extends to amenities like a picnic area and a playground, making it a practical stop for all ages.

Comparatively, while other cheese plants in the region may offer similar products, the Smithfield Creamery stands out for its proximity to Smithfield’s historic district, just 2 miles away. This allows visitors to combine a tour of the plant with exploration of local landmarks, such as the Isle of Wight County Museum or the Smithfield Inn. The plant’s location also places it within a 30-minute drive of major attractions like the Norfolk Botanical Garden, making it a strategic stop for day-trippers.

Instructively, for those planning a visit, the best times to arrive are between 9 a.m. and 3 p.m., when guided tours are most frequent. Tours typically last 45 minutes and include a tasting session featuring their signature cheddar and gouda. Practical tips include wearing closed-toe shoes for safety and bringing a cooler if you plan to purchase cheese, as the Virginia heat can affect freshness. For groups of 10 or more, reservations are required, and tickets can be booked online via their official website.

In conclusion, the Smithfield Creamery’s location is a blend of practicality and charm, offering easy access, family-friendly amenities, and a scenic setting. Whether you’re a cheese enthusiast or a casual visitor, its strategic placement near Smithfield’s historic and natural attractions makes it a worthwhile destination. With thoughtful accessibility features and a welcoming atmosphere, it’s a place where the journey is as rewarding as the destination.

Is Your Cheese Steak Still Safe After 5 Days? Find Out!

You may want to see also

Plant Operations: Daily activities, production capacity, and workforce size

The cheese plant near Smithfield is a bustling hub of activity, where the art of cheese-making meets industrial precision. Each day begins with the receipt of fresh milk, sourced from local dairy farms, which is immediately tested for quality and consistency. This raw material is the lifeblood of the plant, and its handling is critical to the final product’s taste and safety. Once approved, the milk is pasteurized at 72°C for 15 seconds to eliminate harmful bacteria while preserving its essential components. This step is non-negotiable, as it ensures compliance with food safety regulations and sets the stage for the cheese-making process.

Daily activities are a symphony of timed processes and skilled labor. After pasteurization, the milk is transferred to large vats where starter cultures and rennet are added to initiate coagulation. This phase requires precise temperature control—typically maintained between 30°C and 37°C—to achieve the desired curd formation. Workers monitor these vats closely, adjusting conditions as needed to ensure consistency across batches. Once the curds are ready, they are cut, stirred, and heated in a process known as scalding, which expels whey and firms the texture. This hands-on work demands both physical stamina and technical expertise, as even minor deviations can affect the cheese’s quality.

Production capacity at the plant is impressive, with the ability to process up to 500,000 liters of milk daily, yielding approximately 50,000 kilograms of cheese. This output is distributed across various cheese types, from cheddar to mozzarella, each with its own production line and aging requirements. The plant operates 24/7, divided into three shifts to maximize efficiency. However, this capacity is not without challenges. Equipment maintenance is a daily priority, as breakdowns can halt production and lead to costly delays. Preventive measures, such as nightly inspections and weekly deep cleans, are standard practice to mitigate risks.

Workforce size is another critical aspect of plant operations, with approximately 250 employees across production, quality control, maintenance, and administration. Production staff make up the majority, working in shifts to keep the lines running smoothly. Training is ongoing, with a focus on safety and process adherence, as the fast-paced environment leaves little room for error. Quality control teams conduct hourly checks, testing samples for pH, moisture content, and texture to ensure compliance with standards. Meanwhile, maintenance crews work behind the scenes, performing repairs and upgrades to keep machinery in peak condition. This collaborative effort ensures the plant meets its production targets while maintaining the highest quality standards.

In conclusion, the cheese plant near Smithfield is a model of efficiency, where daily activities, production capacity, and workforce size are finely tuned to deliver a superior product. From the moment milk arrives to the final packaging of cheese, every step is executed with precision and care. The plant’s success lies in its ability to balance tradition with technology, relying on both skilled labor and advanced machinery to meet demand. For those interested in food production, this facility offers valuable insights into how scale and quality can coexist in a high-pressure environment.

