The shelf life of cheese packets is a critical consideration for both consumers and manufacturers, as it directly impacts freshness, safety, and quality. Typically, cheese packets, whether individually wrapped or part of a larger package, come with a best by or use by date, which serves as a guideline for optimal consumption. Factors such as the type of cheese, packaging method, and storage conditions play a significant role in determining how long the cheese remains edible. For instance, hard cheeses like cheddar generally last longer than soft cheeses like brie, and vacuum-sealed packets tend to have a longer shelf life compared to those with standard packaging. Proper storage, such as refrigeration at the recommended temperature, is essential to maximize longevity and prevent spoilage. Understanding these factors helps ensure that cheese packets are enjoyed at their best while minimizing food waste.

Explore related products

What You'll Learn

- Storage Conditions Impact: Temperature, humidity, and packaging affect cheese packet shelf life significantly

- Types of Cheese: Hard cheeses last longer than soft varieties in packets

- Preservatives Role: Additives like salt and acids extend cheese packet freshness

- Packaging Materials: Vacuum-sealed or modified atmosphere packaging prolongs shelf life

- Expiration vs. Best By: Understanding date labels ensures safe consumption of cheese packets

Storage Conditions Impact: Temperature, humidity, and packaging affect cheese packet shelf life significantly

Cheese packets, those convenient staples of snacks and quick meals, are surprisingly sensitive to their environment. Their shelf life, often stamped with a "best by" date, is not set in stone. It's a dynamic timeline influenced by the trifecta of storage conditions: temperature, humidity, and packaging.

Think of these factors as the conductors of an orchestra, each playing a crucial role in determining how long your cheese packets remain edible and enjoyable.

Neglecting proper storage is like leaving a delicate instrument exposed to the elements – the result is a disappointing, potentially harmful experience.

Temperature: The Dominant Conductor

Temperature reigns supreme in the cheese packet longevity symphony. High temperatures accelerate the growth of bacteria and mold, leading to spoilage. The ideal storage temperature for most cheese packets falls between 35°F and 40°F (2°C and 4°C). This chilly environment slows down microbial activity, preserving freshness. For extended storage, consider the freezer, where temperatures below 0°F (-18°C) can significantly prolong shelf life, though texture and flavor may be slightly altered upon thawing.

Conversely, exposure to heat, whether from direct sunlight or a warm pantry, acts as a fast-forward button on spoilage. A cheese packet left in a hot car for a few hours can quickly become a breeding ground for bacteria, rendering it unsafe to consume.

Humidity: The Silent Saboteur

Humidity, often overlooked, plays a sneaky role in cheese packet degradation. Excess moisture in the air can cause condensation inside the packaging, creating a damp environment that fosters mold growth. This is particularly problematic for cheeses with higher moisture content, like fresh mozzarella or cream cheese packets. Aim for a storage area with low humidity, ideally below 50%. Using desiccant packets within the packaging can help absorb excess moisture, further extending shelf life.

Packaging: The Protective Barrier

Packaging acts as the first line of defense against the elements. Airtight, moisture-resistant materials like foil-lined pouches or vacuum-sealed bags are ideal. These barriers prevent oxygen and moisture from infiltrating, slowing down oxidation and mold growth. Avoid punctured or torn packaging, as it compromises this protective shield, leaving the cheese vulnerable to spoilage.

Practical Tips for Maximizing Shelf Life

- Refrigerate promptly: After opening, promptly refrigerate cheese packets, even if the label suggests they can be stored at room temperature.

- Use airtight containers: Transfer opened packets to airtight containers to minimize exposure to air and moisture.

- Label and date: Clearly label opened packets with the date to track freshness.

- Freeze for long-term storage: For cheeses suitable for freezing, portion them into smaller quantities before freezing to minimize thawing and refreezing, which can affect texture.