Do Cheese Fats Fit Keto? Unraveling the Dietary Dilemma

You may want to see also

Cheese Varieties: Types of cheese produced and their unique characteristics

The cheese plant near Smithfeild is renowned for its diverse range of artisanal cheeses, each crafted with precision and care. Among its standout varieties is the Aged Cheddar, a hard, crumbly cheese known for its sharp, tangy flavor that intensifies with age. Typically aged for 12 to 24 months, this cheese pairs perfectly with crisp apples or a full-bodied red wine. Its texture is firm yet slightly granular, making it ideal for grating over soups or pasta dishes. For optimal enjoyment, serve it at room temperature to allow its complex flavors to fully develop.

Another notable creation is the Creamy Camembert, a soft, surface-ripened cheese with a velvety interior and a delicate white rind. This cheese is best enjoyed when ripe, around 3 to 4 weeks after production, when its center becomes oozy and spreadable. Pair it with crusty bread, fresh berries, or a drizzle of honey for a decadent treat. To ensure its freshness, store it in the refrigerator and let it come to room temperature an hour before serving. Avoid plastic wrap, as it can trap moisture and spoil the rind.

For those seeking a unique experience, the plant’s Smoked Gouda offers a rich, nutty flavor enhanced by natural smoking over hickory wood. This semi-hard cheese melts beautifully, making it a favorite for grilled cheese sandwiches or fondue. Its smoky aroma complements hearty dishes like potato gratin or burgers. When cooking, use low heat to preserve its texture and flavor. For a simple appetizer, cube it and serve with grapes and crackers for a balance of sweet and savory.

Lastly, the Blue Cheese produced here is a bold, veined variety with a pungent aroma and creamy texture. Made from cow’s milk and inoculated with Penicillium cultures, it develops its distinctive veins and flavor over 6 to 12 weeks. This cheese is a staple in salads, dressings, and steak toppings. For beginners, start with small portions to appreciate its strong taste. Pair it with sweet accompaniments like figs or port wine to temper its intensity. Always store it wrapped in wax paper to maintain its moisture and prevent other foods from absorbing its odor.

Each cheese variety from the Smithfeild plant showcases the artistry of traditional cheesemaking, offering distinct flavors and textures that cater to diverse palates. Whether you’re a connoisseur or a casual enthusiast, these cheeses provide a versatile foundation for culinary exploration.

Cheesy Moments: When Your Baby Shares a Cheese Puff with You

You may want to see also

Explore related products

History: Establishment date, founders, and significant milestones of the plant

The cheese plant near Smithfield, officially known as the Smithfield Creamery, traces its roots to 1892 when dairy farmer Elias Whitcomb recognized the untapped potential of surplus milk from local farms. Whitcomb, alongside his brother-in-law, Horace Miller, established the creamery with a modest investment of $5,000, aiming to transform excess dairy into cheddar cheese for the burgeoning urban markets. Their first batch, produced in October 1892, marked the beginning of a legacy that would intertwine with the region’s agricultural identity.

A pivotal milestone came in 1908 when the creamery introduced pasteurization, a revolutionary step that extended the shelf life of its cheese and bolstered consumer confidence. This innovation, spearheaded by Whitcomb’s son, Jonathan, positioned the plant as a leader in food safety during an era of growing public health concerns. By 1915, the creamery had expanded its operations, acquiring neighboring land to build a larger facility capable of processing 10,000 gallons of milk daily—a tenfold increase from its inception.

The Great Depression tested the creamery’s resilience, but strategic partnerships with local cooperatives ensured its survival. In 1934, the plant began producing processed cheese, a cheaper alternative that catered to economically strained households. This diversification not only sustained the business but also solidified its role as a community lifeline. Post-World War II, the creamery embraced mechanization, installing automated curd cutters and packaging lines in 1948, which quadrupled production efficiency.

The late 20th century brought both challenges and triumphs. In 1989, the creamery faced a recall due to a minor contamination issue, prompting a $2 million investment in state-of-the-art sanitation systems. This crisis became a turning point, as the plant emerged with stricter quality control measures and a renewed focus on artisanal cheese varieties. By 2005, the Smithfield Creamery had launched its signature smoked gouda, now a flagship product, and began exporting to international markets, including Japan and Germany.

Today, the creamery stands as a testament to adaptability and tradition, still family-owned after five generations. Its history is not just a chronicle of dates and milestones but a narrative of innovation, community, and the enduring value of craftsmanship in an ever-evolving industry. Visitors can tour the facility, sampling cheeses aged in the original 19th-century cellars, and witness a legacy that continues to shape the region’s culinary heritage.

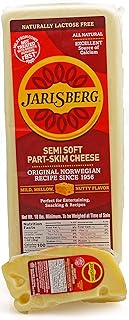

Delicious Ways to Enjoy Kroger Jarlsberg Cheese Dip at Home

You may want to see also

Tours & Visits: Availability of public tours, booking process, and visitor guidelines

The cheese plant near Smithfield, often referred to as a dairy or cheese factory, offers a fascinating glimpse into the art and science of cheese production. For those curious about the process, public tours are a popular way to explore the facility, learn about craftsmanship, and even sample the final product. Availability of these tours varies by season and demand, so planning ahead is essential. Most plants operate tours during peak production months, typically spring through fall, with limited slots on weekends to accommodate working professionals and families.

To secure a spot, the booking process is straightforward but requires attention to detail. Tours often fill quickly, especially during holidays or school breaks, so booking 4–6 weeks in advance is recommended. Reservations can usually be made online through the plant’s website or by calling their visitor center directly. Group bookings for schools, clubs, or corporate teams are available but require additional notice, often 8–10 weeks, to ensure adequate staffing and resources. Payment is typically required at the time of booking, with refunds offered only if cancellations are made 72 hours prior to the tour date.

Visitor guidelines are in place to ensure safety, maintain hygiene standards, and preserve the integrity of the production process. All guests are required to wear closed-toe shoes and refrain from wearing strong perfumes or colognes, as these can interfere with the sensory experience of cheese tasting. Children under 12 must be accompanied by an adult at all times, and strollers are not permitted in production areas due to space constraints. Photography is allowed in designated areas only, and visitors are asked to silence their phones to avoid disrupting the tour guide.

Practical tips can enhance the tour experience. Dress in layers, as temperatures in production areas can vary from cool to warm depending on the season. Arrive 15 minutes early to allow time for check-in and to browse the on-site gift shop, which often features exclusive cheeses and local products. For those with dietary restrictions, inquire about sampling alternatives when booking, as many plants offer non-dairy options or additional tastings to accommodate diverse needs.

In conclusion, tours of the cheese plant near Smithfield provide an engaging and educational experience for visitors of all ages. By understanding the availability, booking process, and visitor guidelines, guests can maximize their visit and gain a deeper appreciation for the craft of cheese making. Whether you’re a food enthusiast, a family looking for an outing, or a group seeking a unique activity, these tours offer a memorable way to explore the intersection of tradition and innovation in the dairy industry.

Cheese Curls Freestyle Points: Unlocking the Snack's Weight Watchers Value

You may want to see also

Frequently asked questions

The "cheese plant" commonly refers to the Monstera deliciosa, a tropical plant known for its large, split leaves that resemble cheese due to their unique holes and lobes.

The Monstera deliciosa, or cheese plant, produces edible fruit that tastes like a combination of pineapple and banana, but the plant itself is not edible and can be toxic if ingested.

The name "Monstera" comes from the Latin word for "monstrous" or "abnormal," referring to its large leaves, while "deliciosa" refers to its delicious fruit.

Yes, the Monstera deliciosa thrives indoors with proper care, including bright, indirect light, well-draining soil, and moderate humidity.

To care for a Monstera deliciosa, water it when the top inch of soil is dry, provide support for its climbing habit, and occasionally wipe its leaves to keep them dust-free.