Remember: While proper storage can significantly extend shelf life, it's crucial to trust your senses. If a cheese packet exhibits signs of spoilage – off odors, mold, or a slimy texture – discard it immediately, regardless of the expiration date.

Perfect Cheese & Cracker Platter: Tips for Elegant, Tasty Arrangements

You may want to see also

Types of Cheese: Hard cheeses last longer than soft varieties in packets

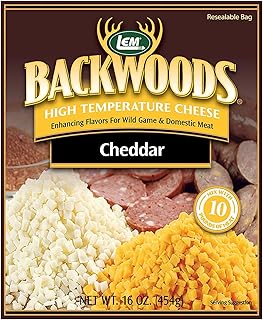

Hard cheeses, such as Parmesan or Cheddar, boast a significantly longer shelf life compared to their softer counterparts when packaged. This durability stems from their lower moisture content, which creates an environment less hospitable to bacteria growth. Typically, hard cheeses in packets can last anywhere from 6 months to a year when stored properly—unrefrigerated and unopened. Once opened, they should be consumed within 3 to 4 weeks if refrigerated, though vacuum sealing can extend this period. This longevity makes hard cheeses a practical choice for pantry stocking or long-term food storage.

Soft cheeses, like Brie or Camembert, present a stark contrast in shelf life due to their higher moisture content and softer texture. Packaged soft cheeses generally last only 1 to 2 weeks in the refrigerator, even when unopened. Once opened, they should be consumed within 3 to 5 days to avoid spoilage. The shorter shelf life necessitates more frequent purchasing and careful monitoring of expiration dates. For those who enjoy soft cheeses, buying smaller quantities or opting for individually wrapped portions can minimize waste.

The packaging itself plays a critical role in determining the shelf life of both hard and soft cheeses. Vacuum-sealed packets or those with modified atmosphere packaging (MAP) can significantly extend freshness by reducing oxygen exposure and inhibiting bacterial growth. Hard cheeses often benefit from wax coatings or foil wraps, which provide an additional barrier against moisture loss and contamination. For soft cheeses, airtight containers or resealable packets are essential to maintain their delicate texture and flavor. Always check the packaging for storage instructions, as some cheeses may require specific conditions to maximize their shelf life.

Practical tips for maximizing cheese shelf life include storing hard cheeses in the coldest part of the refrigerator (usually the bottom shelf) and wrapping them in parchment paper to prevent drying. Soft cheeses should be kept in their original packaging until ready to use and then transferred to an airtight container. Avoid freezing soft cheeses, as this can alter their texture and taste, but hard cheeses can be frozen for up to 6 months without significant quality loss. Labeling packets with the date of opening can help track freshness and ensure timely consumption.

In summary, understanding the shelf life differences between hard and soft cheeses in packets allows for smarter purchasing and storage decisions. Hard cheeses offer versatility and longevity, making them ideal for long-term storage, while soft cheeses require more attentive care due to their shorter lifespan. By leveraging proper packaging and storage techniques, cheese lovers can enjoy their favorite varieties at peak freshness, minimizing waste and maximizing flavor.

Exploring the Distinct Flavors and Textures of This Cheese

You may want to see also

Preservatives Role: Additives like salt and acids extend cheese packet freshness

Cheese packets, those convenient single-serve portions, rely heavily on preservatives to maintain freshness and prevent spoilage. Among these, salt and acids are the unsung heroes, working silently to extend shelf life. Salt, a time-tested preservative, draws moisture out of cheese through osmosis, creating an environment inhospitable to bacteria. Typically, cheese packets contain 1-2% salt by weight, a concentration sufficient to inhibit microbial growth without overpowering the cheese’s natural flavor. Acids, such as citric or lactic acid, lower the pH of the cheese, further discouraging bacterial activity. These additives act synergistically, ensuring the cheese remains safe and palatable for weeks or even months.

Consider the process of adding these preservatives: salt is often incorporated during the cheese-making process, while acids may be added directly to the packaging solution. For instance, shredded cheese packets frequently include a dusting of anti-caking agents like cellulose, paired with a light coating of lactic acid to maintain freshness. This dual approach not only preserves texture but also slows the oxidation process, which can cause off-flavors and discoloration. Manufacturers must balance these additives carefully; excessive salt can make the cheese unappetizing, while too much acid can impart a tangy or sour taste. Precision in dosage is key to achieving the desired shelf life without compromising quality.

From a consumer perspective, understanding the role of these preservatives can inform smarter storage practices. Cheese packets labeled with "high salt content" or "contains lactic acid" are not warnings but assurances of extended freshness. However, once opened, the protective barrier is compromised, and the cheese becomes susceptible to spoilage. To maximize shelf life, store opened packets in airtight containers or resealable bags, and refrigerate promptly. Interestingly, the effectiveness of these preservatives diminishes in humid environments, so keeping cheese packets in a cool, dry place is essential.

Comparatively, natural cheeses without added preservatives have a significantly shorter shelf life, often lasting only a week or two. In contrast, processed cheese packets, fortified with salt and acids, can remain fresh for up to six months. This disparity highlights the critical role of additives in modern food packaging. While some consumers prefer preservative-free options, the convenience and longevity offered by these additives make cheese packets a staple in busy households and on-the-go lifestyles.

In conclusion, the shelf life of cheese packets is a testament to the science of food preservation. Salt and acids, though simple in concept, are powerful tools in the fight against spoilage. By understanding their mechanisms and applications, both manufacturers and consumers can make informed decisions to ensure cheese remains fresh, flavorful, and safe to eat. Whether you’re packing a lunch or stocking a pantry, these preservatives are the silent guardians of your cheese packets.

Cheesy Bruschetta: Exploring the Name and Origin of This Tasty Twist

You may want to see also

Explore related products

Packaging Materials: Vacuum-sealed or modified atmosphere packaging prolongs shelf life

Cheese, a beloved staple in many diets, is highly perishable due to its moisture content and nutrient density, which attract bacteria and mold. To combat this, manufacturers employ advanced packaging techniques like vacuum sealing and modified atmosphere packaging (MAP). These methods significantly extend shelf life by creating environments hostile to spoilage organisms. Vacuum sealing removes oxygen, a key factor in microbial growth, while MAP replaces the air inside the package with a protective gas mixture, often including nitrogen, carbon dioxide, or a blend of gases tailored to the cheese type. For instance, hard cheeses like cheddar thrive in high carbon dioxide environments, which inhibit mold growth, whereas soft cheeses benefit from higher nitrogen levels to maintain texture and flavor.

Consider the practical implications for consumers. Vacuum-sealed cheese can last up to 6 months when stored properly, compared to just 2–3 weeks for unpackaged varieties. MAP extends this further, with some hard cheeses retaining quality for up to a year. However, these benefits hinge on proper storage conditions. Keep vacuum-sealed or MAP cheese packets at temperatures between 2–8°C (36–46°F) to maximize longevity. Avoid puncturing the packaging, as even small tears can reintroduce oxygen and moisture, accelerating spoilage. For opened packets, reseal them tightly or transfer the cheese to an airtight container, consuming it within 3–5 days.

From a cost-effectiveness standpoint, investing in vacuum-sealed or MAP cheese is a smart choice for both retailers and consumers. Reduced waste from extended shelf life translates to lower expenses and less environmental impact. For example, a study found that MAP reduced cheese waste by 30% in retail settings. Consumers also benefit from the ability to purchase larger quantities without fear of spoilage, ideal for meal prepping or bulk storage. When shopping, look for packaging labels indicating "vacuum-sealed" or "modified atmosphere packaging" to ensure you’re getting the longest-lasting product.

Comparing these methods, vacuum sealing is simpler and more cost-effective for manufacturers, making it common for pre-sliced or block cheeses. MAP, while more complex, offers superior control over gas composition, making it ideal for specialty or high-moisture cheeses. For instance, blue cheese in MAP retains its distinctive veins and flavor profile far longer than in vacuum-sealed packaging. Both methods, however, share the limitation of being less effective for extremely soft or fresh cheeses, which still require refrigeration and prompt consumption.

In conclusion, vacuum-sealed and MAP technologies are game-changers for cheese preservation, offering tangible benefits for shelf life, quality, and sustainability. By understanding how these packaging materials work and following proper storage practices, consumers can enjoy cheese at its best while minimizing waste. Whether you’re a retailer, home cook, or cheese enthusiast, these innovations ensure that every packet delivers maximum flavor and value.

Perfect Cheese Tray Portions: How Much Cheese for 100 Guests?

You may want to see also

Expiration vs. Best By: Understanding date labels ensures safe consumption of cheese packets

Cheese packets often carry date labels that confuse consumers: "Expiration" and "Best By." These terms are not interchangeable, and understanding their distinctions is crucial for safe consumption. An expiration date marks the last day a product is safe to eat, while a "Best By" date indicates peak quality. Mistaking one for the other can lead to unnecessary waste or, worse, health risks. For instance, consuming cheese past its expiration date may expose you to harmful bacteria, whereas eating it after the "Best By" date might only mean a slight change in texture or flavor.

Analyzing these labels requires attention to detail. Expiration dates are typically found on highly perishable items like shredded cheese packets, which can spoil quickly due to their increased surface area. In contrast, harder cheeses or sealed packets often carry "Best By" dates, allowing for more flexibility. A study by the USDA found that 20% of consumers discard food based on "Best By" dates, unaware that many products remain safe beyond this point. This highlights the need for education to reduce food waste while ensuring safety.

To navigate these labels effectively, follow a simple rule: prioritize expiration dates over "Best By" dates. If a cheese packet has an expiration date, discard it immediately after that day. For "Best By" dates, use sensory cues—smell, taste, and appearance—to assess quality. For example, if a packet labeled "Best By" last week smells sour or shows mold, discard it despite the date. Conversely, if it appears and smells normal, it’s likely safe to consume within a week of the "Best By" date, especially if refrigerated at 40°F or below.

Comparing these labels to other food categories can provide clarity. Unlike milk, which becomes visibly spoiled after its expiration date, cheese’s deterioration is subtler. Soft cheeses like Brie may develop ammonia odors, while hard cheeses like cheddar might become crumbly. Understanding these nuances ensures you rely on both labels and sensory checks. For instance, a shredded cheese packet with an expiration date should be treated more cautiously than a block of cheddar with a "Best By" date.

In conclusion, mastering the difference between "Expiration" and "Best By" dates empowers you to consume cheese packets safely while minimizing waste. Always check for an expiration date first, and if none exists, use the "Best By" date as a quality guideline. Combine this knowledge with sensory evaluation and proper storage practices, such as airtight containers and consistent refrigeration. By doing so, you’ll enjoy cheese at its best while avoiding unnecessary risks or discards.

Stop the Whine: Turning Complaints into Cheese-Worthy Achievements

You may want to see also

Frequently asked questions

The shelf life of cheese packets varies depending on the type of cheese and packaging. Generally, unopened packets can last 2–6 months in the refrigerator, while individually wrapped cheese snacks may last 1–2 weeks after opening.

Most cheese packets require refrigeration to maintain freshness and prevent spoilage. However, some shelf-stable cheese packets with preservatives can be stored in a cool, dry pantry until opened.

Signs of spoilage include an off odor, mold, discoloration, or a slimy texture. If the packet is swollen or leaking, it’s best to discard it. Always check the expiration date as a precaution.

Yes, cheese packets can be frozen to extend their shelf life by 6–8 months. However, freezing may alter the texture, especially in softer cheeses. Thaw in the refrigerator and use promptly after thawing.